Introduction: Navigating the Global Market for precision turning

In an increasingly interconnected world, sourcing precision turning components poses a significant challenge for international B2B buyers, particularly those from diverse regions such as Africa, South America, the Middle East, and Europe. The demand for high-quality, custom-engineered parts is on the rise, yet navigating the complexities of global supply chains can be daunting. This comprehensive guide on precision turning addresses the key issues faced by buyers, including material selection, production capabilities, and the importance of quality assurance, ensuring that you make informed purchasing decisions.

This guide delves into various aspects of precision turning, encompassing types of processes, applications across industries, and supplier vetting strategies. It highlights the significance of understanding your specific requirements—from tight tolerances to material certifications—while also providing insights into cost considerations and delivery timelines. With a focus on empowering buyers, this resource aims to simplify the procurement process by equipping you with the knowledge needed to identify reliable suppliers and negotiate favorable terms.

By the end of this guide, B2B buyers will be better positioned to optimize their sourcing strategies, ensure timely deliveries, and maintain competitive pricing for precision machined components. Whether you are looking to enhance your supply chain efficiency or gain a competitive edge in your industry, this guide serves as your essential roadmap in the global market for precision turning.

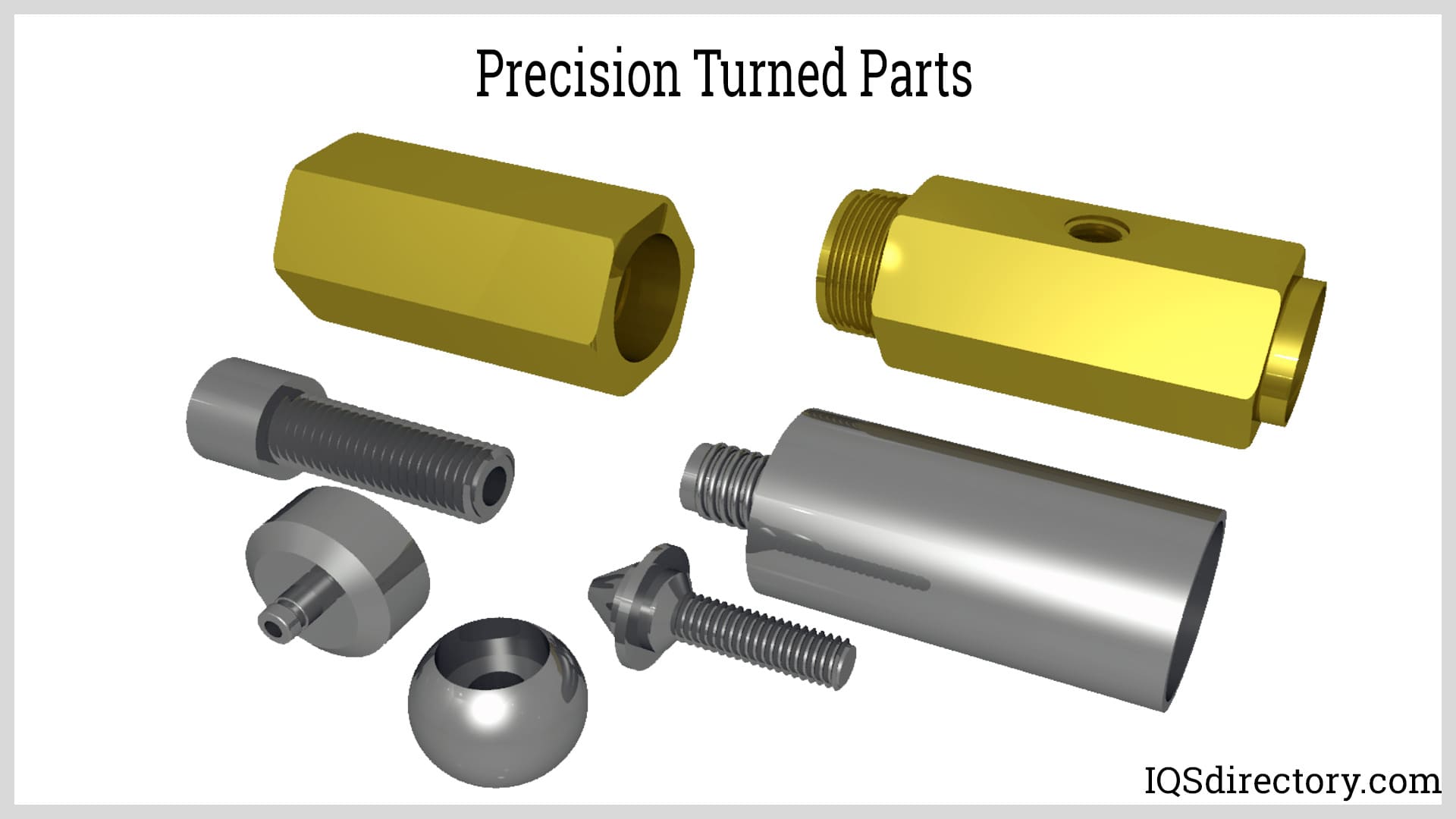

Understanding precision turning Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| CNC Swiss Turning | Uses a guide bushing for stability, ideal for small parts | Aerospace, Medical Devices, Electronics | Pros: High precision, efficient for small parts. Cons: Higher initial setup cost. |

| CNC Multi-Axis Turning | Capable of moving tools in multiple directions | Automotive, Energy, Defense | Pros: Complex shapes, reduced setup time. Cons: Requires skilled operators. |

| Traditional CNC Turning | Standard lathe operations, less complex | General Manufacturing, Prototyping | Pros: Cost-effective for larger components. Cons: Limited precision for intricate designs. |

| Precision Machining | High tolerance machining, often involves secondary operations | Custom Components, Aerospace, Defense | Pros: Exceptional accuracy, versatile materials. Cons: Longer lead times. |

| Live Tooling | Allows for simultaneous milling and turning operations | Automotive, Electronics, Medical Devices | Pros: Reduces cycle time, enhances part complexity. Cons: More expensive machinery. |

What are the Key Characteristics of CNC Swiss Turning?

