Contents

Manufacturing Insight: Pressure Die Casting Machine

Pressure-Die-Casting Machine – from molten metal to near-net shape in seconds, yet that’s only half the story at Honyo Prototype. After the die opens we take every casting straight into our 5-axis CNC machining cells, turning as-cast blanks into aerospace-grade housings, medical-valve bodies and EV motor end-shields with tolerances down to ±0.01 mm and Ra 0.4 µm finishes. No MOQ, no waiting for weeks: upload your STEP file today and you’ll have an Online Instant Quote that couples the casting cycle time with finish-machining hours, so you see the exact cost and lead-time for the fully-machined part before you’ve even poured the first shot.

Technical Capabilities

Critical Clarification: There is a fundamental terminology misunderstanding in your query.

Pressure die casting machines CANNOT perform 3/4/5-axis milling, turning, or handle ABS/Nylon. These are entirely separate processes and machine types. Let me explain why this is a critical error and provide accurate information:

🔧 Why Your Query is Misaligned

- Pressure Die Casting ≠ Machining

- Die casting machines are high-pressure injection systems for molten metal (e.g., aluminum, zinc, magnesium). They do not cut, mill, or turn material.

- 3/4/5-axis milling/turning are CNC subtractive machining processes performed on solid raw materials (e.g., aluminum billets, steel bars). These require CNC machine tools, not die casting machines.

-

ABS/Nylon are thermoplastics – they cannot be die cast. They are processed via plastic injection molding machines, not metal die casting machines.

-

Material Incompatibility

- Aluminum/Steel: Used in die casting for parts (aluminum) or mold dies (steel), but ABS/Nylon are incompatible with die casting. Molten metal temperatures (600–1200°C) would vaporize ABS/Nylon instantly.

-

ABS/Nylon are exclusively processed in plastic injection molding machines (operating at 150–350°C).

-

Tight Tolerances

- Die casting achieves ±0.1mm to ±0.3mm tolerances (typically) due to metal solidification and mold wear.

- 3/4/5-axis CNC milling/turning achieves ±0.005mm to ±0.025mm tolerances – far tighter than die casting. These are separate post-processing steps after die casting.

✅ Correct Technical Specs for Each Process

🏭 1. Pressure Die Casting Machine (for Aluminum/Zinc)

- Function: Inject molten metal into a steel mold under high pressure (100–200 MPa).

- Key Specs:

- Clamping Force: 500–10,000+ tons (e.g., 1,000 tons for automotive parts).

- Injection Speed: 0.5–5 m/s.

- Max. Shot Weight: 0.1–100+ kg (aluminum).

- Mold Temperature: 150–300°C (preheated to prevent thermal shock).

- Tolerance Capability: ±0.1mm (geometric), ±0.05mm for critical features (with precision molds).

- Materials Processed: Aluminum alloys (A380, A383), Zinc (Zamak 3), Magnesium (AZ91D).

- ABS/Nylon?: ❌ Impossible – thermoplastics would ignite.

🔧 2. 3/4/5-Axis CNC Milling Machine (for Post-Processing Die Cast Parts)

- Function: Machining solid metal parts (e.g., trimming die cast edges, drilling holes, sculpting complex geometries).

- Key Specs:

- Travel Axes: X/Y/Z (3-axis); A/B/C rotation (4/5-axis for complex contours).

- Positioning Accuracy: ±0.005mm (ISO 230-2).

- Repeatability: ±0.002mm.

- Spindle Speed: 10,000–24,000 RPM (high-speed machining).

- Materials Processed:

- Aluminum (6061-T6, 7075-T6)

- Steel (4140, 17-4 PH)

- ABS/Nylon? ❌ Not applicable – these require plastic-specific machining (low-speed, sharp tools).

- Tolerance Capability: ±0.005mm to ±0.025mm (achievable with precision tooling and fixturing).

🛠️ 3. CNC Turning Machine (for Rotational Parts)

- Function: Machining cylindrical surfaces (e.g., shafts, flanges from die cast blanks).

- Key Specs:

- Max. Turning Diameter: 200–600mm (varies by machine size).

