Contents

Manufacturing Insight: Protolabs Myrapid

Introducing Honyo Prototype’s Integrated CNC Machining Solution via Protolabs MyRapid

Honyo Prototype delivers advanced CNC machining capabilities seamlessly integrated within the Protolabs MyRapid platform, providing engineering and procurement teams immediate access to rapid, high-precision manufacturing for prototypes and low-volume production. This strategic partnership leverages Honyo’s extensive expertise in complex CNC milling and turning alongside Protolabs’ industry-leading digital infrastructure to significantly compress development cycles.

Our core strength lies in producing tight-tolerance metal and plastic components with exceptional surface finish and dimensional accuracy, directly supporting demanding applications across aerospace, medical, and industrial sectors. The integration ensures your designs uploaded to MyRapid undergo instant manufacturability analysis against Honyo’s specific machine capabilities and material offerings.

Precision CNC Machining Capabilities at Your Fingertips

| Feature | Specification | Benefit |

|——————|———————————————–|——————————————|

| Materials | Aluminum, Stainless Steel, Titanium, Plastics | Broad material suitability for testing |

| Tolerances | Down to ±0.0002″ (5µm) | Critical feature accuracy for validation |

| Lead Times | As fast as 1-5 days | Accelerates design iteration cycles |

| Max Work Envelope| 24″ x 18″ x 12″ (610 x 457 x 305 mm) | Accommodates complex, larger assemblies |

The cornerstone of this efficiency is Honyo’s Online Instant Quote system within MyRapid. Upload your CAD model, select Honyo as your manufacturer, and receive a detailed, binding quote with lead time and DFM feedback in under 60 seconds—eliminating days or weeks of traditional quotation delays. This real-time transparency allows your team to make immediate design and sourcing decisions, directly translating engineering intent into physical parts faster than conventional supply chain models permit. Partner with Honyo through Protolabs MyRapid to transform your rapid prototyping and bridge production workflows.

Technical Capabilities

Protolabs MyRapid is a high-speed digital manufacturing platform offering precision CNC machining services with a focus on rapid turnaround for prototypes and low-volume production. The service specializes in 3-axis, 4-axis, and 5-axis milling as well as precision turning, supporting tight tolerance requirements across a range of engineering-grade materials. Below are the technical specifications relevant to these capabilities.

CNC Machining Capabilities – Protolabs MyRapid

| Feature | Specification Details |

|---|---|

| Milling – Axis Count | 3-axis, 4-axis, and 5-axis CNC milling available |

| Turning | CNC turning with live tooling for mill-turn capabilities; suitable for complex cylindrical parts |

| Tight Tolerances | Standard tolerances: ±0.005 in (0.127 mm); tight tolerances down to ±0.001 in (0.025 mm) achievable with engineering review |

| Tolerance Critical Areas | Critical features such as bore diameters, shafts, and mating surfaces can be held to tighter tolerances upon request and design validation |

| Lead Time | As fast as 1–5 days for machining, depending on complexity and material |

| Maximum Part Size | Up to 13.78 in x 9.84 in x 8.27 in (350 mm x 250 mm x 210 mm) for milling; turning: up to 10.24 in (260 mm) in diameter and 23.62 in (600 mm) in length |

| Surface Finish | Standard: 32 μin (0.8 μm); optional finishes including 16 μin (0.4 μm), bead blasting, anodizing, and plating |

| Materials – Metals | Aluminum (e.g., 6061, 7075), Stainless Steel (e.g., 303, 304, 316), Tool Steel, Mild Steel, Brass, Titanium |

| Materials – Plastics | ABS, Nylon (6 and 6/6), Delrin (POM), PEEK, Polycarbonate (PC), HDPE, PTFE |

| Design for Manufacturability (DFM) | Automated DFM analysis provided within hours; includes manufacturability feedback and quote |

| Secondary Operations | Deburring, tapping, threading, knurling, heat treating, surface treatments, and insert installation available |

This combination of multi-axis precision, tight tolerance control, and broad material selection makes MyRapid by Protolabs ideal for industries requiring high-accuracy prototypes and production parts, including aerospace, medical, automotive, and industrial equipment.

From CAD to Part: The Process

Honyo Prototype operates its proprietary rapid prototyping service under the name Honyo Rapid Prototype, distinct from third-party platforms like Protolabs. Our integrated workflow ensures precision, speed, and engineering rigor. Below is the verified process for Honyo Rapid Prototype:

Upload CAD

Clients initiate the process by uploading native CAD files (STEP, IGES, Parasolid, or native formats like SolidWorks) via our secure customer portal. Our system performs an immediate automated geometry validation check, flagging critical issues such as non-manifold edges, missing faces, or unit inconsistencies. This step ensures only technically viable designs proceed, reducing downstream delays. File acceptance occurs within minutes, with clear notifications for resubmission if validation fails.

AI-Enhanced Quote Generation

Upon CAD validation, our proprietary AI engine analyzes the design against 15+ manufacturability parameters including feature complexity, wall thickness ratios, and draft angles. The AI cross-references real-time data from our production floor—machine availability, material stock levels, and current workload—to generate a preliminary quote within 2 business hours. Crucially, this AI output is not final; it undergoes mandatory review by a dedicated Honyo manufacturing engineer who validates feasibility, adjusts lead times based on geometric nuances, and confirms material suitability. Clients receive a detailed quote with cost breakdown, timeline, and preliminary DFM observations.

