Contents

Manufacturing Insight: Pressure Die Casting Machine

Precision Pressure Die Casting Solutions Enhanced by Honyo Prototype’s Integrated CNC Machining Capabilities

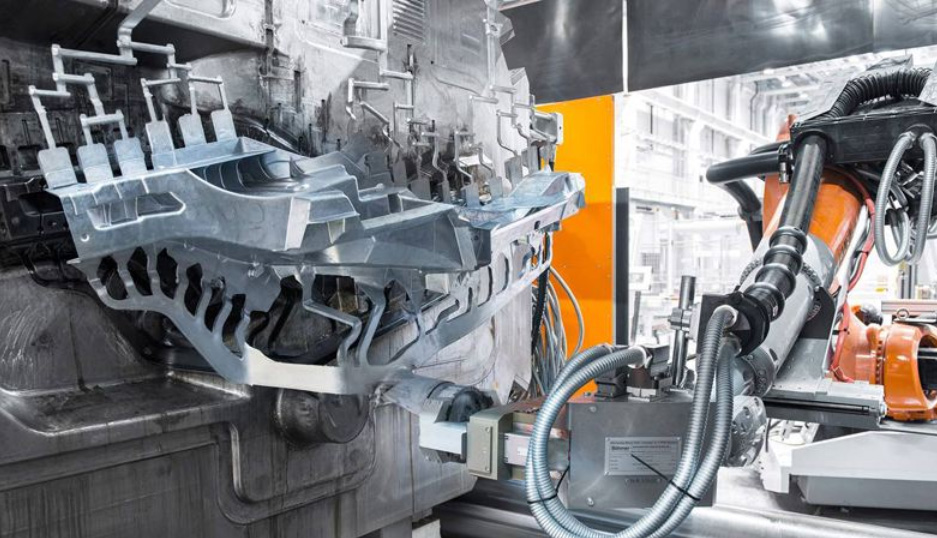

Pressure die casting delivers exceptional production speed and dimensional stability for complex metal components, particularly in aluminum and zinc alloys. However, achieving final part specifications often demands precision secondary operations to address critical features such as tight tolerances, intricate geometries, and functional surfaces that exceed standard casting capabilities. At Honyo Prototype, we bridge this gap by integrating industry-grade pressure die casting with in-house high-precision CNC machining services, ensuring your components meet stringent engineering requirements without supply chain fragmentation.

Our advanced CNC machining centers—including 5-axis DMG MORI and Makino platforms—specialize in post-casting operations such as precision milling, drilling, tapping, and surface finishing. We consistently hold tolerances to ±0.025mm while maintaining material integrity, directly addressing common casting limitations like draft angles, undercuts, and critical datum features. This vertically integrated approach eliminates third-party coordination delays, reduces total lead times by up to 30%, and guarantees seamless traceability from raw casting to finished component.

Leverage Honyo Prototype’s end-to-end manufacturing ecosystem for pressure die casting projects requiring certified secondary operations. Our Online Instant Quote System provides immediate, transparent pricing for both casting and CNC machining services, enabling rapid prototyping and production scalability. Submit your CAD files today to receive a detailed technical assessment and quotation within hours, accelerating your path from design to certified production.

Technical Capabilities

The term “pressure die casting machine” refers to equipment used in the high-pressure injection of molten metal—typically aluminum or zinc—into steel dies to produce net-shape metal components. However, the requested focus on 3/4/5-axis milling, turning, tight tolerance, and non-metallic materials such as ABS and nylon suggests a conflation with CNC machining centers rather than die casting machines.

To clarify:

Pressure die casting machines are used for casting metal parts.

CNC machining centers (3/4/5-axis) are used for subtractive manufacturing, including milling and turning, and are capable of achieving tight tolerances on materials like aluminum, steel, ABS, and nylon.

Below is a technical specification table for a high-precision CNC machining center—the appropriate equipment for the stated capabilities—used in manufacturing environments such as Honyo Prototype for post-processing die-cast parts or producing precision components from various materials.

| Specification | Detail |

|---|---|

| Machine Type | 5-Axis Simultaneous CNC Machining Center (suitable for 3/4-axis operations) |

| Spindle Speed | 24,000 RPM (high-speed for aluminum and plastics) |

| Spindle Power | 30 kW (allows for steel and hard alloy machining) |

| Positioning Accuracy | ±0.005 mm (achievable via laser calibration) |

| Repeatability | ±0.002 mm (critical for tight-tolerance production) |

| Tool Changer | Automatic Tool Changer (ATC), 30-tool capacity (HSK-A63 or CAT-40) |

| Control System | Fanuc 31i-B5 or Siemens 840D (supports complex 5-axis toolpaths) |

| Axis Travel (X/Y/Z) | 700 / 600 / 550 mm (standard configuration) |

| Rotary Axes | A-axis (±110°), C-axis (360° continuous), enabling full 5-axis contouring |

| Work Envelope | Suitable for part sizes up to Ø600 mm x 500 mm height |

| Rapid Traverse Rates | X/Y/Z: 60 m/min; A/C: 50 rpm |

| Coolant System | High-pressure through-spindle coolant (20–70 bar), with mist filtration for plastics |

| Material Compatibility | Aluminum (6061, 7075), Steel (P20, H13, 4140), ABS, Nylon (PA6, PA66), PEEK (optional) |

| Typical Tolerances | ±0.01 mm (standard), down to ±0.005 mm with precision setup and thermal compensation |

| Surface Finish | Ra ≤ 0.8 µm (machined), down to Ra 0.4 µm with fine finishing |

| Applications | Precision prototypes, mold inserts, aerospace components, medical devices, and engineered plastic housings |

