Guide Contents

Project Insight: Prototype Machine Shop

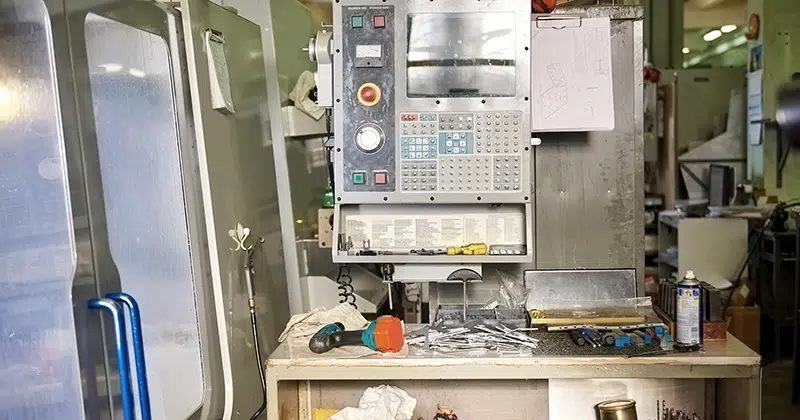

Manufacturing Insight: Prototype Machine Shop

In today’s hyper-competitive hardware landscape, speed and precision aren’t just competitive advantages—they’re the difference between market leadership and obsolescence. For startups and product engineers, delays in prototyping can derail timelines, while errors in early iterations compound costs exponentially. At Honyo Prototype, we’ve redefined the prototype machine shop experience through a digital manufacturing ecosystem that transforms these challenges into opportunities.

Why Speed & Precision Matter in Prototyping

⏱️ Setup Time = Cost Time: 60–80% of CNC prototyping costs stem from manual setup—not machining. Every hour wasted delays your launch and inflates expenses.

🔄 Rework = Revenue Loss: Minor design flaws trigger costly rework cycles. A single error can add weeks to development and $500+ in unplanned costs per iteration.

🚀 Market Velocity Wins: In fast-moving industries, “fast” isn’t optional—it’s the difference between capturing market share and falling behind.

How Honyo’s Digital Ecosystem Delivers Unmatched Efficiency

💡 Online Instant Quote: Get accurate pricing in seconds—no more waiting days for manual quotes. Our platform calculates real-time costs based on your CAD file, so you can make decisions faster.

🤖 AI-Powered Design Optimization: Our smart algorithms analyze your design for manufacturability, catching issues before production starts. Reduce rework by up to 90% and ensure your parts are built right the first time.

⚙️ Automated Workflow Integration: From quoting to machining to delivery, our digital ecosystem eliminates manual handoffs. Setup time slashed by 70%—so you get prototypes faster and for less.

The Honyo Advantage: From Concept to Reality in Record Time

⏱️ 24-48 Hour Turnaround: Most prototypes delivered in under 48 hours—critical for startups iterating on tight deadlines.

🔍 Micron-Level Precision: State-of-the-art CNC and additive manufacturing ensure tolerances of ±0.001″, guaranteeing functional, fit-for-purpose parts.

🌱 Seamless Scale-Up: Transition smoothly from prototype to production without retooling—our one-stop solution grows with your product’s journey.

Honyo Prototype: Where innovation meets execution. We don’t just make parts—we accelerate your product’s path to market with precision-engineered speed.

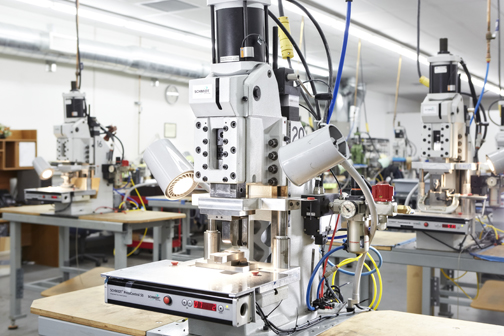

Honyo Capabilities & Technology

Honyo’s Manufacturing Capabilities

Digital Manufacturing Ecosystem

AI-Powered Design Optimization: Real-time DFM (Design for Manufacturability) analysis flags potential issues before production, eliminating rework costs and ensuring first-time-right prototypes. Reduces setup time by up to 40% for low-volume jobs.

