Contents

Manufacturing Insight: Programing Cnc Machine

Precision CNC Programming and Machining Services at Honyo Prototype

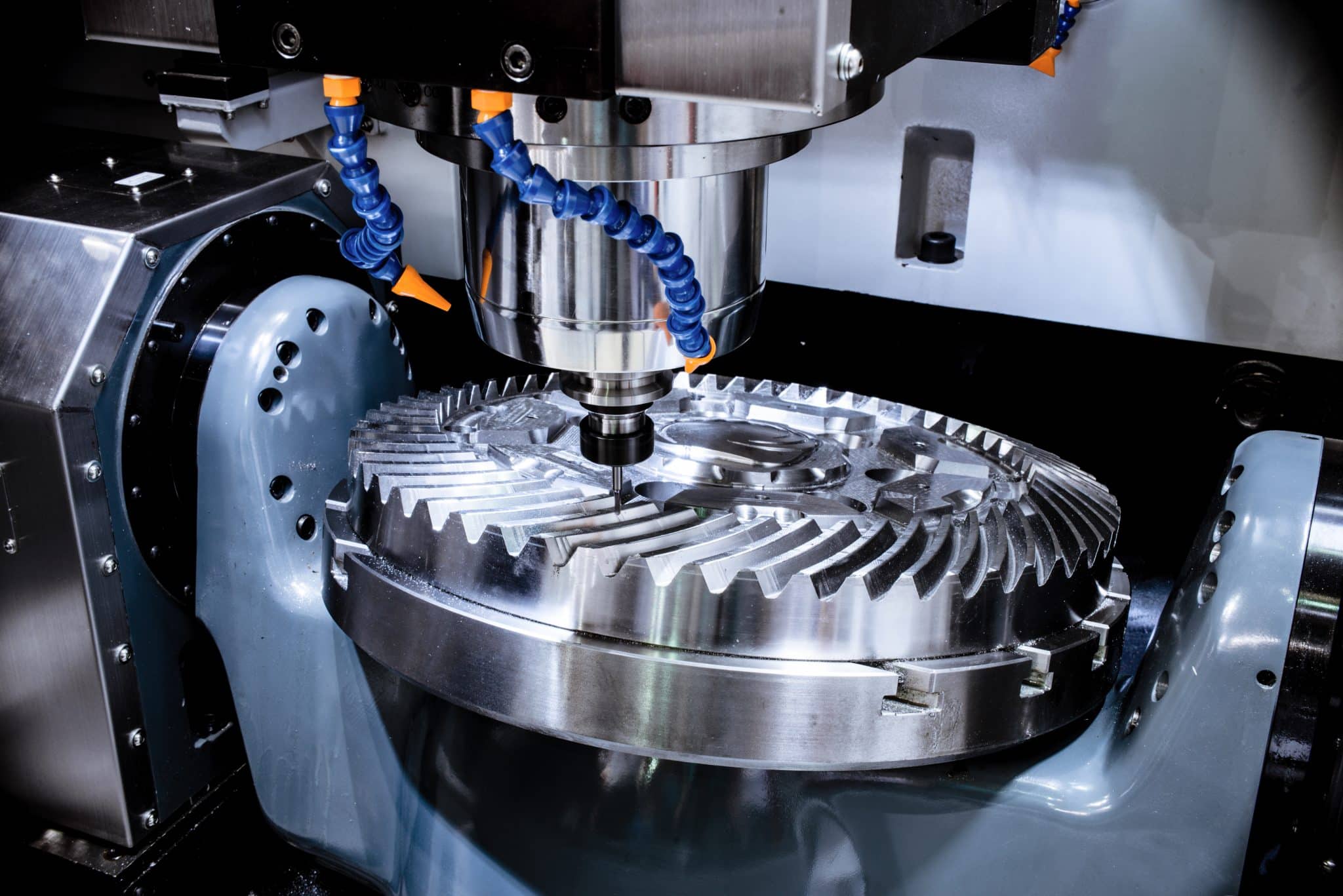

At Honyo Prototype, we transform complex engineering designs into high-precision machined components through advanced CNC programming and manufacturing expertise. Our in-house team of senior CNC programmers and manufacturing engineers utilizes industry-leading CAM software—including Mastercam, Fusion 360, and Siemens NX—to develop optimized toolpaths for 3-axis, 4-axis, and 5-axis milling, turning, and mill-turn operations. Every program undergoes rigorous virtual simulation and dry-run validation to ensure micron-level accuracy, eliminate collisions, and maximize material efficiency before a single chip is cut. This disciplined approach guarantees first-pass success for critical components across aerospace, medical, and industrial automation sectors.