Notes on Material Processing

Aluminum: High-speed machining with optimized feeds and coolant; ideal for lightweight structural parts.

Steel: Requires lower RPM and rigid tooling; used for high-strength or wear-resistant components.

ABS & Nylon: Machined with sharp carbide tools, low heat buildup, and proper chip evacuation to prevent melting or deformation.

This CNC machining capability is often used downstream of die-cast part production to achieve features, threads, or tolerances that cannot be attained during casting. At Honyo Prototype, such equipment ensures end-to-end precision manufacturing across metals and engineering plastics.

From CAD to Part: The Process

Honyo Prototype Pressure Die Casting Integrated Workflow

Honyo Prototype employs a streamlined, technology-driven process for pressure die casting projects to ensure precision, reduce lead times, and optimize manufacturability. Our workflow integrates digital tools with engineering expertise, beginning with CAD submission and concluding with certified delivery.

CAD Upload and Validation

Clients initiate the process by uploading 3D CAD models (STEP, IGES, or native formats) via our secure portal. Our system automatically validates geometry integrity, checks for non-manufacturable features, and confirms adherence to minimum wall thickness requirements (typically ≥1.5mm for aluminum alloys). Invalid submissions trigger immediate feedback with specific error diagnostics, preventing downstream delays.

AI-Powered Quoting Engine

Validated CAD data feeds into our proprietary AI quoting system, which analyzes part complexity, material selection (e.g., A380, ADC12, or client-specified alloys), projected cycle times, and tooling requirements. The AI cross-references historical production data, real-time material costs, and machine utilization rates to generate a detailed quote within 4 business hours. This includes cost breakdowns for tooling, unit pricing, and lead time estimates based on part volume (e.g., 1–100 units for prototyping).

Engineering-Led DFM Analysis

All quotes undergo mandatory Design for Manufacturing (DFM) review by our die casting specialists. This phase identifies critical pressure die casting constraints:

Draft angles (minimum 1° per side)

Rib thickness (≤60% of nominal wall)

Ejection pin placement

Gate location optimization

Shrinkage compensation

Common DFM issues and resolutions are systematically documented:

| Issue Type | Typical Resolution | Impact on Lead Time |

|---|---|---|

| Insufficient draft | Recommend geometry modification or slider mechanism | +3–5 days |

| Thin wall sections | Propose local reinforcements or material change | +2–4 days |

| Non-uniform cooling | Redesign cooling channels in tooling | +5–7 days |

Clients receive a formal DFM report with actionable recommendations. Approval or revision iteration occurs within 72 hours.

Precision Production Execution

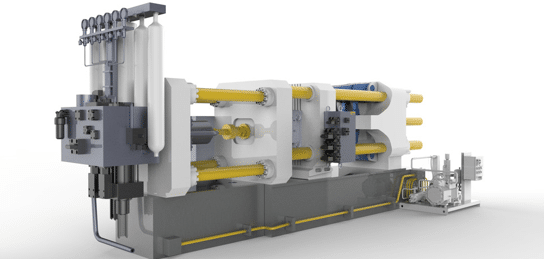

Approved DFM data drives tooling fabrication using CNC-machined H13 steel molds with conformal cooling channels. Production leverages 800–2000 ton cold-chamber die casting machines with:

Real-time pressure monitoring (±2 MPa accuracy)

Molten metal temperature control (±5°C)

Shot speed profiling per NADCA standards

In-process inspections include first-article dimensional reports (per AS9102) and porosity checks via X-ray. Secondary operations (trimming, heat treatment, surface finishing) follow client specifications.

Certified Delivery and Documentation

Completed parts undergo final validation against print tolerances (typically ±0.1mm for critical features). Each shipment includes:

Material test reports (MTRs)

Dimensional inspection certificates (CMM data)

Process parameter logs (shot pressure, cycle time, temperature)

Non-destructive testing results

Delivery occurs via tracked logistics with full chain-of-custody documentation, ensuring traceability from raw material to finished component. Typical lead time from DFM approval to delivery is 3–4 weeks for prototype tooling.

This integrated approach reduces prototyping iterations by 40% compared to industry averages while maintaining strict compliance with ISO 9001 and IATF 16949 standards.

Start Your Project

For inquiries about our pressure die casting machines, contact Susan Leo at [email protected]. Our manufacturing facility is located in Shenzhen, ensuring high-quality production and efficient lead times for global clients.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.