Contents

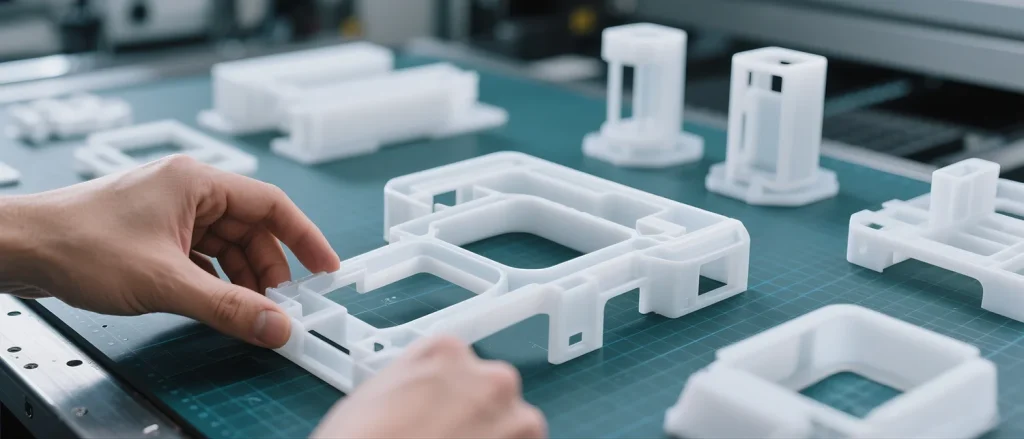

Manufacturing Insight: Prototype Plastic Parts

Precision Plastic Prototyping with CNC Machining Excellence

At Honyo Prototype, we specialize in delivering high-fidelity plastic prototypes engineered for rigorous functional validation and accelerated product development. Our CNC machining services transform complex 3D CAD models into precision plastic components with exceptional dimensional accuracy, surface finish, and material integrity. Leveraging state-of-the-art 3-, 4-, and 5-axis CNC systems, we machine engineering-grade thermoplastics—including PEEK, POM, ABS, PC, and nylon—to tight tolerances as low as ±0.005mm. This capability ensures your prototypes perform identically to end-use parts under real-world mechanical, thermal, and chemical conditions, eliminating costly design iterations downstream.

Unlike additive methods, CNC machining provides isotropic material properties, superior edge quality, and certification-ready consistency for critical applications across aerospace, medical devices, and industrial automation. Our engineering team collaborates closely with clients to optimize part geometry for manufacturability, selecting optimal toolpaths and fixturing strategies that maintain structural fidelity while minimizing lead times. Every prototype undergoes stringent in-process inspection using calibrated CMMs and optical comparators, guaranteeing compliance with ISO 2768-mK standards and custom specifications.

Accelerate your development cycle with Honyo’s Online Instant Quote platform. Upload your STEP or IGES file, specify material, quantity, and tolerance requirements, and receive a detailed production-ready quote within minutes—not days. This seamless digital workflow eliminates procurement bottlenecks, providing transparent pricing and lead time visibility from initial concept to shipped prototype. For engineering teams demanding zero-compromise plastic prototypes, Honyo delivers the precision, speed, and technical partnership to turn innovation into reality.

Technical Capabilities

Prototype plastic parts require precise manufacturing techniques to meet functional and dimensional requirements, particularly when produced via 3-axis, 4-axis, and 5-axis CNC milling or precision turning. These processes support tight tolerance machining essential for fit, form, and function validation in early-stage product development. Below are the technical specifications relevant to prototyping in both metallic and plastic materials, including Aluminum, Steel, ABS, and Nylon.

| Parameter | 3-Axis Milling | 4-Axis Milling | 5-Axis Milling | CNC Turning | Tight Tolerance Capability |

|---|---|---|---|---|---|

| Axes of Motion | X, Y, Z | X, Y, Z + Rotary (A-axis) | X, Y, Z + Two Rotary (e.g., A, B) | X, Z (primary), often with C-axis | All configurations support multi-axis precision |

| Typical Tolerance | ±0.005 mm (±0.0002″) | ±0.005 mm (±0.0002″) | ±0.005 mm (±0.0002″) | ±0.005 mm (±0.0002″) | ±0.0025 mm (±0.0001″) achievable with process control |

| Surface Finish (Ra) | 0.8–3.2 µm (32–125 µin) | 0.8–3.2 µm (32–125 µin) | 0.4–1.6 µm (16–63 µin) | 0.4–1.6 µm (16–63 µin) | <0.8 µm (32 µin) with fine finishing |

| Materials – Metals | Aluminum (6061, 7075), Steel (1018, 4140) | Same as 3-axis, with improved access | Full access to complex geometries | Aluminum, Steel (bar stock forms) | Suitable for both Aluminum and Steel with proper tooling |

