Introduction: Navigating the Global Market for precision prototype

In today’s fast-paced global economy, sourcing precision prototypes can be a daunting challenge for international B2B buyers. The need for high-quality, reliable prototypes is critical across various industries, including aerospace, defense, and medical. However, navigating the complexities of supplier capabilities, material selection, and production processes can leave many organizations feeling overwhelmed. This comprehensive guide aims to demystify the landscape of precision prototyping, offering actionable insights into the types of prototypes available, their diverse applications, and essential criteria for vetting suppliers.

By exploring the intricacies of cost structures, production timelines, and technological advancements, this resource equips decision-makers from regions like Africa, South America, the Middle East, and Europe—including key markets such as Saudi Arabia and Nigeria—with the knowledge necessary to make informed purchasing decisions. Whether you are seeking to optimize your supply chain or enhance product development cycles, this guide serves as a strategic tool to help you identify the right partners and technologies for your precision prototyping needs. With a focus on quality, efficiency, and innovation, you will be empowered to navigate the global market confidently and effectively.

Understanding precision prototype Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| CNC Machining | Utilizes computer-controlled tools for high precision | Aerospace, automotive, medical device manufacturing | Pros: High accuracy, repeatability; Cons: Higher initial setup cost. |

| Laser Cutting | Employs focused laser beams for intricate cuts | Electronics, aerospace components, signage | Pros: Clean edges, minimal material waste; Cons: Limited material thickness. |

| Water Jet Cutting | Uses high-pressure water jets to cut materials | Aerospace, automotive, and architectural designs | Pros: Can cut thick materials; Cons: Slower than laser cutting. |

| Metal Fabrication | Involves bending, cutting, and assembling metals | Construction, automotive, and machinery parts | Pros: Versatile and strong; Cons: Labor-intensive, longer lead times. |

| 3D Printing | Builds prototypes layer by layer from digital models | Rapid prototyping, custom parts for various industries | Pros: Quick turnaround, complex geometries; Cons: Material limitations and surface finish may vary. |

What are the Characteristics of CNC Machining in Precision Prototyping?

CNC machining is a highly automated process that relies on computer numerical control to produce parts with exceptional accuracy. This method is particularly suitable for industries requiring detailed and repeatable components, such as aerospace and medical device manufacturing. When considering CNC machining, buyers should evaluate the complexity of their designs and the initial setup costs, which can be higher than traditional machining methods but ultimately lead to reduced labor costs and enhanced precision.

How Does Laser Cutting Enhance Precision Prototyping?

Laser cutting is distinguished by its ability to create intricate designs with clean edges using focused laser beams. This technique is ideal for applications in the electronics and aerospace sectors, where precision and minimal material waste are critical. Buyers should assess the thickness and type of materials they intend to work with, as laser cutting has limitations on the maximum thickness it can handle, but it excels in speed and precision for thinner materials.

What Advantages Does Water Jet Cutting Offer for B2B Buyers?

Water jet cutting utilizes high-pressure water jets to achieve precise cuts, making it suitable for a variety of materials, including metals, plastics, and glass. This method is advantageous for industries like aerospace and automotive, where the ability to cut thick materials without thermal distortion is a significant benefit. Buyers should consider the trade-off between cutting speed and material thickness, as water jet cutting can be slower compared to other methods, but it allows for greater versatility.

Why is Metal Fabrication a Key Process in Precision Prototyping?

Metal fabrication encompasses a range of processes, including cutting, bending, and assembling metal components. This method is essential for industries such as construction and automotive, where strength and durability are paramount. Buyers should be aware that while metal fabrication is highly versatile, it can be labor-intensive and may result in longer lead times, making it important to plan projects accordingly.

How Does 3D Printing Transform Precision Prototyping?

3D printing, or additive manufacturing, constructs prototypes layer by layer from digital models, allowing for rapid prototyping and the creation of complex geometries. This method is particularly useful for businesses requiring custom parts in short timeframes. However, buyers should consider the material limitations and potential variations in surface finish, which can impact the final product’s quality. The quick turnaround time makes it an attractive option for fast-paced industries looking to innovate.

Key Industrial Applications of precision prototype

| Industry/Sector | Specific Application of Precision Prototype | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Development of lightweight structural components | Enhanced performance and fuel efficiency | Compliance with AS9100D standards, material certification |

| Medical Devices | Prototyping of surgical instruments | Improved patient outcomes and operational efficiency | Biocompatibility, regulatory compliance, rapid prototyping |

| Automotive | Creation of complex engine components | Increased durability and performance | Precision tolerances, material selection, quick turnaround |

| Electronics | Fabrication of circuit boards | Higher reliability and performance in devices | Design for manufacturability, lead times, cost considerations |

| Defense | Manufacturing of custom military equipment | Enhanced operational capabilities and reliability | Security clearances, compliance with military standards |

How is Precision Prototyping Used in Aerospace Applications?

In the aerospace sector, precision prototypes are critical for developing lightweight structural components that meet stringent safety and performance standards. These prototypes allow manufacturers to test various materials and designs, significantly improving fuel efficiency and overall aircraft performance. International B2B buyers in this field must prioritize suppliers that comply with AS9100D standards and can provide certified materials to ensure quality and reliability.

What Role Does Precision Prototyping Play in Medical Devices?

Precision prototyping is essential in the medical device industry for creating surgical instruments and implantable devices. These prototypes facilitate rigorous testing to enhance patient outcomes and operational efficiency in healthcare settings. For buyers, sourcing partners must demonstrate biocompatibility and compliance with health regulations, as well as the ability to deliver rapid prototyping services to meet urgent project timelines.

How Does Precision Prototyping Enhance Automotive Manufacturing?

