Contents

Manufacturing Insight: Prototype Metal

Accelerating Precision Metal Prototyping for Engineering Innovation

In the demanding landscape of product development, rapid iteration of high-fidelity metal prototypes is non-negotiable. Honyo Prototype specializes in sheet metal fabrication engineered explicitly for the prototyping phase, where design validation, functional testing, and manufacturability feedback must align with aggressive development timelines. Unlike volume production-focused vendors, we prioritize agility without compromising on the geometric precision, material integrity, and surface finish required to de-risk your final design.

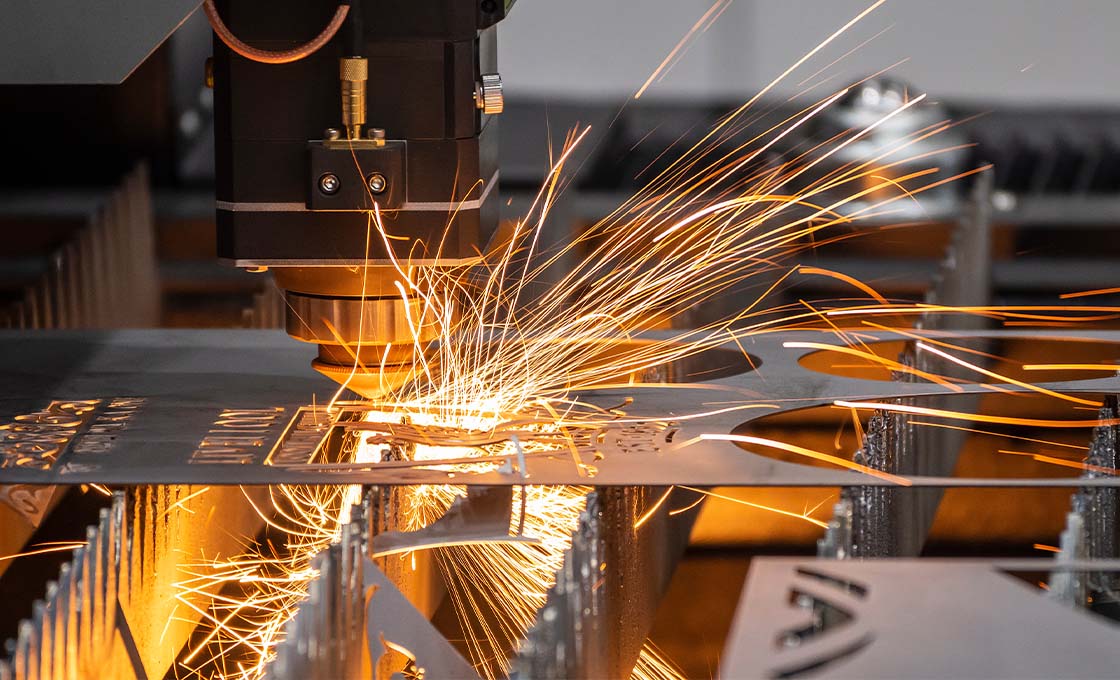

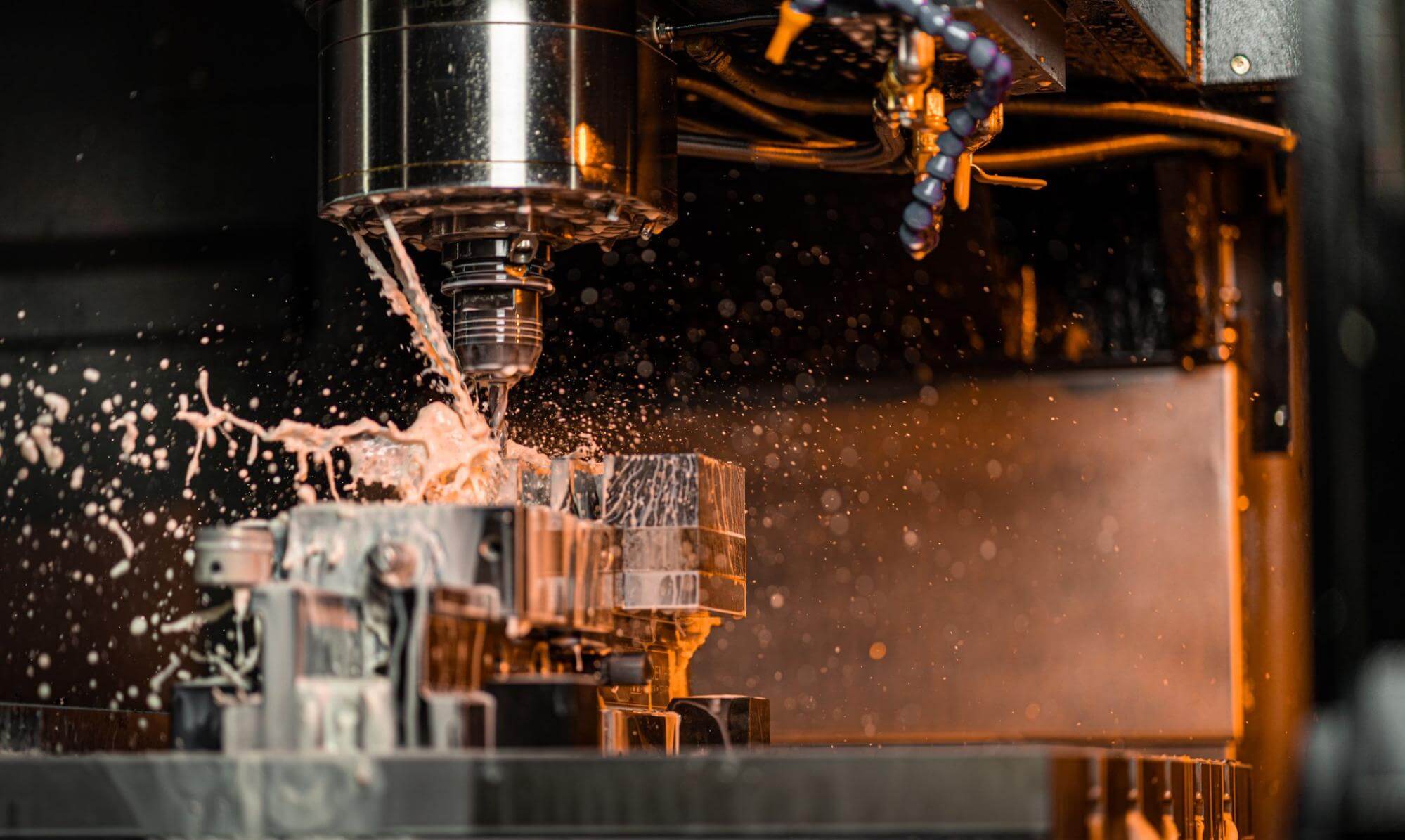

Our end-to-end capabilities span laser cutting, CNC punching, precision bending, welding, and finishing for low-volume runs—from single prototypes to small pre-production batches. We handle complex geometries, tight tolerances (±0.005″), and diverse materials including stainless steel, aluminum, and specialty alloys, ensuring your prototype behaves identically to the intended production part. This eliminates costly late-stage redesigns and accelerates time-to-market.

A critical bottleneck in traditional prototyping is quotation delays. Honyo eliminates this friction with our Online Instant Quote platform. Simply upload your STEP or DXF file, specify material and quantity, and receive a detailed, actionable quote in under 60 seconds—no manual intervention, no waiting. This transparency empowers engineering teams to iterate designs rapidly, validate budgets early, and maintain momentum in the development cycle.

When your prototype metal components demand manufacturing expertise attuned to the urgency of innovation, Honyo delivers the speed, accuracy, and digital efficiency modern engineering requires. Submit your design today and experience seamless transition from concept to physical validation.

