Contents

Manufacturing Insight: Printing In Metal

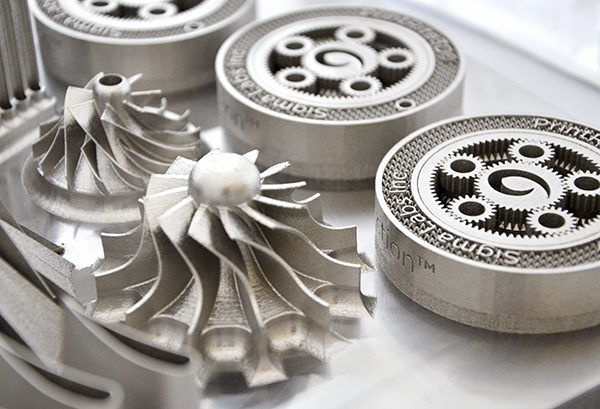

Industrial Metal 3D Printing: Precision Manufacturing Beyond Prototyping

Metal additive manufacturing has evolved from a prototyping tool into a critical industrial production solution, enabling complex geometries, lightweight structures, and rapid iteration impossible with traditional methods. At Honyo Prototype, we leverage advanced Industrial 3D Printing to transform your most demanding design challenges into high-integrity end-use components. Our end-to-end service encompasses design optimization, certified material processing, precision post-printing, and rigorous quality assurance, ensuring parts meet exacting aerospace, medical, and industrial standards.

We specialize in producing fully dense, high-strength components using premium alloys including:

| Material Category | Common Alloys | Typical Applications |

|---|---|---|

| Titanium | Ti6Al4V (Grade 5) | Aerospace brackets, medical implants |

| Stainless Steel | 17-4 PH, 316L | Hydraulic manifolds, tooling inserts |

| Nickel-Based | Inconel 718, 625 | Turbine components, high-temp fixtures |

| Aluminum | AlSi10Mg, Scalmalloy® | Lightweight automotive/aerospace parts |

Critical to reducing your time-to-market, Honyo’s Online Instant Quote system provides transparent, geometry-based pricing within minutes—no manual RFQ delays. Upload your CAD file, specify material and finish requirements, and receive a validated production quote instantly, accelerating your path from concept to certified metal part. Partner with us to eliminate design compromises and leverage industrial-scale metal additive manufacturing with engineering-grade reliability.