In automotive manufacturing, precision prototypes are used to create complex engine components that require high durability and performance. This process enables manufacturers to refine designs and materials, leading to improved vehicle performance and longevity. Buyers in this sector should focus on suppliers that can meet precise tolerances, offer a variety of material options, and provide quick turnaround times to keep pace with industry demands.

Why is Precision Prototyping Important for Electronics?

The electronics industry relies heavily on precision prototypes for fabricating circuit boards and other critical components. These prototypes help ensure higher reliability and performance in electronic devices, which is crucial in a competitive market. Buyers should consider design for manufacturability, lead times, and cost-effectiveness when selecting suppliers, as these factors can significantly impact project success and market readiness.

How is Precision Prototyping Applied in Defense Manufacturing?

In the defense sector, precision prototypes are vital for manufacturing custom military equipment that meets specific operational requirements. These prototypes ensure enhanced capabilities and reliability of defense systems. Buyers in this field must consider suppliers’ security clearances and compliance with military standards, as these factors are paramount for maintaining operational integrity and meeting government regulations.

3 Common User Pain Points for ‘precision prototype’ & Their Solutions

Scenario 1: Tight Deadlines for Prototyping Projects

The Problem: B2B buyers often face the critical challenge of tight deadlines when bringing products to market. In sectors such as aerospace or medical devices, delays in prototyping can lead to significant financial losses and missed opportunities. For instance, a company might require a complex part to be prototyped in a matter of days, but standard manufacturing processes often take weeks, leaving buyers scrambling to meet project timelines.

The Solution: To effectively navigate tight deadlines, buyers should prioritize manufacturers that specialize in rapid prototyping. This involves sourcing a precision prototype provider known for quick turnaround times and advanced manufacturing capabilities, such as CNC machining and laser cutting. When requesting quotes, specify the urgency and complexity of the project, and ask about their expedited processes. Additionally, establishing a clear line of communication with the manufacturer can facilitate faster revisions and approvals. Buyers should also consider investing in design-for-manufacturability (DFM) reviews early in the process to minimize potential delays and ensure that the prototype meets all specifications right from the start.

Scenario 2: Inconsistent Quality Across Prototypes

The Problem: Another common pain point is the inconsistency in quality and precision across different prototypes. B2B buyers may find that prototypes from various manufacturers or even different batches from the same manufacturer do not meet their quality standards, leading to costly reworks and affecting overall product integrity. This inconsistency can stem from variations in materials, machining processes, or even the experience level of the workforce.

The Solution: To combat this issue, buyers should conduct thorough due diligence when selecting a precision prototype manufacturer. Look for companies with certifications, such as AS9100D for aerospace applications, which indicate a commitment to quality management systems. Establishing a robust quality assurance process is also essential; this includes requesting detailed reports on material sourcing, machining processes, and any testing protocols used. Implementing a pilot run of prototypes can help ensure that the first batch meets quality expectations before full-scale production. Moreover, fostering a collaborative relationship with the manufacturer can lead to better understanding and adherence to specific quality standards.

Scenario 3: High Costs of Prototyping and Production

The Problem: Cost is often a significant concern for B2B buyers, especially when dealing with precision prototypes. The expenses associated with high-quality materials, advanced manufacturing techniques, and skilled labor can quickly escalate, putting financial pressure on projects. Buyers may struggle to balance the need for precision and quality with budget constraints, particularly in competitive markets where margins are tight.

The Solution: To manage costs effectively, buyers should explore various sourcing options, including regional manufacturers that can offer competitive pricing without sacrificing quality. Leveraging technology such as additive manufacturing (3D printing) for initial prototypes can reduce material waste and lower costs significantly. Additionally, buyers should clearly define project specifications to avoid unnecessary changes that can lead to increased costs. Engaging in a transparent conversation with the manufacturer about budget constraints can also yield creative solutions, such as phased production or material alternatives that maintain quality while reducing costs. Lastly, consider long-term partnerships with manufacturers, which can often lead to better pricing structures and priority service.

Strategic Material Selection Guide for precision prototype

What Are the Key Properties of Common Materials for Precision Prototyping?

When selecting materials for precision prototypes, it is crucial to consider their properties and how they align with the intended application. Here, we analyze four common materials—aluminum, stainless steel, polycarbonate, and titanium—focusing on their key properties, advantages, disadvantages, and specific considerations for international B2B buyers.

How Does Aluminum Perform in Precision Prototyping?

Aluminum is a lightweight metal known for its excellent corrosion resistance and thermal conductivity. It typically has a temperature rating of up to 150°C and can withstand moderate pressures, making it suitable for various applications, including automotive and aerospace components.

Pros: Aluminum is cost-effective and easy to machine, allowing for rapid prototyping. Its lightweight nature enhances the performance of end products, especially in applications where weight reduction is critical.

Cons: While durable, aluminum can be less suitable for high-stress applications compared to metals like steel. It is also more susceptible to deformation under high pressure.

Impact on Application: Aluminum is compatible with various media, including water and air, but may not be ideal for aggressive chemicals.

Considerations for International Buyers: Buyers from regions such as Africa and the Middle East should ensure compliance with ASTM standards for aluminum alloys. Preferences may vary based on local availability and manufacturing capabilities.

What Are the Benefits of Using Stainless Steel in Prototyping?

Stainless steel is renowned for its strength, durability, and corrosion resistance, with temperature ratings often exceeding 300°C. It is commonly used in industries like medical devices and food processing.

Pros: Its high strength-to-weight ratio and resistance to wear make stainless steel an excellent choice for demanding applications. It also maintains structural integrity under extreme conditions.

Cons: The primary drawback is its higher cost and complexity in machining compared to other materials like aluminum. This can lead to longer lead times and increased production costs.