Technical Capabilities

Technical specifications for prototype metal fabrication processes—laser cutting, bending, and welding—are critical to ensuring dimensional accuracy, structural integrity, and manufacturability. Below is a comparative overview of common materials used in prototyping: Aluminum (6061-T6), Steel (A36 and Stainless 304), ABS (thermoplastic), and Nylon (PA6). Note that ABS and Nylon are non-metallic and typically not welded or bent using metal-forming techniques; their inclusion is for comparative context in multi-material prototypes.

| Material | Laser Cutting Compatibility | Bending Characteristics | Welding Process & Notes | Typical Thickness Range (mm) | Surface Finish Considerations |

|---|---|---|---|---|---|

| Aluminum 6061-T6 | Excellent; requires high-power fiber laser due to reflectivity and thermal conductivity | Good formability; minimum bend radius of 1x material thickness recommended | TIG or MIG welding preferred; requires clean surface and inert gas shielding to prevent porosity | 0.8 – 12.7 | May exhibit oxidation; anodizing possible post-process |

| Steel A36 | Excellent; CO₂ or fiber laser effective; produces sharp edges | Good; minimum bend radius of 1.5x thickness to avoid cracking | MIG, TIG, or spot welding; prone to warping if not fixtured properly; post-weld grinding often required | 0.8 – 25.4 | Mill scale may require removal; paint or powder coat compatible |

| Stainless Steel 304 | Good; fiber laser preferred; slower cut speeds than mild steel | Moderate; higher springback than mild steel; minimum bend radius 2x thickness advised | TIG welding for precision; low heat input to avoid carbide precipitation and corrosion resistance loss | 0.8 – 19.0 | Smooth, corrosion-resistant finish; polishing or passivation available |

