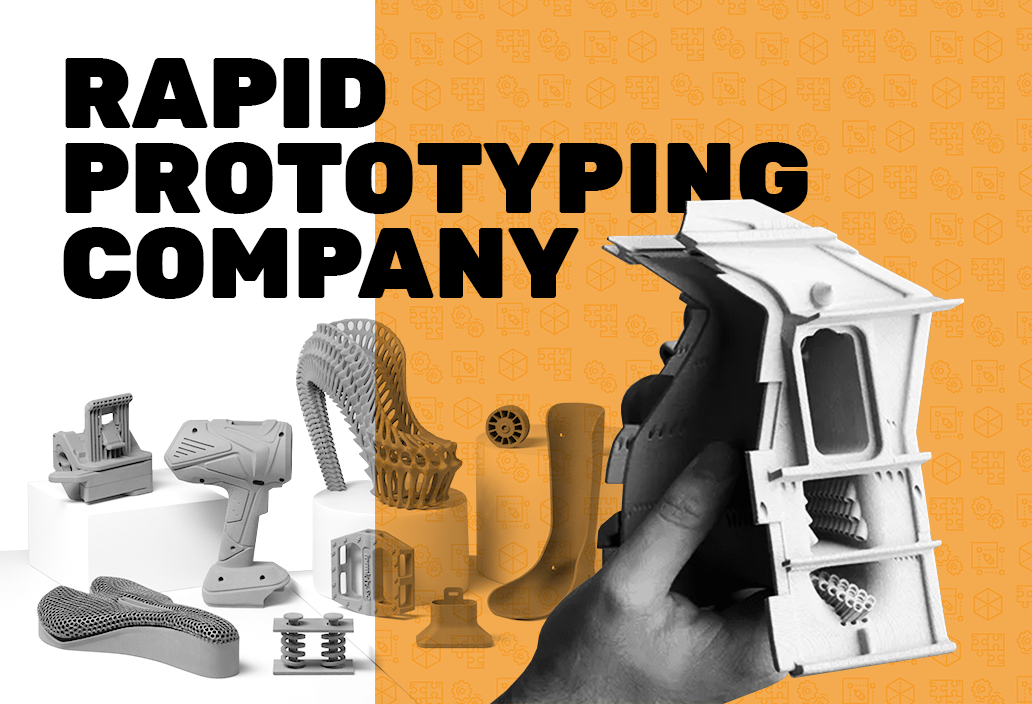

Introduction: Navigating the Global Market for prototype making companies

In today’s fast-paced global market, sourcing reliable prototype making companies can be a daunting challenge for B2B buyers, especially those looking to innovate in regions like Africa, South America, the Middle East, and Europe. The journey from concept to market-ready product requires a nuanced understanding of various prototyping methods, materials, and the capabilities of different suppliers. This guide serves as a comprehensive resource, delving into the diverse types of prototyping services available—from rapid prototyping and 3D printing to traditional manufacturing and engineering firms.

We will explore the applications of prototypes across industries, helping you discern which method aligns best with your project goals, whether you are developing a proof of concept or preparing for mass production. Additionally, we will provide actionable insights on how to effectively vet suppliers, understand associated costs, and navigate intellectual property considerations.

By empowering international B2B buyers with this knowledge, this guide aims to facilitate informed purchasing decisions, enabling you to select the right prototype making partner tailored to your unique needs. Whether you are based in Nigeria seeking local expertise or in Germany aiming for cutting-edge technology, understanding the landscape of prototype making companies will help you accelerate your product development process and stay competitive in the global marketplace.

Understanding prototype making companies Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Rapid Prototyping Companies | Utilize 3D printing technologies for quick turnaround | Initial concept validation, small batch production | Pros: Fast service, lower costs for simple designs. Cons: Limited design support, may lack manufacturing scalability. |

| Product Development Firms | Full-service approach, from design to prototyping to production | Comprehensive product development, market-ready prototypes | Pros: Access to expert design and engineering teams. Cons: Higher costs, may be unsuitable for startups. |

| Manufacturing Companies | Focus on scaling production post-prototype, limited custom work | High-volume production, minor prototype adjustments | Pros: Established manufacturing capabilities, rapid scaling. Cons: Limited support for unique designs, potential IP risks. |

| Engineering Firms | Specialized in technical design and prototyping, often with CAD expertise | Complex prototypes requiring engineering solutions | Pros: In-depth technical expertise, suitable for intricate designs. Cons: May have longer turnaround times and higher costs. |

| 3D Printing Services | Offer a variety of additive manufacturing technologies for prototypes | Low-volume, custom parts, rapid prototyping | Pros: Flexible materials and processes, quick iterations. Cons: Limited to specific designs, not ideal for mass production. |

What Are the Characteristics of Rapid Prototyping Companies?

Rapid prototyping companies primarily utilize 3D printing technologies, allowing for swift creation of prototypes from digital files. They are ideal for businesses looking to validate initial concepts or produce small batches quickly. However, they often lack the comprehensive design support needed for more complex projects, making them best suited for companies with in-house engineering capabilities or straightforward designs.

How Do Product Development Firms Assist in Prototype Creation?

Product development firms provide a holistic approach to prototype creation, encompassing design, engineering, and production services. They are particularly beneficial for startups and businesses looking to bring innovative products to market. While they offer extensive expertise, their services can be costly, which may be a barrier for smaller companies or those with limited budgets.

What Role Do Manufacturing Companies Play in Prototyping?

Manufacturing companies typically focus on scaling production after prototype development. They may offer limited support for custom prototypes, often prioritizing larger volume orders. For businesses aiming to transition quickly from prototype to mass production, these companies can be advantageous; however, they may pose risks concerning intellectual property rights and lack flexibility in design.

Why Choose Engineering Firms for Complex Prototypes?