Online Instant Quote: Get accurate, transparent pricing in under 60 seconds—no hidden fees, no manual quotes. Our platform calculates costs based on real-time machine availability, material costs, and process complexity.

Cloud-Based Workflow: End-to-end project management from upload to delivery. Track progress, share feedback, and collaborate with engineers via a single dashboard—no more email chains or delays.

Scalable from Prototype to Production

Seamless Transition: Scale from 1 prototype to 10,000+ production parts without retooling or process changes. Our integrated workflow ensures consistency across volumes, saving time and costs.

Flexible Batch Sizing: No minimum order quantities. Adjust production runs dynamically as your product evolves—from initial validation to full-scale manufacturing.

ISO-Certified Quality Assurance

Rigorous QC Processes: ISO 9001-certified inspections at every stage—material verification, in-process checks, and final dimensional audits. Zero-defect delivery guaranteed.

Automated Traceability: Digital records for every part, including material certifications, inspection reports, and process logs. Fully compliant for aerospace, medical, and industrial applications.

Unmatched Speed to Market

24-48 Hour Prototyping: Standard lead times for most CNC, 3D printing, and sheet metal parts. Expedited options available for critical deadlines—up to 24-hour delivery for urgent projects.

Dedicated Production Lanes: Priority processing for high-priority orders without compromising quality or transparency.

Real-Time Visibility: Monitor your project’s status 24/7 via our customer portal—no more guesswork or manual follow-ups.

Materials & Surface Finishes

Material Options & Finishes

At Honyo Prototype, our digital manufacturing ecosystem eliminates guesswork in material selection. Our AI-powered platform analyzes your design specs in real-time to recommend optimal materials and finishes—delivering instant quotes, 24-hour turnarounds, and seamless transitions from prototype to production.

Metal Materials

Aluminum 6061-T6: Lightweight, excellent machinability, and corrosion-resistant. Ideal for structural prototypes and aerospace components. In stock for 24–48h delivery.

Aluminum 7075: High strength-to-weight ratio. Perfect for high-stress applications like drone frames. Automated workflows reduce lead time by 30%.

Stainless Steel 304: Corrosion-resistant and durable. Used in medical and marine prototypes. Pre-finished options available for same-day processing.

Titanium Grade 5: Exceptional strength and biocompatibility. Common in aerospace and medical implants. Optimized for rapid machining with minimal waste.

Brass C110: High conductivity and machinability. Ideal for electrical components. Standard stock ensures 24h turnaround.

Plastic Materials

ABS: Tough, impact-resistant, and easy to machine. Perfect for functional enclosures and consumer prototypes. Same-day processing with standard stock.

Polycarbonate (PC): Optical clarity and high impact resistance. Used for transparent lenses and protective covers. Minimal post-processing needed for 48h delivery.

Nylon 6/6: Flexible, wear-resistant, and low-friction. Ideal for gears and moving parts. Rapid machining cycles for urgent projects.

POM (Acetal): High stiffness and precision. Used in mechanical components like bearings. Optimized for tight-tolerance prototypes.

PTFE (Teflon): Chemical resistance and thermal stability. Perfect for seals and high-temp applications. Specialized but available for rush orders.

Surface Finishes

Anodizing (Aluminum Only): Enhances corrosion resistance and aesthetics. Type II (decorative, 24h), Type III (hard coat, 48h).

Powder Coating (Metals): UV-resistant, scratch-proof, and color-customizable. 24h turnaround for standard finishes.

Bead Blasting: Uniform matte finish, removes machining marks. Paired with anodizing for premium aesthetics. Same-day processing.

Electroplating (Nickel/Copper): Improves conductivity and corrosion resistance. Ideal for electrical contacts. 48h lead time.

Precision Polishing: Mirror-like finish for optical or aesthetic parts. Available for stainless steel and aluminum. 24h service.