| ABS (Acrylonitrile Butadiene Styrene) | Moderate; CO₂ laser effective; clean vaporization with proper settings | Not applicable for metal-style air bending; limited cold forming possible with heating | Not weldable via arc processes; ultrasonic or solvent bonding used for joining | 1.0 – 10.0 | Matte or smooth surface; post-machining for tight tolerances |

| Nylon (PA6) | Limited; CO₂ laser cuts but may melt or char; not ideal for precision edges | Not suitable for standard press braking; thermoforming required for shaping | Not compatible with traditional welding; mechanical fastening or adhesive bonding recommended | 1.5 – 15.0 | Natural matte finish; low friction; sensitive to moisture absorption |

Notes:

Laser cutting parameters (power, speed, assist gas) must be optimized per material and thickness.

Bending springback should be compensated for in tooling design, especially with high-strength or elastic materials.

Welding of aluminum and stainless steel requires skilled operators to maintain joint integrity and corrosion performance.

Non-metallic materials such as ABS and Nylon are included for hybrid prototyping applications but require alternative joining and forming methods.

From CAD to Part: The Process

Honyo Prototype executes a streamlined yet rigorous workflow for metal prototype manufacturing designed to balance speed, precision, and cost-effectiveness. Our process begins when a client uploads their CAD file to our secure customer portal. This initiates our integrated digital workflow, ensuring traceability and version control from the first interaction.

The uploaded CAD model undergoes immediate preliminary analysis by our proprietary AI-powered quoting engine. This system evaluates geometric complexity, material requirements specified in the CAD metadata or client notes, dimensional tolerances, and surface finish criteria. Crucially, the AI cross-references real-time data on material costs, machine availability, and current production capacity to generate a technically accurate preliminary quote within hours. This quote includes estimated lead time, material options analysis, and high-level process recommendations, but it is explicitly flagged as preliminary pending human engineering validation.

Following AI quote generation, the project enters the mandatory Design for Manufacturing (DFM) review phase led by our experienced metal fabrication engineers. This is not an automated step; it involves direct engineer-to-engineer collaboration. Our team scrutinizes the design for manufacturability specific to metal processes such as CNC machining, sheet metal fabrication, or additive manufacturing. Key considerations during DFM include:

| DFM Focus Area | Metal-Specific Considerations |

|---|---|

| Geometric Feasibility | Minimum wall thickness, undercuts, internal radii, aspect ratios for stability during machining |

| Tolerance Analysis | Realistic assessment of achievable tolerances vs. design intent; GD&T validation |

| Material Suitability | Verification of specified alloy grade; recommendations for cost/performance optimization |

| Process Selection | Optimal method determination (e.g., 3-axis vs. 5-axis CNC, laser cutting vs. stamping) |

The engineer provides actionable feedback directly within the portal, often suggesting minor design modifications to eliminate costly secondary operations, reduce material waste, or improve structural integrity without compromising function. Client approval of the DFM report and final quote is required before proceeding, ensuring alignment on technical and commercial terms.

Upon DFM sign-off, the project moves to production. Our certified manufacturing facility utilizes advanced CNC machining centers (mills, lathes), laser cutters, press brakes, and finishing lines. Each metal prototype undergoes strict in-process inspection using calibrated CMMs and optical comparators at defined checkpoints. Material certifications and first-article inspection reports (FAIRs) are generated per AS9102 standards for aerospace or equivalent industry requirements. Critical dimensions and surface finishes are verified against the approved DFM-adjusted specifications.

Final delivery encompasses more than physical shipment. Completed metal prototypes undergo rigorous cleaning, deburring, and any requested surface treatments (anodizing, plating, powder coating) before packaging in custom protective crating designed for secure transit. Comprehensive documentation, including as-built dimensional reports, material test certificates, and process validation records, is provided digitally and physically. We utilize tracked freight services with real-time logistics visibility, delivering typically within 5-15 business days post-DFM approval depending on complexity, and provide proactive shipment notifications to ensure seamless client receipt. This closed-loop process guarantees that metal prototypes meet functional validation requirements while minimizing time-to-test for our clients.

Start Your Project

Looking to bring your next product to life with high-quality prototype metal parts? Contact Susan Leo at [email protected] to discuss your project requirements. With our advanced manufacturing capabilities and dedicated engineering support, we deliver precision metal prototypes quickly and reliably.

Our state-of-the-art factory is located in Shenzhen, China—strategically positioned for fast turnaround and seamless global logistics. Whether you need CNC machining, sheet metal fabrication, or rapid prototyping in metal, Honyo Prototype ensures exceptional accuracy and material integrity.

Reach out today to request a quote or technical consultation. Partner with us for faster, smarter, and more cost-effective metal prototyping solutions.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.