Engineering firms specialize in technical design and often employ advanced computer-aided design (CAD) technologies. They are well-suited for creating complex prototypes that require specialized engineering solutions. While their expertise can significantly enhance product viability, the associated costs and longer timelines may not align with the needs of all businesses.

What Are the Benefits and Limitations of 3D Printing Services?

3D printing services provide diverse additive manufacturing options, making them ideal for custom and low-volume parts. Their ability to iterate quickly allows businesses to experiment with different designs. However, these services may not be suitable for mass production, and their effectiveness can be limited by the complexity of the design and material choices.

Key Industrial Applications of prototype making companies

| Industry/Sector | Specific Application of Prototype Making Companies | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Consumer Electronics | Development of new electronic devices and gadgets | Accelerated time-to-market for innovative products | Expertise in electronic prototyping and compliance with standards |

| Automotive | Creation of automotive components and systems prototypes | Enhanced design validation and testing efficiency | Capability to handle complex geometries and materials |

| Healthcare | Prototyping of medical devices and equipment | Improved patient safety and regulatory compliance | Experience with biocompatible materials and FDA regulations |

| Aerospace | Design and testing of aircraft components and systems | Reduction in development costs and risk mitigation | Knowledge of aerospace standards and lightweight materials |

| Industrial Equipment | Prototyping of machinery and equipment for manufacturing processes | Increased productivity and operational efficiency | Understanding of heavy-duty materials and durability requirements |

How Are Prototype Making Companies Used in Consumer Electronics?

In the consumer electronics sector, prototype making companies play a crucial role in the rapid development of new gadgets and devices. They help businesses transform innovative ideas into tangible prototypes that can be tested and showcased. This accelerates the time-to-market, allowing companies to stay competitive in a fast-paced industry. International buyers, particularly in regions like Africa and South America, should prioritize companies with expertise in electronic prototyping and adherence to international compliance standards to ensure product safety and market readiness.

What Role Do Prototype Makers Play in the Automotive Industry?

In the automotive industry, prototype making companies are essential for developing new components and systems. These companies facilitate the creation of prototypes that enable rigorous design validation and testing before mass production. This process helps manufacturers identify potential issues early, reducing costs associated with later-stage modifications. Buyers in Europe, such as those in Germany, should consider sourcing partners that can manage complex geometries and diverse materials, ensuring that prototypes meet stringent automotive standards.

How Do Healthcare Prototyping Services Enhance Medical Device Development?

Prototype making companies are pivotal in the healthcare sector, particularly for the prototyping of medical devices and equipment. They assist in creating prototypes that not only meet design specifications but also comply with regulatory requirements, ensuring patient safety. For international buyers in the Middle East, understanding the nuances of biocompatible materials and FDA regulations is critical when selecting a prototyping partner, as these factors significantly influence the success of medical device innovations.

Why Are Aerospace Prototyping Services Important for Aircraft Development?

In the aerospace industry, prototype making companies contribute significantly to the design and testing of aircraft components. By creating prototypes, these companies help reduce development costs and mitigate risks associated with new designs. Buyers in this sector should seek partners with a strong understanding of aerospace standards and experience with lightweight materials, as these factors are crucial for ensuring compliance and performance in high-stakes environments.

How Can Prototype Making Companies Improve Industrial Equipment Design?

Prototype making companies are vital in the industrial equipment sector, where they assist in prototyping machinery and manufacturing processes. This support leads to increased productivity and operational efficiency by allowing businesses to test and refine their designs before full-scale production. International buyers, particularly from developing regions, should focus on sourcing partners that understand heavy-duty materials and durability requirements, ensuring that prototypes can withstand demanding industrial environments.

3 Common User Pain Points for ‘prototype making companies’ & Their Solutions

Scenario 1: Navigating Prototype Development Complexity

The Problem: Many B2B buyers, particularly startups and small businesses, find themselves overwhelmed by the complexity of prototype development. They may have innovative ideas but lack the technical expertise to translate these ideas into a working prototype. This often results in confusion about which type of prototyping service to choose—whether to go with a 3D printing service, a product design firm, or a manufacturing company. The pressure to meet tight deadlines while ensuring quality further complicates the decision-making process.

The Solution: To address this challenge, buyers should start by clearly defining their prototype’s purpose and requirements. A structured approach involves creating a detailed specification document that outlines the product’s intended use, materials, design constraints, and budget. Once this is established, engaging with a product design and prototyping company that offers end-to-end services can simplify the process. These companies typically have the expertise to navigate various prototyping methods and can provide guidance on the best practices for Design for Manufacturability (DFM). Additionally, buyers should prioritize firms that offer comprehensive consultations and can assist with everything from initial sketches to final production, ensuring that the prototype meets both functional and aesthetic requirements.

Scenario 2: Intellectual Property Concerns in Prototyping

The Problem: Intellectual property (IP) theft is a significant concern for many B2B buyers, especially those in competitive markets. When collaborating with prototype making companies, buyers often worry about sharing sensitive information that could be misappropriated. This fear can lead to hesitation in engaging with necessary partners, ultimately stalling innovation and product development.

The Solution: To mitigate IP risks, buyers should prioritize prototyping companies that offer robust confidentiality agreements and a clear outline of their IP protection policies. Before entering any agreements, it’s essential to conduct thorough due diligence on potential partners. This can include reviewing their reputation in the industry, asking for references, and understanding their track record in handling proprietary information. Additionally, implementing non-disclosure agreements (NDAs) before sharing any sensitive details can provide an extra layer of security. Buyers should also consider working with companies that have established processes for IP management, ensuring that all innovations remain protected throughout the development process.

