Contents

Manufacturing Insight: Program For Cnc Machine

Precision CNC Machining Solutions for Demanding Prototype and Production Requirements

Honyo Prototype delivers advanced CNC machining services engineered to meet the exacting standards of aerospace, medical, automotive, and industrial sectors. Our multi-axis milling and turning capabilities, supported by state-of-the-art HAAS and DMG MORI equipment, consistently achieve tolerances down to ±0.0002″ across aluminum, titanium, stainless steel, and engineered plastics. With in-house CAD/CAM programming and rigorous first-article inspection protocols, we ensure dimensional accuracy and surface finishes that exceed AS9100 and ISO 13485 requirements on every run.

Accelerate Your Development Cycle with Real-Time Quoting

Eliminate traditional quoting delays with Honyo’s Online Instant Quote platform. Upload your 3D model or technical drawing to receive a detailed manufacturing assessment—including lead time, material optimization insights, and DFM feedback—in under 90 seconds. This seamless integration between design validation and production planning reduces time-to-prototype by up to 65% compared to conventional RFQ processes.

Technical Capabilities Snapshot

| Parameter | Specification |

|——————–|———————————–|

| Max Work Envelope | 5-axis: 20″ x 16″ x 12″ |

| Tolerance Range | ±0.0002″ to ±0.001″ (feature-dependent) |

| Lead Time | As fast as 3 business days |

| Materials Supported| 50+ metals, plastics, composites |

Engineers and procurement teams leverage our end-to-end CNC ecosystem—from rapid prototyping to low-volume production—to mitigate supply chain risks while maintaining uncompromised quality. Initiate your project with a validated manufacturing solution today.

Technical Capabilities

Technical Specifications for CNC Program – 3/4/5-Axis Milling and Turning with Tight Tolerance Requirements

The following technical specifications define the programming standards and operational parameters for CNC programs used in precision 3-axis, 4-axis, and 5-axis milling, as well as CNC turning operations. These programs are optimized for tight tolerance machining (±0.0005″ to ±0.005″) across a range of engineering-grade materials including aluminum, steel, ABS, and nylon.

| Parameter | Specification |

|---|---|

| Machine Compatibility | 3-axis, 4-axis (indexed or continuous), and 5-axis simultaneous milling centers; CNC turning centers with live tooling |

| Control Systems Supported | Fanuc, Siemens Sinumerik, Heidenhain, Haas, Mazak, and Mitsubishi M-Series |

| Programming Method | G-code generated via CAM software (e.g., Mastercam, Siemens NX, Fusion 360, HyperMill) with post-processing tailored to machine tool kinematics |

| Tolerance Range | ±0.0005″ (12.7 µm) for critical features; ±0.001″ to ±0.005″ (25.4–127 µm) for general precision features |

| Surface Finish (Typical) | 32–125 µin Ra, achievable down to 16 µin Ra with fine finishing passes and optimized toolpaths |

| Toolpath Strategies | High-speed machining (HSM), trochoidal milling, adaptive clearing, contour spiral finishing, and precise facing/turning cycles |

| Coordinate Systems | Multiple work coordinate systems (G54–G59), with on-the-fly WCS rotation (G68.2, PLANE SPATIAL) for 5-axis positioning |

| Fixture & Setup Considerations | Modular fixturing, tombstones for 4-axis, and trunnion/rotary tables for 5-axis; alignment via probing (touch-trigger or laser) |

| Material-Specific Parameters | |

| Aluminum (6061, 7075, etc.) | High spindle speeds (12,000–25,000 RPM), aggressive feed rates, climb milling preferred, coolant through spindle (CTS) or mist for chip evacuation |

| Steel (4140, 1018, Stainless 304/316) | Lower RPM (3,000–10,000), high-torque cutting, peck drilling with flood coolant, use of carbide or coated inserts; stress-relieved stock recommended |

| ABS (Acrylonitrile Butadiene Styrene) | Moderate speeds (8,000–12,000 RPM), sharp uncoated or diamond-coated tools, minimal clamping pressure to prevent deformation, air blast for chip removal |

| Nylon (PA6, PA66, reinforced grades) | Low to moderate RPM (6,000–10,000), sharp tools with high rake angles, air cooling preferred, attention to thermal expansion during long cycles |

| Turning Capabilities | Precision OD/ID turning, tapering, threading (UNF, NPT, metric), grooving, and parting; sub-micron repeatability on guide ways with servo tuning |

| In-Process Verification | On-machine probing for setup validation, tool length and wear compensation (G10, G37), and first-article inspection integration |

| File Output Format | ISO standard G-code (EIA 660), with option for machine-specific binary or compressed formats where applicable |

All programs are subject to dry-run verification, toolpath simulation, and post-processor validation prior to shop floor deployment. Programs are version-controlled and documented per AS9100/ISO 9001 standards for traceability in high-integrity applications.