Our CNC machining capabilities span a comprehensive range of engineering-grade materials, including aluminum alloys (6061, 7075), stainless steels (303, 316, 17-4 PH), titanium (Grade 5), brass, and high-performance plastics like PEEK and Delrin. All processes adhere to ISO 9001-certified quality management systems, with real-time in-process inspection via Renishaw probes and post-machining verification using Zeiss CMMs. Whether you require rapid prototyping, bridge production, or full-volume manufacturing, Honyo delivers tight-tolerance parts with consistent repeatability and documented traceability.

Accelerate your project timeline with Honyo’s Online Instant Quote platform, engineered specifically for technical buyers and design engineers. Upload your STEP, IGES, or native CAD file alongside detailed specifications, and receive a comprehensive quote within hours—not days. The system automatically analyzes geometric complexity, material requirements, and tolerances to provide transparent pricing, lead time estimates, and actionable manufacturability feedback. This seamless integration of quoting intelligence with our CNC programming workflow ensures your project transitions from design to machining without delay, reducing time-to-market while maintaining uncompromising quality standards.

Material & Tolerance Capabilities

| Parameter | Specification Range |

|——————–|—————————————–|

| Positional Accuracy | ±0.005 mm (±0.0002″) |

| Surface Finish | As low as Ra 0.4 μm (16 μin) |

| Max Work Envelope | 1,200 x 600 x 500 mm (47″ x 24″ x 20″) |

| Key Materials | Aluminum, Steel, Titanium, Brass, PEEK |

Technical Capabilities

CNC Machining Technical Specifications for 3/4/5-Axis Milling and Turning – Focus on Tight Tolerance Applications

The following table outlines the technical specifications relevant to CNC machining operations with an emphasis on 3-axis, 4-axis, and 5-axis milling, as well as precision turning, for materials including Aluminum, Steel, ABS, and Nylon. These parameters are typical for high-accuracy prototyping and low-volume production at Honyo Prototype.

| Parameter | 3-Axis Milling | 4-Axis Milling | 5-Axis Milling | CNC Turning | Notes |

|---|---|---|---|---|---|

| Axis Configuration | X, Y, Z linear axes | X, Y, Z + one rotary (A or B) | X, Y, Z + two rotary axes (e.g., A & B) | X, Z linear + C-axis (rotary spindle) | 5-axis enables complex contours without re-fixturing |

| Positioning Accuracy | ±0.005 mm (±0.0002 in) | ±0.005 mm (±0.0002 in) | ±0.005 mm (±0.0002 in) | ±0.003 mm (±0.0001 in) | Verified via laser interferometry |

| Repeatability | ±0.002 mm (±0.0001 in) | ±0.002 mm (±0.0001 in) | ±0.002 mm (±0.0001 in) | ±0.001 mm (±0.00004 in) | Critical for tight-tolerance batch consistency |

| Typical Tolerance Range | ±0.0125 mm (±0.0005 in) | ±0.0125 mm (±0.0005 in) | ±0.010 mm (±0.0004 in) | ±0.005 mm to ±0.010 mm | Achievable with process control and metrology |

| Surface Finish (Ra) | 0.8 – 3.2 µm (32–125 µin) | 0.8 – 3.2 µm (32–125 µin) | 0.4 – 1.6 µm (16–63 µin) | 0.4 – 1.6 µm (16–63 µin) | Fine finishes achievable with polishing passes |

| Spindle Speed Range | 8,000 – 24,000 RPM | 8,000 – 24,000 RPM | 10,000 – 30,000 RPM | 1,500 – 6,000 RPM (high-speed up to 12,000) | Higher speeds for Aluminum and plastics |

| Tooling Interface | BT30, BT40, or HSK-F63 | BT40 or HSK-F63 | HSK-A63 or HSK-C40 | Capto C4, C5 or ER collets | High-rigidity holders for precision |

| Materials Supported | Aluminum, Steel, ABS, Nylon | Aluminum, Steel, ABS, Nylon | Aluminum, Steel, ABS, Nylon | Aluminum, Steel, ABS, Nylon | All materials compatible with tight-tolerance machining |

| Aluminum Machinability | Excellent – high feed rates, sharp tools | Excellent – complex features | Excellent – sculpted surfaces | Excellent – high RPM turning | Use carbide tools with coolant |