Scenario 3: Cost Overruns and Budget Mismanagement

The Problem: Many B2B buyers experience frustration with unexpected costs during the prototyping phase. Initial quotes can often change dramatically once the project is underway, leading to budget overruns and misallocation of resources. This is particularly prevalent when buyers do not have a clear understanding of the full scope of the prototyping process, including materials, labor, and potential revisions.

The Solution: To combat cost-related issues, buyers should take a proactive approach by establishing a detailed budget that includes a contingency fund for unforeseen expenses. It is also crucial to obtain a comprehensive quote that outlines all costs associated with the project. Engaging in a transparent dialogue with the chosen prototype making company about potential cost variables can help set realistic expectations. Additionally, buyers should seek out firms that utilize a project management system, allowing for continuous tracking of expenses against the initial budget. This not only enhances accountability but also allows for timely adjustments if costs begin to escalate beyond the agreed limits. Furthermore, opting for companies that provide clear milestone payments can help manage cash flow and ensure that expenses align with project deliverables.

Strategic Material Selection Guide for prototype making companies

What Are the Key Materials Used in Prototype Making?

When selecting materials for prototype making, companies must consider various factors, including the intended application, performance requirements, and cost-effectiveness. Here, we analyze four common materials used in the prototype development process: plastics, metals, composites, and ceramics. Each material has unique properties, advantages, and limitations that can significantly impact the final product’s performance and suitability for the market.

How Do Plastics Perform in Prototype Development?

Plastics, particularly thermoplastics like ABS (Acrylonitrile Butadiene Styrene) and PLA (Polylactic Acid), are widely used in prototype making due to their versatility and ease of processing. Key properties include a temperature rating of up to 100°C for ABS, good impact resistance, and corrosion resistance.

Pros: Plastics are lightweight, cost-effective, and can be easily molded into complex shapes. They are suitable for a variety of applications, including consumer products and automotive parts.

Cons: However, plastics may not withstand high temperatures or heavy loads, and their mechanical properties can degrade over time.

Impact on Application: For products exposed to moisture or chemicals, selecting a plastic with appropriate resistance is crucial.

Considerations for International Buyers: Compliance with standards such as ASTM D638 for tensile properties is essential. Buyers in regions like Europe may prefer biodegradable options like PLA, aligning with sustainability trends.

What Role Do Metals Play in Prototyping?

Metals, including aluminum and stainless steel, are favored for their strength and durability. Aluminum offers a good strength-to-weight ratio and excellent corrosion resistance, while stainless steel is known for its high-temperature resistance and toughness.

Pros: Metals provide superior mechanical properties, making them ideal for functional prototypes that require structural integrity.

Cons: The manufacturing complexity is higher, often requiring specialized machining or welding processes.

Impact on Application: Metal prototypes are particularly suited for applications in aerospace and automotive industries, where safety and performance are paramount.

Considerations for International Buyers: Buyers should be aware of material certifications, such as ISO 9001, and common standards like DIN EN 10088 for stainless steel.

How Do Composites Enhance Prototype Performance?

Composite materials, such as carbon fiber reinforced polymers (CFRP), combine the best properties of different materials. They offer high strength, low weight, and excellent fatigue resistance.

Pros: Composites are incredibly strong and lightweight, making them ideal for high-performance applications in aerospace and sports equipment.

Cons: The cost of composites can be significantly higher than that of metals and plastics, and their manufacturing processes can be complex and time-consuming.

Impact on Application: Composites are particularly effective in applications requiring high stiffness and low weight, such as in drone manufacturing.

Considerations for International Buyers: Compliance with aerospace standards like AS9100 is critical for buyers in the aerospace sector.

What Advantages Do Ceramics Offer in Prototyping?

Ceramics are known for their hardness and thermal stability. They can withstand high temperatures and are resistant to wear and corrosion, making them suitable for specific applications.

Pros: Ceramics are excellent for high-temperature applications and are often used in electronic components and cutting tools.

Cons: They are brittle and can be prone to cracking under stress, which limits their use in structural applications.

Impact on Application: Ceramics are ideal for applications requiring thermal resistance, such as in automotive engines or electronic insulators.

Considerations for International Buyers: Buyers should consider compliance with standards like ASTM C20 for ceramic materials, particularly in industries with strict regulatory requirements.

Summary Table of Material Properties for Prototype Making

| Material | Typical Use Case for prototype making companies | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Plastics | Consumer products, automotive parts | Lightweight and cost-effective | Limited temperature resistance | Low |

| Metals | Aerospace, automotive components | High strength and durability | Complex manufacturing processes | Medium |

| Composites | Aerospace, sports equipment | High strength-to-weight ratio | High cost and complex processing | High |

| Ceramics | Electronic components, cutting tools | Excellent thermal stability | Brittle and prone to cracking | Medium |

This analysis provides a comprehensive overview of the materials commonly used in prototype making, offering valuable insights for international B2B buyers. Understanding the properties, advantages, and limitations of each material can aid in making informed decisions that align with product requirements and market expectations.

In-depth Look: Manufacturing Processes and Quality Assurance for prototype making companies

What Are the Main Stages of Manufacturing Processes in Prototype Making Companies?

The manufacturing processes employed by prototype making companies are critical for transforming concepts into tangible products. These processes typically involve four main stages: material preparation, forming, assembly, and finishing. Each stage plays a vital role in ensuring the prototype meets the specifications and quality standards required for further development or market introduction.

How Is Material Prepared for Prototyping?

Material preparation is the initial phase where the raw materials are selected and processed to meet the design requirements. This can involve cutting, machining, or treating materials to ensure they are suitable for the forming stage. Common materials used include plastics, metals, and composites, each requiring specific preparation techniques. For instance, metals may need to be cut and shaped using CNC machining, while plastics could be prepped for injection molding.

