Contents

Manufacturing Insight: Precision Titanium Components

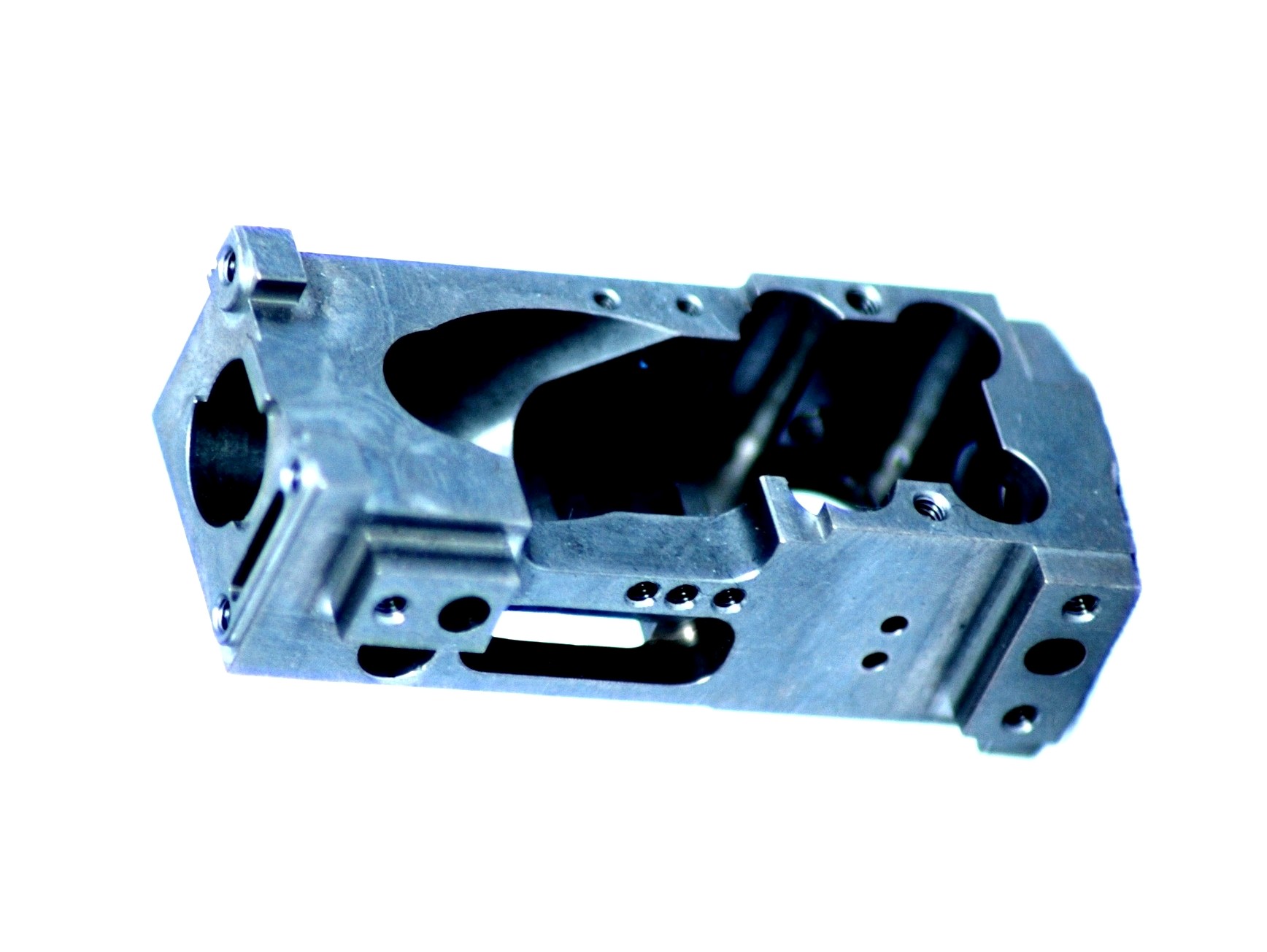

Honyo Prototype delivers mission-critical precision titanium components engineered for performance in the most demanding aerospace, medical, and industrial applications. Our advanced CNC machining capabilities specifically address the unique challenges of titanium alloys, including thermal management, work hardening, and maintaining tight tolerances under complex geometries. We leverage multi-axis milling and turning centers with specialized tooling and proven process parameters to consistently achieve aerospace-grade tolerances and surface finishes while mitigating chatter and galling inherent in titanium processing. This expertise ensures your components meet stringent material property and dimensional requirements for critical assemblies. To accelerate your prototyping and low-volume production timelines, utilize our Online Instant Quote system for rapid, transparent pricing on precision titanium parts directly from your design files. Seamlessly transition from design validation to certified production with Honyo’s integrated engineering and manufacturing solutions.

Technical Capabilities

Precision titanium components are engineered to meet stringent dimensional accuracy and surface finish requirements, commonly used in aerospace, medical, and high-performance industrial applications. These components are typically manufactured using advanced 3-axis, 4-axis, and 5-axis CNC milling and turning processes to achieve complex geometries and tight tolerances. While titanium is the primary focus, similar high-precision techniques are applied across a range of materials including aluminum, steel, ABS, and nylon.

