Contents

Manufacturing Insight: Production Machining Companies

Honyo Prototype: Precision CNC Machining for Production Partnerships

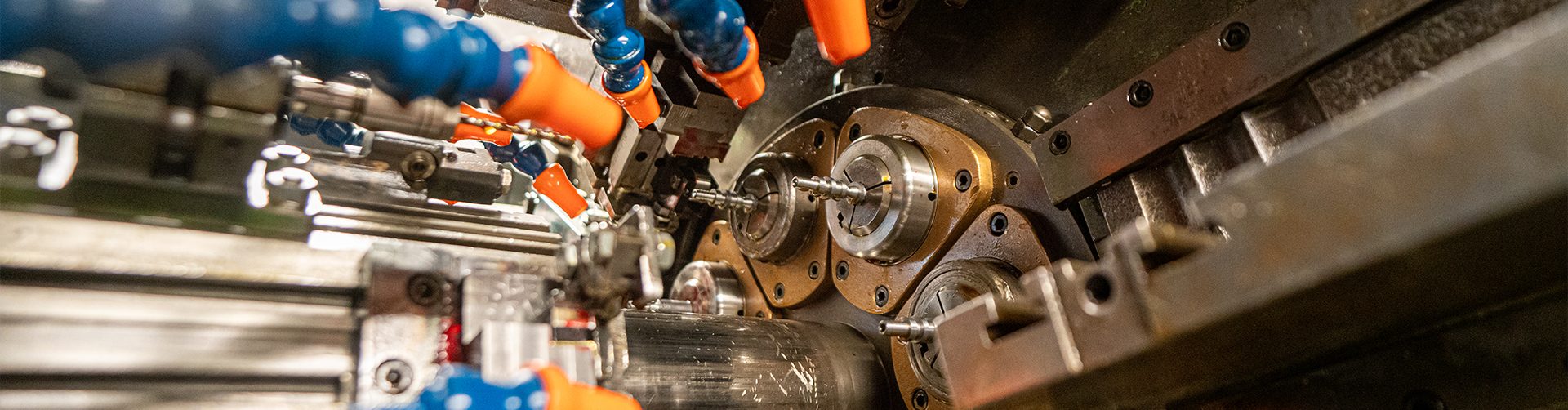

For production machining companies seeking scalable, high-integrity component manufacturing, Honyo Prototype delivers advanced CNC machining services engineered to bridge prototyping and full-scale production. Our technical infrastructure centers on state-of-the-art 3-, 4-, and 5-axis CNC milling and turning centers, operating under stringent quality protocols to achieve tight tolerances down to ±0.0002 inches across diverse materials including aerospace alloys, medical-grade stainless steels, and engineering plastics. We specialize in transforming complex CAD models into mission-critical parts with repeatable precision, supporting volumes from single prototypes to sustained production runs exceeding 10,000 units annually.

A core differentiator for production partners is our Online Instant Quote platform. This technical solution eliminates traditional quoting bottlenecks by providing immediate, data-driven cost and lead time estimates for CNC-machined parts. Upload your STEP or IGES file, specify material and volume requirements, and receive a validated manufacturing assessment within minutes—accelerating your sourcing cycle without sacrificing engineering rigor. Our system intelligently analyzes geometric complexity, fixture requirements, and toolpath efficiency to generate actionable quotes, ensuring transparency from RFQ to delivery.

Partner with Honyo Prototype to leverage manufacturing expertise where precision, scalability, and speed directly impact your production timelines and cost structure.

| Service Capability | Technical Specification | Production Relevance |

|---|---|---|

| Dimensional Accuracy | ±0.0002″ (5µm) repeatability | Ensures interchangeability in assemblies |

| Max Work Envelope | 24″ x 18″ x 16″ (609 x 457 x 406 mm) | Accommodates complex sub-assemblies |

| Material Range | Aluminum 7075-T6, Inconel 718, PEEK, Titanium | Meets aerospace/medical compliance needs |

| Volume Flexibility | 1 to 10,000+ parts annually | Scales from pilot to high-volume runs |

| Online Quote Response Time | < 2 minutes for qualified geometries | Reduces procurement cycle by 7–10 days |

Technical Capabilities

Production Machining Capabilities – Technical Specifications

Production machining companies specializing in high-precision CNC machining typically support advanced 3, 4, and 5-axis milling operations, as well as multi-axis turning (including Swiss-type and turning centers with live tooling). These capabilities enable the production of complex geometries with tight dimensional tolerances, often down to ±0.0002” (5 µm), depending on part geometry and material. Such manufacturers serve industries including aerospace, medical, defense, and industrial equipment, where repeatability, material integrity, and precision are critical.