B2B buyers should consider suppliers who have a diverse range of material options and the capability to prepare these materials efficiently. Ensuring that the prototype company uses high-quality materials is essential, as it directly impacts the final product’s durability and performance.

What Techniques Are Utilized in the Forming Stage?

The forming stage encompasses the methods used to create the prototype’s shape. This may involve various techniques such as 3D printing, injection molding, CNC machining, and sheet metal fabrication. Each technique has its advantages and is suited for different types of prototypes.

- 3D Printing: Ideal for rapid prototyping, this method allows for complex geometries and quick iterations. It’s particularly useful for creating initial models and functional prototypes.

- Injection Molding: Best suited for producing high volumes of prototypes with consistent quality, this technique is often employed once the design is finalized.

- CNC Machining: This method provides precision and is excellent for prototypes requiring tight tolerances.

B2B buyers should assess the capabilities of prototype companies to ensure they can utilize the right forming techniques for their specific needs.

How Does Assembly Take Place in Prototype Manufacturing?

Assembly is the stage where different components of the prototype are brought together. This can involve joining various parts using adhesives, screws, or welding, depending on the materials used and the prototype’s design complexity. Effective assembly is critical for ensuring the prototype functions as intended.

Buyers should inquire about the assembly processes utilized by potential suppliers, including any automated systems that might enhance efficiency and precision. Additionally, understanding the assembly techniques can provide insights into the prototype’s final performance and longevity.

What Are the Finishing Techniques Used for Prototypes?

Finishing involves adding the final touches to the prototype, which may include painting, coating, or surface treatment. This stage is essential for enhancing the prototype’s aesthetics and functionality. Finishing processes can also improve durability and resistance to environmental factors.

For B2B buyers, it’s important to consider how finishing techniques might affect the prototype’s market readiness. Suppliers should be able to offer a range of finishing options that align with the intended use of the prototype.

What Quality Assurance Practices Are Essential in Prototype Making?

Quality assurance (QA) is a critical aspect of the prototype manufacturing process, ensuring that the final product meets specified standards and functions as intended. Effective QA practices involve adhering to international standards, implementing quality checkpoints, and conducting various testing methods.

Which International Standards Should Prototype Companies Follow?

International standards such as ISO 9001 provide a framework for quality management systems, helping companies ensure consistent quality in their products and services. Other industry-specific certifications, such as CE marking for products sold in Europe or API standards for oil and gas equipment, may also be relevant depending on the prototype’s application.

B2B buyers should verify that their chosen prototype making companies comply with these standards, as this compliance indicates a commitment to quality and reliability.

What Are the Key Quality Control Checkpoints in Prototype Manufacturing?

Quality control (QC) checkpoints are integral to the manufacturing process, allowing for the identification and correction of issues at various stages. Common QC checkpoints include:

- Incoming Quality Control (IQC): Ensures that raw materials meet specified standards before production begins.

- In-Process Quality Control (IPQC): Monitors production processes to catch defects early.

- Final Quality Control (FQC): Conducts comprehensive checks on the finished prototype to ensure it meets all requirements.

These checkpoints help maintain high-quality standards throughout the manufacturing process. B2B buyers should inquire about the QC protocols in place at potential suppliers to ensure thorough oversight.

What Testing Methods Are Commonly Used in Prototype Quality Assurance?

Testing methods vary depending on the prototype’s intended use and industry standards. Common testing methods include:

- Functional Testing: Verifies that the prototype operates as intended.

- Stress Testing: Assesses how the prototype withstands various stresses and conditions.

- Dimensional Inspection: Ensures that the prototype meets design specifications.

Understanding the testing methods employed by prototype companies can provide B2B buyers with confidence in the reliability and performance of their products.

How Can B2B Buyers Verify Supplier Quality Control?

To ensure that a prototype making company adheres to stringent quality control measures, B2B buyers should consider the following verification methods:

- Audits: Conducting on-site audits can provide firsthand insight into a supplier’s quality management practices and manufacturing processes.

- Quality Reports: Requesting detailed quality reports can help assess a supplier’s track record in meeting quality standards.

- Third-Party Inspections: Engaging third-party inspection services can offer an unbiased assessment of the prototype’s quality and compliance with relevant standards.

For international buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, understanding the nuances of quality certifications and supplier capabilities is vital. Collaborating with suppliers who demonstrate transparency in their QC practices can mitigate risks and enhance product reliability.

In conclusion, a thorough understanding of manufacturing processes and quality assurance practices is essential for B2B buyers in selecting the right prototype making companies. By focusing on material preparation, forming, assembly, and finishing techniques, along with robust quality assurance measures, businesses can ensure they receive high-quality prototypes that meet their needs and expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘prototype making companies’

Introduction

In the competitive landscape of product development, selecting the right prototype making company is essential for bringing innovative ideas to life. This practical sourcing guide provides a step-by-step checklist designed to help B2B buyers navigate the complexities of identifying, evaluating, and engaging prototype manufacturers. Whether you are in Africa, South America, the Middle East, or Europe, these steps will ensure you make informed decisions that align with your project needs.

Step 1: Define Your Prototype Requirements

Before reaching out to potential suppliers, clarify your prototype specifications. Consider the type of prototype you need—be it a proof of concept, functional prototype, or a pre-production model.

– Key Details to Include:

– Material preferences (plastics, metals, etc.)

– Intended use and functionality of the prototype

– Expected timeline for delivery.

Step 2: Research and Shortlist Potential Suppliers

Conduct thorough research to identify companies that specialize in the type of prototype you need. Use industry directories, trade shows, and online platforms to compile a list of potential suppliers.

– Considerations:

– Company experience in your specific industry.

– Geographic location and its relevance to shipping and communication.

– Reviews and testimonials from previous clients.