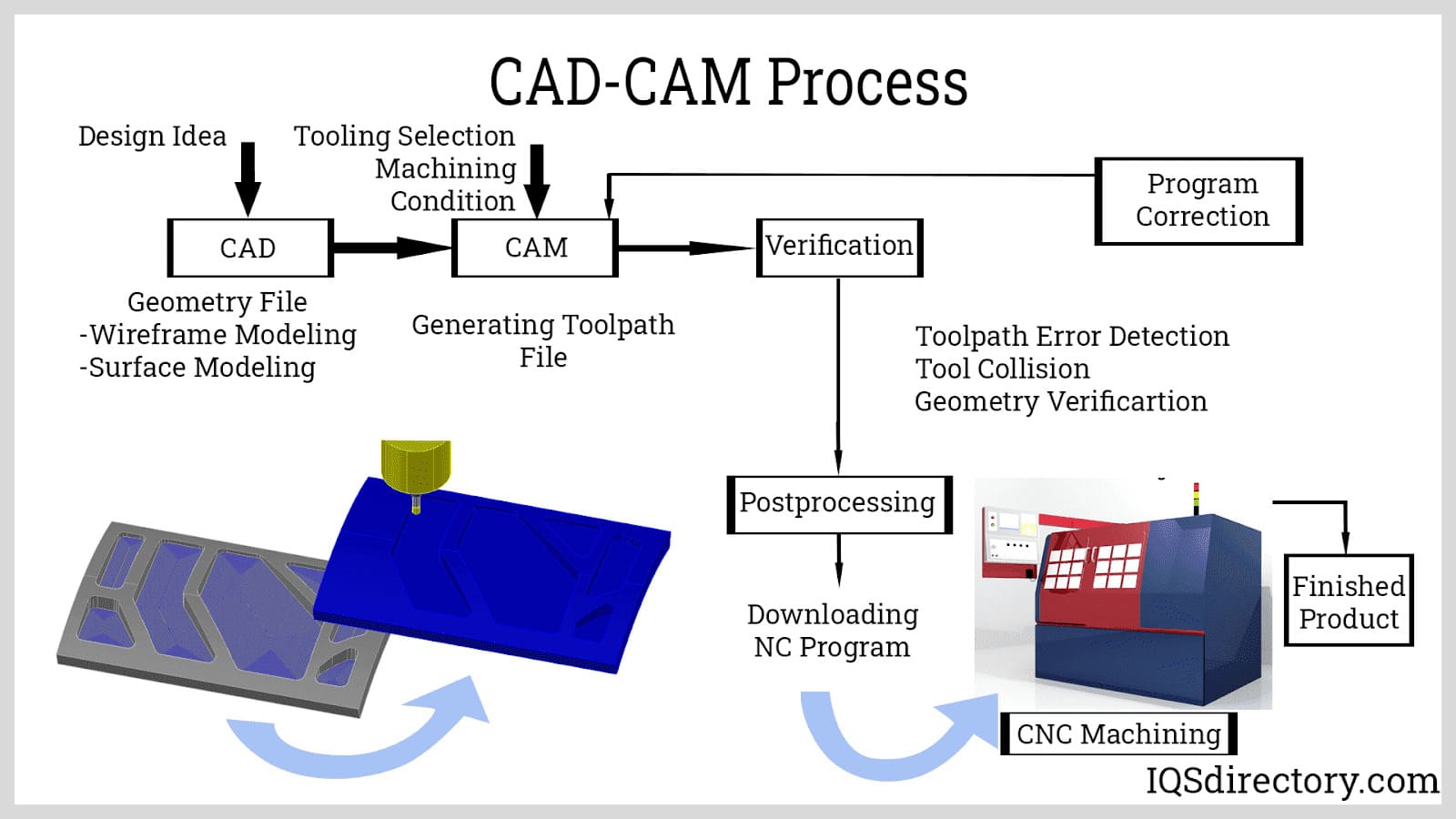

From CAD to Part: The Process

Honyo Prototype CNC Machining Process Workflow

Honyo Prototype executes a streamlined, technology-driven CNC machining process designed to minimize lead times while ensuring precision and manufacturability. Our workflow integrates AI augmentation with expert engineering oversight, specifically tailored for rapid prototyping and low-volume production. Below is a detailed explanation of each stage.

Upload CAD

Customers initiate the process by uploading native or neutral CAD files via our secure online portal. We accept industry-standard formats including STEP AP203/214, IGES, Parasolid, and native SOLIDWORKS, Fusion 360, or Creo files. STEP is strongly recommended for preserving geometric integrity and parametric data. Upon upload, our system performs an automated file validation check to confirm unit consistency, surface continuity, and absence of corrupt geometry. Invalid files trigger an immediate notification with specific error details, preventing downstream delays.

AI-Powered Quoting

Validated CAD data enters our proprietary AI quoting engine, trained on 12+ years of machining cost and time data from 50,000+ completed projects. The algorithm analyzes geometric complexity, feature density, material stock requirements, and machine time estimates based on Honyo’s certified machine capabilities. Crucially, the AI cross-references real-time