CNC Swiss Turning is characterized by its use of a guide bushing, which stabilizes the workpiece and allows for high precision in machining small parts, typically ranging from 0.093″ to 1.25″ in diameter. This method is particularly suitable for industries requiring tight tolerances, such as aerospace and medical device manufacturing. B2B buyers should consider the initial setup costs and the need for specialized training when opting for this technology, but the benefits of efficiency and precision often outweigh these concerns.

How Does CNC Multi-Axis Turning Benefit B2B Buyers?

CNC Multi-Axis Turning enables complex tool movements, allowing for the creation of intricate shapes in a single setup. This technology is particularly advantageous for industries like automotive and defense, where precision and speed are paramount. Buyers should note that while this method can significantly reduce manufacturing time and increase relational precision, it necessitates skilled operators and can involve higher initial costs for machinery.

What Should Buyers Know About Traditional CNC Turning?

Traditional CNC Turning remains a staple in manufacturing due to its simplicity and cost-effectiveness for larger components. It typically involves standard lathe operations without the advanced features of Swiss or multi-axis machines. This method is well-suited for general manufacturing and prototyping. Buyers should weigh the lower precision levels against the reduced costs, particularly for less complex parts.

Why Choose Precision Machining for Custom Components?

Precision Machining is essential for producing high-tolerance components that may require secondary operations, such as milling or drilling. It is commonly used in industries like aerospace and defense, where accuracy is critical. While the versatility in material choice and exceptional accuracy are major advantages, buyers should be prepared for potentially longer lead times and higher costs associated with specialized machinery.

What Advantages Does Live Tooling Offer in Precision Turning?

Live Tooling integrates milling capabilities into turning operations, enabling simultaneous machining processes. This results in reduced cycle times and the ability to create more complex parts in a single setup. Industries such as automotive and electronics benefit significantly from this technology. However, the investment in advanced machinery can be substantial, and buyers must consider the associated operational costs when making purchasing decisions.

Key Industrial Applications of precision turning

| Industry/Sector | Specific Application of Precision Turning | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Manufacturing of engine components | Ensures high reliability and performance of aircraft parts | Certification for quality standards (e.g., AS9100) |

| Medical Devices | Production of surgical instruments | Guarantees precision and safety in medical procedures | Compliance with regulatory standards (e.g., ISO 13485) |

| Electronics | Creation of connectors and small components | Supports miniaturization and high-performance electronics | Ability to produce high-volume, tight-tolerance parts |

| Automotive | Production of drivetrain components | Enhances vehicle performance and fuel efficiency | Just-in-time delivery capabilities and material certifications |

| Defense | Fabrication of firearm components | Increases reliability and effectiveness of defense systems | Security clearances and adherence to strict specifications |

How is Precision Turning Used in the Aerospace Sector?

In the aerospace industry, precision turning is crucial for manufacturing engine components, landing gear parts, and structural components. These parts require extremely tight tolerances to ensure safety and performance under high-stress conditions. Buyers in this sector must prioritize suppliers who have certifications such as AS9100 to guarantee compliance with stringent aerospace standards. Additionally, on-time delivery is essential to meet production schedules and avoid costly delays.

What Role Does Precision Turning Play in Medical Device Manufacturing?

Precision turning is extensively utilized in the production of surgical instruments, implants, and diagnostic equipment. The accuracy of these components directly impacts patient safety and treatment efficacy. Buyers from the medical sector need to ensure that their suppliers comply with ISO 13485 standards, which govern quality management systems for medical devices. Furthermore, the ability to produce custom components with quick turnaround times is vital for keeping up with the dynamic needs of the healthcare market.

How is Precision Turning Beneficial for the Electronics Industry?

In the electronics sector, precision turning is employed to manufacture connectors, housings, and other small components that are increasingly miniaturized. The ability to produce high volumes of parts with tight tolerances ensures that electronic devices function reliably. International buyers should consider sourcing from manufacturers who can demonstrate high levels of consistency and quality assurance. Additionally, the capability for rapid prototyping can be a significant advantage in this fast-paced industry.

Why is Precision Turning Important for Automotive Applications?

Precision turning is essential in the automotive industry for producing drivetrain components such as gears, shafts, and bearings. These components contribute to the overall efficiency and performance of vehicles. Buyers should look for suppliers that offer just-in-time delivery and can provide material certifications to ensure quality and compliance with automotive standards. Collaborating with manufacturers who utilize lean manufacturing principles can also help reduce costs and improve production timelines.

How Does Precision Turning Support Defense Manufacturing?

In the defense sector, precision turning is critical for fabricating firearm components, ammunition parts, and other equipment that require exceptional reliability. The precision of these components can directly affect operational effectiveness in critical situations. Buyers in this industry must ensure that their suppliers have the necessary security clearances and adhere to strict specifications. Additionally, having a robust quality control system in place is essential for maintaining the integrity of defense products.

3 Common User Pain Points for ‘precision turning’ & Their Solutions

Scenario 1: Difficulty Meeting Tight Tolerances

The Problem: Many B2B buyers in industries such as aerospace and medical devices face challenges when sourcing precision-turned components that require exceptionally tight tolerances (±0.0001 inches). Inconsistent quality can lead to production delays, increased costs, and ultimately, a compromise in product reliability. Buyers may find themselves frustrated when suppliers fail to meet specified tolerances, leading to rework and wasted materials.

The Solution: To ensure that you consistently receive components that meet stringent tolerance requirements, it is crucial to work with ISO-certified manufacturers experienced in precision turning. When sourcing suppliers, request detailed documentation of their quality control processes, including the use of advanced measurement tools like Coordinate Measuring Machines (CMM) and optical comparators. During the quote phase, communicate your tolerance specifications clearly and establish a quality assurance plan that includes in-process inspections and material certifications. This proactive approach not only mitigates the risk of receiving subpar components but also fosters a collaborative relationship with your supplier, enhancing overall production efficiency.