Impact on Application: Stainless steel is compatible with a wide range of media, including corrosive substances, making it suitable for various environments.

Considerations for International Buyers: Buyers should verify compliance with international standards such as DIN and JIS, particularly in sectors like food and pharmaceuticals where hygiene is paramount.

Why Choose Polycarbonate for Precision Prototyping?

Polycarbonate is a high-performance plastic known for its impact resistance and optical clarity. It is suitable for applications requiring transparency and toughness, such as protective covers and lenses.

Pros: Polycarbonate is lightweight and can be molded into complex shapes, facilitating intricate designs. It also offers excellent UV resistance and can endure temperatures up to 120°C.

Cons: While it is durable, polycarbonate can be more prone to scratching than metals. Additionally, its chemical resistance may not match that of metals, limiting its use in certain environments.

Impact on Application: Polycarbonate is compatible with various media but may degrade when exposed to certain solvents or chemicals.

Considerations for International Buyers: Compliance with safety standards is essential, especially for applications in consumer products. Buyers should also consider local regulations regarding plastic materials.

What Advantages Does Titanium Offer for Precision Prototyping?

Titanium is a lightweight, high-strength metal with excellent corrosion resistance and temperature ratings exceeding 600°C. It is widely used in aerospace, medical, and high-performance automotive applications.

Pros: Titanium’s strength and durability make it ideal for high-stress applications. It is also biocompatible, making it suitable for medical implants.

Cons: The primary disadvantage is its high cost and the complexity involved in machining titanium, which can lead to longer production times.

Impact on Application: Titanium is compatible with various aggressive media, including seawater, making it an excellent choice for marine applications.

Considerations for International Buyers: Buyers should be aware of ASTM standards for titanium alloys and the availability of specialized machining services in their region.

Summary Table of Material Selection for Precision Prototyping

| Material | Typical Use Case for precision prototype | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Automotive and aerospace components | Lightweight and cost-effective | Less suitable for high-stress applications | Low |

| Stainless Steel | Medical devices and food processing | High strength and durability | Higher cost and machining complexity | High |

| Polycarbonate | Protective covers and lenses | Impact-resistant and lightweight | Prone to scratching and chemical sensitivity | Medium |

| Titanium | Aerospace and medical implants | Exceptional strength and corrosion resistance | High cost and machining complexity | High |

This guide provides a comprehensive overview of material selection for precision prototyping, enabling international B2B buyers to make informed decisions tailored to their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for precision prototype

What Are the Main Stages of Manufacturing Processes for Precision Prototypes?

The manufacturing process for precision prototypes typically involves several critical stages, ensuring the final product meets the required specifications and quality standards. These stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Precision Prototyping?

Material preparation is the first stage and involves selecting the right materials based on the prototype’s specifications. Common materials include metals, plastics, and composites. The preparation process may include cutting raw materials to size, cleaning surfaces, and ensuring they meet specified tolerances. Advanced technologies such as laser cutting and water jet cutting are often employed to achieve precise dimensions, allowing for efficient and accurate preparation.

What Techniques Are Used in Forming Precision Prototypes?

Once the materials are prepared, the forming stage begins. This phase includes various techniques such as CNC machining, bending, and stamping. CNC machining is particularly popular for its ability to create complex geometries with high precision. For instance, vertical milling machines and CNC lathes are commonly used to shape components accurately. Bending processes, often performed using press brakes, enable the creation of specific angles and shapes required in the design. Each technique must be carefully chosen based on the prototype’s requirements to ensure optimal results.

How Is Assembly Conducted in Precision Prototype Manufacturing?

The assembly stage involves integrating various components to create the final prototype. This may include attaching machined parts, adding electronic components, or integrating systems from different suppliers. Effective assembly requires skilled technicians who can ensure that each part fits correctly and functions as intended. Moreover, this stage often necessitates collaboration with suppliers to verify that their components meet the quality standards required for the final product.

What Finishing Processes Are Commonly Used for Precision Prototypes?

Finishing is the final stage of the manufacturing process and is crucial for achieving the desired aesthetic and functional qualities. Common finishing techniques include painting, anodizing, and surface treatments like polishing or de-burring. These processes not only enhance the appearance of the prototype but also improve its durability and resistance to wear and corrosion. The choice of finishing technique will depend on the intended application of the prototype and customer specifications.

How Is Quality Assurance Implemented in Precision Prototyping?

Quality assurance (QA) is an integral part of the precision prototyping process, ensuring that each component and the final product meet established standards. Adhering to international quality standards, such as ISO 9001, is crucial for maintaining a robust QA system. This standard emphasizes a process-oriented approach, focusing on continuous improvement and customer satisfaction.

What International Standards and Industry-Specific Certifications Are Relevant?

For B2B buyers, understanding the relevant international and industry-specific standards is essential. In addition to ISO 9001, there are standards like AS9100 for aerospace, API for oil and gas, and CE marking for products sold within the European Economic Area. These certifications indicate that the manufacturer adheres to strict quality management systems and regulatory compliance, which is particularly important for buyers from regions like Africa and South America, where regulatory frameworks may vary.

What Are the Key Quality Control Checkpoints in Precision Prototype Manufacturing?

Quality control (QC) checkpoints throughout the manufacturing process help identify issues early on. Key checkpoints include:

- Incoming Quality Control (IQC): This involves inspecting raw materials and components as they arrive at the facility to ensure they meet specifications.

- In-Process Quality Control (IPQC): During the manufacturing process, operators perform checks to ensure that each stage meets quality standards and tolerances.

- Final Quality Control (FQC): After assembly, a comprehensive inspection verifies that the finished prototype meets all design specifications and quality criteria.

These checkpoints help maintain high standards and prevent defects from progressing through the production process.

What Common Testing Methods Are Used in Quality Assurance?