Step 3: Evaluate Supplier Capabilities

Assess the capabilities of each shortlisted supplier to ensure they can meet your requirements. Request information about their manufacturing processes, technologies, and the types of prototypes they specialize in.

– Key Questions to Ask:

– What prototyping technologies do you utilize (e.g., 3D printing, CNC machining)?

– Do you have in-house design engineers, and what is their level of expertise?

– Can you provide examples of past projects similar to mine?

Step 4: Verify Certifications and Compliance

Ensure that the suppliers you are considering have the necessary certifications and comply with industry standards. This is crucial for ensuring quality and reliability.

– Certifications to Look For:

– ISO 9001:2015 for quality management.

– Industry-specific certifications relevant to your product (e.g., medical devices, automotive).

– Compliance with local and international regulations.

Step 5: Request Proposals and Quotes

Once you have narrowed down your list, reach out to your top candidates for proposals and quotes. Provide them with your defined requirements and ask for detailed responses that outline their approach to your project.

– What to Expect:

– Breakdown of costs, including design, materials, and production.

– Timelines for each phase of the prototyping process.

– Conditions related to ownership of intellectual property (IP) and confidentiality agreements.

Step 6: Conduct Supplier Interviews

Engage in discussions with potential suppliers to gauge their understanding of your project and their communication skills. This is also an opportunity to establish rapport and clarify any uncertainties.

– Focus Areas:

– Their willingness to collaborate and adapt to your needs.

– Availability of ongoing support and communication during the prototyping process.

– Understanding of design for manufacturability (DFM) principles.

Step 7: Make Your Decision and Formalize the Agreement

After evaluating all proposals and interviews, select the supplier that best aligns with your needs. Ensure you draft a detailed agreement that outlines the scope of work, timelines, costs, and confidentiality clauses.

– Important Elements to Include:

– Milestones for project deliverables.

– Payment terms and conditions.

– Provisions for revisions and quality checks.

By following this checklist, you can streamline your sourcing process and select a prototype making company that not only meets your technical requirements but also contributes to the successful launch of your product.

Comprehensive Cost and Pricing Analysis for prototype making companies Sourcing

What Are the Key Cost Components for Prototype Making Companies?

Understanding the cost structure of prototype making is crucial for B2B buyers. The primary components that contribute to the overall costs include:

-

Materials: The choice of materials significantly impacts the cost. Common materials like plastics, metals, and composites vary in price based on quality and availability. For instance, high-performance materials may elevate costs but offer better durability and functionality.

-

Labor: Skilled labor is essential for the design, engineering, and manufacturing processes. The labor cost can vary based on the geographic location of the supplier, with regions like Europe typically experiencing higher labor costs compared to Africa or South America.

-

Manufacturing Overhead: This includes the expenses related to the facility, utilities, and equipment maintenance. Companies that invest in advanced technologies may have higher overhead costs, which can be reflected in their pricing.

-

Tooling: Custom tooling is often required for specific prototypes, especially for injection molding. Tooling costs can be substantial and are typically amortized over the production volume, making them a critical consideration for buyers planning to scale production.

-

Quality Control (QC): Ensuring that prototypes meet quality standards can incur additional costs. Certifications and compliance with industry standards (such as ISO) may also add to the overall expense, but they are essential for maintaining product integrity.

-

Logistics: Shipping and handling costs can vary significantly based on the distance, shipping method, and Incoterms used. International buyers should consider these factors, as they can substantially influence the total cost.

-

Margin: Finally, the profit margin of the prototype making company will also factor into the pricing. This can vary widely based on the supplier’s market position, expertise, and the complexity of the project.

How Do Price Influencers Affect Prototype Costs?

Several factors influence the pricing of prototypes, which are essential for B2B buyers to understand:

-

Volume/MOQ: Minimum Order Quantities (MOQ) can lead to cost reductions. Companies may offer better pricing for larger volumes, which can benefit buyers planning for mass production.

-

Specifications and Customization: Custom designs and specifications often lead to increased costs due to the additional engineering and design efforts required. Buyers should be clear about their requirements to avoid unexpected expenses.

-

Material Selection: The choice of materials directly impacts pricing. Premium materials may offer better performance but come at a higher cost.

-

Quality and Certifications: Prototypes that require specific certifications or high-quality standards will generally incur higher costs. International buyers should verify the certifications relevant to their market.

-

Supplier Factors: The supplier’s location, expertise, and reputation can influence pricing. Established suppliers with advanced capabilities may charge more but offer reliability and superior quality.

-

Incoterms: The shipping terms agreed upon can affect logistics costs and risk management. Understanding Incoterms is vital for international transactions to avoid additional charges.

What Are the Best Negotiation Tips for B2B Buyers?

International B2B buyers, particularly from regions like Africa and South America, should consider the following tips to optimize costs:

-

Conduct Thorough Research: Understanding market rates and supplier capabilities can empower buyers during negotiations.

-

Leverage Volume Discounts: If you anticipate needing multiple prototypes, negotiate for bulk pricing to reduce costs.

-

Focus on Total Cost of Ownership (TCO): Rather than just looking at initial pricing, consider the long-term costs associated with maintenance, quality, and logistics.

-

Clarify Payment Terms: Discussing payment terms upfront can prevent financial strain and help manage cash flow effectively.

-

Be Open to Alternatives: If a supplier’s initial quote exceeds your budget, explore alternative materials or design adjustments that could reduce costs without compromising quality.

Disclaimer Regarding Prices

The costs associated with prototype making can vary widely based on the factors discussed above. Prices mentioned in discussions or quotes should be treated as indicative and subject to change based on market conditions and specific project requirements. Always seek detailed quotes and clarifications from suppliers to ensure accurate budgeting.