Scenario 2: Inconsistent Delivery Times

The Problem: Timely delivery is critical for maintaining production schedules. B2B buyers often struggle with suppliers who fail to deliver precision-turned parts on time, resulting in production bottlenecks and inventory shortages. This inconsistency can severely impact project timelines and increase costs due to expedited shipping or last-minute sourcing from alternative suppliers.

The Solution: To combat delivery inconsistencies, engage with suppliers who utilize lean manufacturing principles and Just-In-Time (JIT) delivery systems. When initiating partnerships, discuss your production schedules and deadlines upfront, emphasizing the importance of timely deliveries. Implementing a Kanban system can also help streamline inventory management, allowing you to maintain optimal stock levels and reorder points. Additionally, establish clear communication channels with your supplier, including regular updates on production status. This transparency not only builds trust but also allows for swift adjustments in case of unforeseen delays, ultimately ensuring that you receive your precision-turned parts when you need them.

Scenario 3: Limited Material Options and Certifications

The Problem: Buyers often encounter difficulties when suppliers offer a limited range of materials for precision turning, which can restrict product development and innovation. Furthermore, the lack of material certifications, such as conflict-free sourcing or heat treatment documentation, can raise compliance issues, particularly for buyers in highly regulated industries like defense or healthcare.

The Solution: When searching for precision turning suppliers, prioritize those who provide a diverse selection of materials and have the capability to offer relevant certifications. Engage in discussions regarding your specific material needs and compliance requirements during the initial stages of sourcing. It is beneficial to partner with suppliers who are experienced in working with a variety of materials, including specialized alloys and plastics, and who can provide detailed documentation for each batch produced. Consider establishing a long-term relationship with a supplier who can adapt to your evolving material needs, ensuring that you have access to the right resources without compromising on quality or compliance. This proactive approach not only enhances your product offerings but also minimizes the risk of regulatory setbacks.

Strategic Material Selection Guide for precision turning

What Are the Key Properties of Common Materials Used in Precision Turning?

When selecting materials for precision turning, understanding their properties is essential for ensuring optimal performance in various applications. Below are analyses of four common materials used in precision turning, highlighting their key properties, advantages, disadvantages, and specific considerations for international B2B buyers.

How Do Stainless Steels Perform in Precision Turning Applications?

Key Properties: Stainless steels, particularly grades 304 and 316, are known for their excellent corrosion resistance and ability to withstand high temperatures. They typically have a tensile strength ranging from 70,000 to 100,000 psi, making them suitable for high-stress applications.

Pros & Cons: The primary advantage of stainless steel is its durability and resistance to rust and corrosion, which is crucial for components exposed to harsh environments. However, it can be more expensive than carbon steels and may require specialized tooling and machining techniques, increasing manufacturing complexity.

Impact on Application: Stainless steel is widely used in industries such as medical devices, food processing, and aerospace. Its compatibility with various media, including water and chemicals, makes it a versatile choice.

Considerations for International Buyers: Compliance with international standards such as ASTM and DIN is crucial. Buyers from Africa, South America, and the Middle East should ensure that suppliers can provide material certifications and quality assurances to meet local regulations.

What Role Does Aluminum Play in Precision Turning?

Key Properties: Aluminum alloys, particularly 6061 and 7075, are lightweight yet strong, with a density of about 2.7 g/cm³. They exhibit good corrosion resistance and can be anodized for enhanced durability.

Pros & Cons: The key advantage of aluminum is its low weight, which is beneficial for applications requiring lightweight components. However, it has a lower tensile strength compared to steel, which may limit its use in high-stress applications. Additionally, aluminum can be more challenging to machine due to its softness, potentially leading to tool wear.

Impact on Application: Aluminum is commonly used in automotive, aerospace, and consumer electronics industries due to its favorable strength-to-weight ratio. It is also suitable for applications involving electrical conductivity.

Considerations for International Buyers: Buyers should be aware of the different alloy designations and ensure compliance with local standards. In regions like Europe and South America, understanding the specific alloy requirements for applications is essential.

How Does Brass Compare in Precision Turning Applications?

Key Properties: Brass, an alloy of copper and zinc, is known for its excellent machinability and corrosion resistance. It has a tensile strength ranging from 60,000 to 80,000 psi and is often used in applications requiring good thermal and electrical conductivity.

Pros & Cons: The primary advantage of brass is its ease of machining, which allows for complex shapes and tight tolerances. However, it can be more expensive than other materials like steel and may not be suitable for high-stress applications due to its lower strength.

Impact on Application: Brass is commonly used in plumbing fittings, electrical connectors, and decorative applications due to its aesthetic appeal. Its compatibility with various fluids makes it ideal for plumbing and HVAC systems.

Considerations for International Buyers: Buyers should consider the varying compositions of brass and ensure they meet specific application requirements. Familiarity with local standards and certifications is vital, especially in regions with stringent regulations.

What Are the Benefits of Using Plastics in Precision Turning?

Key Properties: Engineering plastics such as PEEK and Nylon offer excellent chemical resistance and can operate in a wide temperature range. They are lightweight and have good electrical insulating properties.

Pros & Cons: The advantage of using plastics is their versatility and lower weight compared to metals. They can also be more cost-effective for low-volume production. However, they may not withstand high temperatures or mechanical stresses as well as metals, limiting their use in certain applications.

Impact on Application: Plastics are widely used in the automotive, medical, and consumer goods industries. Their compatibility with various chemicals makes them suitable for applications in corrosive environments.

Considerations for International Buyers: Buyers should ensure that the selected plastics meet relevant standards for their specific applications. Understanding the local market’s preferences for material certifications is also important.