material pricing from our vendor network and current shop floor capacity. Within 90 minutes, customers receive a formal quote detailing unit cost, lead time, material options, and surface finish specifications. Unlike generic quoting tools, our system flags high-risk geometries (e.g., deep cavities with aspect ratios >8:1) requiring engineering review before final pricing.

DFM Analysis and Engineering Collaboration

All quotes undergo mandatory Design for Manufacturability (DFM) review by Honyo’s senior CNC engineers. This phase combines AI-driven suggestions with human expertise to optimize designs for cost and yield. Our DFM report identifies actionable improvements such as:

| DFM Issue Category | Example Findings | Resolution Impact |

|---|---|---|

| Tool Access Constraints | Undercuts requiring 5-axis vs. 3-axis machining | Reduces cost by 22-35% through process simplification |

| Wall Thickness & Tolerance Conflicts | 0.5mm walls with ±0.025mm tolerances in aluminum | Recommends minimum 0.8mm walls or relaxed tolerances |

| Material Utilization | Inefficient stock sizing increasing raw material waste | Proposes alternative billet dimensions saving 15-20% material |

Customers receive a collaborative portal link to discuss DFM recommendations via markup tools or scheduled engineering calls. No production proceeds without customer sign-off on the DFM report, ensuring alignment on quality-cost tradeoffs.