Alternatives Analysis: Comparing prototype making companies With Other Solutions

Exploring Alternatives to Prototype Making Companies

In the realm of product development, businesses often face the challenge of selecting the most effective method for creating prototypes. While prototype making companies offer specialized services, there are alternative solutions that can also meet the needs of B2B buyers. This analysis will compare prototype making companies against two viable alternatives: in-house prototyping and open-source prototyping tools.

Comparison Table

| Comparison Aspect | Prototype Making Companies | In-House Prototyping | Open-Source Prototyping Tools |

|---|---|---|---|

| Performance | High quality, tailored designs with expert guidance. | Varies based on team skills and available resources. | Quality depends on user expertise and community support. |

| Cost | Generally higher, but varies by complexity and service level. | Initial investment in tools and materials; ongoing labor costs. | Usually low-cost or free, but may require investment in training. |

| Ease of Implementation | Streamlined process with professional support. | Requires skilled personnel and can be time-consuming to set up. | User-friendly for tech-savvy teams; setup may require technical knowledge. |

| Maintenance | Minimal; companies handle updates and revisions. | Ongoing maintenance and updates depend on internal capabilities. | Community-driven; updates depend on user engagement and contributions. |

| Best Use Case | Best for complex, high-stakes products needing expert input. | Suitable for companies with skilled teams and clear prototyping needs. | Ideal for startups or teams looking for cost-effective, flexible solutions. |

In-House Prototyping: Advantages and Disadvantages

In-house prototyping allows companies to have complete control over the design and production process. This method can be beneficial for organizations with established engineering teams, as it enables rapid iterations and quick modifications. However, the main drawbacks include the potential for inconsistent quality and the need for significant investment in equipment and training. For businesses with limited resources or expertise, this approach may lead to inefficient use of time and materials.

Open-Source Prototyping Tools: Advantages and Disadvantages

Open-source prototyping tools provide a cost-effective way for businesses to create prototypes without the need for expensive services. These platforms often come with a wealth of community resources, tutorials, and templates, making them accessible for teams with varying skill levels. However, the success of this approach largely depends on the user’s technical proficiency and the community’s engagement. While it can be an excellent option for startups or smaller enterprises, the lack of professional support may pose challenges for more complex projects.

Conclusion: How to Choose the Right Prototyping Solution

When selecting a prototyping solution, B2B buyers should consider their specific needs, resources, and project complexity. Prototype making companies are ideal for businesses seeking high-quality, tailored prototypes with expert guidance, especially for intricate products. Conversely, companies with skilled teams may benefit from in-house prototyping, while startups looking for flexibility and low costs might find open-source tools more suitable. Ultimately, evaluating the trade-offs between quality, cost, and expertise will help buyers make informed decisions that align with their product development goals.

Essential Technical Properties and Trade Terminology for prototype making companies

What Are the Key Technical Properties in Prototype Making?

Understanding the essential technical properties involved in prototype making is crucial for B2B buyers, especially when evaluating potential partnerships with prototype manufacturing companies. Here are some key specifications:

1. Material Grade

Material grade refers to the specific classification of materials based on their properties, such as strength, flexibility, and thermal resistance. Common material grades include ABS plastic, aluminum alloys, and stainless steel. In B2B contexts, selecting the right material grade ensures that the prototype can withstand its intended use, which is vital for testing and demonstration purposes.

2. Tolerance

Tolerance indicates the permissible limit of variation in a physical dimension. It is expressed in terms of a range (e.g., ±0.1 mm) and is essential for ensuring that parts fit together correctly during assembly. For B2B buyers, understanding tolerance is critical as it impacts the functionality of the prototype and can lead to costly adjustments or redesigns if not adequately specified.

3. Surface Finish

Surface finish describes the texture of a surface after manufacturing, which can affect both aesthetics and functionality. Common finishes include polished, matte, and anodized. For businesses, the right surface finish can enhance product appeal, facilitate better adhesion for coatings, and improve durability against wear and tear.

4. Dimensional Stability

Dimensional stability refers to the ability of a material to maintain its dimensions when subjected to changes in temperature and humidity. This property is particularly important for prototypes that will undergo testing in various environmental conditions. For B2B buyers, ensuring dimensional stability can reduce the risk of failure in the final product and enhance reliability.

5. Mechanical Properties

Mechanical properties include strength, elasticity, and toughness, which determine how a material behaves under various forces. These properties are crucial for prototypes that need to endure stress during testing phases. Buyers should assess these properties to ensure that the prototype can meet performance standards and fulfill market requirements.

What Are Common Trade Terms in Prototype Manufacturing?

Familiarity with industry jargon can significantly enhance communication and negotiation with prototype making companies. Here are some important terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of prototypes, working with an OEM can facilitate access to specialized components that enhance the prototype’s functionality. Understanding OEM relationships can help buyers evaluate potential partnerships and supply chain strategies.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest amount of a product that a supplier is willing to sell. For B2B buyers, knowing the MOQ is essential when planning production runs, as it can affect budget allocation and inventory management. Negotiating lower MOQs may be beneficial for startups or companies testing new products.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and other details for specific goods or services. It is a critical tool for buyers to gather competitive bids and assess potential vendors. Crafting a well-defined RFQ can lead to better pricing, terms, and understanding of supplier capabilities.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in shipping goods. They clarify who pays for shipping, insurance, and tariffs, which is crucial for international transactions. Understanding Incoterms helps B2B buyers manage logistics costs and mitigate risks in cross-border trading.

5. DFM (Design for Manufacturing)

DFM is the practice of designing products in a way that simplifies their manufacturing. By considering manufacturing processes during the design phase, buyers can reduce costs and production time. For companies looking to streamline their prototype development, DFM principles are invaluable for ensuring efficient scaling to mass production.

By grasping these technical properties and trade terms, international B2B buyers can make informed decisions, ensuring effective collaboration with prototype making companies.