Testing methods vary depending on the prototype’s intended application but typically include:

- Dimensional Inspection: Using tools like calipers and coordinate measuring machines (CMM) to ensure that components meet specified dimensions.

- Functional Testing: Verifying that the prototype operates as intended under real-world conditions.

- Material Testing: Assessing the mechanical properties of materials, such as tensile strength and hardness, to ensure they meet required specifications.

Implementing these testing methods allows manufacturers to detect defects and make necessary adjustments before the product is delivered to the customer.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers should take proactive steps to verify the quality control practices of potential suppliers. This can include:

- Conducting Audits: Regular audits of the supplier’s facility can provide insight into their manufacturing processes and quality control systems.

- Requesting Quality Reports: Suppliers should provide documentation of their quality control measures, including results from inspections and tests.

- Engaging Third-Party Inspectors: Hiring independent inspectors to evaluate the manufacturing processes and finished products can add an extra layer of assurance.

These actions can help mitigate risks and ensure that the supplier adheres to the required quality standards, particularly for international buyers where regulations and standards may differ.

What Are the Quality Control Nuances for International B2B Buyers?

For international B2B buyers, understanding the nuances of quality control in different regions is vital. Factors such as local regulations, supply chain logistics, and cultural differences can impact quality assurance practices. Buyers from Africa, South America, the Middle East, and Europe should consider the following:

- Regulatory Compliance: Familiarize yourself with the specific quality standards and regulations in your region and ensure your supplier is compliant.

- Supply Chain Dynamics: Be aware of potential delays or issues in the supply chain that could affect quality. Establishing clear communication with suppliers can help mitigate these risks.

- Cultural Understanding: Recognizing cultural differences in business practices can facilitate smoother interactions and better collaboration with suppliers.

By navigating these nuances, B2B buyers can enhance their procurement strategies and ensure they receive high-quality precision prototypes that meet their needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘precision prototype’

Introduction

In today’s competitive global market, sourcing precision prototypes is a critical process for businesses looking to innovate and stay ahead. This guide provides a clear checklist to help B2B buyers navigate the complexities of procuring precision prototypes, ensuring that they select the right suppliers and achieve high-quality results. Each step is designed to streamline your sourcing process, minimize risks, and enhance collaboration with your chosen manufacturers.

Step 1: Define Your Technical Specifications

Clearly outlining your technical specifications is essential to ensure that potential suppliers understand your precise needs. This includes dimensions, tolerances, materials, and any specific finishes required. A comprehensive specification document will help avoid miscommunication and set the foundation for a successful prototype development.

- Include detailed drawings: Use CAD files or detailed sketches to illustrate your requirements.

- Specify industry standards: Indicate if your prototype must comply with certain industry regulations or certifications.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers that specialize in precision prototyping. Look for companies with a proven track record in your industry and consider their capabilities, technologies, and experience.

- Check online reviews and testimonials: Investigate feedback from previous clients to gauge satisfaction and reliability.

- Evaluate their portfolio: Review case studies or examples of past projects to assess their expertise and quality of work.

Step 3: Evaluate Supplier Certifications

Before engaging with a supplier, verify their certifications to ensure they adhere to recognized quality standards. Certifications such as ISO 9001 or AS9100D indicate a commitment to quality management and process improvement.

- Request certification documentation: Ensure that the certifications are current and relevant to your industry.

- Inquire about quality control processes: Understand their approach to maintaining quality throughout the production process.

Step 4: Request Detailed Quotes

Once you’ve narrowed down potential suppliers, request detailed quotes that outline pricing, timelines, and terms of service. A well-structured quote will help you compare options and make informed decisions.

- Breakdown of costs: Ensure the quote includes material, labor, and any additional fees to avoid hidden costs.

- Production timelines: Confirm lead times and delivery schedules to align with your project timelines.

Step 5: Conduct Supplier Visits or Virtual Tours

If feasible, visit the supplier’s facilities or request a virtual tour to evaluate their capabilities firsthand. This step allows you to assess their machinery, workforce, and overall production environment.

- Observe quality control measures: Look for evidence of rigorous quality control processes in action.

- Meet the team: Engaging with the production team can provide insights into their expertise and commitment to customer service.

Step 6: Establish Clear Communication Channels

Effective communication is vital for the successful execution of your project. Establish clear channels for ongoing communication with your supplier from the outset.

- Designate a point of contact: Ensure that both your team and the supplier have designated representatives for efficient information exchange.

- Set regular check-ins: Schedule periodic updates to discuss progress, address concerns, and make necessary adjustments.

Step 7: Finalize Contracts and Agreements

Before commencing production, ensure that all contractual agreements are clearly defined and mutually agreed upon. This includes payment terms, delivery schedules, and quality expectations.

- Review legal implications: Consult with legal counsel to ensure that all terms protect your interests.

- Include clauses for revisions: Address how changes to specifications or timelines will be handled during the production process.

By following this step-by-step checklist, B2B buyers can confidently navigate the sourcing process for precision prototypes, ensuring that they select the right partners and achieve successful project outcomes.

Comprehensive Cost and Pricing Analysis for precision prototype Sourcing

What Are the Key Cost Components in Precision Prototype Sourcing?

When sourcing precision prototypes, understanding the cost structure is critical for effective budgeting and financial planning. The primary cost components include:

-

Materials: The choice of raw materials significantly impacts cost. High-performance materials often used in aerospace or medical applications can be more expensive than standard metals. Sourcing locally versus internationally can also affect pricing due to shipping and import tariffs.

-

Labor: Skilled labor is essential for precision manufacturing. The cost of labor varies by region, with developed countries typically having higher labor costs compared to emerging markets. It is essential to consider the expertise required for complex prototypes, which may demand higher wages.