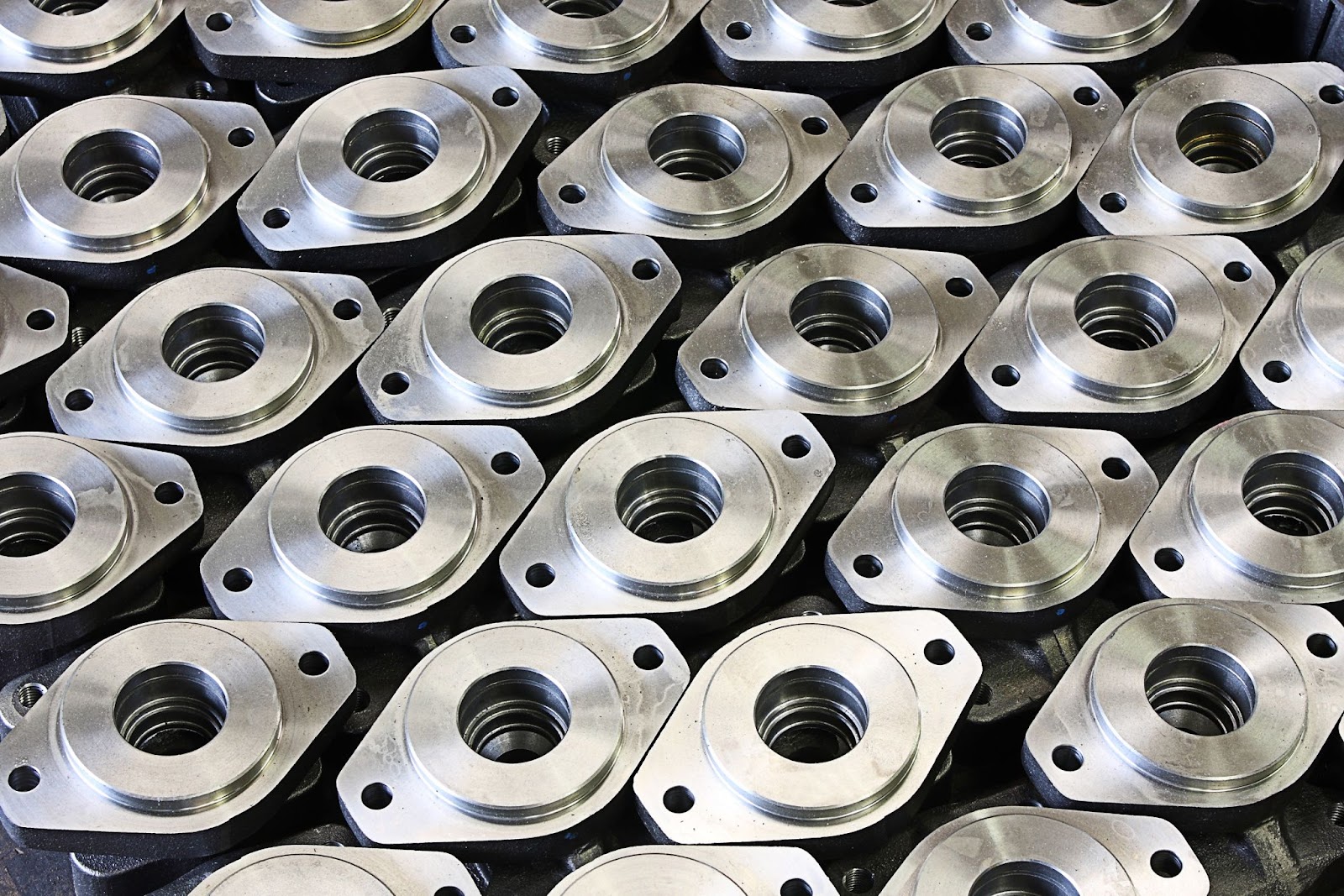

Precision Production Execution

Approved designs move to our climate-controlled machining floor featuring 32 CNC centers (18x 3-axis, 10x 5-axis DMG MORI/Hermle, 4x Swiss-type lathes). Key production protocols include:

Material certification traceability with lot-specific CoC documentation

In-process inspections at critical stages using Faro Arm CMM and optical comparators

Real-time machine monitoring via MTConnect for tool wear compensation and vibration analysis

First-article inspection reports (FAIR) compliant with AS9102 for aerospace/medical builds

All programs undergo dry-run verification in NCSIMUL prior to metal cutting. Complex 5-axis operations use Renishaw probing for automated workholding calibration, achieving <0.005mm positional accuracy.

Quality-Controlled Delivery

Final parts undergo dimensional verification against original CAD per ISO 2768-mK standards, with full FAIR packages available upon request. We package components using static-dissipative foam-in-place systems for shock-sensitive geometries, with serialized labels for traceability. Shipments include digital delivery certificates accessible via our customer portal, showing:

Actual measured dimensions from final inspection

Machine program revision number and operator ID

Material test reports (MTRs) with heat treatment documentation

Standard lead time from DFM sign-off to shipment is 5-7 business days for 1-100 parts, with expedited 72-hour options for critical path components.

This integrated workflow reduces design-to-delivery cycles by 40% compared to traditional machine shops, while our DFM-first approach typically eliminates 2-3 prototype iterations through upfront manufacturability validation. All processes adhere to ISO 9001:2015 and IATF 16949 standards for automotive and medical device production.

Start Your Project

For a reliable and efficient CNC machining program, contact Susan Leo at [email protected]. Our manufacturing facility is based in Shenzhen, ensuring high-quality production with fast turnaround times. Let Honyo Prototype support your precision manufacturing needs with expert programming and machining services.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.