Navigating Market Dynamics and Sourcing Trends in the prototype making companies Sector

What Are the Current Market Dynamics in the Prototype Making Sector?

The global prototype making sector is undergoing significant transformation driven by technological advancements and evolving market demands. Key trends include the rise of digital manufacturing technologies such as 3D printing, CNC machining, and injection molding, which are becoming more accessible to startups and SMEs across regions like Africa, South America, the Middle East, and Europe. This democratization of technology enables faster prototyping cycles and cost-effective solutions, allowing companies to bring products to market more rapidly.

Furthermore, the trend towards on-demand production is gaining traction, as companies are increasingly adopting just-in-time manufacturing strategies. This approach minimizes inventory costs and enhances supply chain efficiency, a crucial factor for international B2B buyers looking to optimize operational expenditures. Additionally, as businesses focus on innovation, there is a growing emphasis on collaboration between engineering teams and prototyping firms. This synergy allows for the integration of design for manufacturability (DFM) principles from the outset, reducing the risk of costly redesigns later in the production process.

Moreover, the increasing importance of digital platforms for sourcing and collaboration cannot be overlooked. Tools that facilitate online quoting and project management are streamlining the sourcing process, making it easier for international buyers to find suitable prototype makers. As such, buyers from diverse regions, including Nigeria and Germany, must stay abreast of these evolving dynamics to effectively navigate the prototype making landscape.

How Is Sustainability Influencing Sourcing Decisions in Prototype Making?

Sustainability has emerged as a critical factor influencing sourcing decisions in the prototype making sector. International buyers are increasingly recognizing the environmental impact of their supply chains, prompting a shift towards more sustainable practices. This includes the adoption of eco-friendly materials and processes that minimize waste and energy consumption. For instance, many prototype makers are investing in biodegradable plastics and recyclable materials, which not only reduce carbon footprints but also appeal to environmentally-conscious consumers.

Moreover, the importance of ethical sourcing cannot be overstated. Companies are expected to ensure that their supply chains adhere to ethical standards, which include fair labor practices and responsible sourcing of raw materials. As a result, buyers are looking for prototype making companies that can provide transparency regarding their sourcing practices and demonstrate compliance with sustainability certifications.

Green certifications, such as ISO 14001 and LEED, are becoming increasingly important in the prototype making industry. These certifications signal a company’s commitment to sustainable practices and can enhance a buyer’s confidence in their sourcing decisions. By prioritizing sustainability and ethical sourcing, international B2B buyers can not only mitigate risks associated with environmental regulations but also enhance their brand reputation and appeal to a broader customer base.

How Has the Prototype Making Sector Evolved Over Time?

The evolution of the prototype making sector is marked by significant technological advancements and shifts in market needs. Initially dominated by traditional manufacturing methods, the industry has witnessed a transition to digital technologies, particularly with the introduction of 3D printing in the 1980s. This innovation revolutionized prototyping by allowing for rapid iterations and cost-effective production of complex designs.

As the market matured, the focus shifted towards creating more sophisticated prototypes that incorporate advanced materials and manufacturing techniques. The rise of computer-aided design (CAD) software further accelerated this evolution, enabling designers and engineers to create highly detailed models that can be easily translated into physical products.

In recent years, the integration of digital manufacturing and automation has transformed how prototypes are developed, enabling faster turnaround times and more efficient production processes. This evolution reflects a broader trend in the manufacturing sector towards innovation, flexibility, and responsiveness to market demands, positioning the prototype making industry as a vital component of modern product development strategies. As international B2B buyers seek to capitalize on these advancements, understanding the historical context of this evolution can inform more strategic sourcing decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of prototype making companies

-

How do I choose the right prototype making company for my needs?

Choosing the right prototype making company involves evaluating several key factors. First, assess your specific needs—are you looking for rapid prototyping, complex engineering support, or low-volume production? Second, consider the company’s expertise in your industry and their ability to protect your intellectual property. Additionally, review their past projects and client testimonials. Finally, compare pricing models and turnaround times to ensure they align with your budget and schedule. -

What types of prototypes can I create with a prototyping company?

Prototyping companies offer various types of prototypes, including proof of concept, functional prototypes, and pre-production models. A proof of concept prototype is ideal for validating an idea, while functional prototypes are used for testing usability and performance. Pre-production prototypes are designed to closely mimic the final product for market testing. Understanding the purpose of your prototype will help you communicate effectively with the prototyping company and select the right type. -

What are the typical payment terms when working with prototype making companies?

Payment terms vary by company and can include upfront deposits, milestone payments, or payment upon completion. Many companies require a deposit (often 30-50%) before starting work, with the remainder due upon project completion or delivery. It’s essential to clarify these terms in advance to ensure that they align with your cash flow and budget. Additionally, inquire about any potential hidden fees, such as revisions or additional materials. -

What is the minimum order quantity (MOQ) for prototype production?

Minimum order quantities can differ significantly among prototype making companies. Some may accept low MOQs, particularly for initial prototypes, while others might require larger quantities for cost-effective production. If you are a startup or small business, look for companies that specialize in low-volume production or that have flexible MOQ policies. Always confirm the MOQ before starting the project to avoid unexpected costs. -

How do I ensure quality assurance (QA) in my prototype production?

To ensure quality assurance during prototype production, request detailed quality control processes from the prototyping company. Look for companies that are ISO-certified, as this indicates adherence to international quality standards. Additionally, discuss inspection protocols, including material checks and dimensional accuracy, before production begins. Regular updates and feedback loops throughout the development process can also help maintain quality. -

What logistical considerations should I keep in mind when sourcing a prototype making company internationally?