-

Manufacturing Overhead: This includes costs related to facility maintenance, utilities, and equipment depreciation. Overhead can vary widely depending on the manufacturer’s location and operational efficiency.

-

Tooling: Custom tooling can represent a significant upfront investment. Costs depend on the complexity of the tooling required, with specialized tools for intricate designs driving prices higher.

-

Quality Control (QC): Ensuring that prototypes meet stringent quality standards incurs costs associated with inspections, testing, and certifications. Industries like aerospace and medical devices often require additional certifications, which can elevate costs.

-

Logistics: Transportation costs, including shipping and handling, play a vital role in the overall pricing. International shipping can introduce additional complexities such as customs duties and longer lead times.

-

Margin: Manufacturers add a profit margin to cover their risks and operational costs. This can vary based on competition, market demand, and the supplier’s reputation.

How Do Price Influencers Affect Precision Prototype Costs?

Several factors influence the final pricing of precision prototypes:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often reduce the per-unit cost due to economies of scale. Buyers should negotiate MOQs that align with their budgetary constraints while ensuring they receive a competitive price.

-

Specifications and Customization: Highly customized prototypes typically incur higher costs due to additional design and engineering work. Clearly defining specifications can help avoid unexpected expenses during the production phase.

-

Materials: The choice between standard and specialized materials can significantly impact costs. Understanding material properties and their implications on performance can aid in making cost-effective decisions.

-

Quality and Certifications: Higher quality requirements and additional certifications can increase costs. Buyers should weigh the necessity of these factors against their project requirements.

-

Supplier Factors: The supplier’s location, experience, and reputation can influence pricing. Established suppliers may charge more for their services, reflecting their reliability and quality assurance practices.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is vital for international transactions. They determine the responsibilities of buyers and sellers concerning shipping, insurance, and tariffs, which can affect overall costs.

What Negotiation and Cost-Efficiency Strategies Should Buyers Consider?

B2B buyers should adopt strategic approaches to maximize cost efficiency when sourcing precision prototypes:

-

Negotiation: Build strong relationships with suppliers to negotiate better terms. Leverage volume commitments or long-term contracts to secure favorable pricing. Be prepared to discuss specifics, such as payment terms and delivery schedules.

-

Total Cost of Ownership (TCO): Consider the TCO rather than just the upfront costs. This includes evaluating maintenance, operational efficiency, and potential downtime associated with the prototypes.

-

Pricing Nuances for International Buyers: Buyers from regions like Africa, South America, the Middle East, and Europe should be aware of currency fluctuations, import tariffs, and local market conditions. These factors can significantly impact final costs.

-

Requesting Quotes: Always request detailed quotes from multiple suppliers. This helps in comparing costs and understanding the breakdown of expenses, which can aid in informed decision-making.

Disclaimer on Indicative Prices

The pricing for precision prototypes can vary widely based on numerous factors, including specifications, materials, and supplier capabilities. Therefore, the prices mentioned in any discussions or advertisements should be considered indicative and subject to change based on market conditions and specific project requirements. Always consult with suppliers for the most accurate and up-to-date pricing information.

Alternatives Analysis: Comparing precision prototype With Other Solutions

Introduction: What Are the Alternatives to Precision Prototyping?

In the fast-evolving landscape of manufacturing, B2B buyers often seek innovative solutions that can enhance their production capabilities. While precision prototyping offers numerous advantages, it is essential to consider alternative methods that may align better with specific project requirements or budget constraints. This analysis provides a comparative overview of precision prototyping against two viable alternatives: additive manufacturing (3D printing) and traditional machining.

Comparison Table

| Comparison Aspect | Precision Prototype | Additive Manufacturing (3D Printing) | Traditional Machining |

|---|---|---|---|

| Performance | High precision and accuracy | Variable precision, depends on technology | High precision for complex geometries |

| Cost | Moderate to high, depending on complexity | Generally lower for low-volume production | Can be high for complex designs |

| Ease of Implementation | Requires skilled personnel and setup | User-friendly, especially for prototyping | Complex setup and tooling required |

| Maintenance | Regular maintenance of machinery needed | Minimal maintenance; occasional software updates | Regular maintenance required |

| Best Use Case | Aerospace, medical, and automotive parts | Rapid prototyping and low-volume production | High-volume manufacturing and durable parts |

Detailed Breakdown of Alternatives

Additive Manufacturing (3D Printing)

Additive manufacturing, commonly known as 3D printing, is a method that builds components layer by layer from digital models. This technology excels in producing complex geometries and customized parts quickly. Its major advantage lies in lower costs for low-volume production, making it ideal for startups and companies testing new designs. However, the precision can vary widely based on the 3D printing technology used (e.g., FDM, SLA). Buyers may also find limitations in material choices and post-processing needs, which can affect the final quality of the product.

Traditional Machining

Traditional machining encompasses a range of subtractive manufacturing processes, including milling, turning, and drilling. This method is known for its ability to produce highly precise and durable parts from a variety of materials. It is particularly effective for high-volume production runs where consistent quality and repeatability are crucial. However, the setup costs and lead times can be significant, especially for complex designs that require specialized tooling. Additionally, traditional machining often involves more waste material compared to precision prototyping and additive manufacturing.

Conclusion: How to Choose the Right Solution for Your Needs

Selecting the right manufacturing method requires a thorough understanding of your specific project requirements, including design complexity, production volume, and budget constraints. Precision prototyping offers exceptional quality and speed, making it suitable for industries like aerospace and medical. In contrast, additive manufacturing is beneficial for rapid prototyping and customization, while traditional machining is ideal for high-volume production. By evaluating these alternatives against your operational needs, you can make an informed decision that aligns with your business objectives and enhances your competitive edge in the market.