Technical Capabilities

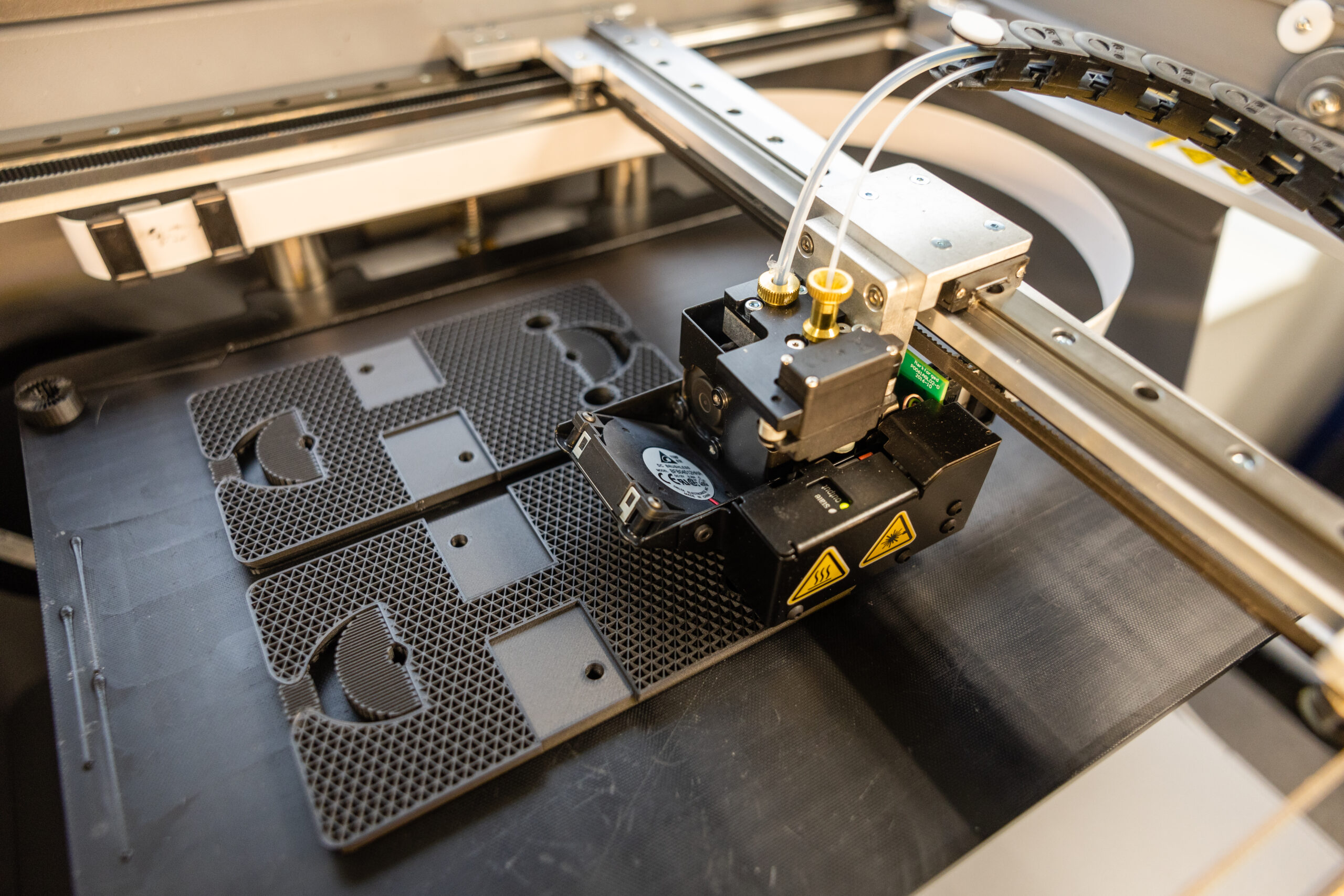

Stereolithography (SLA), Selective Laser Sintering (SLS), Multi Jet Fusion (MJF), and Direct Metal Laser Sintering (DMLS) are additive manufacturing technologies used to produce functional prototypes and end-use parts. While SLA, SLS, and MJF are primarily polymer-based processes, DMLS is specifically designed for metal printing. Below is a technical comparison of these technologies with a focus on their compatibility with materials such as Aluminum, Steel, ABS, and Nylon.

| Technology | Process Description | Typical Materials | Max Build Volume (approx.) | Layer Thickness Range | Surface Finish (Ra) | Tolerance | Key Applications |

|---|---|---|---|---|---|---|---|

| SLA (Stereolithography) | Uses UV laser to cure liquid photopolymer resin layer by layer | Photopolymer resins (standard, engineering, castable); not compatible with metals or ABS | 1450 x 800 x 500 mm (industrial) | 25–200 µm | 0.8–2.5 µm | ±0.1 mm (small parts), ±0.3% (larger parts) | High-detail prototypes, molds, dental models |

| SLS (Selective Laser Sintering) | High-power laser sinters powdered material, typically nylon-based | Nylon (PA 11, PA 12), Glass-filled Nylon; not compatible with metals or ABS (ABS not typically used in SLS) | 750 x 550 x 550 mm | 80–120 µm | 8–15 µm | ±0.3 mm | Functional prototypes, end-use parts, complex geometries |

| MJF (Multi Jet Fusion) | Inkjet array deposits fusing and detailing agents on powder bed, then heated by lamps | Nylon (PA 12), Glass-filled PA 12; not compatible with metals or ABS | 380 x 280 x 380 mm | 80 µm | 4–8 µm | ±0.2 mm | High-strength functional parts, batch production |

| DMLS (Direct Metal Laser Sintering) | High-power laser fully melts metal powder to create dense metal parts | Aluminum (AlSi10Mg, AlSi7Mg), Stainless Steel (17-4 PH, 316L), Titanium, Inconel; not compatible with ABS or Nylon | 250 x 250 x 325 mm (typical) | 20–50 µm | 10–20 µm (as-built), can be improved with post-processing | ±0.1 mm | Aerospace, medical implants, tooling, high-performance components |

Notes on Materials:

Aluminum: Processable only via DMLS; commonly used in lightweight structural components.

Steel: Specifically stainless steel variants (e.g., 17-4 PH, 316L) are used in DMLS for high-strength, corrosion-resistant parts.