| Steel Machinability | Good – slower speeds, rigid setup | Good – stress-relieved stock recommended | Good – intermittent cuts managed via toolpath | Good – hardened steels up to 58 HRC possible | Pre-hardened steels commonly used |

| ABS Machinability | Very Good – low melt temp, sharp tools | Very Good – minimal clamping force | Very Good – avoid heat buildup | Good – chip control critical | Use low rake tools, air blast cooling |

| Nylon Machinability | Good – prone to deflection, sharp tools | Good – secure fixturing | Good – thermal expansion considered | Good – consistent feed rates | Avoid excessive heat; use clearance angles |

| Work Envelope (Typical Max) | 700 x 400 x 300 mm | 600 x 500 x 400 mm | 500 x 400 x 350 mm | Ø 300 mm x 500 mm length | Size varies by machine model |

| Metrology Integration | On-machine probing (optional) | On-machine probing + alignment | Full 5-axis inspection via probing | In-process gauging (optional) | Enables closed-loop tolerance control |

Additional Notes:

Tight tolerance machining (±0.010 mm or better) requires strict environmental control, pre-machined stress-relieved stock, and iterative inspection using CMM or optical comparators. Multi-axis milling reduces setup steps and improves geometric accuracy for complex parts. CNC turning is optimal for cylindrical components requiring concentricity and surface quality. Material selection impacts tool life, cycle time, and achievable precision—Aluminum and ABS allow faster machining, while steel and Nylon require optimized parameters.

