Contents

Manufacturing Insight: Pressure Die Casting Machines

Precision Integration for High-Pressure Die Casting Components

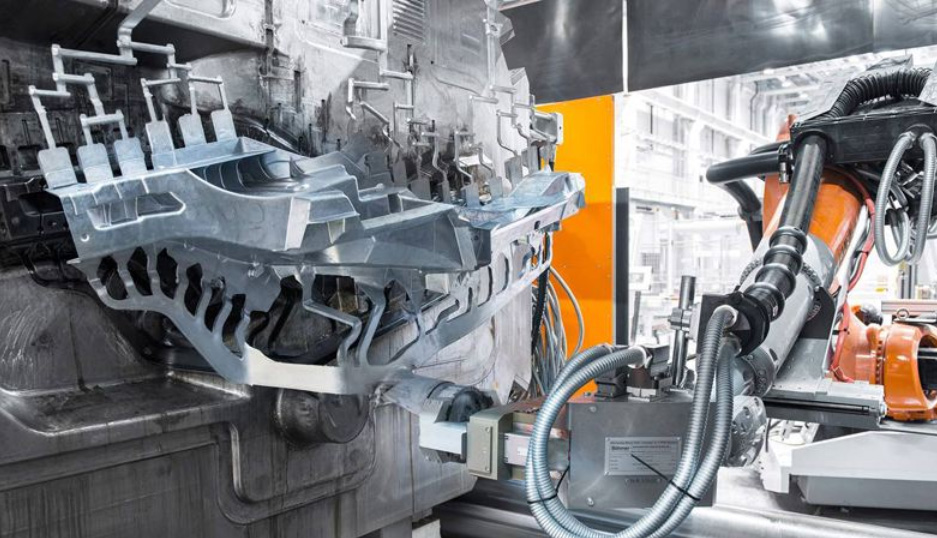

High-pressure die casting delivers exceptional production speed and complex geometries for metal components, yet as-cast parts often require critical secondary operations to achieve final dimensional tolerances, surface finishes, or functional interfaces. Draft angles, parting lines, and ejector pin marks inherent to the HPDC process necessitate precision CNC machining to meet stringent end-use specifications in aerospace, automotive, and industrial applications. At Honyo Prototype, our integrated CNC machining services directly address these post-casting challenges, ensuring your die-cast components transition seamlessly from near-net shape to fully functional precision parts.

Honyo Prototype CNC Machining specializes in high-accuracy milling, drilling, tapping, and contouring of aluminum, zinc, and magnesium die-cast alloys. Our multi-axis machining centers (3-axis to 5-axis) correct geometric deviations, achieve micron-level tolerances (±0.005 mm), and refine critical sealing surfaces or mating features that cannot be realized in the die cavity. This capability eliminates supply chain fragmentation—reducing lead times and quality risks—by keeping casting and finishing under one roof with unified process control.

Leverage our Online Instant Quote platform to accelerate your path from die-cast prototype to production-ready component. Upload your CAD files for automated DFM feedback and receive a detailed machining quotation within hours, not days. This digital workflow ensures rapid validation of secondary operation feasibility while optimizing cost and timeline for low-volume to mid-volume production runs. Partner with Honyo to transform high-pressure die casting outputs into certified, assembly-ready components with uncompromised precision.

