Introduction: Navigating the Global Market for precision processing

In an increasingly interconnected world, sourcing precision processing services can pose a significant challenge for international B2B buyers. With diverse suppliers and varying standards across regions such as Africa, South America, the Middle East, and Europe—including emerging markets like Vietnam and Saudi Arabia—making informed decisions is crucial. Precision processing, encompassing techniques like precision machining, laser cutting, and ultraprecision manufacturing, requires a deep understanding of both the technology and the specific needs of your industry.

This comprehensive guide serves as an essential resource for navigating the complexities of the global precision processing market. It covers a wide array of topics, including the different types of precision processing available, their applications across various industries, and critical factors for supplier vetting. Additionally, we delve into cost considerations, providing insights that help you evaluate and compare options effectively.

By equipping you with the knowledge to identify reliable suppliers and understand the nuances of precision processing, this guide empowers B2B buyers to make informed purchasing decisions. Whether you are looking to enhance your product quality, reduce production costs, or accelerate time-to-market, understanding precision processing is key to achieving your business goals in today’s competitive landscape.

Understanding precision processing Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Precision Machining | High dimensional accuracy, typically within microns | Aerospace, automotive, medical devices | Pros: High precision, repeatability; Cons: Higher costs and longer lead times. |

| Ultraprecision Machining | Accuracy below 1 micron, specialized equipment required | Semiconductor manufacturing, optical lenses | Pros: Exceptional quality; Cons: Limited suppliers, higher investment. |

| Precision Laser Processing | Utilizes lasers for cutting and engraving; minimal waste | Electronics, automotive, medical components | Pros: Clean cuts, versatility; Cons: Initial setup costs can be high. |

| CNC Machining | Computer-controlled tools for consistent manufacturing | Prototyping, mass production | Pros: High efficiency, flexibility; Cons: Requires skilled operators. |

| Grinding and Lapping | Achieves fine surface finishes and tight tolerances | Tooling, aerospace components | Pros: Superior surface quality; Cons: Slower process, may require multiple steps. |

What Are the Characteristics of Precision Machining?

Precision machining is characterized by its ability to achieve high dimensional accuracy, typically within microns. This process is essential in industries such as aerospace, automotive, and medical devices, where the integrity of parts is critical. Buyers should consider the specific tolerances required for their applications, as well as the machining capabilities of potential suppliers. While precision machining can provide exceptional quality and repeatability, it often comes with higher costs and longer lead times, which may impact project timelines and budgets.

How Does Ultraprecision Machining Differ from Standard Precision Machining?

Ultraprecision machining is a specialized subset that achieves accuracy levels below 1 micron, making it ideal for manufacturing semiconductors and optical lenses. This type of processing requires advanced technology and expertise, which can limit the number of suppliers capable of meeting these stringent requirements. For B2B buyers, the investment in ultraprecision machining can lead to superior product quality and performance, but it necessitates careful consideration of supplier capabilities and potential costs.

What Are the Benefits of Precision Laser Processing?

Precision laser processing employs laser technology to cut and engrave materials with minimal waste. This method is particularly valuable in the electronics, automotive, and medical sectors, where precision and cleanliness are paramount. Buyers should weigh the advantages of clean cuts and versatility against the initial setup costs, which can be significant. Additionally, understanding the material compatibility and specific applications for laser processing is crucial for achieving desired outcomes.

Why Choose CNC Machining for Your Manufacturing Needs?

CNC (Computer Numerical Control) machining offers high efficiency and flexibility, making it suitable for both prototyping and mass production. This process utilizes computer-controlled tools to ensure consistent manufacturing, which is particularly advantageous for complex designs. Buyers should consider the skill level of operators, as skilled personnel are necessary to optimize the CNC machining process. While CNC machining can streamline production, it may require a higher initial investment in technology and training.

How Do Grinding and Lapping Enhance Surface Quality?

Grinding and lapping are techniques used to achieve fine surface finishes and tight tolerances in various applications, including tooling and aerospace components. These processes are essential for ensuring the functionality and performance of precision parts. B2B buyers should evaluate the specific requirements for surface quality and tolerances, as these processes can be slower and may involve multiple steps. Nonetheless, the superior surface quality achieved through grinding and lapping can significantly enhance product performance and longevity.

Key Industrial Applications of precision processing

| Industry/Sector | Specific Application of Precision Processing | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Manufacturing of engine components and transmission systems | Enhanced safety and reliability of aircraft operations | Certifications and compliance with aerospace standards |

| Medical Devices | Production of surgical instruments and implants | Improved patient outcomes and reduced surgical risks | Stringent quality control and biocompatibility testing |

| Automotive | Precision machining of engine parts and transmission systems | Increased performance and fuel efficiency of vehicles | Supplier reliability and capability for tight tolerances |

| Electronics | Fabrication of semiconductor components and circuit boards | Higher efficiency and performance of electronic devices | Advanced technology and expertise in micro-manufacturing |

| Oil & Gas | Precision drilling and component manufacturing | Enhanced operational efficiency and safety in extraction | Durability and resistance to extreme conditions |

How is Precision Processing Used in Aerospace Manufacturing?

In the aerospace industry, precision processing is crucial for the manufacturing of engine components and transmission systems. The stringent requirements for safety and performance necessitate components that meet exact specifications and tolerances. Precision machining ensures that parts fit perfectly, reducing the risk of mechanical failures. International buyers must consider certifications and compliance with aerospace standards, as these are vital for maintaining safety and reliability in flight operations.

What Role Does Precision Processing Play in Medical Devices?