Essential Technical Properties and Trade Terminology for precision prototype

What Are the Key Technical Properties Relevant to Precision Prototypes?

Understanding the critical technical properties of precision prototypes is essential for B2B buyers involved in sectors such as aerospace, defense, and medical manufacturing. Here are several key specifications to consider:

1. Material Grade

Material grade refers to the classification of materials based on their composition and properties. Common materials used in precision prototypes include metals (like aluminum and stainless steel), plastics, and composites. The choice of material directly impacts the durability, weight, and cost of the final product. Selecting the appropriate material grade ensures that the prototype meets the specific performance and regulatory standards required by the industry.

2. Tolerance

Tolerance indicates the permissible limit of variation in a physical dimension. For precision prototypes, tolerances can be very tight, often within a few micrometers. High-precision tolerances are crucial for ensuring that parts fit together correctly and function as intended. In B2B contexts, understanding tolerance specifications helps buyers communicate their needs effectively and avoid costly reworks or failures in the final application.

3. Surface Finish

Surface finish describes the texture and smoothness of a prototype’s surface. It can influence not only the aesthetic appeal but also the performance characteristics, such as friction and corrosion resistance. Different surface finishes may be required based on the application, such as anodizing for aluminum parts or polishing for stainless steel. Buyers must consider surface finish requirements to ensure the prototype is suitable for its intended environment.

4. Dimensional Accuracy

Dimensional accuracy refers to how closely a manufactured part matches its intended design specifications. Achieving high dimensional accuracy is vital for prototypes that will undergo further testing or integration into larger systems. In B2B procurement, knowing the required dimensional accuracy can assist in selecting the right manufacturing partner and technology.

5. Heat Treatment

Heat treatment is a process used to alter the physical and sometimes chemical properties of a material. This can enhance hardness, strength, and ductility, making it an essential property for components exposed to stress or extreme conditions. Buyers should consider the heat treatment processes available and how they can affect the performance of the final prototype.

6. Production Volume

While not a technical property per se, understanding production volume is critical for precision prototyping. Whether the need is for low-volume, high-mix production or high-volume manufacturing, it can significantly influence costs, lead times, and manufacturing techniques. Buyers must clearly communicate their volume requirements to ensure efficient and cost-effective production.

What Are the Common Trade Terms in Precision Prototyping?

Familiarity with trade terminology can streamline communication and negotiations in the precision prototyping landscape. Here are some essential terms to know:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products or components that are used in another company’s end product. Understanding OEM relationships can help buyers identify potential partners and ensure the quality and compatibility of components in their prototypes.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to produce or sell. Knowing the MOQ is crucial for buyers to plan their procurement strategies effectively, especially when dealing with specialized prototypes that may not be produced in large quantities.

3. RFQ (Request for Quotation)

An RFQ is a document that buyers send to suppliers to solicit price quotes for specific products or services. Including detailed specifications in an RFQ can lead to more accurate quotes and better procurement outcomes.

4. Incoterms

Incoterms (International Commercial Terms) define the responsibilities of buyers and sellers for the delivery of goods under sales contracts. Understanding these terms is essential for international transactions, as they clarify who bears the risk and costs during shipping.

5. Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the product. For precision prototypes, lead time can be influenced by factors like material availability and manufacturing processes. Buyers must factor lead time into their project timelines to ensure timely delivery.

6. CAD (Computer-Aided Design)

CAD is a technology used for creating precision drawings and technical illustrations. Familiarity with CAD can facilitate better communication between buyers and manufacturers, ensuring that prototypes align with design specifications.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions that enhance their procurement processes and foster successful partnerships in the precision prototyping industry.

Navigating Market Dynamics and Sourcing Trends in the precision prototype Sector

What Are the Key Market Dynamics and Trends in Precision Prototyping?

The precision prototyping sector is currently experiencing significant growth driven by advancements in technology and increasing demand for customized manufacturing solutions. Global drivers include the rise of Industry 4.0, which emphasizes automation and smart manufacturing, enabling companies to produce high-quality prototypes at reduced costs and faster turnaround times. B2B buyers are increasingly seeking suppliers that leverage advanced techniques such as CNC machining, laser cutting, and waterjet cutting to meet their specific needs.

Emerging trends include the adoption of additive manufacturing technologies, which allow for complex geometries and reduced waste, appealing to industries such as aerospace, automotive, and medical devices. Additionally, international buyers from regions like Africa, South America, the Middle East, and Europe are prioritizing suppliers that can offer flexible production capabilities to accommodate short runs and rapid prototyping. This demand for agility in sourcing is leading to a collaborative approach where manufacturers work closely with clients to co-develop solutions tailored to their unique specifications.

How Are Sustainability and Ethical Sourcing Impacting the Precision Prototype Sector?

Sustainability is becoming an essential consideration for B2B buyers in the precision prototyping sector. Environmental impacts associated with manufacturing processes are under scrutiny, prompting companies to seek suppliers committed to sustainable practices. This includes minimizing waste, reducing energy consumption, and utilizing eco-friendly materials. Buyers are increasingly looking for partners who have obtained ‘green’ certifications, indicating adherence to environmental standards and practices.

Ethical sourcing is also gaining traction, as companies recognize the importance of maintaining transparent supply chains. This involves ensuring that materials are sourced responsibly and that labor practices meet ethical standards. Buyers are encouraged to engage with manufacturers who demonstrate a commitment to sustainability through the use of recycled materials, energy-efficient processes, and certifications that validate their environmental and ethical practices. By prioritizing sustainability and ethical sourcing, businesses can not only enhance their brand reputation but also contribute to a more sustainable future.

What Is the Historical Context of Precision Prototyping?