Summary Table of Material Selection for Precision Turning

| Material | Typical Use Case for Precision Turning | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Medical devices, aerospace components | Excellent corrosion resistance | Higher cost and machining complexity | High |

| Aluminum | Automotive parts, consumer electronics | Lightweight and good corrosion resistance | Lower tensile strength | Medium |

| Brass | Plumbing fittings, electrical connectors | Excellent machinability and aesthetics | Higher cost and lower strength | Medium |

| Plastics | Automotive, medical, consumer goods | Versatile and cost-effective | Limited temperature and stress tolerance | Low |

This strategic material selection guide provides insights into the properties and considerations of common materials used in precision turning, aiding international B2B buyers in making informed decisions tailored to their specific needs.

In-depth Look: Manufacturing Processes and Quality Assurance for precision turning

What Are the Main Stages of Manufacturing Processes in Precision Turning?

Precision turning is a critical process in the manufacturing of components that require exact dimensions and superior finish. This process typically involves several stages: material preparation, forming, assembly, and finishing. Understanding these stages can help B2B buyers ensure that they are sourcing from suppliers who adhere to high standards of quality and efficiency.

How Is Material Prepared for Precision Turning?

Material preparation is the initial step in precision turning. It involves selecting the right type of raw material, such as metals, plastics, or composites, that meet the specifications of the end product. The material is typically delivered in bar stock form, which is then cut to length based on the requirements of the specific job.

In many cases, suppliers will conduct an Incoming Quality Control (IQC) check to assess the quality of the raw materials. This may include verifying certificates of compliance to ensure that the materials are free from defects and meet the necessary industry standards. B2B buyers should inquire about the supplier’s material certification practices, especially when sourcing from international suppliers.

What Techniques Are Commonly Used in the Forming Stage?

The forming stage involves utilizing CNC (Computer Numerical Control) lathes and Swiss-type lathes, which are integral to the precision turning process. These machines operate by rotating the material while a cutting tool removes excess material to create the desired shape.

Key techniques include:

- CNC Swiss Machining: Ideal for producing small, intricate components, Swiss machines can perform multiple operations simultaneously, significantly reducing production time.

- Multi-Axis Turning: This technique allows for the creation of complex geometries by enabling tool movement in multiple directions, thus enhancing design capabilities.

During this stage, in-process quality control (IPQC) is crucial. Operators should regularly check dimensions and tolerances throughout the machining process to catch any discrepancies early on.

How Is Assembly Managed in Precision Turning?

Assembly may not be a primary focus in precision turning, as many components produced are often standalone parts. However, when assembly is required, it’s essential to ensure that each part fits together correctly and functions as intended.

Quality assurance during assembly often involves thorough inspections, including functional testing and visual inspections. B2B buyers should confirm that their suppliers follow stringent assembly protocols to guarantee that all components meet the specified tolerances.

What Finishing Techniques Are Utilized to Ensure Quality?

Finishing techniques are crucial for enhancing the surface quality and functionality of turned components. Common finishing processes include:

- Deburring: Removing sharp edges and burrs to ensure safety and functionality.

- Surface Treatments: Techniques such as anodizing, plating, or passivation are often employed to improve corrosion resistance and surface hardness.

The final quality control (FQC) stage involves comprehensive inspections to verify that all specifications have been met. This can include dimensional checks, surface finish evaluations, and functional tests, depending on the component’s application.

How Are Quality Assurance Measures Implemented in Precision Turning?

Quality assurance is a vital aspect of precision turning, especially for B2B buyers who require consistent quality in their components. Many manufacturers adhere to international standards such as ISO 9001, which provides a framework for quality management systems.

What International Standards Should B2B Buyers Be Aware Of?

Understanding international standards is essential for B2B buyers, particularly when sourcing from different regions. Key standards include:

- ISO 9001: Ensures that suppliers maintain a quality management system that enhances customer satisfaction and meets regulatory requirements.

- CE Marking: Indicates that products conform to EU safety, health, and environmental protection standards, essential for buyers in European markets.

- API Certification: Important for manufacturers producing components for the oil and gas industry, indicating compliance with industry-specific requirements.

Buyers should verify that their suppliers are compliant with these standards, as they directly impact the quality and reliability of the components.

How Can B2B Buyers Verify Supplier Quality Control Procedures?

B2B buyers can take several steps to ensure that their suppliers maintain robust quality control procedures. Here are a few actionable strategies:

-

Supplier Audits: Conducting regular audits of suppliers’ facilities can provide insight into their quality assurance processes and adherence to standards.

-

Quality Reports: Requesting detailed quality reports that outline testing methods, inspection results, and any corrective actions taken can help buyers assess supplier reliability.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased assessment of a supplier’s quality control practices, especially for international transactions where direct oversight may be challenging.

-

Certifications and Documentation: Always request and verify certifications for materials and processes. This documentation can be critical for ensuring that components meet the necessary specifications and standards.

What Are the Quality Control Checkpoints in Precision Turning?

Quality control checkpoints play a significant role in maintaining the integrity of the manufacturing process. Common checkpoints include:

- Incoming Quality Control (IQC): Inspecting raw materials upon arrival to ensure they meet specifications.

- In-Process Quality Control (IPQC): Monitoring the manufacturing process to catch defects during production.

- Final Quality Control (FQC): Conducting thorough inspections of finished products before shipment to ensure they meet all requirements.

By understanding these checkpoints, B2B buyers can better evaluate a supplier’s commitment to quality and reliability in their precision turning processes.

Conclusion

For B2B buyers, particularly those operating in diverse regions such as Africa, South America, the Middle East, and Europe, understanding the manufacturing processes and quality assurance measures in precision turning is crucial. By focusing on material preparation, forming techniques, assembly protocols, and finishing processes, buyers can ensure that they select suppliers capable of delivering high-quality components. Furthermore, leveraging international standards and implementing robust verification methods will enhance trust and reliability in the supply chain, ultimately leading to more successful partnerships.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘precision turning’

To effectively procure precision turning components, it’s essential to follow a structured approach. This guide provides a checklist that will help B2B buyers navigate the complexities of sourcing precision-turned parts. By adhering to these steps, buyers can ensure they make informed decisions that align with their operational needs.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the foundation of your sourcing process. This includes details such as dimensions, tolerances, material types, and surface finishes. Clearly defined specifications help prevent miscommunication with suppliers and ensure that the components meet your quality and performance requirements.