ABS: A thermoplastic commonly used in FDM (Fused Deposition Modeling), not compatible with SLA, SLS, MJF, or DMLS. SLA uses photopolymers that mimic ABS properties but are chemically distinct.

Nylon: Used in SLS and MJF processes; offers excellent mechanical properties, durability, and chemical resistance. Not used in SLA or DMLS.

Each technology serves distinct applications based on material requirements, mechanical performance, and production volume. DMLS is the only process listed that enables true metal printing.

From CAD to Part: The Process

Honyo Prototype Metal Additive Manufacturing Process Overview

Honyo Prototype utilizes industrial-grade metal additive manufacturing (AM) technologies, including Direct Metal Laser Sintering (DMLS) and Electron Beam Melting (EBM), to transform digital designs into functional metal components. Our end-to-end workflow ensures technical rigor, cost transparency, and on-time delivery for mission-critical applications. Below is a detailed explanation of each phase.

Upload CAD

Clients initiate the process by uploading native CAD files (STEP, IGES, or native formats like SLDPRT) via our secure, encrypted portal. The system performs an initial validation check for file integrity, unit consistency, and geometric completeness. All data is protected under ISO 27001-certified cybersecurity protocols, with optional NDAs enforced prior to file submission. Unsupported formats trigger an automated notification requesting conversion to ensure manufacturing fidelity.

AI Quote Generation

Our proprietary AI engine analyzes the validated CAD geometry against real-time parameters including material selection (e.g., Inconel 718, Ti-6Al-4V, 17-4 PH stainless steel), machine availability, build volume utilization, and regional energy costs. The algorithm cross-references historical production data to predict support structure requirements, estimated build time, and post-processing labor. Clients receive a formal quotation within 2 business hours, detailing unit cost, lead time, material certifications, and compliance with standards such as ASTM F3301 or AMS7000.

Design for Manufacturability (DFM) Review

Honyo’s engineering team conducts a rigorous DFM analysis, typically completed within 24–48 hours. This phase identifies critical issues such as inadequate wall thickness (<0.4 mm), unsupported overhangs exceeding 45 degrees, or features prone to thermal distortion. We provide a prioritized DFM report with actionable recommendations—such as reorienting the part to minimize supports or adjusting tolerances—delivered via secure PDF with markups. Clients must approve revisions before proceeding; 12% of projects require iterative adjustments at this stage to mitigate production risks.

Production Execution

Approved designs move to production in our climate-controlled AM facility. Key steps include:

Build Preparation: Slicing the model with adaptive layer thickness (20–50 μm), generating optimized support structures, and nesting parts for maximum build plate utilization.

Printing: Executing builds on certified EOS M 400-4 or Renishaw RenAM 500Q systems under inert argon atmospheres, with real-time melt pool monitoring via in-situ cameras and thermal sensors.

Post-Processing: Removing supports via CNC milling, stress-relieving in vacuum furnaces, precision machining critical features (±0.05 mm tolerance), and surface finishing (e.g., vibratory polishing, bead blasting).

Quality Assurance: Performing 100% dimensional inspection via CMM, porosity checks through X-ray CT scanning, and mechanical validation per material datasheets. Non-conforming parts trigger root-cause analysis before rework.

Delivery and Documentation

Completed parts undergo final packaging with anti-corrosion VCI paper and serialized tracking labels. Each shipment includes:

A Certificate of Conformance (CoC) with traceable material lot numbers

Dimensional inspection reports (PDF and XML formats)

As-built CT scan data (optional, per client requirement)

Packing slip with customs documentation for international shipments

Standard lead time from CAD approval to delivery is 7–10 business days, with expedited options available. All deliveries are tracked via our client portal until proof of delivery is confirmed.

This integrated workflow ensures Honyo Prototype delivers production-ready metal AM components with repeatable quality, minimized iteration cycles, and full traceability for aerospace, medical, and industrial clients.

Start Your Project

Discover the future of manufacturing with metal 3D printing from Honyo Prototype. Our advanced direct metal laser sintering (DMLS) technology enables complex, high-precision metal parts ideal for aerospace, medical, and industrial applications. With our state-of-the-art facility in Shenzhen, we deliver rapid turnaround and exceptional quality for prototyping and low-volume production.

Contact Susan Leo today to discuss your metal printing project. Email at [email protected] for a fast response and technical consultation tailored to your requirements.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.