The precision prototyping industry has evolved significantly over the past few decades, transitioning from traditional manufacturing methods to advanced technologies that allow for greater precision and customization. Initially, prototyping relied heavily on manual processes and basic machining techniques. However, the advent of computer-aided design (CAD) and computer-aided manufacturing (CAM) revolutionized the industry, enabling faster and more accurate production of prototypes.

As industries began to demand more complex designs and shorter lead times, the introduction of CNC machining and laser cutting technologies further transformed the landscape. Today, precision prototyping serves as a crucial step in product development across various sectors, including aerospace, automotive, and healthcare. This evolution reflects a broader trend towards innovation and efficiency, positioning precision prototyping as a vital component of modern manufacturing.

Through this historical lens, B2B buyers can appreciate the advancements that have led to the current capabilities in precision prototyping, allowing them to make informed decisions when sourcing from potential suppliers.

Frequently Asked Questions (FAQs) for B2B Buyers of precision prototype

-

How do I ensure the quality of precision prototypes before making a large order?

To ensure quality, start by requesting samples or prototypes from your potential supplier. Evaluate their certifications, such as ISO 9001 or AS9100D, which indicate adherence to high-quality manufacturing standards. Additionally, inquire about their quality assurance processes, including inspections and testing methods. Establish a clear communication channel to discuss your specifications and requirements, and consider conducting an on-site visit if possible to assess their capabilities and facilities. -

What factors should I consider when choosing a supplier for precision prototyping?

When selecting a supplier, consider their expertise in your specific industry, such as aerospace or medical devices, as well as their technological capabilities, including the machinery and processes they utilize. Evaluate their track record through client testimonials and case studies. Additionally, assess their responsiveness, flexibility in customization, and ability to meet your timelines. Pricing, payment terms, and shipping logistics should also align with your budget and operational needs. -

What is the typical lead time for precision prototype manufacturing?

Lead times can vary significantly based on the complexity of the design, the materials used, and the supplier’s capacity. Generally, expect a lead time ranging from a few days to several weeks for prototype production. To expedite the process, provide detailed specifications and maintain open communication with your supplier. If you’re working on a tight schedule, discuss rush order options and their associated costs upfront. -

Are there minimum order quantities (MOQ) for precision prototypes?

Many suppliers have a minimum order quantity, but this can vary based on the type of prototype and the materials involved. Some may offer flexibility for initial prototypes, allowing for smaller orders to help you test the market. It’s essential to communicate your needs clearly and negotiate the terms upfront to ensure that the MOQ aligns with your project’s requirements and budget. -

What payment terms should I expect when sourcing precision prototypes?

Payment terms can differ among suppliers, but common practices include upfront deposits, net 30, or net 60 payment options. Some suppliers may offer discounts for early payments or larger orders. It’s crucial to discuss and agree upon payment terms before finalizing any contracts to avoid misunderstandings. Ensure that the terms are documented in the purchase agreement to protect both parties. -

How can I customize my precision prototype to meet specific requirements?

Customization begins with clear communication of your project specifications, including design files, material preferences, and functional requirements. Most suppliers offer design assistance and can provide insights on manufacturability. Utilize CAD software to create detailed designs and collaborate closely with your supplier during the development phase to ensure that the final product meets your expectations. -

What logistics considerations should I be aware of when sourcing precision prototypes internationally?

When sourcing internationally, consider shipping times, customs regulations, and import duties that may affect delivery schedules and costs. Work with suppliers who have experience in international shipping and can provide clear documentation for customs clearance. Establish a logistics plan that includes tracking shipments and managing potential delays to ensure timely receipt of your prototypes. -

How do I handle intellectual property (IP) concerns when working with overseas suppliers?

To protect your intellectual property, start by conducting due diligence on potential suppliers, including their reputation and past projects. Utilize non-disclosure agreements (NDAs) to safeguard sensitive information before sharing designs or specifications. Additionally, consider registering your IP in the countries where your suppliers operate to strengthen your legal protection. Open communication about IP rights and responsibilities is crucial for a successful partnership.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 6 Precision Prototype Manufacturers & Suppliers List