Precision processing is integral to the production of surgical instruments and implants in the medical sector. This technology allows manufacturers to create complex geometries and fine details that are essential for effective medical procedures. By ensuring high dimensional accuracy and surface finish, precision processing contributes to better patient outcomes and minimized surgical risks. Buyers in this field should prioritize suppliers with stringent quality control processes and expertise in biocompatibility testing to meet regulatory standards.

How Does Precision Processing Enhance Automotive Performance?

In the automotive industry, precision machining is employed to create engine parts and transmission systems that enhance vehicle performance and fuel efficiency. The ability to manufacture components with tight tolerances leads to improved fit and function, which is critical for vehicle safety and reliability. International buyers should focus on sourcing suppliers with a proven track record in automotive manufacturing, ensuring that they can meet the necessary specifications and provide consistent quality.

Why is Precision Processing Important for Electronics Manufacturing?

Precision processing is essential for the fabrication of semiconductor components and circuit boards in the electronics sector. This technology enables the production of intricate designs that enhance the efficiency and performance of electronic devices. As the demand for smaller and more powerful electronics grows, buyers must seek suppliers with advanced technology and expertise in micro-manufacturing to stay competitive in this rapidly evolving market.

How Does Precision Processing Contribute to Oil & Gas Operations?

In the oil and gas industry, precision processing is utilized for precision drilling and the manufacturing of components that withstand extreme conditions. This ensures that equipment operates efficiently and safely during extraction processes. For international buyers, it is crucial to consider the durability and resistance of materials used in these applications, as well as the supplier’s ability to deliver consistent quality under demanding operational circumstances.

3 Common User Pain Points for ‘precision processing’ & Their Solutions

Scenario 1: Inconsistent Quality in Precision Machining

The Problem: B2B buyers often face the challenge of inconsistent quality in precision machined parts, which can lead to increased production costs and delayed timelines. This inconsistency may arise from variations in the machining process, the quality of the materials used, or insufficient quality control measures. When these issues occur, it can result in defective components that require rework or replacement, ultimately affecting the overall supply chain and customer satisfaction.

The Solution: To overcome this problem, it is crucial to partner with precision processing companies that have stringent quality assurance protocols in place. Buyers should conduct thorough due diligence when selecting a supplier, looking for certifications such as ISO 9001, which indicates a commitment to quality management systems. Additionally, implementing a robust quality control process that includes regular inspections and audits can help ensure that all parts meet the specified tolerances and surface finishes. Establishing clear communication with the supplier about quality expectations and tolerances can further mitigate risks associated with inconsistency.

Scenario 2: Difficulty in Achieving Tight Tolerances

The Problem: Many industries, particularly aerospace and medical, require components that adhere to extremely tight tolerances, often within microns. B2B buyers may struggle with suppliers who lack the necessary capabilities or technologies to achieve these precision levels. This limitation can lead to parts that do not meet regulatory standards or operational requirements, forcing companies to either accept subpar products or delay projects while searching for better options.

The Solution: Buyers should prioritize working with precision processing firms that specialize in high-precision machining techniques, such as CNC machining and wire EDM (Electrical Discharge Machining). These technologies are designed to achieve the tight tolerances required for critical applications. When sourcing suppliers, buyers should inquire about their experience with similar projects and request case studies or references that demonstrate successful outcomes. Additionally, engaging in early-stage design discussions can help identify potential challenges in achieving the desired tolerances and allow for adjustments in the design phase to facilitate manufacturability.

Scenario 3: High Production Costs with Low Volume Runs

The Problem: For businesses that require low-volume production runs of precision components, the cost can be prohibitively high. Traditional machining processes often favor high-volume production due to economies of scale, leading to inflated prices for smaller orders. This situation can be particularly challenging for startups or companies testing new products, where large quantities are not feasible.

The Solution: To address this issue, B2B buyers should consider leveraging advanced manufacturing techniques such as additive manufacturing (3D printing) or flexible machining services that cater specifically to low-volume needs. These methods can significantly reduce setup costs and waste, making precision parts more accessible for smaller orders. Additionally, buyers should discuss their specific requirements with suppliers to explore custom solutions, such as batch processing or the use of modular tooling, which can optimize production efficiency and reduce costs. Investing in prototyping services can also help refine designs before committing to larger production runs, ensuring that the final product meets specifications while minimizing financial risks.

Strategic Material Selection Guide for precision processing

What Are the Key Properties of Common Materials Used in Precision Processing?

When selecting materials for precision processing, it is essential to consider their properties that directly affect product performance. Below are analyses of four common materials used in the industry, focusing on their key properties, advantages, disadvantages, and implications for international B2B buyers.

1. Stainless Steel

Key Properties:

Stainless steel is known for its excellent corrosion resistance, high strength, and ability to withstand elevated temperatures. It typically has a temperature rating of up to 870°C (1600°F) and can endure high-pressure environments.

Pros & Cons:

The durability of stainless steel makes it suitable for various applications, including medical devices and automotive components. However, its cost can be higher than other materials, and its manufacturing complexity can increase due to the need for specialized machining techniques.

Impact on Application:

Stainless steel is compatible with a wide range of media, making it ideal for applications in food processing, pharmaceuticals, and chemical industries.

Considerations for International Buyers:

Buyers from regions like Africa and the Middle East should ensure compliance with international standards such as ASTM and DIN for stainless steel grades. Understanding local market preferences for specific grades can also influence procurement decisions.

2. Aluminum

Key Properties:

Aluminum is lightweight, has good corrosion resistance, and excellent thermal conductivity. It can withstand temperatures up to 660°C (1220°F) and is often used in applications requiring weight reduction.

Pros & Cons:

The primary advantage of aluminum is its low density, which is beneficial for applications in aerospace and automotive sectors. However, it may not be as strong as steel, and its lower melting point can limit its use in high-temperature environments.