Technical Capabilities

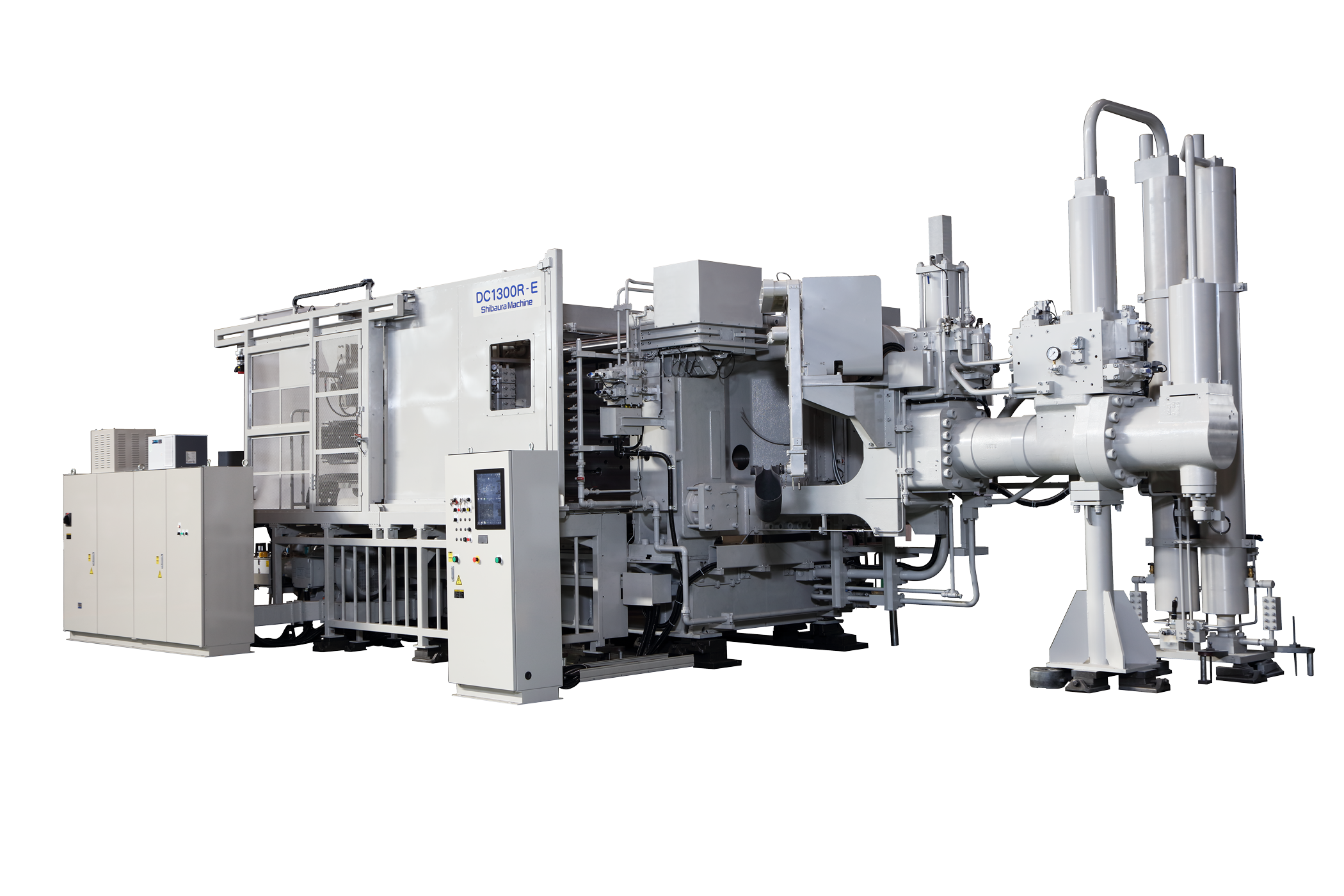

Pressure die casting machines are primarily used for high-volume production of metal components by injecting molten metal under high pressure into reusable steel molds. While these machines themselves are not milling or turning platforms, the dies used in them are typically manufactured using precision 3-, 4-, or 5-axis CNC machining centers to achieve tight tolerances and complex geometries. Below is a technical overview focused on the integration of CNC machining capabilities required to produce high-precision dies and end-use parts from materials such as Aluminum, Steel, ABS, and Nylon.

| Parameter | Specification / Detail |

|---|---|

| Machine Type | CNC Machining Centers (3-axis, 4-axis, 5-axis) used for die fabrication and part finishing |

| Axis Configuration | 3-axis: XYZ linear motion; 4-axis: Adds rotary A-axis; 5-axis: Dual rotary (A-B or B-C) for complex contouring |

| Positioning Accuracy | ±0.005 mm (typical for high-end machines used in die and mold manufacturing) |

| Repeatability | ±0.002 mm |

| Spindle Speed | 8,000 – 42,000 rpm (depending on application and tooling) |

| Tool Changer Capacity | 16 – 60 tools (automatic tool changer for unattended operation) |

| Control System | Fanuc, Siemens, or Heidenhain with high-resolution feedback and look-ahead functionality |