Key Technical Capabilities:

| Parameter | Specification |

|---|---|

| Machining Processes | 3-axis, 4-axis, and 5-axis CNC milling; CNC turning (including mill-turn) |

| Material Types | Titanium (Grade 2, Grade 5/Ti-6Al-4V), Aluminum (6061, 7075), Steel (4140, 17-4 PH), ABS, Nylon (6, 6/6) |

| Tolerance Range | ±0.0002″ (±0.005 mm) typical; tight tolerances down to ±0.0001″ (±0.0025 mm) |

| Surface Finish | 16–32 μin (0.4–0.8 μm) Ra standard; up to 8 μin (0.2 μm) Ra with polishing |

| Feature Complexity | High complexity with multi-faceted contours, undercuts, and deep cavities |

| Max Work Envelope (Milling) | 5-axis: 24″ x 30″ x 20″ (610 x 762 x 508 mm); 3/4-axis up to 40″ (1016 mm) X |

| Max Turning Diameter | 12″ (305 mm) with live tooling and sub-spindle capability |

| Tooling Systems | High-speed spindles up to 20,000 RPM; automated tool changers (ATC) |

| Quality Control | CMM inspection, laser probing, first-article inspection (FAI), PPAP support |

| Secondary Operations | Deburring, passivation (for Ti/steel), anodizing (Al), stress relieving |

Titanium components require specialized cutting strategies due to low thermal conductivity and high chemical reactivity, necessitating coated carbide tools, controlled feed rates, and high-pressure coolant. Aluminum and steel parts benefit from higher material removal rates, while ABS and nylon are machined with sharp tools and optimized speeds to prevent melting or deformation. All materials are held to consistent geometric dimensioning and tolerancing (GD&T) standards per ASME Y14.5.

From CAD to Part: The Process

Honyo Prototype Precision Titanium Component Manufacturing Process

Honyo Prototype executes precision titanium component production through a rigorously controlled, vertically integrated workflow designed to mitigate material-specific risks while ensuring dimensional accuracy and structural integrity. Titanium’s high strength-to-weight ratio, corrosion resistance, and biocompatibility demand specialized handling; our process addresses inherent challenges including thermal conductivity limitations, chemical reactivity, and stringent industry compliance requirements. Below is our end-to-end methodology:

CAD Upload and Validation

Clients initiate the process by uploading native CAD files (STEP, IGES, or native SOLIDWORKS/Creo formats) via our secure customer portal. Our system performs automated validation checks for geometric integrity, unit consistency, and manufacturability flags specific to titanium alloys. Critical parameters such as wall thickness tolerances below 0.5mm, undercuts, and internal cavities are cross-referenced against titanium’s minimum feature size constraints. Invalid or ambiguous geometries trigger immediate client notification with suggested resolutions before proceeding.

AI-Powered Quoting Engine

Validated CAD data feeds into our proprietary AI quoting system, which integrates real-time variables including: titanium grade availability (e.g., Ti-6Al-4V ELI vs. Gr 2), machine time calculations based on hardness (330–360 HB for Ti-6Al-4V), toolpath complexity, and scrap rate projections. The AI references our historical database of 12,000+ titanium jobs to predict secondary operation costs (e.g., stress-relief annealing, chemical milling) and material yield loss. Quotes include alloy-specific lead time estimates and certification costs (e.g., AMS 4928, ASTM F136), delivered within 2 business hours with ±5% cost accuracy.

Collaborative DFM Analysis

Engineers conduct titanium-optimized Design for Manufacturability (DFM) within 48 hours of quote acceptance. This phase focuses on:

Thermal Management: Adjusting tool engagement angles to prevent localized heating (>400°C) that causes alpha-case embrittlement.

Fixturing Strategy: Designing low-clamp-force jigs to avoid part distortion during milling of thin-walled features.

Surface Integrity: Specifying cryogenic cooling or minimum chip-thickness parameters to eliminate microcracks in medical-grade components.

DFM reports include annotated CAD markups and alternative geometry suggestions. Clients approve revisions via our digital collaboration platform before production release.

Precision Production Execution

All titanium components undergo production in climate-controlled cells with ISO Class 8 cleanroom standards for medical/aerospace parts. Key stages:

| Phase | Critical Controls | Titanium-Specific Protocols |

|---|---|---|

| Material Sourcing | Mill test reports, batch traceability | Vacuum-arc remelted billets; full EN 10204 3.1 certification |

| Machining | In-process CMM verification at 25% intervals | Dedicated carbide tooling (no cobalt); 100% coolant filtration to prevent iron contamination |

| Post-Processing | Ra measurements, microstructure validation | Electropolishing for biocompatibility; HIP treatment for AM parts to eliminate porosity |

| Inspection | First-article inspection per AS9102 | Beta transus verification; XRF alloy verification on all critical surfaces |

Certified Delivery and Traceability

Completed components ship with full documentation package including:

Material test reports with actual chemical composition vs. ASTM standards

Dimensional inspection report (per ASME Y14.5) showing GD&T compliance

Sterilization validation (for medical devices) or non-destructive testing records (e.g., FPI, X-ray)

Parts are vacuum-sealed with VCI paper to prevent oxidation during transit. Our blockchain-enabled traceability system provides clients real-time access to production logs, including machine spindle load data and environmental conditions during critical operations.

This integrated approach ensures titanium components meet the most demanding specifications—reducing client rework rates by 73% versus industry averages while maintaining 99.2% on-time delivery for aerospace Tier 1 suppliers. All processes adhere to AS9100 Rev D and ISO 13485 standards, with material certifications extending to final part serialization for full lifecycle accountability.

Start Your Project

For precision titanium components manufactured to the highest industry standards, contact Susan Leo at [email protected]. With our advanced production facility located in Shenzhen, Honyo Prototype delivers consistent quality, tight-tolerance machining, and rapid turnaround for demanding applications across aerospace, medical, and industrial sectors.

Leverage our in-house capabilities and engineering expertise to accelerate your prototyping and production timelines.

Contact:

Susan Leo

Email: [email protected]

Factory Location: Shenzhen, China

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.