Impact on Application:

Aluminum’s compatibility with various media makes it suitable for automotive parts and packaging materials, but caution is needed in applications involving strong acids or bases.

Considerations for International Buyers:

Buyers should be aware of the common standards such as JIS for aluminum grades and consider the availability of specific alloys in their local markets, especially in South America and Europe.

3. Titanium

Key Properties:

Titanium boasts a high strength-to-weight ratio, excellent corrosion resistance, and can withstand temperatures up to 1,600°C (2,912°F). Its biocompatibility makes it ideal for medical applications.

Pros & Cons:

While titanium is incredibly durable and suitable for high-performance applications, its high cost and complex machining requirements can be significant drawbacks.

Impact on Application:

Titanium is particularly effective in aerospace, medical, and marine applications due to its corrosion resistance and strength.

Considerations for International Buyers:

Buyers must consider the availability of titanium grades and compliance with international standards, particularly in regions like Europe where stringent regulations may apply.

4. Inconel

Key Properties:

Inconel is a family of nickel-chromium superalloys known for their ability to withstand extreme temperatures and corrosive environments. It can operate effectively at temperatures exceeding 1,000°C (1,832°F).

Pros & Cons:

The primary advantage of Inconel is its ability to maintain strength and oxidation resistance at high temperatures. However, it is one of the more expensive materials and can be challenging to machine.

Impact on Application:

Inconel is commonly used in aerospace, chemical processing, and nuclear applications where high performance is critical.

Considerations for International Buyers:

International buyers should be aware of the specific grades of Inconel that meet their application requirements and ensure compliance with relevant standards like ASTM.

Summary Table of Material Selection for Precision Processing

| Material | Typical Use Case for precision processing | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Medical devices, automotive components | Excellent corrosion resistance | Higher cost and manufacturing complexity | High |

| Aluminum | Aerospace parts, packaging materials | Lightweight and good thermal conductivity | Lower strength compared to steel | Medium |

| Titanium | Aerospace, medical implants | High strength-to-weight ratio | High cost and complex machining | High |

| Inconel | Aerospace, chemical processing | High performance in extreme environments | Expensive and challenging to machine | High |

This guide provides a comprehensive overview of material selection for precision processing, enabling international B2B buyers to make informed decisions based on their specific application needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for precision processing

What Are the Key Stages in the Manufacturing Process of Precision Processing?

Precision processing involves a series of meticulously coordinated manufacturing stages that ensure high-quality outputs. The main stages typically include material preparation, forming, assembly, and finishing. Each stage incorporates specific techniques and equipment designed to achieve tight tolerances and superior surface finishes.

Material Preparation

The first step in the manufacturing process is material preparation, which involves selecting the right raw materials that meet the specifications for the final product. This may include metals, plastics, or composite materials, which are often subjected to preliminary treatments like annealing or surface hardening to enhance their properties. Advanced techniques such as laser cutting or water jet cutting may also be used to shape raw materials into manageable pieces before further processing.

