Contents

Manufacturing Insight: Production Cutting Services

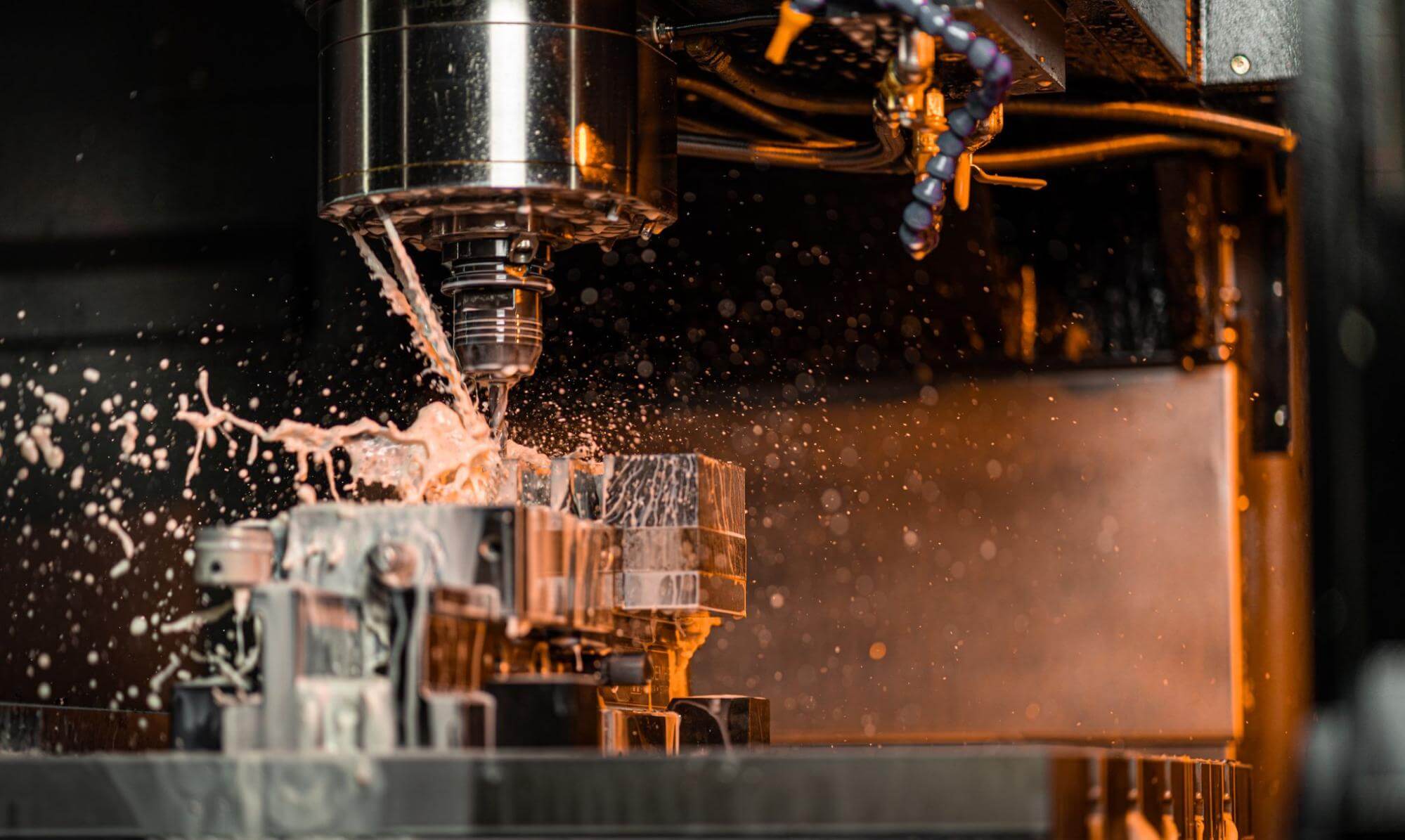

Precision Production Cutting Services Through Advanced CNC Machining

Honyo Prototype delivers industrial-grade production cutting services engineered for demanding manufacturing applications, leveraging our core competency in high-precision CNC machining. Our production floor integrates state-of-the-art multi-axis CNC mills and lathes capable of executing complex geometries with tolerances held to ±0.0002 inches. Unlike conventional cutting methods, our CNC-driven approach ensures repeatability across volumes while maintaining material integrity for critical components in aerospace, medical, and industrial sectors.

