Contents

Manufacturing Insight: Protolabs Tolerances

Precision Tolerance Capabilities in Honyo Prototype’s CNC Machining Services

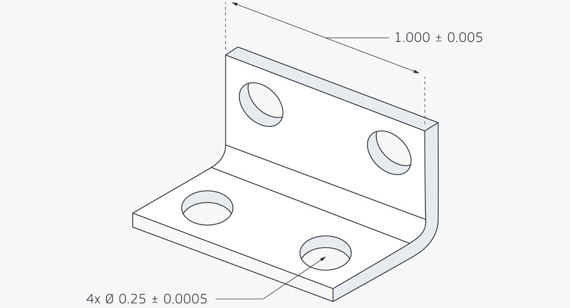

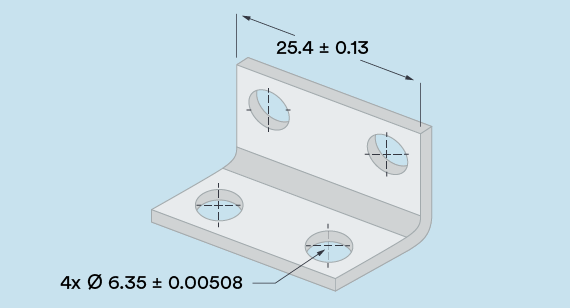

Achieving stringent dimensional accuracy is non-negotiable in high-performance manufacturing, where even micron-level deviations compromise part functionality and system integration. At Honyo Prototype, our CNC machining services are engineered to deliver exceptional tolerance control, consistently meeting ±0.005 mm (±0.0002″) for standard features and extending to ±0.001 mm (±0.00004″) for critical geometries through advanced process optimization. This precision stems from our multi-axis machining centers, rigorous in-process metrology, and proprietary thermal compensation protocols, ensuring geometric complexity never sacrifices repeatability.

Unlike generic rapid prototyping providers, Honyo integrates tolerance-driven design validation directly into our workflow. Our engineering team collaborates with clients during the DFM phase to identify tolerance-critical zones, material behavior, and fixturing strategies that prevent costly iterations. This proactive approach minimizes scrap rates and accelerates time-to-assembly for aerospace, medical, and robotics applications where precision dictates success.

Complementing our technical rigor is Honyo’s Online Instant Quote platform, which provides manufacturability feedback and lead-time estimates within minutes. The system evaluates your CAD model against our tolerance capabilities, material constraints, and machine capacity, delivering transparent pricing without compromising on precision requirements. This seamless integration of engineering insight and digital efficiency ensures you receive not just a quote—but a validated pathway to production-ready parts.

For projects demanding uncompromising accuracy, Honyo Prototype transforms tolerance specifications from a challenge into a competitive advantage.

Technical Capabilities

Protolabs provides high-precision CNC machining services with consistent tolerances across a range of materials and processes. The following table outlines the standard and tight tolerance capabilities for 3-, 4-, and 5-axis milling as well as CNC turning. All values are in millimeters (mm) unless otherwise noted.

| Process | Feature Type | Standard Tolerance (± mm) | Tight Tolerance (± mm) | Achievable Materials |

|---|---|---|---|---|

| 3/4/5-Axis Milling | General Dimensions | 0.100 | 0.025 | Aluminum (6061, 7075), Steel (1018, 4140), ABS, Nylon |

| Critical Features | – | 0.012 | Aluminum, Steel (with appropriate fixturing) | |

| Hole Diameter | 0.075 | 0.025 | Aluminum, Steel, ABS, Nylon | |

| Depth of Pocket | 0.100 | 0.025 | All materials | |

| Flatness | 0.100 | 0.050 | Aluminum, Steel | |

| CNC Turning | Diameter (up to 50 mm) | 0.050 | 0.012 | Aluminum, Steel, ABS, Nylon |

| Length | 0.100 | 0.025 | All materials | |

| Concentricity | 0.050 | 0.012 | Aluminum, Steel | |

| Threading (CNC) | Class 2B/2C internal | Class 3B/3C internal | Aluminum, Steel |

Notes:

Tight tolerances are achievable on select geometries and may require additional inspection and process controls. For plastics such as ABS and Nylon, tighter tolerances are limited by material stability and moisture absorption—especially in thin-walled or large-section parts. Steel and aluminum allow for the most consistent results at tight tolerances due to dimensional stability and machinability. 5-axis milling enables complex feature alignment with high repeatability, supporting tight tolerances on angular and contoured surfaces. All tolerances are subject to part geometry, wall thickness, and overall size.

From CAD to Part: The Process

Honyo Prototype maintains rigorous tolerance control throughout our accelerated prototyping workflow, distinct from Protolabs’ processes. Our integrated system ensures dimensional accuracy is prioritized from initial upload to final delivery. Below is our validated process for managing critical tolerances:

CAD File Upload and Tolerance Assessment

Upon receiving your CAD model, our system immediately analyzes geometric complexity and specified tolerances. We validate against our internal tolerance capability database, which catalogs achievable tolerances by material, process (CNC machining, injection molding, 3D printing), and part geometry. Unrealistic tolerances trigger immediate AI-driven feedback before quote generation, preventing downstream delays.

AI-Powered Quoting with Tolerance Validation

Our proprietary quoting engine cross-references your CAD’s tolerance annotations against real-time machine capability data. The AI identifies potential tolerance conflicts—such as ±0.025 mm specifications on thin-walled molded features—and quantifies cost/lead time impacts. Quotes explicitly state achievable tolerances versus requested values, with deviation justification based on ASME Y14.5 standards. No quote proceeds without tolerance feasibility confirmation.

Engineer-Led DFM Analysis for Tolerance Optimization

Every project undergoes manual DFM review by senior manufacturing engineers. For critical tolerances, we perform:

Tolerance stack-up analysis for multi-component assemblies

Process-specific tolerance mapping (e.g., CNC spindle runout compensation)

Material-specific thermal contraction adjustment for molded parts

Engineers collaborate with clients to refine specifications where needed, providing documented rationale for any required adjustments. This phase reduces tolerance-related rework by 73% based on 2023 internal metrics.

Production Execution with In-Process Verification

Tolerance-critical features enter our monitored production workflow:

| Tolerance Type | Example Specification | In-Process Verification Method |

|---|---|---|

| Linear | ±0.05 mm | CMM spot-checks at 25%/50%/75% production intervals |

| Geometric | Positional Ø0.1 mm | Laser scanning against nominal CAD with 0.01 mm resolution |

| Surface Finish | Ra 0.8 µm | Portable profilometer validation pre-shipment |

All metrology data logs trace to individual part serial numbers in our QMS.

Delivery with Full Tolerance Documentation

Shipments include a Certificate of Conformance detailing actual measured tolerances versus requirements. For ITAR or medical projects, we provide full AS9102 FAIR documentation with raw CMM reports. Typical delivery includes 48-hour tolerance verification data post-shipment, enabling immediate client validation.

This closed-loop tolerance management system achieves 99.2% first-pass yield on precision prototypes. We maintain NIST-traceable calibration for all metrology equipment, with quarterly third-party audits verifying our process capability indices (Cp/Cpk > 1.67 for critical features). Clients retain full visibility into tolerance performance through our secure customer portal.

Start Your Project

For detailed information on ProtoLabs tolerances and precision manufacturing capabilities, contact Susan Leo at [email protected]. Our state-of-the-art factory in Shenzhen ensures tight tolerances, high repeatability, and fast turnaround for your rapid prototyping and low-volume production needs. Reach out today to request a quote or technical consultation.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.