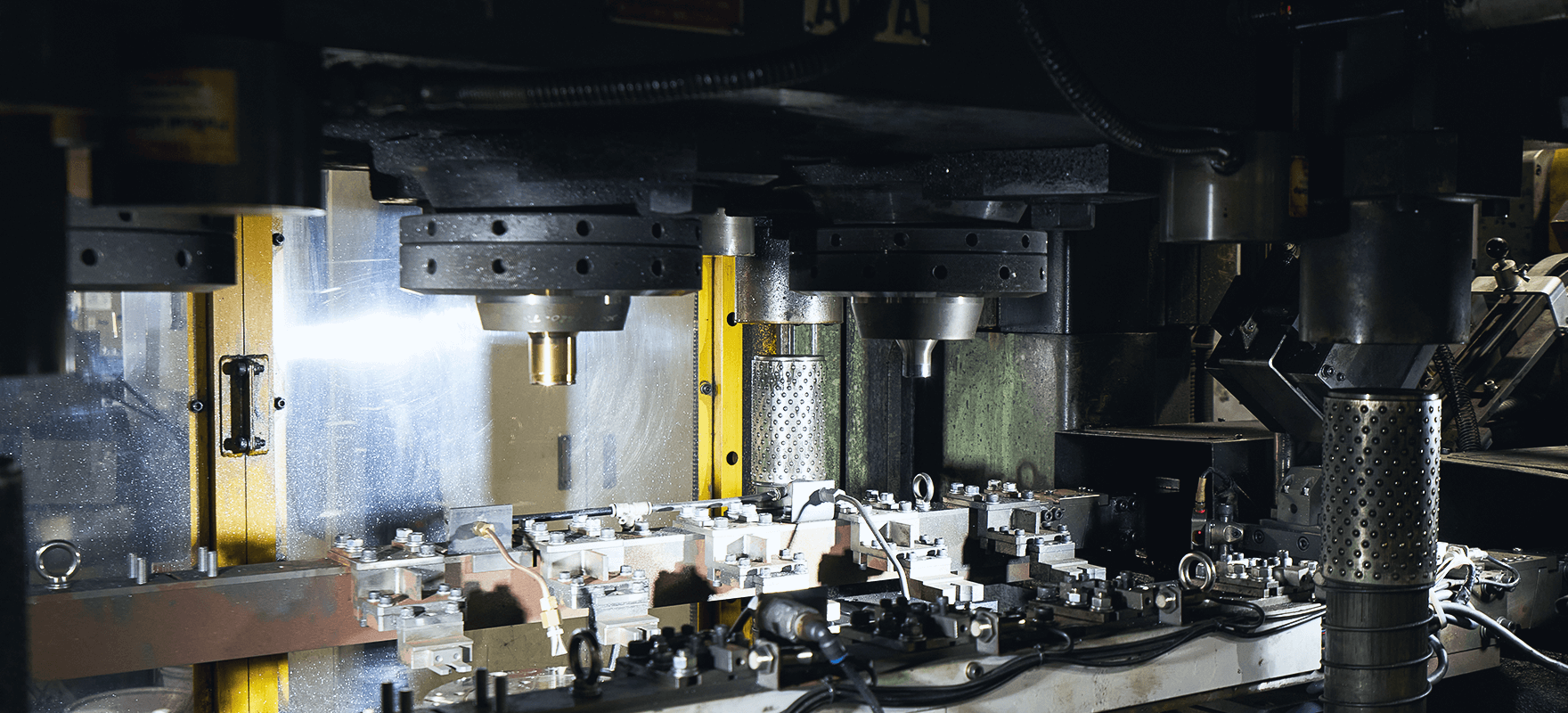

Forming

The forming stage involves converting the prepared materials into desired shapes through processes like machining, casting, or molding. Precision machining techniques—such as CNC turning, milling, and grinding—are commonly employed to achieve dimensional accuracy within microns. For complex geometries, techniques like wire EDM (Electrical Discharge Machining) may be utilized, allowing for intricate designs that would be difficult to achieve through traditional machining.

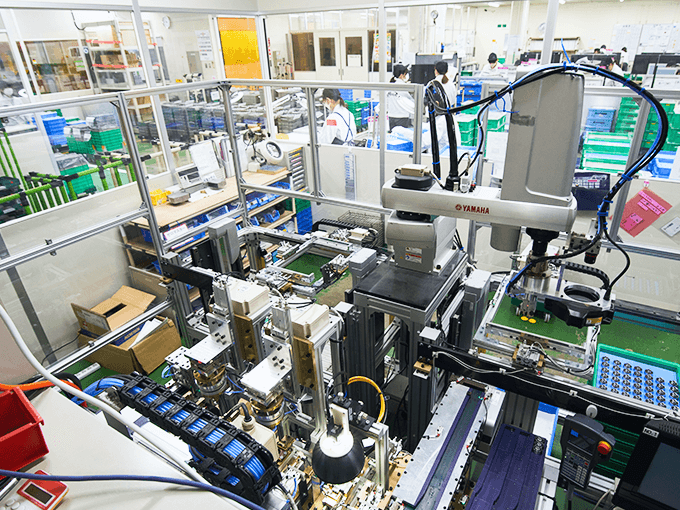

Assembly

Once components are formed, the assembly stage begins. This involves fitting together various parts into a final product. Precision assembly often requires specialized tools and techniques, such as automated assembly lines or robotic systems, to ensure consistent quality and efficiency. The assembly process may also include the application of adhesives or fasteners that are rigorously tested to meet the required strength and durability standards.

Finishing

The finishing stage enhances the product’s surface quality and prepares it for final inspection. Techniques such as polishing, lapping, and coating are commonly used to achieve the desired surface finish and protect against environmental factors. This stage is crucial for industries like aerospace and medical devices, where surface integrity is paramount.

How Is Quality Assurance Implemented in Precision Processing?

Quality assurance in precision processing is essential to ensure that products meet stringent industry standards and customer expectations. Implementing a robust quality control (QC) system involves adhering to international standards, performing regular inspections, and utilizing effective testing methods.

What International Standards Should B2B Buyers Look For?

International standards such as ISO 9001 provide a framework for quality management systems that can be applied across various industries. Compliance with these standards signifies that a manufacturer has established processes for quality assurance, thereby reducing risks associated with product defects. Additionally, industry-specific certifications, such as CE marking for European markets or API standards for oil and gas, are critical indicators of a supplier’s commitment to quality.

What Are the Key Quality Control Checkpoints?

Quality control checkpoints are integral to the manufacturing process. Typically, these include:

- Incoming Quality Control (IQC): This step involves inspecting raw materials and components upon receipt to ensure they meet specified criteria before production begins.

- In-Process Quality Control (IPQC): Regular inspections during the manufacturing stages help identify defects early and prevent defective products from progressing further in the production cycle.

- Final Quality Control (FQC): The final inspection ensures that the completed products conform to specifications before they are shipped to customers.

What Common Testing Methods Are Utilized?

Various testing methods are employed to assess product quality, including dimensional inspections, non-destructive testing (NDT), and functional tests. Advanced techniques such as coordinate measuring machines (CMM) can provide precise measurements of critical dimensions, while NDT methods like ultrasonic or X-ray testing help identify internal defects without damaging the products.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, especially those operating in international markets, verifying a supplier’s quality control processes is crucial for mitigating risks and ensuring product reliability.

What Steps Can Buyers Take to Ensure Quality?

1. Supplier Audits: Conducting regular audits of potential suppliers can provide insights into their manufacturing processes and quality control systems. This can be done on-site or through third-party auditing firms that specialize in quality assurance.

-

Requesting Quality Reports: Buyers should ask suppliers for quality assurance reports that detail their QC processes, inspection results, and any corrective actions taken for non-conformance issues. These documents serve as evidence of the supplier’s commitment to quality.

-

Third-Party Inspections: Engaging third-party inspection services can offer an impartial assessment of the supplier’s quality control measures. These services can perform random inspections during production or before shipment, providing an additional layer of assurance.

What Are the Quality Control Nuances for International B2B Buyers?

When sourcing from international suppliers, B2B buyers must navigate various quality control nuances that can impact product quality and compliance. Cultural differences, language barriers, and varying industry standards can complicate the procurement process.

