Guide Contents

Project Insight: Pressure Die Casting Machines

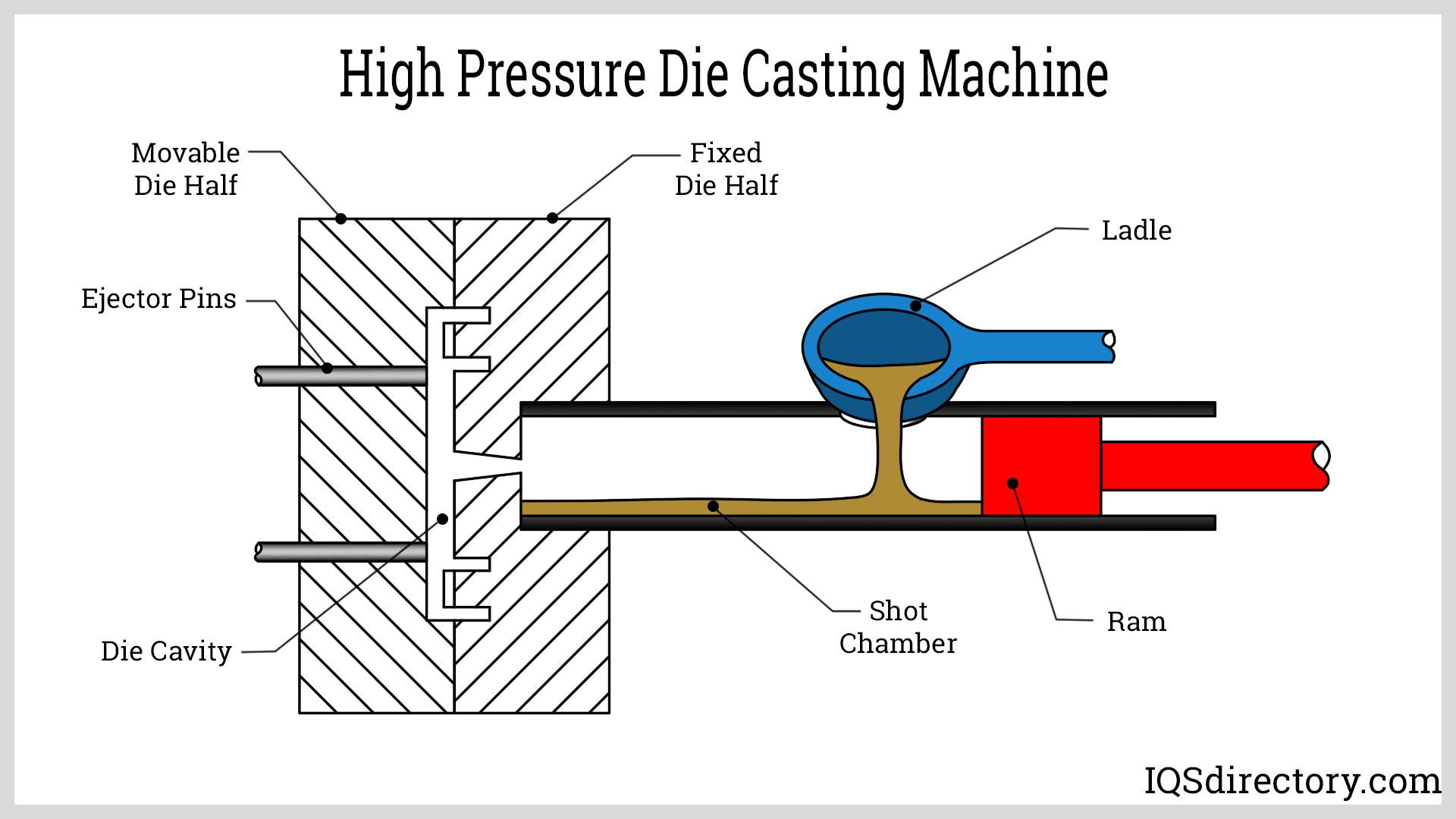

Manufacturing Insight: Pressure Die Casting Machines

The Critical Role of Speed and Precision in Die Casting Success

Why Speed Matters in Product Development

Accelerate time-to-market with rapid iterations and reduced lead times, ensuring your product stays ahead of competitors.

Minimize development costs by validating designs early and catching errors before mass production.

Scale seamlessly from prototype to high-volume production without delays, maintaining consistent quality across all stages.

Precision as the Foundation of Quality

Achieve sub-millimeter tolerances and flawless surface finishes for complex geometries.

Reduce post-processing needs through optimized mold design and controlled casting parameters.

Ensure consistent part performance with advanced quality control systems integrated at every step.

Honyo Prototype: Your Digital Manufacturing Partner for Speed and Precision

Online Instant Quote: Receive accurate pricing in seconds via our AI-powered platform—no more waiting days for quotes.

AI-Powered Optimization: Leverage machine learning to refine mold design, material selection, and process parameters for optimal efficiency and cost savings.