Step 2: Identify Industry Standards and Certifications

Understanding the relevant industry standards and certifications is crucial for quality assurance. Look for suppliers who adhere to ISO certifications or specific industry standards relevant to your sector, such as aerospace, medical, or automotive. This ensures that the supplier has implemented rigorous quality control processes and can deliver consistent results.

Step 3: Evaluate Potential Suppliers

Before making a commitment, thoroughly vet potential suppliers. Request detailed company profiles, case studies, and references from clients in similar industries or regions. Assess their production capabilities, technology used, and experience in handling specific materials or intricate designs. This evaluation minimizes risks associated with quality and delivery times.

Step 4: Request and Review Sample Parts

Always request sample parts to evaluate the supplier’s quality firsthand. Reviewing samples allows you to assess the precision of their machining, surface finish, and adherence to your specifications. Pay attention to the supplier’s ability to meet tolerances, as this can significantly impact the performance of your final product.

Step 5: Understand Lead Times and Production Capacity

Discuss lead times and the supplier’s production capacity to ensure they can meet your demands. Understanding their manufacturing schedule and ability to scale production is critical, especially if you anticipate fluctuations in order volume. Make sure they can provide Just-In-Time (JIT) delivery if your production process requires it.

Step 6: Assess Quality Control Processes

Investigate the quality control measures that the supplier has in place. Effective quality control systems should include in-process inspections, material certifications, and final inspections before shipment. Inquire about their equipment and methods for testing tolerances, as this will give you confidence in their commitment to quality.

Step 7: Negotiate Terms and Establish a Clear Agreement

Once you’ve selected a supplier, negotiate terms that are favorable for both parties. This includes pricing, payment terms, delivery schedules, and penalties for non-compliance. A clear written agreement helps to protect both you and the supplier, ensuring that expectations are understood and met throughout the engagement.

By following this checklist, B2B buyers can enhance their sourcing strategy for precision turning components, ultimately leading to successful partnerships and high-quality outcomes.

Comprehensive Cost and Pricing Analysis for precision turning Sourcing

What Are the Key Cost Components in Precision Turning?

Understanding the cost structure of precision turning is essential for B2B buyers aiming to optimize their sourcing decisions. The primary cost components include:

-

Materials: The choice of raw materials significantly impacts pricing. Common materials used in precision turning, such as aluminum, brass, stainless steel, and plastics, can vary greatly in cost. Buyers should consider both the material’s price and its suitability for the intended application.

-

Labor: Skilled labor is essential for precision turning, particularly for complex components. Labor costs can fluctuate based on the region and the level of expertise required. For instance, sourcing from countries with higher labor costs may lead to increased prices, but potentially better quality.

-

Manufacturing Overhead: This encompasses costs related to equipment maintenance, utilities, and facility management. Overhead is often distributed across production runs, making it critical for buyers to consider the supplier’s operational efficiency.

-

Tooling: Specialized tooling, such as custom dies and fixtures, is necessary for precision turning. The initial investment in tooling can be substantial, but it is often amortized over larger production runs.

-

Quality Control (QC): Rigorous QC processes are vital to ensure that components meet specified tolerances. The costs associated with inspection and testing should be factored into the overall pricing structure.

-

Logistics: Transportation and handling costs can vary significantly based on distance, shipping methods, and Incoterms. Buyers should assess logistics costs to avoid unexpected expenses.

-

Margin: Suppliers typically add a markup to cover risks and ensure profitability. Understanding the margin can help buyers gauge the competitiveness of a supplier’s pricing.

How Do Price Influencers Affect Precision Turning Costs?

Several factors influence the pricing of precision turning components:

-

Volume and Minimum Order Quantity (MOQ): Higher order volumes generally lead to lower per-unit costs due to economies of scale. Buyers should negotiate MOQs that align with their production needs to maximize cost efficiency.

-

Specifications and Customization: The complexity of the required components and any custom specifications can drive up costs. Buyers should clearly communicate their requirements to avoid misalignment and unexpected expenses.

-

Material Selection: Premium materials will increase costs but may be necessary for specific applications, such as aerospace or medical devices, where performance and safety are critical.

-

Quality Certifications: Suppliers that offer certifications (e.g., ISO, material certifications) may command higher prices due to the assurance of quality. Buyers should weigh the necessity of certifications against their budget.

-

Supplier Factors: The supplier’s location, reputation, and production capabilities can influence pricing. Established suppliers with advanced technologies may offer better quality but at a premium.

-

Incoterms: Understanding shipping terms (e.g., FOB, CIF) is crucial for budgeting. Different terms can affect total landed costs and should be negotiated upfront.

What Are the Best Negotiation Tips for International B2B Buyers?

When sourcing precision turning components internationally, consider these tips to enhance negotiation outcomes:

-

Evaluate Total Cost of Ownership (TCO): Look beyond the initial price to assess all costs associated with sourcing, including logistics, duty fees, and potential tariffs. This holistic view can lead to more informed purchasing decisions.

-

Leverage Volume Discounts: If feasible, consolidate orders to negotiate better pricing. Suppliers are often more willing to offer discounts for larger commitments.

-

Be Clear About Specifications: Providing detailed technical drawings and specifications can prevent costly misunderstandings that lead to rework or delays.

-

Research Local Markets: Understanding the pricing landscape in the supplier’s region can provide leverage in negotiations. Buyers should research typical costs and supplier capabilities in their target regions.

-

Build Relationships: Establishing strong relationships with suppliers can lead to more favorable terms and better service. Trust and communication are key in international dealings.

-

Stay Informed About Market Trends: Keeping abreast of trends in material costs, labor rates, and technological advancements can help buyers anticipate price changes and negotiate effectively.

Disclaimer on Pricing

The prices and cost structures mentioned are indicative and can vary significantly based on market conditions, supplier capabilities, and specific project requirements. Buyers should conduct thorough research and obtain quotes from multiple suppliers to ensure competitive pricing.