Understanding Regional Standards

It’s essential for buyers from Africa, South America, the Middle East, and Europe to be aware of the specific quality standards that apply within their regions. For example, European buyers may prioritize CE certification, while buyers in the Middle East might focus on compliance with local regulations. Understanding these nuances can help buyers set appropriate expectations for quality and compliance.

Building Strong Supplier Relationships

Establishing strong relationships with suppliers can facilitate better communication regarding quality control processes. Regular discussions about quality expectations, shared challenges, and collaborative problem-solving can foster a culture of quality that benefits both parties.

In summary, precision processing involves complex manufacturing stages and stringent quality assurance practices that are critical for producing high-quality products. By understanding these processes, B2B buyers can make informed decisions and establish strong partnerships with suppliers, ensuring that their needs for precision and reliability are met.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘precision processing’

Introduction

In the competitive landscape of precision processing, selecting the right supplier can significantly impact your product quality and operational efficiency. This checklist provides a structured approach for B2B buyers to source precision processing services effectively, ensuring that all critical factors are considered to make an informed decision.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the foundation of successful sourcing. Detail the dimensions, tolerances, materials, and surface finishes required for your components. This clarity will facilitate accurate quotes from potential suppliers and ensure they have the capabilities to meet your needs.

- Consider using industry standards for precision tolerances relevant to your sector.

- Specify any unique processing requirements, such as the need for laser cutting or CNC machining.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers that specialize in precision processing. Look for companies with a strong reputation in the industry, as well as those that have experience with your specific materials and applications.

- Utilize industry directories and trade associations to compile a list of candidates.

- Leverage online reviews and testimonials to gauge past performance and reliability.

Step 3: Evaluate Supplier Capabilities

Before committing to a supplier, assess their technical capabilities. Ensure they can handle the specific requirements of your project and have the necessary equipment for precision machining.

- Request detailed information about their machinery and technology used in the processing.

- Inquire about their experience with similar projects to validate their expertise.

Step 4: Verify Certifications and Compliance

Confirm that potential suppliers hold relevant certifications and adhere to industry standards. This step is critical for ensuring quality control and regulatory compliance.

- Look for certifications such as ISO 9001 or specific industry-related accreditations.

- Ask about their quality assurance processes and how they maintain compliance with safety regulations.

Step 5: Request Samples and Prototypes

Before making a final decision, request samples or prototypes of your components. This allows you to evaluate the quality of their work firsthand and assess their attention to detail.

- Clearly communicate your specifications for the sample to ensure it meets your requirements.

- Analyze the sample for dimensional accuracy, surface finish, and overall quality.

Step 6: Discuss Pricing and Terms

Engage in discussions about pricing, payment terms, and lead times. Understanding the total cost of ownership, including shipping and potential tariffs, is essential for budgeting.

- Compare quotes from multiple suppliers to gauge market pricing.

- Ensure that all terms are clearly laid out in a written agreement to avoid misunderstandings later.

Step 7: Establish Communication Protocols

Effective communication is vital for a successful partnership. Set clear expectations for communication frequency and channels to ensure that any issues are addressed promptly.

- Specify preferred methods of communication (email, phone, etc.) and response times.

- Establish a point of contact within both organizations to streamline communication.

By following this checklist, B2B buyers can enhance their sourcing process for precision processing, leading to better quality products and stronger supplier relationships.

Comprehensive Cost and Pricing Analysis for precision processing Sourcing

What Are the Key Cost Components in Precision Processing Sourcing?

Understanding the cost structure of precision processing is crucial for international B2B buyers. The primary components of costs in this sector include:

-

Materials: The choice of materials significantly influences pricing. High-quality metals, such as titanium or Inconel, are more expensive than standard aluminum or plastics. Additionally, sourcing materials from different regions can impact costs due to local availability and market fluctuations.

-

Labor: Skilled labor is essential for precision machining, as it requires a deep understanding of complex processes and machinery. Labor costs vary by region; for instance, labor may be more affordable in some South American countries compared to Europe, but this can be offset by the need for specialized training and expertise.

-

Manufacturing Overhead: This includes the costs of maintaining machinery, utilities, and facility expenses. In precision processing, where high-tech equipment is used, overhead can be substantial. Buyers should inquire about how these costs are allocated in quotes.

-

Tooling: Tooling costs can vary widely depending on the complexity of the parts being produced. Custom tooling for unique specifications often requires significant upfront investment, which can be amortized over high-volume orders.

-

Quality Control (QC): Rigorous QC processes are vital in precision processing to ensure that parts meet stringent specifications. This may involve additional testing and certification, which can add to the overall cost.

-

Logistics: Shipping costs can fluctuate based on the distance from the supplier, the size and weight of the products, and the chosen shipping method. Incoterms also play a crucial role in determining who bears the costs and responsibilities of transportation.

-

Margin: Suppliers will include a profit margin in their pricing. Understanding the industry standards for margins can help buyers negotiate better terms.

How Do Price Influencers Impact Precision Processing Costs?

Several factors can influence the pricing of precision processing services:

-

Volume/MOQ: Ordering in larger quantities typically reduces the per-unit cost due to economies of scale. Buyers should consider their minimum order quantities (MOQ) and aim to consolidate orders when possible.

-

Specifications and Customization: Custom parts require additional design and engineering work, leading to higher costs. Standardized parts can be produced more efficiently, reducing overall expenses.

-

Materials: The choice of materials not only affects the base cost but also impacts machining time and wear on tools. Buyers should weigh the cost against performance requirements.

-

Quality and Certifications: Parts that require higher levels of certification (e.g., ISO standards) will incur additional costs due to the rigorous testing and documentation needed.