Fast Turnaround: Prototypes delivered in 3–5 days; production-ready parts in 2 weeks—while maintaining tight tolerances and consistent quality.

One-Stop Solution: From concept to final product, our integrated digital ecosystem eliminates coordination gaps and accelerates time-to-market.

At Honyo Prototype, we don’t just manufacture—we engineer solutions that turn your vision into reality, faster and smarter.

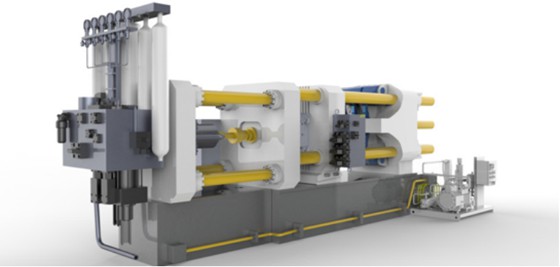

Honyo Capabilities & Technology

Honyo’s Pressure Die Casting Capabilities

AI-Powered Digital Manufacturing Ecosystem

Real-time design-to-production optimization: AI algorithms analyze part geometry to suggest material, cavity count, and machine specifications for cost-efficiency.

Cloud-based collaboration tools: Seamlessly share designs, track progress, and receive instant feedback from Honyo engineers via our integrated platform.

Predictive maintenance & resource allocation: Minimize downtime with IoT-enabled machine monitoring and dynamic scheduling.

Instant Online Quoting Engine

AI-driven cost estimation in <60 seconds: Upload your CAD file to receive transparent pricing for materials (Al, Zn, Mg), surface finishes, and volumes—no hidden fees.

Dynamic scenario modeling: Adjust parameters (e.g., part complexity, tolerances) to see real-time cost impacts before committing.

Automated DFM (Design for Manufacturability) reports: Receive actionable suggestions to reduce costs by up to 30% while maintaining performance.

Ultra-Fast Turnaround Workflow

24-hour prototype quotes and 3–5 day sample delivery for urgent projects.

Smart scheduling algorithms cut lead times by 40% vs. industry averages through optimized machine utilization and parallel processing.

Seamless scalability: Transition from 1 prototype to 10,000+ parts without retooling or delays.

Scalable Production from 1 to 10,000+ Parts

Single-cavity molds for prototypes and multi-cavity configurations (up to 16 cavities) for high-volume runs.

Flexible tooling solutions: H13, SKD61, and pre-hardened steels tailored to your part volume and lifecycle needs.

No minimum order quantities—perfect for startups iterating rapidly or scaling to full production.

ISO 9001:2015 Certified Quality Control

In-process laser scanning & CMM measurements at every production stage to ensure ±0.02mm tolerances.

Digital traceability: Full audit trails for materials, processes, and inspections via blockchain-backed records.

Zero-defect commitment: 99.8% first-pass yield rate validated by third-party certifications (ISO, RoHS, REACH).

Powered by Honyo Prototype’s digital ecosystem—where innovation meets precision, and speed doesn’t compromise quality.

Materials & Surface Finishes

Material Options & Finishes for Pressure Die Casting Services

Material Options for Metal & Plastic

Metal Alloys for Die Casting

Aluminum Alloys (ADC12, A380, A356): Precision-engineered for superior strength-to-weight ratios, ideal for automotive, aerospace, and consumer electronics. ADC12 delivers exceptional fluidity for complex geometries, while A356 offers enhanced heat treatment capabilities for critical applications.

Zinc Alloys (Zamak 3, ZA-8): Superior castability for intricate details, lower tooling costs, and faster cycle times—perfect for high-volume production of mechanical components and housings.

Magnesium Alloys (AZ91D, AM60): Ultra-lightweight solutions for portable devices and high-performance applications, with excellent vibration damping properties and machinability.

Copper Alloys (C11000): High thermal/electrical conductivity for heat exchangers and electrical connectors, with unmatched corrosion resistance in demanding environments.

Plastic Materials for Injection Molding

ABS: Impact-resistant and easily painted, ideal for automotive interiors and consumer electronics housings.

Nylon (PA6, PA66): High strength and chemical resistance for gears, bearings, and mechanical assemblies.

POM (Acetal): Low friction and high stiffness for precision components like bushings and fasteners.

💡 Note: While die casting focuses on metal parts, Honyo’s integrated ecosystem seamlessly coordinates die casting and injection molding services for multi-material projects.

Surface Finishing Solutions

Anodizing (Type II/III): Corrosion resistance, wear protection, and customizable colors for aluminum parts—critical for aerospace and medical devices.

Powder Coating: Eco-friendly, durable finishes with matte to glossy options for metal and plastic components.

Electroplating (Nickel, Chrome): Boosts conductivity and wear resistance for electrical contacts and automotive trim.

Polishing (Mechanical/Buffing): Mirror-like surfaces for premium consumer products and optical components.