- Positioning Accuracy: ±0.005mm.

- Spindle Speed: 1,000–6,000 RPM.

- Materials Processed: Aluminum, steel, titanium (not ABS/Nylon).

- Tolerance Capability: ±0.01mm (standard), ±0.005mm (precision).

🧪 4. Plastic Injection Molding Machine (for ABS/Nylon)

- Function: Injecting molten thermoplastics into molds (150–350°C).

- Key Specs:

- Clamp Force: 50–5,000+ tons (depends on part size).

- Screw Diameter: 25–100mm.

- Materials Processed: ABS, Nylon (PA6, PA66), Polycarbonate, PP.

- Tolerance Capability: ±0.05mm to ±0.2mm (typically looser than metal CNC).

📌 Critical Workflow for Die Cast Parts

If you need tight-tolerance aluminum parts, the process is:

1. Die Casting: Produce near-net-shape aluminum part (e.g., housing).

2. CNC Machining:

– Use a 3/4/5-axis mill to refine features (e.g., mounting holes, sealing surfaces).

– Use turning for cylindrical features (e.g., shafts).

3. ABS/Nylon? → Requires separate plastic injection molding, not die casting or metal machining.

💡 Recommendation for Honyo Prototype

- If you need die casting specs: Provide details on part size, material (Al/Zn/Mg), and production volume.

- If you need CNC machining specs: Specify part geometry, material (Al/steel), and tolerance requirements.

- If you need ABS/Nylon parts: Specify injection molding requirements (not die casting).

⚠️ Never attempt to cast ABS/Nylon in a die casting machine – it will cause catastrophic failure, toxic fumes, and fire.

Let me know your actual project requirements, and I’ll provide precise technical specs for the correct process. For example:

– “I need die casting specs for an aluminum automotive bracket (±0.1mm tolerance).”

– “I need 5-axis CNC milling specs for a steel aerospace component (±0.005mm tolerance).”

– “I need injection molding specs for an ABS consumer product.”

I’m here to help – just clarify the process! 😊

From CAD to Part: The Process

Honyo Prototype – Pressure-Die-Casting Workflow

(from first mouse-click to parts-in-hand)

-

Upload CAD

• Portal accepts any 3-D file (STEP, IGES, XT, SolidWorks, Creo, Catia, etc.).

• Geometry is instantly validated: wall-thickness check, under-cut flag, draft-angle scan, parting-line hint.

• If the file is a multi-body assembly the AI separates “casting” from “machined-after-casting” features and tags critical surfaces (seal groves, bush bores, knurl zones, etc.). -

AI Quote (≤ 30 min)

• Machine-learning model trained on 1.2 M real shots pulls: alloy price (Al 46000, AlSi10Mg, Zamak-3, ZA-8, Mg AZ91D), cavitation possibility, slide & core count, cycle-time estimate, trim force, post-machining hours, surface spec (as-cast, chromate, powder, e-coat, anodise).

• Outputs: piece price, tooling price (single-cavity, family, or unit-die), lead-time, 3-year price ladder, and a “confidence score”.

• Customer can toggle options (shrink porosity class, heat-treat, impregnation) and watch price & delivery update live. -

DFM (Design-for-Manufacture) – 24 h engineering package

a. Tooling layout: parting line, gate position, overflow & vent map, ejector pin grid, draft ≥ 0.5° on Al, ≥ 0.3° on Zn.

b. Simulation: MAGMA or FLOW-3D, 3-step iteration to keep porosity ≤ 2 % in critical zone, predicted cold-fill risk < 1 %.

c. Alloy & temper recommendation to hit mechanical spec (yield, hardness, salt-spray).

d. Post-cast machining stock allowance (0.3–0.8 mm on datum faces).

e. QC plan: X-ray level, CMM datums, leak-test pressure, cosmetic sampling AQL.

f. Customer signs off via one-click e-approval; drawings locked in PLM. -

Production

4.1 Die build (H-13 or 8407 steel, 48–52 HRC)

• Rough CNC → hardening → vacuum quench → finish CNC → wire-EDM gate & vent → polishes to SPI A-2 or customer texture.