Below is a summary of typical technical specifications for production machining services focused on milling and turning of common engineering materials:

| Capability | Specification |

|---|---|

| Machining Types | 3-axis, 4-axis, and 5-axis CNC milling; CNC turning (2-axis and multi-axis with live tooling); Swiss machining for small, complex turned parts |

| Tolerances | Standard: ±0.001” (25 µm); Tight: ±0.0002” to ±0.0005” (5–12 µm) achievable with process control and inspection protocols |

| Materials – Metals | Aluminum (6061, 7075, 2024, etc.), Stainless Steel (303, 304, 316, 17-4 PH), Tool Steel, Carbon Steel (1018, 4140), Titanium (Grade 2, 5), Inconel |

| Materials – Plastics | ABS, Nylon (6, 6/6), Delrin (POM), PEEK, Polycarbonate, HDPE, PTFE |

| Maximum Work Envelope (Typical Milling) | 3-axis: Up to 40″ × 20″ × 20″; 5-axis: Up to 30″ × 24″ × 20″ (varies by machine) |

| Maximum Turning Diameter | Up to 2.5” (63.5 mm) for Swiss-type; up to 12” (305 mm) for standard CNC lathes |

| Spindle Speed (Milling) | Up to 20,000 RPM (high-speed options available) |

| Surface Finish | Typical: 32–64 µin Ra; Fine finishes down to 8–16 µin Ra with polishing or grinding |

| Positioning Accuracy (Machines) | ±0.0001” (2.5 µm) with laser calibration and thermal compensation |

| Quality & Inspection | In-process probing, CMM (Coordinate Measuring Machine), optical comparators, surface roughness testers, GD&T compliance (ASME Y14.5) |

| Production Volume | Prototype to high-volume production (1–100,000+ parts) with automation and bar feeders |

| Secondary Operations | Deburring, anodizing, passivation, plating, heat treatment, welding, assembly, laser marking |

These specifications reflect industry-standard capabilities among advanced production machining partners. Actual performance may vary based on equipment brands (e.g., DMG MORI, Haas, Makino, Hardinge), tooling, fixturing, and quality systems (e.g., ISO 9001:2015, AS9100, ISO 13485).

From CAD to Part: The Process

Honyo Prototype Production Machining Workflow Overview

Honyo Prototype delivers end-to-end precision manufacturing for production machining companies through a streamlined digital workflow designed for speed, quality, and scalability. Our process eliminates traditional bottlenecks by integrating AI-driven analysis with expert engineering oversight, ensuring manufacturability and cost efficiency from initial design to final delivery. Below is a detailed explanation of each phase.

CAD Upload and System Validation

Clients initiate the process by uploading native CAD files (STEP, IGES, Parasolid, or native SOLIDWORKS/Creo formats) via our secure customer portal. Our system performs immediate automated validation checks for file completeness, unit consistency, and geometric integrity. This step ensures the dataset is production-ready and prevents downstream delays caused by corrupted or incomplete models. All uploaded CAD data is protected under ISO 27001-compliant security protocols, with strict access controls and audit trails for intellectual property protection.

AI-Powered Quoting with Engineering Oversight

Within minutes of CAD validation, our proprietary AI engine generates a preliminary quote by analyzing geometric complexity, material requirements, tolerance specifications, and estimated machine hours. The AI cross-references real-time data on material costs, machine availability, and historical production metrics. Crucially, this output is not final—it undergoes mandatory review by a dedicated Honyo manufacturing engineer who validates the AI’s assumptions, adjusts for nuanced factors like fixturing complexity or secondary operations, and confirms feasibility. Clients receive a transparent, detailed quote with cost breakdowns and lead time projections within 4 business hours for standard parts.

Engineering-Driven DFM Analysis

Upon quote acceptance, our manufacturing engineering team conducts a rigorous Design for Manufacturability (DFM) review. This phase identifies potential production risks such as non-optimal wall thicknesses, inaccessible tool paths, excessive tolerance stacking, or suboptimal material utilization. We provide actionable feedback through annotated 3D models and a formal DFM report, highlighting specific modifications to reduce cost, improve yield, or accelerate throughput—without compromising functional requirements. For production-volume orders, we collaborate with the client’s engineering team to implement iterative design refinements, often reducing part cost by 15–30% and eliminating scrap risks before machining begins.

Precision Production Execution

Approved designs move to our climate-controlled production floor, where CNC machining (3-axis to 5-axis milling/turning), Swiss screw machining, and automated bar-feeding systems execute the build. Every production run follows documented work instructions with first-article inspection (FAI) per AS9102 standards. In-process checks using calibrated CMMs and optical comparators monitor critical dimensions, while statistical process control (SPC) ensures consistency across batches. For high-volume orders, we deploy robotic pallet systems for lights-out manufacturing, maintaining ±0.005mm tolerances with full traceability of materials, machine parameters, and operator logs.

Quality-Certified Delivery and Logistics

Final parts undergo comprehensive post-production inspection against the original CAD and client specifications, including surface finish verification and material certification validation. We provide full documentation packages (including PPAP Level 3 where required), material test reports, and dimensional inspection reports. Parts are packaged per client-specified requirements—ESD-safe, serialized, or kitted for JIT delivery—and shipped via tracked logistics partners with real-time shipment visibility. Standard lead times for production batches range from 7–20 days depending on complexity and volume, with expedited options available for critical paths.

This integrated workflow ensures production machining companies receive consistent, high-integrity components with minimized time-to-market and total cost of ownership. By embedding engineering expertise within each digital phase, Honyo transforms design intent into scalable production reality.

Start Your Project

Looking for precision production machining solutions from a trusted partner? Honyo Prototype delivers high-quality, scalable machining services from our ISO-certified factory in Shenzhen, China. With advanced CNC capabilities and a focus on tight-tolerance components, we support high-volume production runs across aerospace, medical, automotive, and industrial sectors.

Contact Susan Leo today to discuss your production requirements and receive a competitive quote.

Email: [email protected]

Leverage our Shenzhen manufacturing base for faster turnaround, consistent quality, and cost-efficient scaling—backed by rigorous quality control and on-time delivery.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.