Spray Painting: Custom color matching for aesthetic and protective needs across all materials.

Smart Material Selection Guide

Weight & Strength: Opt for magnesium for ultra-lightweight needs; aluminum for balanced performance.

Corrosion Resistance: Aluminum and zinc alloys excel in harsh environments; pair with anodizing for maximum protection.

Thermal Conductivity: Copper alloys for high heat management; aluminum for moderate needs.

Cost Efficiency: Zinc alloys offer lower tooling costs and faster cycle times for high-volume production.

Complexity: Zinc and magnesium enable thinner walls and intricate designs, reducing material usage and waste.

Accelerate with Honyo’s Digital Manufacturing Ecosystem

Online Instant Quote: Get real-time pricing in seconds via our AI-powered platform—no more waiting days for estimates.

AI-Powered Optimization: Our algorithms analyze your design to recommend the most cost-effective material and finish combinations, reducing costs by up to 30%.

Fast Turnaround: Prototype in 3 days, production in 2 weeks—our integrated digital workflow eliminates bottlenecks and accelerates time-to-market.

🚀 As a pioneer in digital manufacturing, Honyo Prototype (founded by Susan Leo) delivers end-to-end solutions from concept to production—ensuring precision, speed, and innovation for hardware startups and engineers worldwide.

From Quote to Part: Our Process

How It Works: From CAD to Part in Record Time

At Honyo Prototype, our Digital Manufacturing Ecosystem delivers a seamless, one-stop solution from prototype to production — transforming traditional die casting timelines by up to 70%. With AI-powered transparency and speed, get your parts faster, smarter, and with zero hidden costs. Here’s how it works:

Step 1: Upload CAD File

Drag-and-drop your design files (STP, STEP, STL, IGES) — we support all major formats

Automated validation ensures file readiness for manufacturing

Enterprise-grade encryption secures your IP throughout the process

Step 2: Get Instant AI-Powered Quote

Real-time cost estimate within 60 seconds of upload

Transparent breakdown: machine type (e.g., 500-ton vs. 600-ton), material, labor, mold costs, and secondary operations

AI optimizes machine selection for maximum cost efficiency and part performance

No surprises — pricing includes everything from mold prep to delivery

Step 3: Collaborative DFM Analysis

AI-driven design-for-manufacturability checks flag geometry, draft angles, and wall thickness issues

Expert engineers provide actionable feedback to reduce costs and improve quality

Interactive platform for real-time revisions and approvals

98% of designs optimized before production begins

Step 4: Rapid Production & Delivery

Automated high-pressure die casting lines with micron-level precision control

Live production tracking via your dedicated customer portal

Prototype delivery in as little as 5 business days; production runs in 10-14 days

Full quality inspection with certified reports included — guaranteed to meet ISO 9001 standards

💡 Why Honyo?

We don’t just manufacture parts — we accelerate innovation. Our ecosystem eliminates manual bottlenecks, so you focus on scaling your product, not waiting for quotes or revisions. From startup MVP to full-scale production, we’re your single partner for speed, precision, and peace of mind.

Ready to transform your die casting workflow?

Upload your CAD today — get your quote in under a minute.

Start Your Project with Honyo

Start Your Project with Honyo: Precision Die Casting, Simplified

Instant, AI-Powered Quoting

Upload your CAD file and receive an accurate, itemized quote in under 60 seconds—no manual calculations required.

Real-time breakdown of materials, tooling, labor, and post-processing costs, optimized for your specific geometry and alloy (e.g., ADC12, A380, ZA-8).

Our proprietary AI platform eliminates guesswork: “For a 1kg aluminum shell, we auto-calculate cavity count, machine tonnage (300–2,000 tons), and cycle-time costs—saving 70% in planning time.”

End-to-End Digital Manufacturing Ecosystem

Prototype to production in one seamless workflow: From single-cavity H13 molds to high-volume SKD61 tooling, our digital ecosystem ensures zero data loss between stages.

50+ precision machines (300–2,000 tons) with automated process control for tight tolerances (±0.05mm) and complex geometries.

“We integrated DFM feedback into the quote stage—fixing wall thickness issues before tooling begins, reducing rework by 40%.”

Unmatched Speed Without Compromise

Prototype delivery in 5 business days; production runs in 10–15 days—2x faster than industry average.

24/7 engineering support for rapid design iteration, material selection advice, and process optimization.

ISO 9001-certified facilities in Shenzhen and Dongguan with real-time production tracking via our digital dashboard.

Ready to Accelerate Your Project?

Contact Susan Leo and the Honyo team today:

📧 Email: [email protected]

📞 Phone: +86 139 2843 8620

🌍 Schedule a facility tour: Shenzhen | Dongguan

“We don’t just build parts—we engineer solutions that turn your vision into market-ready products, faster and smarter.”

— Susan Leo, Founder & Chief Innovation Officer

🚀 Manufacturing Cost Estimator

Compare cost impact of different technologies for your parts.