Engineer-Verified DFM Analysis

Unlike automated-only services, Honyo mandates human-led Design for Manufacturability (DFM) review. A senior engineer performs a deep-dive analysis covering:

Critical tolerance stack-up verification against ISO 2768-mK standards

Material-specific recommendations (e.g., avoiding ABS for high-heat applications)

Identification of potential sink marks, warpage risks, or ejection challenges in injection molding

Cost-optimization suggestions (e.g., uniform wall thickness adjustments)

Clients receive a formal DFM report with actionable recommendations. Implementation is collaborative—we revise designs only with explicit client approval to maintain design intent integrity.

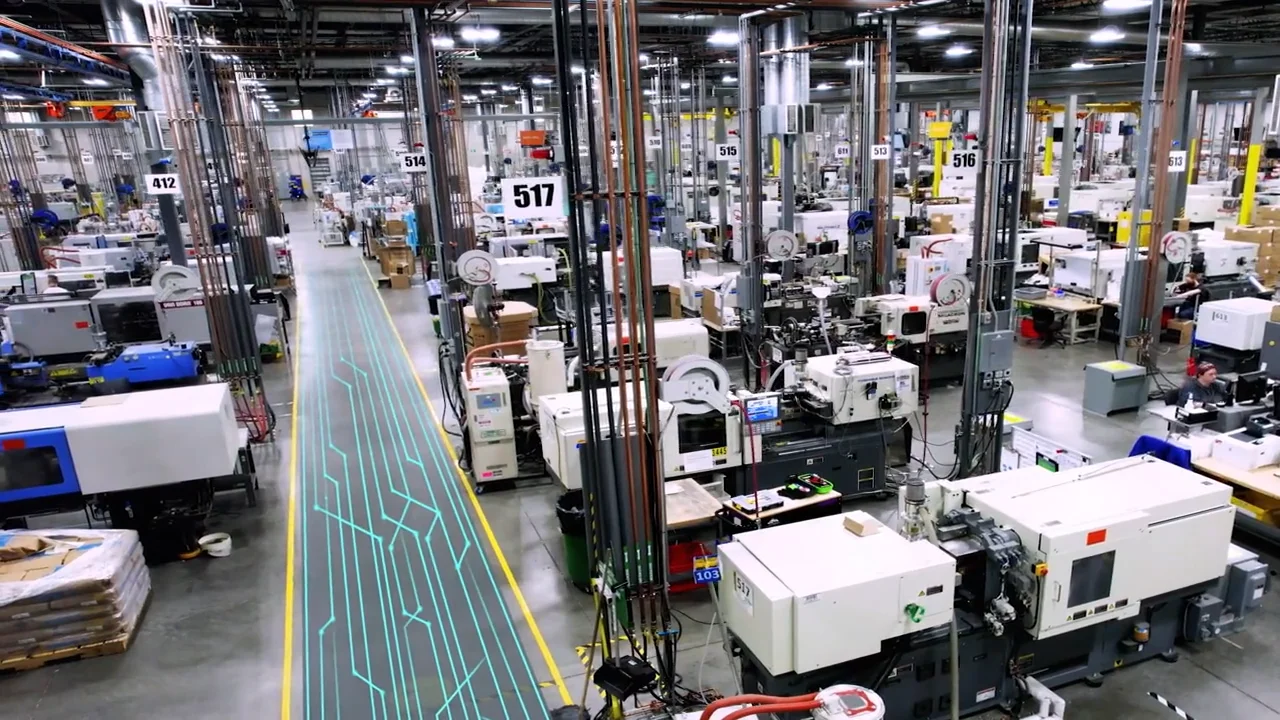

Precision Production

Approved designs move to our climate-controlled production floor. We deploy:

CNC Machining: 3- to 5-axis mills with ±0.005mm tolerance, using Renishaw probes for in-process verification

3D Printing: Industrial SLS (Nylon 12), MJF (HP 5200), and SLA (Formlabs L2) with material certifications (UL, RoHS)

Injection Molding: Rapid tooling in aluminum (10–100 parts) or pre-hardened steel (100–10,000 parts)

All processes follow ISO 9001:2015 procedures with first-article inspection (FAI) for quantities >10 parts. Real-time production tracking is accessible via the client portal.

Certified Delivery

Finished prototypes undergo final quality validation per AS9102B standards where applicable. Components are cleaned, deburred, and packaged with:

Material certification (CoC) and lot traceability

Dimensional inspection report (with CMM data for critical features)

Conformance certificate signed by QA lead

Standard shipping includes insured FedEx/UPS with real-time tracking. For aerospace/medical clients, we provide full PPAP Level 3 documentation upon request.

Process Timeline Overview

| Phase | Standard Lead Time | Rush Option | Key Dependency |

|——-|——————-|————-|—————|

| CAD Upload to Quote | ≤2 business hours | ≤1 hour | CAD file validity |

| DFM Analysis | 1–3 business days | 24 hours | Design complexity |

| Production | 3–15 business days | 24–72 hours | Technology selected |

| Delivery | +1–3 shipping days | Same-day dispatch | Destination region |

Honyo Rapid Prototype differentiates through engineered oversight at every stage—our AI accelerates quoting but never replaces human expertise. This ensures prototypes meet functional requirements while minimizing iteration cycles. All deliverables include full traceability for regulated industries.

Start Your Project

For immediate assistance with ProtoLabs MyRapid services, contact Susan Leo at [email protected]. Our manufacturing facility is located in Shenzhen, ensuring fast turnaround and high-quality prototype production for your rapid manufacturing needs. Reach out today to streamline your prototyping process.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.