-

Supplier Factors: The reputation, reliability, and location of suppliers can influence pricing. Established suppliers may charge more but can often provide assurance of quality and timely delivery.

-

Incoterms: Understanding Incoterms is essential for B2B buyers, as they dictate who is responsible for shipping, insurance, and tariffs, which can significantly affect the total cost.

What Are the Best Negotiation Tips for International B2B Buyers?

-

Leverage Volume Discounts: When possible, consolidate orders to negotiate better pricing based on volume.

-

Assess Total Cost of Ownership (TCO): Consider not only the purchase price but also logistics, maintenance, and potential downtime when evaluating suppliers.

-

Understand Pricing Nuances: Be aware of how currency fluctuations, geopolitical factors, and local market conditions can affect pricing, especially in regions like Africa, South America, and the Middle East.

-

Build Relationships: Developing strong relationships with suppliers can lead to better terms and more favorable pricing over time.

-

Request Transparent Quotes: Ask suppliers for detailed quotes that break down costs. This clarity can help identify areas for negotiation and improve cost-efficiency.

Disclaimer on Indicative Prices

Pricing in precision processing can fluctuate due to various factors, including market demand, material availability, and economic conditions. Therefore, it is advisable for buyers to conduct thorough market research and seek multiple quotes to obtain an accurate understanding of current pricing trends.

Alternatives Analysis: Comparing precision processing With Other Solutions

Understanding Alternative Solutions to Precision Processing

When evaluating manufacturing and processing methods, it is essential to explore various alternatives to precision processing. Each solution offers unique benefits and challenges that can significantly impact a business’s operational efficiency, product quality, and overall costs. Below, we compare precision processing with two prominent alternatives: traditional machining and additive manufacturing.

Comparison Table

| Comparison Aspect | Precision Processing | Traditional Machining | Additive Manufacturing |

|---|---|---|---|

| Performance | High accuracy (microns) | Moderate accuracy; depends on the technique used | Variable accuracy; often lower than precision processing |

| Cost | Higher initial investment, lower long-term costs due to efficiency | Lower initial costs, but longer production times | Moderate initial costs, variable material costs |

| Ease of Implementation | Requires specialized equipment and training | Widely understood, easier to implement | Requires specific software and skilled operators |

| Maintenance | High maintenance due to advanced machinery | Moderate maintenance, dependent on equipment age | Generally low maintenance; technology is evolving |

| Best Use Case | Complex parts requiring tight tolerances | High-volume production of simpler parts | Custom parts, prototypes, and complex geometries |

Detailed Breakdown of Alternatives

Traditional Machining: What Are Its Advantages and Disadvantages?

Traditional machining encompasses various processes, including turning, milling, and drilling. This method is well-established, making it easier for companies to find skilled labor and implement the technology. While it has a lower initial cost, its performance can be inconsistent, particularly with complex designs that require high precision. Additionally, traditional machining often involves longer lead times and greater waste, which can negate some cost advantages in high-volume production scenarios.

Additive Manufacturing: Is It the Future of Production?

Additive manufacturing (3D printing) is an innovative approach that builds parts layer by layer. It offers the flexibility to create complex geometries that would be difficult or impossible with traditional methods. This technology allows for rapid prototyping, reducing time to market. However, the accuracy of additive manufacturing may not match that of precision processing, particularly for applications requiring tight tolerances. Material costs can also vary widely, and businesses need to invest in software and training to fully leverage this technology.

Conclusion: How to Choose the Right Solution for Your Needs

Selecting the appropriate processing solution hinges on a variety of factors including the specific requirements of your project, budget constraints, and long-term operational goals. Precision processing stands out for its accuracy and efficiency, making it ideal for industries demanding high-quality standards, such as aerospace and medical devices. On the other hand, traditional machining may be suitable for simpler, high-volume applications, while additive manufacturing excels in customization and rapid prototyping. B2B buyers should thoroughly assess their unique needs and long-term objectives to make an informed decision that aligns with their operational strategy.

Essential Technical Properties and Trade Terminology for precision processing

What Are the Key Technical Properties of Precision Processing?

In precision processing, several critical specifications define the quality and suitability of the manufactured parts. Understanding these properties is essential for B2B buyers to ensure that their products meet industry standards and performance requirements.

1. Material Grade

Material grade refers to the specific classification of materials based on their properties and intended use. In precision processing, common materials include stainless steel, aluminum, titanium, and various alloys. The choice of material grade directly impacts the part’s durability, weight, and resistance to corrosion, making it crucial for industries like aerospace, automotive, and medical devices. Selecting the appropriate material grade ensures that the final product meets functional and regulatory requirements.

2. Tolerance

Tolerance is the permissible limit or limits of variation in a physical dimension. In precision processing, tight tolerances (measured in microns) are often required to ensure that components fit together correctly and function as intended. Tighter tolerances generally lead to higher production costs, so understanding the necessary tolerance levels is vital for balancing quality and cost-effectiveness.

3. Surface Finish

Surface finish refers to the texture of a surface after machining. It is crucial for parts that require minimal friction, such as those in engines or medical devices. Different finishing techniques, like polishing or grinding, can achieve varying levels of smoothness. A proper surface finish not only improves performance but also affects the aesthetic quality of the product, which can be a significant factor in consumer markets.

4. Dimensional Accuracy

Dimensional accuracy refers to how closely a manufactured part matches its intended dimensions. Precision processing aims for high dimensional accuracy, often within a few microns. This property is critical for components that must fit precisely in assemblies, especially in high-stakes industries such as aerospace and healthcare. High dimensional accuracy reduces the risk of assembly failures and enhances overall product reliability.