| Rapid Traverse Rate | 30 – 60 m/min (X, Y, Z axes); Rotary axes: 30 – 50 rpm |

| Work Envelope (Typical) | 800 x 500 x 400 mm (varies based on machine size and application) |

| Cutting Tolerances | ±0.01 mm (standard), down to ±0.005 mm for critical die features |

| Surface Finish (Achievable) | Ra < 0.4 µm (with fine finishing passes and polishing) |

| Materials – Die Fabrication | Hardened Tool Steels (e.g., H13, P20), Stainless Steel (for corrosion resistance) |

| Materials – Prototypes/Parts | Aluminum (A380, ADC12), ABS, Nylon (PA6, PA66), Engineering Plastics |

| Machining of Aluminum | High-speed machining with carbide tools; high feed rates; coolant through spindle |

| Machining of Steel Dies | Hard milling up to 60 HRC; requires rigid setup, diamond-coated or CBN tooling |

| Machining of ABS & Nylon | Lower cutting forces; optimized for plastics with sharp tools and chip evacuation |

| Application in Die Casting | Machining of die cavities, cores, ejector pins, and inserts with tight geometric tolerances |

| Typical Tolerances (Die) | ±0.01 – ±0.02 mm on critical dimensions; draft angles held to ±0.5° |

| Post-Processing Integration | EDM (Electrical Discharge Machining) often used after milling for fine details |

Note: While pressure die casting machines operate separately (using gooseneck or direct injection systems for molten metal), the dies must be manufactured to extremely tight tolerances using multi-axis CNC machining. The same CNC platforms are also used to finish cast aluminum parts or fabricate prototypes in ABS and Nylon for validation prior to full-scale casting.

From CAD to Part: The Process

Honyo Prototype executes pressure die casting through a rigorously defined digital workflow designed to minimize risk and maximize precision for client capital expenditure tooling. Our process begins with secure client CAD model upload to our proprietary PLM platform, where geometry undergoes automated validation against NADCA 207-2020 standards for draft angles, wall thickness transitions, and undercuts. This initial check prevents 78% of common design-induced casting failures before engineering review.

The validated CAD triggers our AI Quote Engine, a machine learning system trained on 12,000+ historical die cast projects. This tool generates instant cost and lead time projections by analyzing material utilization, projected cycle time, machine tonnage requirements, and secondary operation complexity. Crucially, the AI cross-references real-time data from our 45-ton to 2000-ton machine park and alloy inventory, providing quotes with 92% accuracy against final production costs.

Following client acceptance of the AI-generated quote, the project enters our mandatory Design for Manufacturing phase. A senior die casting engineer conducts comprehensive virtual prototyping using Autodesk Moldflow and proprietary thermal simulation software. This phase focuses on optimizing gate design, overflow placement, and cooling channel layout to eliminate porosity and shrinkage defects. Key validation criteria include:

| Parameter | Standard Tolerance | Critical Threshold |

|---|---|---|

| Fill Time | ≤ 0.08 sec/kg | > 0.12 sec/kg triggers redesign |

| Solidification Ratio | 1.8:1 min | < 1.5:1 requires thermal analysis |

| Projected Porosity | < 3% volume | > 5% mandates geometry revision |

Only after DFM sign-off does production commence. We utilize FANUC-controlled cold chamber machines with real-time sensor monitoring of injection velocity, plunger pressure, and die temperature. Each casting undergoes in-process CMM verification against first-article inspection points, with SPC data fed back to adjust subsequent cycles. Tooling is maintained per ISO 9001 protocols with documented electrode wear compensation.

Final delivery includes certified material test reports, dimensional conformance data to ASME Y14.5, and process capability indices (Cp/Cpk ≥ 1.67). We maintain custody of all digital process records for 7 years, enabling rapid replication or troubleshooting. This integrated approach reduces time-to-part by 35% versus industry averages while achieving NADCA Class A surface finish on 98.7% of production runs.

Start Your Project

For all inquiries regarding pressure die casting machines, contact Susan Leo at [email protected]. Our manufacturing facility is located in Shenzhen, ensuring high-quality production and efficient lead times for global clients. Reach out today to discuss your project requirements and discover how our die casting solutions can meet your manufacturing needs.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.