When sourcing a prototype making company internationally, consider shipping costs, lead times, and customs regulations. Shipping can significantly affect your timeline and budget, so choose a company with a clear logistics plan. Additionally, understand the customs duties that may apply to your prototypes upon import. It may be beneficial to work with companies that have experience in international shipping to streamline the process. -

How can I protect my intellectual property when working with prototype makers?

Protecting your intellectual property (IP) is crucial when collaborating with prototype makers. Start by having a non-disclosure agreement (NDA) in place before sharing any sensitive information. Choose companies that are willing to sign NDAs and have established IP protection practices. Additionally, consider working with firms that have a transparent process for handling IP rights, ensuring you retain ownership of your designs and concepts. -

What types of materials are commonly used in prototype making, and how do I choose the right one?

The choice of materials for prototype making depends on the prototype’s purpose and functionality. Common materials include plastics, metals, and composites, each offering different properties such as strength, flexibility, and weight. For functional prototypes, consider materials that mimic the final product’s characteristics. Discuss your requirements with the prototyping company to understand the best material options available and their implications on cost and production time.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 Prototype Making Companies Manufacturers & Suppliers List

1. Protolabs – Rapid Prototyping & Injection Molding Services

Domain: protolabs.com

Registered: 2006 (19 years)

Introduction: Protolabs offers a range of rapid prototyping and on-demand production services including:

1. **Injection Molding Services**:

– Plastic Injection Molding

– Liquid Silicone Rubber Molding

– Overmolding

– Insert Molding

– Family and Multi-Cavity Molding

– Low-volume molding up to 100,000+ parts with no MOQ required

– 100+ plastic, elastomeric, and silicone rubber materi…

2. Top Prototype Firms – DesignRush

Domain: designrush.com

Registered: 2015 (10 years)

Introduction: 20 Top Product Prototype Companies – Jul 2025 Rankings | DesignRush. The directory includes agencies specializing in product design and prototyping for startups, entrepreneurs, SMEs, and large companies. Key details include average ratings from verified reviews, project budgets ranging from $10,000 to $50,000+, and hourly rates from $25 to $149. Notable agencies include Naked Development, Altar.io…

3. Prototype House – Comprehensive Product Design Services

Domain: prototypehouse.com

Registered: 2010 (15 years)

Introduction: Prototype House, Inc offers a full suite of end-to-end product design services including: 1. Concept Ideation & Design 2. 3D CAD Engineering & Technical Drawings 3. Software & Electrical Engineering 4. 3D Printing & Functional Prototypes 5. Manufacturing & Product Launch Support 6. Product Design 7. Feasibility Studies 8. Concept Validation Research 9. Technical Drawings & Tech Packs 10. Prototype…

4. HLH Prototypes – Rapid Prototype Manufacturing Solutions

Domain: hlhprototypes.com

Registered: 2012 (13 years)

Introduction: HLH Prototypes specializes in Rapid Prototype Manufacturing Services, offering a range of solutions including: 3D Printing (SLA, SLS, FDM, DMLS, Projet MJP), CNC Machining, Rapid Injection Moulding, Carbon Fiber 3D Printing, Sheet Metal Work, Vacuum Casting, Aluminum Forging, Die Casting, and Export Tooling. They cater to various industries such as Aerospace & UAV, Automotive, Telecommunications, …

5. UPTIVE MFG – Key Product Details

Domain: uptivemfg.com

Registered: 2023 (2 years)

Introduction: Key product details include: 1. UPTIVE Advanced Manufacturing – Services: Rapid prototyping, Additive manufacturing, CNC machining, Sheet metal fabrication, Injection molding and tooling, Post-processing and finishing. Technologies: Direct Metal Laser Sintering (DMLS), Selective Laser Sintering (SLS), Fused Deposition Modeling (FDM), Stereolithography (SLA), HP Multi Jet Fusion (MJF), PolyJet (PJP…

6. LanPDT – Prototyping Solutions

Domain: lanpdt.com

Registered: 2014 (11 years)

Introduction: Prototyping Company offers product prototype manufacturing services, focusing on transforming ideas into physical products. Their services include product discovery, product design, prototyping, manufacturing, and research. They cater to various sectors such as personal care, pet products, sports and fitness, and product packaging development. The company emphasizes the importance of prototypes in…

7. 3ERP – Rapid Prototyping & Manufacturing Services

Domain: 3erp.com

Registered: 2000 (25 years)

Introduction: Rapid Prototyping Services, Low-Volume Manufacturing, CNC Machining Services (CNC Milling, CNC Turning, 5-Axis CNC Machining, Precision Machining), Injection Molding Services (Mold Tool Making, Rapid Tooling, Plastic Injection Molding, Liquid Silicone Rubber Molding), Sheet Metal Services (Laser Cutting, Metal Bending), 3D Printing, Custom Extrusion, Urethane Casting, Die Casting Solutions, Surfac…

Strategic Sourcing Conclusion and Outlook for prototype making companies

In navigating the prototype development landscape, strategic sourcing emerges as a pivotal factor for international B2B buyers. Understanding the various types of prototype making companies—ranging from 3D printing services to comprehensive product design firms—enables businesses to identify the right partners for their unique needs. Key considerations include the complexity of the product, the level of engineering support required, and the potential for scaling production.

By aligning with the appropriate prototype makers, companies can safeguard intellectual property, enhance design for manufacturability (DFM), and streamline the transition from concept to market-ready products. For buyers in emerging markets across Africa, South America, the Middle East, and established regions like Europe, leveraging global expertise while maintaining local relevance can unlock significant competitive advantages.

As we look to the future, the demand for innovative prototypes will only increase. We encourage B2B buyers to engage proactively with prototype making companies, fostering partnerships that not only bring ideas to life but also set the stage for sustainable growth and market leadership. Embrace the journey of prototyping with strategic sourcing at its core to drive your product success.