5. Hardness

Hardness measures a material’s resistance to deformation, typically assessed through various testing methods. In precision processing, hardness is essential for components subjected to wear and tear, such as gears and cutting tools. Selecting materials with the appropriate hardness ensures longevity and performance under operational stresses.

What Are Common Trade Terms in Precision Processing?

Familiarity with industry jargon can significantly enhance communication and negotiation between B2B buyers and suppliers. Here are some common terms used in precision processing:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In precision processing, OEMs often rely on precision processors to create components that meet strict specifications. Understanding OEM dynamics helps buyers identify potential suppliers and streamline their supply chain.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. In precision processing, MOQs can affect the cost and feasibility of production runs. Buyers should be aware of MOQs to plan their purchasing strategies effectively, ensuring that they don’t overcommit to quantities they cannot use.

3. RFQ (Request for Quotation)

An RFQ is a document used by buyers to solicit price offers from suppliers for specific products or services. In precision processing, an RFQ helps buyers obtain competitive pricing and understand the capabilities of different manufacturers. A well-prepared RFQ can lead to better negotiations and cost savings.

4. Incoterms (International Commercial Terms)

Incoterms are a set of rules that define the responsibilities of buyers and sellers in international transactions. Understanding these terms is crucial for B2B buyers engaged in global sourcing, as they clarify who is responsible for shipping, insurance, and tariffs. Proper use of Incoterms helps avoid misunderstandings and ensures smoother transactions.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions in the precision processing landscape, ultimately leading to better product quality and successful partnerships.

Navigating Market Dynamics and Sourcing Trends in the precision processing Sector

What Are the Current Market Dynamics and Key Trends in Precision Processing?

The precision processing sector is experiencing significant growth, driven by the global demand for high-quality, accurate manufacturing processes across various industries. Key drivers include the increasing complexity of products, particularly in aerospace, automotive, and medical sectors, which require tighter tolerances and superior surface finishes. As international B2B buyers, especially from Africa, South America, the Middle East, and Europe, navigate this landscape, they must remain aware of emerging technologies, such as additive manufacturing, automation, and advanced materials, that are reshaping sourcing strategies.

Emerging trends indicate a shift towards digital transformation in precision processing. Technologies like IoT (Internet of Things) and AI (Artificial Intelligence) are enhancing operational efficiencies, enabling predictive maintenance, and optimizing supply chain management. Companies are increasingly leveraging data analytics to streamline processes and improve decision-making. Furthermore, the integration of Industry 4.0 practices is becoming essential, allowing manufacturers to maintain competitiveness through real-time monitoring and agile production methods.

For international buyers, understanding regional market dynamics is crucial. Variations in manufacturing capabilities, labor costs, and regulatory environments across different regions can significantly impact sourcing decisions. For example, while countries like Vietnam offer cost-effective manufacturing solutions, the Middle East and Europe may provide advanced technology and skilled labor, albeit at a higher price point. A tailored approach that considers local market conditions will be key to successful sourcing in this evolving landscape.

How Important Is Sustainability and Ethical Sourcing in the Precision Processing Sector?

Sustainability is increasingly at the forefront of B2B sourcing strategies, with a growing emphasis on minimizing environmental impact and promoting ethical supply chains. In the precision processing sector, the manufacturing processes often consume significant resources and generate waste. As international buyers become more environmentally conscious, they are seeking partners who prioritize sustainable practices. This shift is not only a response to consumer demand but also a regulatory requirement in many regions.

Ethical sourcing involves ensuring that materials are obtained responsibly, with a focus on fair labor practices and minimal environmental degradation. Certifications such as ISO 14001 for environmental management systems and ISO 45001 for occupational health and safety are becoming essential for suppliers aiming to demonstrate their commitment to sustainability. Furthermore, the use of ‘green’ materials—those that are recyclable, biodegradable, or derived from sustainable sources—is gaining traction among precision processing companies.

Investing in sustainable practices can yield long-term cost savings and improve brand reputation. Buyers who prioritize sustainability will likely find that their suppliers are more innovative and resilient, capable of adapting to regulatory changes and market demands while maintaining high-quality standards.

What Is the Brief Evolution of Precision Processing in the B2B Context?

The precision processing sector has evolved significantly over the past few decades, transitioning from traditional machining methods to sophisticated, high-tech solutions. Initially, precision machining focused on basic operations like turning and milling. However, as technology advanced, the introduction of CNC (Computer Numerical Control) machines allowed for greater accuracy and repeatability, revolutionizing the industry.

In recent years, the advent of advanced materials and processes, such as laser cutting and 3D printing, has further transformed precision processing. These innovations enable manufacturers to create complex geometries and achieve tight tolerances that were previously unattainable. Today, precision processing is not only about accuracy but also about efficiency and sustainability, making it a critical component of modern manufacturing strategies for B2B buyers globally.

As this sector continues to evolve, staying informed about technological advancements and market trends will be crucial for businesses looking to leverage precision processing to enhance their competitive advantage.

Frequently Asked Questions (FAQs) for B2B Buyers of precision processing

-

How do I evaluate the quality of precision processing suppliers?

To evaluate the quality of precision processing suppliers, consider their certifications, such as ISO 9001, which indicate adherence to international quality management standards. Request samples of their work to assess precision and surface finish. Additionally, inquire about their quality control processes, including inspection protocols and machinery maintenance. It’s also wise to check client testimonials and case studies to gauge reliability and performance. Engaging in a trial project can provide firsthand experience with their capabilities before committing to larger orders. -

What are the common applications of precision processing in various industries?