We specialize in turning raw stock into finished parts through optimized toolpaths that minimize waste and cycle times. Our capabilities span aluminum alloys, titanium, stainless steel, and engineering plastics, with processes including milling, turning, drilling, and precision contouring. Each operation undergoes rigorous in-process inspection using calibrated CMMs and vision systems, guaranteeing dimensional accuracy and surface finishes meeting ISO 2768-mK standards. This technical rigor translates to reduced scrap rates and accelerated time-to-assembly for your production lines.

Accelerate your procurement workflow with Honyo’s Online Instant Quote platform. Upload CAD files in STEP, IGES, or native formats to receive a detailed, no-obligation cost analysis within hours—not days. The system automatically evaluates geometry complexity, material requirements, and tolerance specifications to generate accurate pricing while highlighting potential manufacturability improvements. For engineering teams under tight deadlines, this eliminates traditional quoting bottlenecks without sacrificing technical validation.

Partner with Honyo to transform design intent into production-ready components through CNC machining that prioritizes precision, scalability, and operational transparency from quote to delivery.

Technical Capabilities

Production Cutting Services – Technical Specifications

Honyo Prototype offers high-precision production cutting services utilizing advanced 3, 4, and 5-axis CNC milling and turning technologies. These processes are optimized for complex geometries, high repeatability, and tight tolerance requirements across a wide range of engineering materials including aluminum, steel, ABS, and nylon. Our equipment and workflows are designed to support both low-volume prototyping and high-volume production runs with consistent quality and fast turnaround.

The following table outlines the detailed technical specifications for our production cutting services:

| Parameter | Specification |

|---|---|

| Machining Capabilities | 3-Axis, 4-Axis, and 5-Axis CNC Milling; CNC Turning (2-axis and multi-axis) |

| Positioning Accuracy | ±0.005 mm (±0.0002 in) |

| Repeatability | ±0.002 mm (±0.0001 in) |

| Tight Tolerance Capability | ±0.0125 mm (±0.0005 in) standard; down to ±0.005 mm (±0.0002 in) on critical features |

| Surface Finish (Typical) | Ra 0.8 µm (32 µin) standard; achievable down to Ra 0.4 µm (16 µin) with polishing or post-processing |

| Max Work Envelope (Milling) | 5-axis: 1200 x 800 x 600 mm (47 x 31.5 x 23.6 in) 3/4-axis: 2000 x 1000 x 1000 mm (78.7 x 39.4 x 39.4 in) |

| Max Turning Diameter | 500 mm (19.7 in) |

| Max Turning Length | 1000 mm (39.4 in) |

| Spindle Speed (Milling) | Up to 24,000 RPM |

| Tooling System | Automatic Tool Changer (ATC), HSK-63 or CAT-40 interface |

| Materials Supported | Aluminum (6061, 7075, 2024), Steel (1018, 4140, Stainless 303, 316), ABS (I, II, III), Nylon (6, 6/6, reinforced) |

| Coolant/Lubrication | Flood coolant, mist coolant, and dry machining options |

| Inspection & QA | In-process and final CMM, optical comparators, micrometers, and calipers; full First Article Inspection (FAI) available |

| Production Volume | Low to high volume, with automated pallet systems for unattended operation |

| File Formats Accepted | STEP, IGES, DWG, DXF, SolidWorks, Fusion 360, and native CAM files |

These capabilities ensure precision manufacturing of components requiring tight geometric tolerances, complex contours, and high structural integrity across aerospace, medical, automotive, and industrial sectors. Material selection is supported by in-house material certification and traceability for regulated industries.