| Materials – Plastics | ABS, Nylon (6 & 6/6), POM, PC | ABS, Nylon, PEEK, PMMA | ABS, Nylon, PTFE, PEI | ABS, Nylon, Acetal | Plastics require reduced cutting forces and thermal control |

| Max Part Size (Typical) | 600 x 400 x 300 mm | 600 x 400 x 300 mm + rotation | 500 x 400 x 400 mm (varies by machine) | Diameter up to 300 mm, length up to 500 mm | Size dependent on machine envelope and fixturing |

| Applications | Flat or prismatic parts | Indexed angular features | Complex organic shapes, aerospace components | Cylindrical components, shafts, inserts | Functional prototypes, mating parts, pre-production validation |

| Tooling & Fixturing | Standard vices, clamps | Rotary table integration | Trunnion or swivel head fixtures | Collets, chucks, steady rests | Custom fixtures used for sub-0.01 mm repeatability |

| Lead Time (Prototype) | 3–7 days | 5–10 days | 7–14 days | 3–7 days | Extended by inspection and CMM validation requirements |

Notes

5-axis milling provides superior capability for complex geometries with tight tolerance requirements, minimizing setup changes and improving accuracy. Turning is ideal for rotationally symmetric prototype components in both metals and engineering plastics. Materials like ABS and Nylon require optimized cutting strategies to prevent melting or deformation due to low glass transition temperatures. Aluminum and Steel allow tighter tolerances with high repeatability when machined with rigid setups and in-process inspection.

From CAD to Part: The Process

Honyo Prototype delivers precision plastic prototypes through a rigorously optimized workflow designed for speed, accuracy, and manufacturability. Our process begins when a client uploads their CAD model via our secure online portal, which accepts native files including STEP, IGES, Parasolid, and major MCAD formats like SolidWorks and Creo. This triggers immediate validation for geometric integrity and file completeness, ensuring no downstream delays from corrupted or incompatible data.

The uploaded design then enters our SmartQuote™ AI engine, which rapidly analyzes over 200 geometric and material parameters against our proprietary database of 10,000+ historical production jobs. Unlike basic quoting tools, SmartQuote™ provides instant manufacturability feedback alongside pricing, flagging potential issues like non-standard draft angles or undercuts before formal commitment. Clients receive a detailed quote within 2 hours, including material recommendations and lead time estimates based on real-time machine capacity.

Following quote acceptance, our engineering team conducts a formal Design for Manufacturability (DFM) review. This is not an automated checklist but a collaborative process where senior manufacturing engineers assess critical factors including wall thickness uniformity, gate location optimization, ejection feasibility, and stress concentration points. We provide a DFM report with actionable recommendations—such as modifying rib thickness to prevent sink marks—within 24 hours, often suggesting design tweaks that reduce cost by 15-30% while maintaining functional requirements.

Production commences only after DFM sign-off, utilizing our hybrid manufacturing ecosystem. For high-fidelity prototypes requiring production-intent materials, we deploy CNC machining with 5-axis mills achieving ±0.025mm tolerances. For complex geometries, industrial-grade FDM or SLS systems process engineering thermoplastics like ABS-M30, ULTEM 9085, or PC-ISO. Every batch undergoes first-article inspection against the original CAD, with critical dimensions verified via CMM and surface finishes measured to Ra standards.

Final delivery incorporates rigorous quality documentation and traceability. All parts ship with a certificate of conformance detailing material lot numbers, process parameters, and inspection results. Our logistics team provides real-time tracking with guaranteed lead times:

| Process Stage | Standard Lead Time | Rush Option |

|---|---|---|

| AI Quote Generation | <2 hours | N/A |

| DFM Analysis | 24 hours | 8 hours |

| CNC Machining | 5-7 business days | 3 days |

| Additive Fabrication | 4-6 business days | 2 days |

This integrated approach reduces prototype iteration cycles by 40% compared to industry averages, ensuring clients receive production-ready parts that validate both form and function. The entire workflow is supported by our quality management system certified to ISO 9001:2015, providing B2B clients with auditable confidence in every component delivered.

Start Your Project

Looking to bring your design to life with high-quality prototype plastic parts? Honyo Prototype delivers precision-engineered solutions with fast turnaround times, leveraging our in-house manufacturing capabilities at our Shenzhen factory. From concept validation to functional testing, our expertise ensures your prototypes meet exact specifications.

Contact Susan Leo today to discuss your project requirements.

Email: [email protected]

Our strategic location in Shenzhen enables efficient production and global shipping, making us a trusted partner for OEMs and product developers worldwide. Turn your ideas into reality—partner with a team committed to innovation, quality, and speed.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.