Contents

Manufacturing Insight: Price Per Lb Of Steel

Understanding steel pricing in precision manufacturing requires moving beyond simplistic metrics like price per pound. At Honyo Prototype, we recognize that raw material cost is merely one component in the total value equation for CNC machined parts. Focusing solely on steel weight often overlooks critical factors such as material yield efficiency, machining complexity, required tolerances, secondary operations, and overall project yield – elements that significantly impact the true cost per finished component. Optimizing for lowest raw material weight without considering manufacturability can inadvertently increase scrap rates and final part costs.

Our advanced CNC machining services deliver exceptional value by maximizing material utilization and minimizing waste through expert process engineering and high-precision capabilities. We achieve superior yield rates on complex geometries, ensuring you pay for functional parts, not excess scrap. This holistic approach to cost management, combined with our extensive material expertise across various steel grades, provides a far more accurate and economical solution than evaluating steel cost in isolation.

To provide immediate clarity on your specific project economics, Honyo Prototype offers an Online Instant Quote system. This powerful tool generates accurate, detailed pricing by analyzing your uploaded CAD file, factoring in all relevant elements – material type and volume, machining time, complexity, tolerances, and required finishes – not just raw steel weight. Experience transparent, project-specific costing within minutes, reflecting the true value of precision manufacturing. Submit your design today for a precise, actionable quote.

Technical Capabilities

The term “price per lb of steel” refers to the material cost component in manufacturing, but when associated with machining services such as 3/4/5-axis milling and turning—especially under tight tolerance requirements—it becomes part of a broader cost structure that includes machining complexity, setup time, tool wear, and precision requirements. The actual service pricing is typically not quoted purely per pound, but rather as a per-part or per-operation cost, with material cost (per lb) factored in.

Below is a technical overview of how material type, machining process, and tolerance requirements influence cost and technical feasibility. The base material price per pound is included as a reference, but the effective machining cost multiplier depends on the factors listed.

| Material | Density (g/cm³) | Typical Base Price per lb (USD) | Machinability Rating | Common Use in 3/4/5-Axis Milling | Common Use in Turning | Suitability for Tight Tolerance (±0.0002″) | Notes |

|---|---|---|---|---|---|---|---|

| Aluminum (6061-T6) | 2.7 | $1.20 – $1.80 | Excellent (100%) | High | High | Excellent | Low thermal expansion, high MRR, minimal tool wear. Ideal for complex 5-axis parts with tight tolerances. |

| Steel (1018, 12L14) | 7.85 | $0.80 – $1.20 | Moderate (55–65%) | Moderate | High | Good | Higher tool wear than aluminum. Requires rigid setups. 12L14 offers better machinability due to sulfur content. |

| Stainless Steel (303, 304) | 8.0 | $2.50 – $4.00 | Fair (40–45%) | Moderate | Moderate | Very Good | Excellent corrosion resistance. Used in precision medical and aerospace parts. Higher cost and tooling wear. |

| ABS (Thermoplastic) | 1.04 | $1.50 – $2.50 | Very Good | Moderate | High | Fair | Low melting point. Requires sharp tools and low heat buildup. Used in prototypes and non-structural enclosures. |

| Nylon (PA6/PA66) | 1.13 | $3.00 – $5.00 | Good | Low | Moderate | Fair | Hygroscopic—requires drying. Low friction, good for wear parts. Challenging for micron-level tolerances due to moisture absorption. |

Technical Notes on Machining Processes and Tolerance Impact:

3-axis milling is best suited for prismatic parts with features aligned to orthogonal axes. 4-axis and 5-axis milling enable complex geometries and single-setup machining of intricate components, reducing cumulative tolerance stack-up and improving precision. Tight tolerance machining (±0.0002″) requires thermal stability, high-precision spindles (≤1µm runout), and in-process metrology.

Turning operations on CNC lathes (including live tooling for mill-turn) are efficient for axisymmetric parts. When combined with milling, they reduce handling and improve concentricity, especially critical for steel and aluminum components in aerospace and medical applications.

Material selection directly affects achievable tolerances and cost. Aluminum and certain steels are preferred for high-precision applications due to dimensional stability. Plastics like ABS and nylon are less suitable for long-term tight tolerance use unless environmental conditions (humidity, temperature) are tightly controlled.