Alternatives Analysis: Comparing precision turning With Other Solutions

Exploring Viable Alternatives to Precision Turning

In the quest for high-quality machined components, precision turning is a well-established method. However, various alternatives can also meet the demands of modern manufacturing. Understanding these alternatives helps B2B buyers make informed decisions based on their specific needs, including production volume, component complexity, and cost-effectiveness.

Comparison Table of Precision Turning and Alternative Methods

| Comparison Aspect | Precision Turning | CNC Milling | Additive Manufacturing |

|---|---|---|---|

| Performance | High precision with tight tolerances | Versatile for complex geometries | Excellent for rapid prototyping |

| Cost | Moderate, depending on volume | Generally higher due to setup time | Variable; often lower for low volumes |

| Ease of Implementation | Requires skilled operators and setup | Requires more training and setup | Easier for initial setups, less skill-intensive |

| Maintenance | Routine maintenance needed | Regular maintenance required | Low maintenance for printers |

| Best Use Case | High-volume, tight-tolerance components | Complex, multi-faceted parts | Prototyping, custom low-volume parts |

Understanding CNC Milling as an Alternative to Precision Turning

CNC milling is a machining process that employs rotary cutters to remove material from a workpiece. It excels in creating intricate designs and complex geometries that precision turning may struggle with due to its linear cutting motion. One advantage of CNC milling is its versatility; it can handle a wide range of materials and shapes. However, the setup time can be longer, making it less cost-effective for high-volume production compared to precision turning. Furthermore, the need for skilled operators and regular maintenance can add to operational costs, making it ideal for companies that require complex parts but have the budget and resources to manage these factors.

Evaluating Additive Manufacturing as a Competitor

Additive manufacturing, commonly known as 3D printing, builds parts layer by layer, offering unparalleled design flexibility. It is particularly advantageous for creating prototypes and low-volume custom parts, as it requires minimal setup and can produce complex geometries without the constraints of traditional machining methods. The initial investment in 3D printers can be lower for small production runs, but costs can escalate with material selection and part size. However, the surface finish may not always meet the stringent tolerances required in industries like aerospace or medical, where precision turning shines. Thus, while additive manufacturing is transformative for prototyping and small batches, it may not always be suitable for high-precision applications.

Conclusion: How to Choose the Right Solution for Your Needs

When selecting the right manufacturing solution, B2B buyers should weigh their specific requirements against the strengths and weaknesses of each method. Precision turning stands out for high-volume production with tight tolerances, making it ideal for industries that prioritize quality and efficiency. CNC milling offers versatility for complex designs, while additive manufacturing provides flexibility for rapid prototyping. By understanding the nuances of each alternative, businesses can align their manufacturing strategies with their operational goals, ensuring they choose the most effective solution for their component needs.

Essential Technical Properties and Trade Terminology for precision turning

What Are the Key Technical Properties in Precision Turning?

In the realm of precision turning, several technical specifications are crucial for ensuring the quality and functionality of manufactured components. Understanding these properties can significantly impact the efficiency and effectiveness of your procurement process.

1. Material Grade

The material grade refers to the specific classification of materials used in manufacturing, such as stainless steel, aluminum, or brass. Each grade has distinct mechanical properties, including tensile strength, corrosion resistance, and machinability. For B2B buyers, selecting the right material grade is vital, as it directly affects the component’s performance in its intended application.

2. Tolerance

Tolerance is the permissible limit of variation in a physical dimension. In precision turning, tolerances can be as tight as ±0.0001 inches. High precision tolerances are critical for components that must fit together seamlessly in assemblies, especially in industries like aerospace and medical devices. A clear understanding of tolerance specifications helps buyers avoid costly rework or project delays.

3. Surface Finish

Surface finish is the texture of a surface after machining, measured in microinches or micrometers. It plays a crucial role in wear resistance, friction, and aesthetic quality. Depending on the application, specific surface finish requirements may be mandated to ensure optimal performance. Buyers must communicate their surface finish needs to manufacturers to ensure compliance with industry standards.

4. Dimensional Accuracy

Dimensional accuracy refers to how closely a manufactured part matches its intended design specifications. This property is essential for ensuring that components fit correctly in assemblies, which is particularly important in high-precision applications. For B2B buyers, verifying dimensional accuracy can minimize assembly issues and improve overall product reliability.

5. Heat Treatment

Heat treatment is a process that alters the physical and sometimes chemical properties of a material to achieve desired characteristics like increased hardness or improved ductility. Components requiring specific strength or wear resistance often undergo heat treatment. Understanding the need for heat treatment can help buyers specify the correct processing methods for their applications.

6. Lead Time

Lead time is the time taken from the placement of an order to the delivery of the finished product. In precision turning, shorter lead times can be crucial for maintaining production schedules. Buyers should assess the lead times offered by suppliers to ensure they align with project timelines, particularly in just-in-time (JIT) manufacturing environments.

What Are Common Trade Terms Used in Precision Turning?

Navigating the landscape of precision turning requires familiarity with specific industry jargon. Understanding these terms can enhance communication with suppliers and streamline the procurement process.

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. For buyers, working with OEMs can provide access to high-quality components tailored to specific application requirements, often leading to better integration and performance.

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. This term is important for B2B buyers as it can impact inventory costs and production planning. Understanding MOQs can help businesses manage budgets and avoid overstocking or stockouts.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specified products or services. This process helps buyers compare costs and services among different vendors. A well-structured RFQ can lead to better pricing and service terms, ultimately enhancing procurement efficiency.

4. Incoterms (International Commercial Terms)

Incoterms are a set of internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps buyers understand shipping responsibilities, risk management, and cost allocation, which is crucial for effective global sourcing.

5. CNC (Computer Numerical Control)

CNC refers to the automated control of machining tools by means of a computer. CNC technology enhances precision and repeatability in manufacturing. For buyers, understanding CNC capabilities allows for better alignment of production needs with available technologies, optimizing component quality and cost.