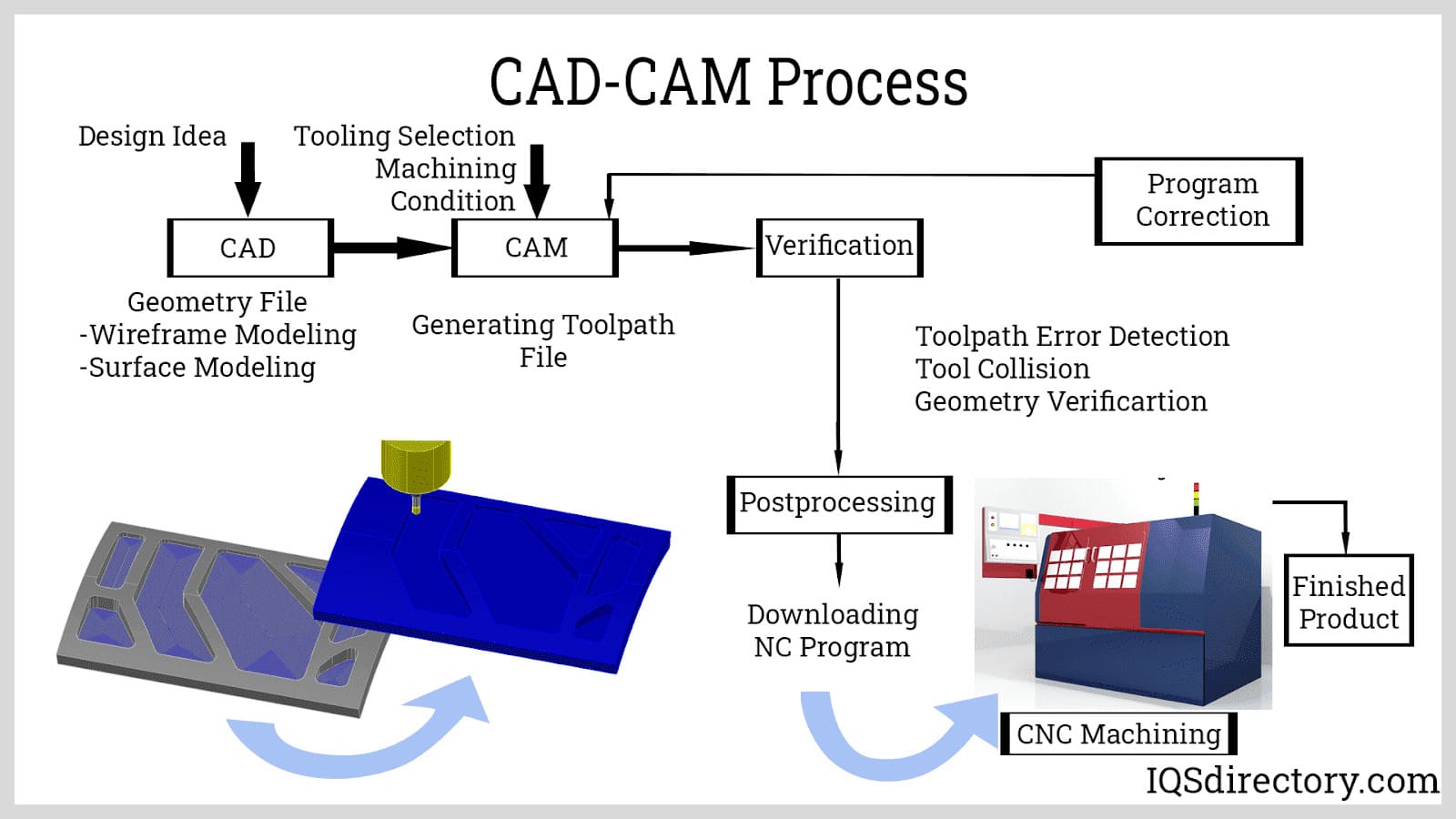

From CAD to Part: The Process

Honyo Prototype employs a rigorously structured CNC machining workflow designed to maximize precision, efficiency, and client transparency from initial design upload through final delivery. This integrated process leverages both advanced automation and deep engineering expertise to ensure manufacturability and cost-effectiveness.

CAD Upload and Initial Processing

Clients initiate the process by uploading native CAD files (STEP, IGES, Parasolid, or native formats like SolidWorks) via our secure online portal. Our system performs immediate automated validation checks for file integrity, unit consistency, and geometric completeness. Invalid or corrupted files trigger instant client notifications with specific error diagnostics, preventing downstream delays. Validated files are routed directly to our AI-powered quoting engine with all geometric metadata preserved.

AI-Powered Quoting with Engineering Oversight

Our proprietary AI engine analyzes the CAD geometry to generate a preliminary quote within minutes. This system evaluates critical factors including:

Material utilization efficiency and scrap estimation

Estimated machine runtime based on feature complexity and toolpath density

Secondary operation requirements (tapping, deburring, etc.)

Fixture and workholding complexity

Crucially, this AI output undergoes mandatory review by a Senior Manufacturing Engineer. The engineer validates the AI’s assumptions against real-world machining constraints, adjusts for material-specific cutting parameters, and incorporates shop floor capacity considerations. Clients receive a technically grounded quote with clear rationale for cost drivers, not just an automated number.

Engineering-Led DFM Analysis

Upon quote acceptance, our DFM phase begins with dedicated engineers conducting a comprehensive manufacturability review. This is not an automated check but a hands-on analysis where engineers:

Identify features requiring specialized tooling or non-standard processes

Propose geometric modifications to reduce cycle time (e.g., adjusting fillet radii, minimizing deep pockets)

Verify tolerance feasibility against machine capabilities (±0.005mm standard)

Flag potential workholding challenges for thin-walled or complex geometries

Clients receive a formal DFM report with specific, actionable recommendations. We collaborate iteratively with design teams to implement changes that optimize cost without compromising functional requirements, documenting all revisions for traceability.

Precision CNC Production Execution

Approved designs move to production with strict protocols:

CAM programming is performed in Mastercam or Fusion 360 by certified programmers, generating optimized toolpaths validated through virtual machine simulation.

All G-code undergoes post-processor verification against the specific CNC machine’s control system (e.g., Haas VF-2, DMG MORI) to prevent control-specific errors.

First-article inspection is conducted using calibrated CMMs or optical comparators against the original CAD model, with full inspection reports provided.

In-process quality checks occur at critical stages for multi-operation parts, ensuring dimensional stability before proceeding.

Quality-Controlled Delivery

Final parts undergo comprehensive quality validation:

Dimensional verification against all critical features per ASME Y14.5

Surface finish measurement using profilometers where specified

Material certification documentation included with shipment

Parts are packaged using anti-static, shock-absorbing materials appropriate for delicate prototypes. Clients receive full digital documentation including:

As-machined dimensional report

Material certificates

Process validation records

Shipping manifest with real-time logistics tracking

This closed-loop process ensures every component meets stringent prototype-grade requirements while maintaining the agility needed for rapid iteration. Our integration of AI for initial assessment with irreplaceable human engineering judgment at critical decision points delivers both speed and reliability expected in professional prototyping partnerships.

Start Your Project

Looking to streamline your CNC programming process? Contact Susan Leo today to discuss your precision manufacturing needs. With our advanced CNC capabilities and factory located in Shenzhen, Honyo Prototype delivers fast, accurate, and reliable results for prototyping and low-volume production.

Email Susan Leo at [email protected] to get started.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.