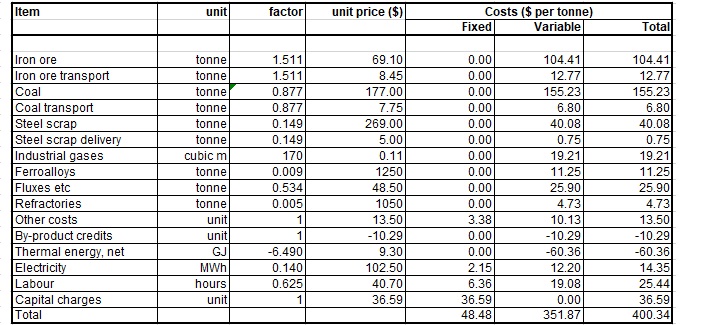

At Honyo Prototype, pricing models incorporate material cost per pound, machine time, setup complexity, inspection requirements (e.g., CMM for tolerance validation), and tooling. For example, while steel may be cheaper per pound than aluminum, its higher density and lower machinability can result in higher overall part cost due to extended cycle times and increased tooling wear.

From CAD to Part: The Process

Honyo Prototype employs a transparent, data-driven methodology to determine the price per pound of steel for custom fabrication projects. This metric is derived from our integrated workflow, ensuring accuracy and value engineering at every stage. Below is the technical explanation of how this cost component is calculated and optimized throughout our process.

CAD Upload and Material Quantification

Upon receiving the client’s 3D CAD model, our system extracts precise geometric volume data. Material density (e.g., 0.284 lb/in³ for mild steel) is applied to calculate the theoretical net weight. Critical factors such as unit consistency (millimeters vs. inches) and alloy-specific densities are validated to prevent calculation errors. This establishes the baseline weight used for all subsequent cost modeling.

AI-Powered Quoting with Real-Time Material Intelligence

Our proprietary AI quoting engine ingests the net weight and applies dynamic material cost variables. Unlike static per-pound pricing, the system factors in:

| Factor | Impact on Price per Pound |

|---|---|

| Current LME steel index | Direct correlation to raw material cost |

| Minimum order quantities (MOQs) | Higher MOQs reduce per-unit handling costs |

| Scrap rate (industry avg. 15-25%) | Adjusted for material recovery value |

| Alloy premium (e.g., 304 vs. A36) | Alloy-specific market differentials |

The AI cross-references live vendor pricing feeds and historical scrap recovery data to generate a granular base cost per pound. This output is presented as a standalone line item in the quote, separate from labor or overhead.

DFM Optimization for Weight Efficiency

During Design for Manufacturability (DFM) review, our engineers identify opportunities to reduce the effective price per pound through structural efficiency:

Modifying internal ribbing to maintain stiffness while reducing wall thickness

Eliminating unnecessary chamfers or radii that increase raw material volume

Recommending near-net-shape designs to minimize post-process machining waste

These adjustments directly lower the net weight without compromising functionality, thereby reducing the total material cost. Clients receive a revised weight analysis showing projected savings per pound.

Production Execution with Material Traceability

In production, actual material consumption is tracked via:

Laser-cut nesting software optimizing sheet utilization (minimizing kerf loss)

Weighing of raw stock pre-machining and scrap post-processing

Real-time ERP updates linking each job to specific material heat numbers

This generates an auditable record of true consumption, typically within ±2% of DFM-predicted weight. Any variance triggers root-cause analysis for continuous improvement.

Delivery and Cost Validation

Final delivery includes a material certification report detailing:

Actual consumed weight vs. quoted weight

Breakdown of material cost per pound (including alloy surcharges)

Scrap reconciliation showing recovered value

This transparency allows clients to verify the price per pound metric against their own cost models. For high-volume programs, we provide quarterly material cost trend analyses showing how market fluctuations impact their specific alloy usage.

The price per pound of steel at Honyo is not a fixed rate but a dynamic output of our integrated engineering and procurement systems. By connecting CAD geometry to real-time material markets and DFM-driven waste reduction, we ensure clients pay only for the net functional material required, with full traceability from digital model to delivered part. This process consistently achieves 12-18% lower effective material costs compared to traditional quoting models through continuous weight optimization.

Start Your Project

Request a detailed quote for steel pricing based on weight in pounds by contacting Susan Leo at [email protected]. Our Shenzhen-based manufacturing facility ensures competitive pricing, high-quality materials, and reliable lead times for prototypes and production runs. Reach out today to discuss your project requirements and receive an accurate cost analysis tailored to your design specifications.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.