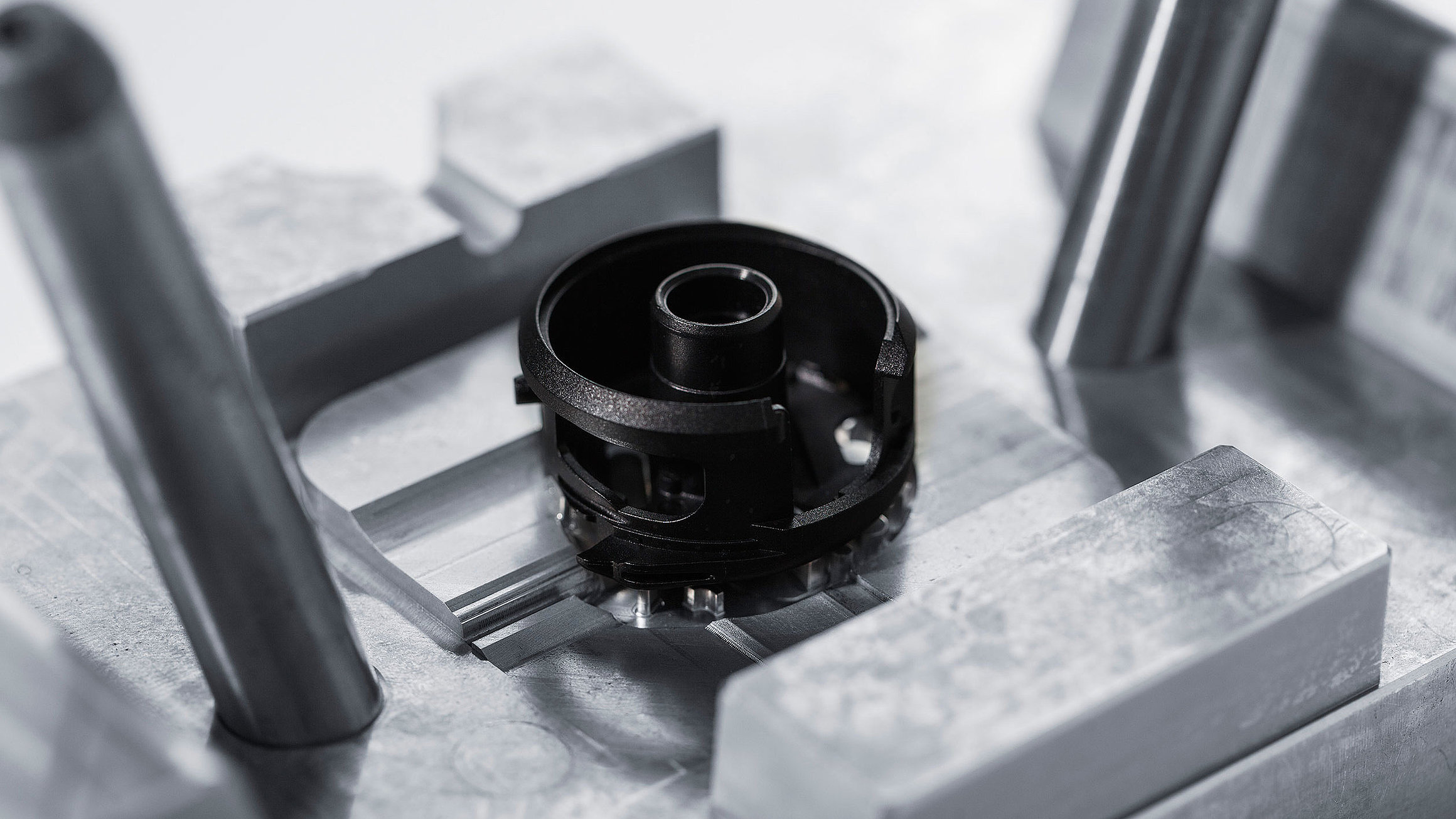

1. Precision Prototyping & Manufacturing – Sheet Metal Solutions

Domain: precisionproto.com

Registered: 2003 (22 years)

Introduction: Precision Prototyping & Manufacturing specializes in transforming sheet metal into complex parts and integrating them into assemblies with vendor supplied composite and machined parts. They offer services such as Water Jet Cutting, Press Brake, De-Burring, Material Handling, and Inspection. PPM is an AS9100D Certified Company.

2. Precision Prototype and Machine LLC – Mosin Nagant Scope Mounts

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Precision Prototype and Machine LLC offers a variety of products primarily focused on hunting and firearm accessories. Key items include:

1. Mosin Nagant Scope Mount 91/30, M44, M91, M38, T53, M91/59 – Price: $53.95

2. Low Profile Mosin Nagant Scope Mount for the 91/30, Picatinny Style Rail – Price: $53.79

3. German Mauser K98, Gewehr 98, Swede M96, Turkish M38 Front Sight Adjusting Tool – Pric…

3. Find and Update – Machining Services

Domain: find-and-update.company-information.service.gov.uk

Introduction: Machining services

4. Precision Prototype & Manufacturing – Advanced Laser Cutting Solutions

Domain: laser-cutting-services.com

Registered: 2001 (24 years)

Introduction: Precision Prototype & Manufacturing, Inc. specializes in advanced laser cutting technology for prototype development and manufacturing. They offer tailored laser cutting solutions for various materials, including metals and specialized alloys. Their portfolio includes components for aerospace applications, electronics, and bespoke prototyping solutions. The company emphasizes collaboration with cl…

5. Precision Prototype & Machine – Defense Manufacturing

Domain: linkedin.com

Registered: 2002 (23 years)

Introduction: This company, Precision Prototype & Machine – Defense Manufacturing, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

6. Huachen Precision – CNC Machined Parts & 3D Printing

Domain: prototypingparts.com

Registered: 2021 (4 years)

Introduction: Best Precision Prototyping Manufacturer and Supplier, Huachen Precision Manufacturing Co., Ltd. offers a range of services including CNC Turning/Milling, 3D Printing, Sheet Metal, Urethane Casting, Injection Moulding, and Die Casting. Key products include: 3/4/5 Axis CNC Machined Parts, MJF(HP)/SLA/SLS/SLM 3D Printing Parts, Laser Cutting/Bending Sheet Metal Parts, Urethane Casting/Overmold Parts,…

Strategic Sourcing Conclusion and Outlook for precision prototype

In the ever-evolving landscape of precision prototyping, strategic sourcing emerges as a critical component for international B2B buyers seeking to enhance their competitive edge. By prioritizing collaboration with manufacturers who offer advanced technologies and a comprehensive suite of services—including CNC machining, laser cutting, and metal fabrication—businesses can ensure timely delivery of high-quality components tailored to their specific needs. This proactive approach not only reduces production costs but also minimizes time-to-market, allowing companies to respond swiftly to emerging trends and demands.

For buyers from regions such as Africa, South America, the Middle East, and Europe, the value of partnering with experienced manufacturers cannot be overstated. Leveraging local expertise and global best practices can result in innovative solutions that drive operational efficiency and product excellence. As you consider your sourcing strategies, focus on building relationships with manufacturers who are committed to quality and precision.

Looking ahead, the future of precision prototyping is bright, with advancements in technology promising even greater capabilities. Now is the time to act—engage with strategic partners who can help you navigate this landscape and achieve your production goals. Together, let’s redefine what’s possible in the realm of precision manufacturing.