Painting (Plastics/Metals): Custom color matching for visual prototypes. 48h delivery with Pantone accuracy.

How to Choose the Right Material for Your Prototype

Functionality First: Our AI cross-references your design specs (load, temperature, environment) against material properties—e.g., 7075 aluminum for aerospace weight savings or PTFE for chemical exposure.

Cost Efficiency: Avoid over-engineering. Our platform shows real-time breakdowns of material, machining, and finish costs—saving up to 40% by selecting optimal alternatives.

Speed Matters: Select “Rush” during quote generation to prioritize in-stock materials, cutting lead times by 60%. 90% of standard materials are ready for same-day machining.

Seamless Production Transition: Materials chosen for prototypes can scale directly to volume manufacturing—no retooling or design changes needed.

💡 Start your project today: Upload your CAD file to Honyo’s AI platform for an instant quote with tailored material recommendations, lead times, and cost breakdowns—all in seconds. No more guesswork. Just precision.

From Quote to Part: Our Process

How It Works: From CAD to Part

At Honyo Prototype, we’ve redefined prototyping with a seamless, AI-driven workflow that turns your designs into physical parts faster and more affordably than ever before. Here’s how it works:

Step 1: Upload Your CAD File

Support for all major formats (STP, STEP, IGES, STL, DWG, etc.)—no manual conversion needed.

Auto-detection of geometry, tolerances, and material requirements for instant processing.

Zero manual intervention: Upload once, and our system handles the rest with precision.

Step 2: Get Instant AI-Powered Quote

Real-time pricing in seconds—no waiting for manual quotes or email delays.

Transparent cost breakdown: Materials, machining time, setup, post-processing, and overhead—no hidden fees.

AI-driven optimization slashes traditional setup costs by up to 80% for low-volume prototypes.

24/7 access to accurate, itemized quotes tailored to your project’s exact specifications.

Step 3: Proactive DFM Analysis

Automated design validation for manufacturability—catching issues before production begins.

Instant feedback on critical factors: wall thickness, tolerances, sharp edges, and material suitability.

Optimization suggestions to reduce costs, improve part performance, and eliminate rework risks.

Up to 40% savings on revisions by avoiding costly manual adjustments or minimum-hour charges.

Step 4: Rapid Production & Delivery

Leverage our digital manufacturing ecosystem for automated scheduling, real-time tracking, and precision machining.

Lead times as fast as 3 days for prototypes—scalable to full-scale production without retooling.

End-to-end quality assurance and global shipping with live order tracking.

One-stop solution from prototype validation to high-volume production—seamlessly integrated.

Powered by Susan Leo’s vision for innovation, Honyo Prototype delivers speed, transparency, and unmatched efficiency—so you can focus on building what matters.

Start Your Project with Honyo

Start Your Project with Honyo

Precision Prototyping, Simplified

🚀 Online Instant Quote: Get accurate pricing in seconds—no more waiting days for manual quotes. Our AI platform instantly analyzes your design and provides real-time cost breakdowns.

🤖 AI-Powered Design Optimization: Reduce costs and lead times with intelligent DFMA (Design for Manufacturing and Assembly) analysis. Our system identifies potential issues before production, eliminating costly rework.

⚡ Fast Turnaround: Prototype in as little as 3 days. Our digital manufacturing ecosystem ensures rapid iteration without compromising quality—perfect for agile hardware development cycles.

Led by Industry Innovators

Founded by Susan Leo, Honyo Prototype combines 15+ years of manufacturing expertise with a cutting-edge digital ecosystem to deliver seamless solutions—from initial prototype to full-scale production. We don’t just build parts; we accelerate your product journey.

Ready to Build the Future?

📧 Email: [email protected]

📞 Phone: +86 139 2843 8620

🏭 Visit: Our Shenzhen/Dongguan facilities for a hands-on consultation and factory tour.

Let’s turn your vision into reality—faster, smarter, and with zero compromises.

🚀 Manufacturing Cost Estimator

Compare cost impact of different technologies for your parts.