6. Lean Manufacturing

Lean manufacturing is a systematic method for waste minimization within a manufacturing system. It emphasizes efficiency and continuous improvement. B2B buyers should consider suppliers that adopt lean principles, as they can provide faster turnaround times and reduce production costs without compromising quality.

Understanding these technical properties and trade terminology equips B2B buyers with the knowledge to make informed decisions in the precision turning market, ultimately leading to more successful sourcing and procurement strategies.

Navigating Market Dynamics and Sourcing Trends in the precision turning Sector

What Are the Current Market Dynamics and Key Trends in the Precision Turning Sector?

The precision turning sector is experiencing robust growth driven by several global factors. The rise of automation and Industry 4.0 technologies is reshaping manufacturing processes, enabling companies to achieve higher precision and efficiency. This trend is particularly relevant for international B2B buyers in regions like Africa, South America, the Middle East, and Europe, where there is a growing demand for high-quality, precision-engineered components. Additionally, the ongoing shift towards digital supply chain solutions allows for improved transparency and real-time tracking of orders, enhancing inventory management and reducing lead times.

Emerging technologies such as CNC Swiss machining and multi-axis turning are becoming critical in addressing the demand for complex components across various industries, including automotive, aerospace, and medical devices. These technologies allow for the production of intricate parts with tight tolerances, which are increasingly required as industries evolve towards more sophisticated applications. Furthermore, the trend towards customization is pushing suppliers to offer flexible manufacturing solutions that can quickly adapt to changing client specifications, presenting new opportunities for B2B partnerships.

Global sourcing strategies are also evolving, with buyers seeking to diversify their supply chains to mitigate risks associated with geopolitical tensions and supply chain disruptions. This shift is prompting companies to explore partnerships with manufacturers in emerging markets, such as Vietnam and Brazil, where skilled labor and competitive pricing are available. As a result, international B2B buyers must stay informed about these dynamics to optimize their sourcing strategies and capitalize on new market opportunities.

How Is Sustainability and Ethical Sourcing Impacting the Precision Turning Industry?

Sustainability and ethical sourcing have emerged as pivotal considerations in the precision turning sector. As environmental concerns gain prominence, manufacturers are increasingly held accountable for their production practices and the environmental impact of their operations. This trend is particularly relevant for B2B buyers who prioritize sustainable partnerships and seek suppliers committed to reducing their carbon footprints.

To meet these demands, many precision turning companies are adopting ‘green’ certifications and utilizing environmentally friendly materials in their processes. Certifications such as ISO 14001, which focuses on effective environmental management systems, are becoming essential for manufacturers looking to attract environmentally conscious clients. Additionally, suppliers are exploring the use of recycled materials and eco-friendly coatings to align their products with sustainability goals.

Ethical sourcing practices are also gaining traction, as buyers are keen on ensuring that their supply chains are free from unethical labor practices and environmental degradation. This focus on ethical sourcing extends to the traceability of materials used in production, with buyers increasingly favoring manufacturers who can provide evidence of responsible sourcing. By prioritizing sustainability and ethical practices, B2B buyers not only enhance their brand reputation but also contribute to a more sustainable future in the precision turning industry.

How Has the Precision Turning Sector Evolved Over Time?

The evolution of the precision turning sector has been marked by significant technological advancements and changing market demands. Initially, precision turning relied heavily on manual machining processes, which limited the complexity and precision of the components produced. However, with the advent of CNC (Computer Numerical Control) technology in the late 20th century, manufacturers began to automate their operations, leading to improved accuracy and efficiency.

As industries became more specialized, the need for high-precision components surged, prompting manufacturers to invest in advanced machining techniques such as CNC Swiss machining. This evolution has enabled the production of intricate parts with tight tolerances, catering to the specific needs of sectors like aerospace and medical devices. Today, precision turning is characterized by a focus on customization, sustainability, and technological integration, positioning it as a critical component in the global manufacturing landscape.

As the industry continues to evolve, international B2B buyers must stay attuned to these trends to effectively navigate the complexities of sourcing precision-engineered components.

Frequently Asked Questions (FAQs) for B2B Buyers of precision turning

-

1. How do I solve issues with inconsistent quality in precision turned parts?

To address inconsistent quality, establish a clear communication channel with your supplier regarding quality expectations. Request detailed quality assurance documentation, including material certifications and inspection reports. It’s also beneficial to inquire about the supplier’s quality control processes, such as in-house inspections and the use of advanced measurement tools. Regular audits and establishing a feedback loop can help ensure that the supplier adheres to the agreed-upon standards consistently. -

2. What is the best approach for vetting suppliers of precision turning components?

Vetting suppliers involves several key steps. Begin by assessing their certifications, such as ISO or AS9100, which indicate adherence to quality management standards. Review their manufacturing capabilities, including machinery and technology used. Request references from existing clients and examine their track record for on-time deliveries and customer service. Additionally, consider visiting the facility to evaluate their operations and quality control processes firsthand. -

3. How can I customize precision turned parts to meet my specific needs?

Customization starts with clear communication of your requirements to the supplier. Provide detailed specifications, including dimensions, tolerances, materials, and finishes. Many precision turning suppliers offer design assistance and can collaborate on prototypes to refine the product. Utilizing advanced manufacturing techniques, such as CNC Swiss machining, allows for intricate designs and tight tolerances. Ensure that the supplier can accommodate your customization requests within your desired timeline. -

4. What are typical minimum order quantities (MOQs) for precision turning components?

Minimum order quantities can vary widely based on the supplier and the complexity of the parts. Generally, MOQs may range from a few hundred to several thousand units. It’s important to discuss your project scope with potential suppliers to understand their policies. Some suppliers may offer flexibility for initial orders, especially for prototypes or low-volume runs. Clarifying MOQs upfront can help prevent misunderstandings and ensure you can meet your production needs. -