• Trial sample T1 shot within 10–12 days of DFM approval.

4.2 Die-cast cell set-up

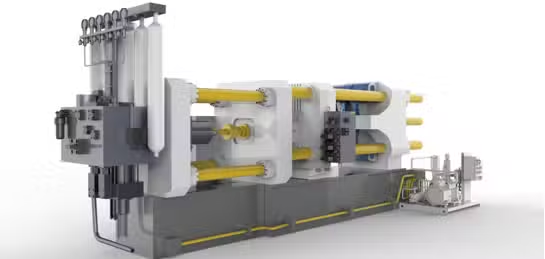

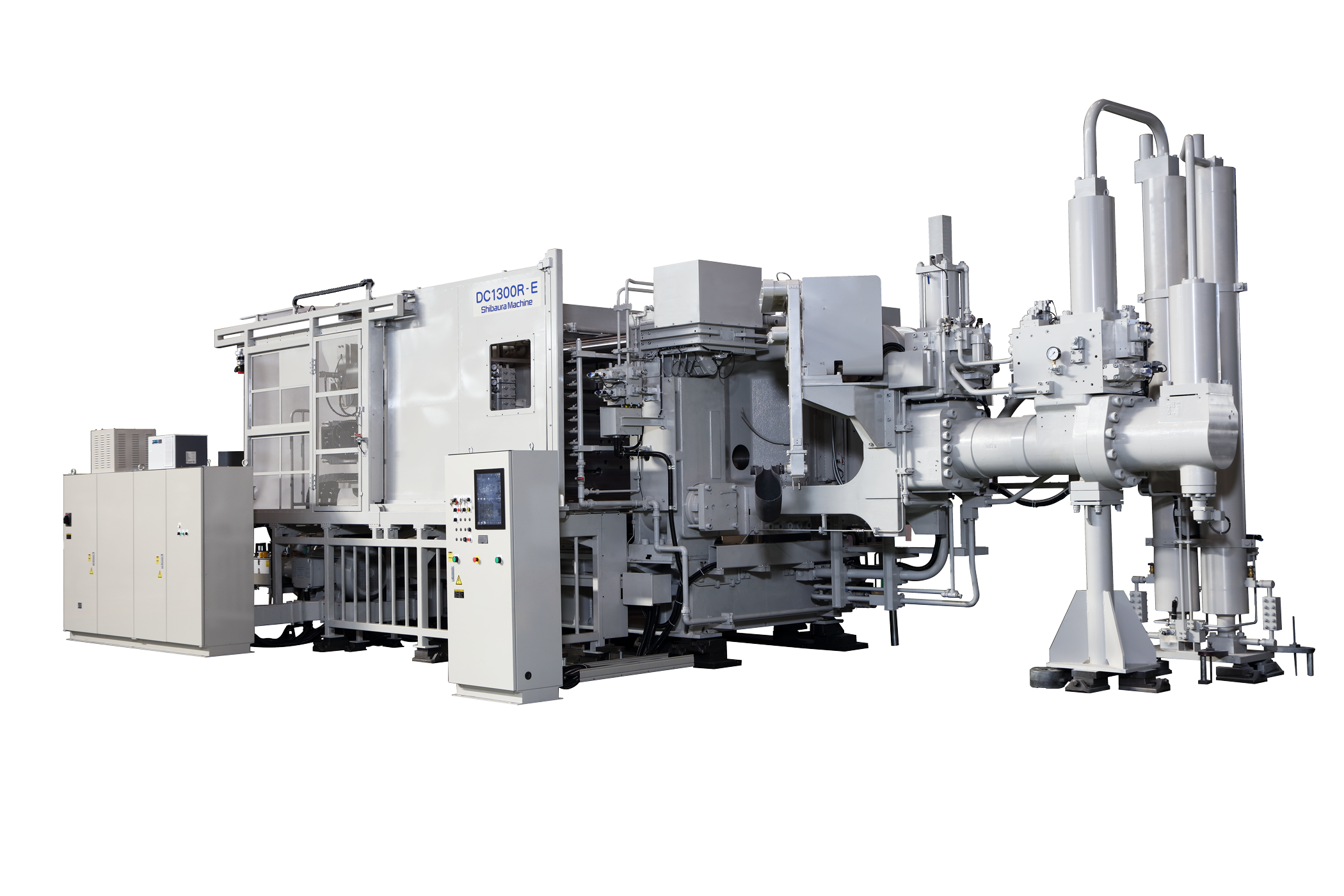

• 280 T – 1 250 T Buhler, Toshiba, LK cold-chamber machines; auto-ladle, auto-spray, vacuum-assisted when needed.

• Real-time shot-profile monitoring: plunger speed, intensification pressure 600–900 bar, metal temp ±5 °C.

4.3 Trim & de-burr

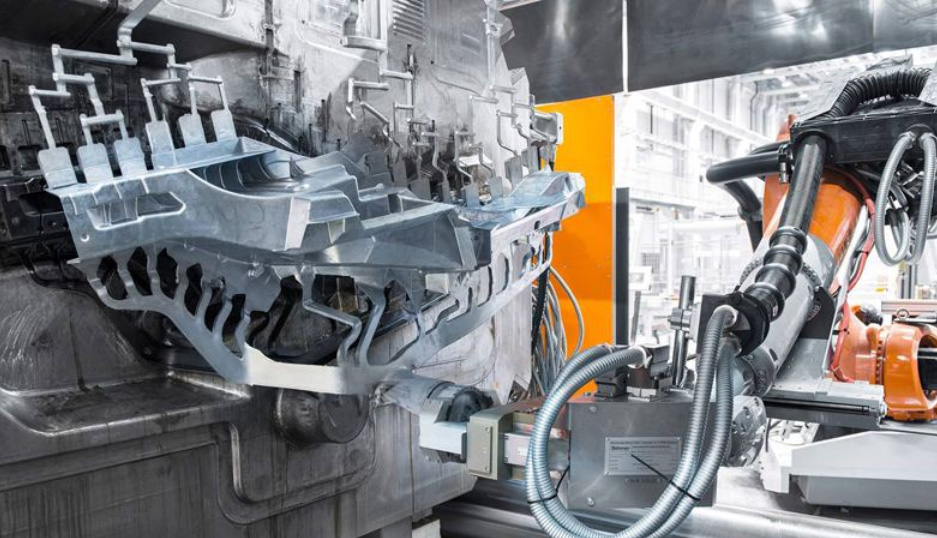

• Custom trim die in 4140 steel, 60 T press; robots place casting, trim, quench to < 80 °C in 20 s.

4.4 Post-casting operations (as required)

• Impregnation (MIL-STD-276), heat treatment (T5, T6, T7), CNC 5-axis finishing, vibratory tumble, shot-blast 120# glass bead.

• Surface: chromate (MIL-DTL-5541), e-coat, powder coat 60–80 µm, anodise Type II/III, nickel-chrome plate.

4.5 QC & logistics

• 100 % leak-test for pressure-tight parts, 3-D CMM report against GD&T, X-ray batch sampling, material cert, RoHS/REACH compliance sheet.

• Parts packed in ESD or VCI bags, shock-absorb dividers, barcode/QR label, MSDS enclosed. -

Delivery

• Standard: 15 days tooling + 7 days first article, 3–5 days ship (DHL/FedEx/UPS) to global door.

• Express option: 7 days tooling + 3 days casting, 2 days airfreight.

• Track & trace link sent when parts leave Honyo; digital quality folder (PPAP level 3 if required) downloadable same day.

That is the complete Honyo “Upload-CAD → AI-Quote → DFM → Production → Delivery” path for every pressure-die-casting project.

Start Your Project

Contact Susan Leo: [email protected] | Shenzhen Factory

Precision pressure die casting solutions, engineered for excellence.

Honyo Prototype: Your trusted Shenzhen-based partner for high-quality, cost-effective die casting services.

🚀 Rapid Prototyping Estimator