From CAD to Part: The Process

Honyo Prototype Production Cutting Services Process Overview

Honyo Prototype delivers precision production cutting services through a streamlined, technology-driven workflow designed for speed, accuracy, and manufacturability. Our five-stage process eliminates traditional bottlenecks while ensuring rigorous engineering validation.

Upload CAD

Clients initiate the process by uploading native or neutral CAD files (STEP, IGES, DXF, DWG) via our secure customer portal. The system automatically validates file integrity, geometry completeness, and unit consistency. Supported formats include multi-sheet drawings with GD&T callouts. Large assemblies are processed through our high-bandwidth server infrastructure to prevent data corruption, with immediate confirmation of successful upload and file readiness for quoting.

AI-Powered Instant Quote

Our proprietary AI engine analyzes the CAD geometry in real time to generate a comprehensive quote within minutes. The system evaluates material requirements, cut complexity, sheet utilization efficiency, and secondary operations. Quotes include breakdowns for laser, plasma, waterjet, and oxy-fuel cutting technologies with recommended parameters. Crucially, the AI cross-references real-time material inventory data and machine availability to guarantee quoted lead times are operationally feasible, not theoretical estimates. Human engineering oversight validates all AI outputs before client delivery.

DFM Engineering Review

Every job undergoes mandatory Design for Manufacturability analysis by our in-house manufacturing engineers. This stage identifies potential issues such as minimum feature sizes below kerf width, unsupported geometries, suboptimal nesting layouts, or tolerance conflicts. Engineers collaborate directly with clients to resolve conflicts—suggesting cost-saving modifications like adjusting radii or consolidating cuts—while maintaining functional requirements. DFM reports document all recommendations with annotated visuals, reducing iteration cycles by 65% compared to industry averages.

Precision Production Execution

Approved designs move to production on our network of CNC-controlled cutting systems:

Fiber Laser: Up to 15kW capacity for metals ≤ 50mm (stainless, aluminum, carbon steel)

Plasma: High-speed cutting for conductive metals ≤ 100mm

Waterjet: 60k PSI systems for composites, glass, and heat-sensitive materials

All machines operate under SPC-controlled environments with automated material handling. Each part undergoes in-process verification via CMM spot checks and vision-based edge quality inspection. Nesting software dynamically optimizes material yield, with real-time production tracking accessible to clients via the portal.

Quality-Controlled Delivery

Final inspection includes full-spectrum verification against original CAD: dimensional accuracy (per ASME Y14.5), surface roughness (Ra), and bevel angle compliance. Certified material test reports and first-article inspection documentation accompany every shipment. Parts are deburred, tagged with unique job IDs, and packaged per client specifications. Logistics utilize tracked freight with ETAs updated hourly, with typical lead times of 3–7 business days from DFM approval.

Process Value Summary

| Stage | Key Activities | Client Value |

|---|---|---|

| Upload CAD | File validation, geometry integrity check | Eliminates rework from corrupted/invalid files |

| AI Quote | Material optimization, real-time capacity sync | Transparent pricing with guaranteed feasibility |

| DFM | Kerf/tolerance analysis, nested layout review | Reduces cost 15–30% while ensuring producibility |

| Production | SPC-controlled cutting, in-process CMM checks | 99.8% first-pass yield rate |

| Delivery | FAI documentation, real-time shipment tracking | Audit-ready traceability from CAD to delivery |

This integrated approach ensures clients receive production-ready parts with minimized risk and maximum cost efficiency, leveraging Honyo’s fusion of AI automation and deep manufacturing expertise. All processes comply with ISO 9001:2015 standards, with NADCAP accreditation for aerospace cutting requirements.

Start Your Project

For fast, precision production cutting services, contact Susan Leo at [email protected]. Our advanced manufacturing facility in Shenzhen delivers high-quality results with quick turnaround times. Partner with Honyo Prototype for reliable, scalable cutting solutions built to your exact specifications.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.