5. What payment terms should I expect when sourcing precision turning parts internationally?

Payment terms can differ significantly between suppliers. Common options include advance payment, net 30/60/90 days, or payment upon delivery. It’s advisable to negotiate terms that align with your cash flow and project timelines. Consider using secure payment methods, such as letters of credit, especially for large orders. Always ensure that terms are clearly outlined in the contract to avoid disputes later. -

6. How does logistics impact the sourcing of precision turned components?

Logistics plays a crucial role in the timely delivery of precision turned parts. Factors such as shipping methods, transit times, and customs clearance can affect your supply chain. To minimize delays, work with suppliers who have experience in international shipping and can provide reliable logistics solutions. Establish clear timelines and consider using just-in-time (JIT) inventory strategies to align with your production schedules. -

7. What quality assurance measures should I look for in precision turning suppliers?

Quality assurance measures are vital for ensuring that parts meet your specifications. Look for suppliers who implement rigorous inspection processes, including in-process checks and final inspections using advanced measurement tools like CMMs. Request documentation of their quality control procedures and certifications. It’s also beneficial to discuss how they handle non-conformance and corrective actions to maintain high standards. -

8. How can I ensure compliance with international standards when sourcing precision turned parts?

Ensuring compliance with international standards involves understanding the regulations relevant to your industry and region. Collaborate with suppliers who are familiar with these standards and can provide certifications for their products. Engage in thorough documentation practices, including compliance declarations and testing reports. Regular audits and third-party inspections can also help verify adherence to quality and safety standards throughout the supply chain.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 8 Precision Turning Manufacturers & Suppliers List

1. Precision Turning Specialties – Swiss Turning & Precision Parts

Domain: precisionturning.com

Registered: 2002 (23 years)

Introduction: Precision Turning Specialties offers Swiss Turning and precision parts with consistent high quality in every shipment and on-time deliveries. They manufacture turned parts ranging from .093″ to 2″ diameter and work with various materials. Their capabilities include CNC Swiss Machining with features like live milling, cross drilling, cross tapping, rigid tapping, and subspindles for secondary opera…

2. Precision Turning Corporation – Custom Tight Tolerance Components

Domain: precisionturning.net

Registered: 2002 (23 years)

Introduction: Precision Turning Corporation specializes in manufacturing small, custom tight tolerance components with tolerances of +/- .0001 inches. They produce components up to 1-1/4 inches in diameter using state-of-the-art CNC Swiss screw machines and a full range of secondary equipment. The company has been in operation since 1996 and is ISO 9001:2015 certified, ensuring high levels of quality and servic…

3. Mori Seiki – CNC Lathes

Domain: precisionturninginc.com

Registered: 2012 (13 years)

Introduction: CNC LATHES: Mori Seiki NL-1500SY – Single turret, Live milling, Sub spindle lathe, Y-axis, 2.0″ bar capacity, 11″ long parts, 2 angled live heads. Mori Seiki SL-204SMC – Single turret, Live milling, Sub spindle lathe, 2.5″ bar capacity, 6″ long parts, 1 angled live head. Mori Seiki SL-154SY – Single turret, Live milling, Sub spindle lathe, Y-axis, 1.75″ bar capacity, 6″ long parts, 2 angled live h…

4. Scovie Precision Turning – Custom CNC Precision Turning Services

Domain: scovieprecisionturning.com

Registered: 2019 (6 years)

Introduction: Scovie Precision Turning offers custom CNC precision turning services, including prototyping and production runs. They utilize both CNC and manual lathes to machine close tolerance parts according to customer specifications. The company specializes in precision turning of various sizes, shapes, materials, and complexities, ensuring tight tolerances and quick turnaround for prototypes, small batche…

5. Precision Turning USA – CNC Machining & Manual Services

Domain: precisionturningusa.com

Registered: 2023 (2 years)

Introduction: CNC Machining, CNC Mill-Turn, Manual Turning, Manual Milling

6. FC Precision Turning – Precision Machined Components

Domain: fcprecision.com

Registered: 1998 (27 years)

Introduction: FC Precision Turning Ltd. specializes in precision machined components and assemblies for the aircraft, nuclear, and commercial industries. They utilize a wide range of materials, including aluminum and high tensile alloys. The company emphasizes a tight process with detailed inspections during machining and before shipping to ensure quality. They employ state-of-the-art CNC turning and milling eq…

7. Precision Turning Corporation – CNC Swiss Machining

Domain: linkedin.com

Registered: 2002 (23 years)

Introduction: This company, Precision Turning Corporation – CNC Swiss Machining, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

8. Ripley Machine – CNC Swiss Precision Turning

Domain: ripley-machine.com

Registered: 2015 (10 years)

Introduction: CNC Swiss Precision Turning is a specialized method of precision machining that utilizes a sliding headstock mechanism and a guide bushing to minimize part deflection and enhance precision. Swiss machines can have up to 13 axes and incorporate live tooling, allowing for simultaneous secondary operations. Ripley Machine invested in a CNC Swiss machine to automate a countersink operation, reducing c…

Strategic Sourcing Conclusion and Outlook for precision turning

How Can Strategic Sourcing Enhance Your Precision Turning Operations?

In the dynamic landscape of precision turning, strategic sourcing is pivotal for international B2B buyers aiming to optimize their supply chains and enhance product quality. By partnering with ISO-certified manufacturers and those employing advanced CNC Swiss machining techniques, companies can ensure high precision and consistency in components critical to their operations. The emphasis on lean manufacturing practices not only reduces waste but also accelerates turnaround times, enabling buyers to meet stringent production schedules.

Moreover, the ability to procure materials with certifications such as conflict-free and heat-treated options adds an essential layer of compliance and quality assurance. As global markets evolve, leveraging suppliers who prioritize quality control and have robust inspection processes will be key to maintaining competitive advantage.

Looking ahead, international buyers from Africa, South America, the Middle East, and Europe should actively engage with suppliers who demonstrate a commitment to innovation and customer collaboration. By doing so, you can unlock new opportunities for growth and efficiency in your precision turning projects. Now is the time to reassess your sourcing strategies and forge partnerships that will drive your business forward in this ever-evolving industry.