Precision processing is widely utilized in industries such as aerospace, automotive, medical devices, and electronics. In aerospace, it ensures the production of lightweight, high-strength components critical for safety and performance. The automotive sector relies on precision machining for engine parts and transmission systems. Medical devices require stringent tolerances and surface finishes for safety and functionality. In electronics, precision processing is essential for creating intricate parts like circuit boards and semiconductor components, demonstrating its versatility across diverse applications. -

What customization options are typically available for precision processing services?

Most precision processing suppliers offer customization options to meet specific project requirements. This may include tailored machining processes such as CNC milling, turning, or electrical discharge machining (EDM). Buyers can request modifications in dimensions, tolerances, materials, and finishes. It’s essential to communicate your specifications clearly during the initial discussions. Many suppliers also provide design support to optimize your product for manufacturability, ensuring that the end product aligns with your expectations and operational needs. -

What are the typical minimum order quantities (MOQs) for precision processing?

Minimum order quantities (MOQs) for precision processing can vary significantly based on the supplier and the complexity of the parts. Generally, MOQs may range from a few pieces for simple components to hundreds or thousands for more complex machined parts. Discussing your needs with potential suppliers can help negotiate MOQs that align with your project requirements. Smaller companies may offer lower MOQs, while larger suppliers might require higher volumes to justify setup and production costs. -

What payment terms are common in international precision processing contracts?

Payment terms in international precision processing contracts typically include options like upfront deposits, milestone payments, and net payment terms (e.g., net 30 or net 60 days). It’s advisable to establish clear payment schedules in your contract to mitigate risks. Some suppliers may offer payment through letters of credit, which provide an additional layer of security for both parties. Always clarify payment terms before finalizing contracts to avoid misunderstandings and ensure a smooth transaction process. -

How do logistics and shipping impact precision processing projects?

Logistics and shipping are critical aspects of precision processing projects, especially in international trade. They can affect lead times, costs, and the overall success of your supply chain. Ensure that your supplier has a reliable logistics partner to manage shipping efficiently. Consider factors like shipping methods, customs clearance, and import/export regulations in your country. Discussing these logistics in advance can help mitigate delays and ensure that your precision components arrive on time and in perfect condition. -

What quality assurance (QA) measures should I expect from suppliers?

Reputable precision processing suppliers implement rigorous quality assurance (QA) measures to ensure that products meet specified tolerances and standards. Expect suppliers to conduct various tests, including dimensional inspections, surface roughness evaluations, and material verification. Many suppliers use advanced technologies like coordinate measuring machines (CMM) for precise measurements. Additionally, inquire about their compliance with industry standards and any certifications they hold, which can provide further assurance of their commitment to quality. -

How can I ensure effective communication with my precision processing supplier?

Effective communication with your precision processing supplier is vital for project success. Establish clear channels of communication, such as dedicated email contacts or project management tools, to facilitate ongoing dialogue. Discuss project timelines, expectations, and any potential challenges upfront to foster transparency. Regular updates on project progress and addressing concerns promptly can help maintain a strong working relationship. Consider scheduling periodic check-ins or reviews to ensure alignment throughout the project lifecycle.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 Precision Processing Manufacturers & Suppliers List

1. Precision Process – Electroplating & Chemical Processing Equipment

Domain: precisionprocess.com

Registered: 1998 (27 years)

Introduction: Precision Process is a full-service manufacturer of electroplating and chemical processing equipment, established in 1996. Key products include:

– Rack and Barrel Plating

– Reel-to-Reel Plating

– Wire Rod, Tube, and Conduit

– Material Handling Equipment (Accumulators, Payoffs, Take-ups, Edge Guiders, WTI Web Guides)

– Plating Accessories (Automatic Chemical Replenishment, Automatic Rectifier …

2. Precision Processing – Deer Processing Services

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: Precision Processing is a deer processing service located in Russellville, AL. The page has 719 likes and 909 followers, and it falls under the sport and recreation category. It currently has not been rated, with only one review available.

3. Precision Processing Co – Contract Processing Services

Domain: precisionprocessingco.com

Registered: 2024 (1 years)

Introduction: Precision Processing Co offers contract processing services for the mortgage industry. Their services include working with lenders on loan approvals, collecting conditions, and coordinating closings. They operate on a no-win, no-fee basis, meaning they only get paid if the loan closes. The team consists of experienced professionals, including Lauren Love, Co-Founder and Senior Processor, and Brook…

4. Nikon – Precision Machining Solutions

Domain: ngpd.nikon.com

Registered: 1993 (32 years)

Introduction: Precise processing, also known as precision machining, achieves higher dimensional accuracy and surface roughness than general lathes and presses. It typically involves machining to an accuracy of several microns (1 micron = 1/1000 mm) to several tens of microns, while ultraprecise processing achieves accuracy of less than 1 micron. Techniques include laser cutting, lapping, polishing, and honing,…

5. Novanta Photonics – Precision Laser Processing Solutions

Domain: novantaphotonics.com

Registered: 2020 (5 years)

Introduction: Precision Laser Processing solutions by Novanta Photonics offer micron-level accuracy, high repeatability, and versatility for various applications. Key features include:

– Fast and reliable processing with extreme precision, consistency, and quality.

– Non-contact method of processing sensitive materials with no tool wear or replacement, ensuring consistent results over time.

– Applications in…

6. LinkedIn – Dedicated API

Domain: linkedin.com

Registered: 2002 (23 years)

Introduction: To scrape Linkedin use our dedicated Linkedin API.

7. Precision Process & Control – Automation & Process Design Solutions

Domain: precisionprocessandcontrol.com

Registered: 2022 (3 years)

Introduction: Precision Process & Control specializes in process design, project management, and automation services primarily within the Dairy and Food & Beverage sectors. Key offerings include:

– Custom Process Design

– Automation & Controls

– Panel Design & Build

– Control and Automation System Design

– High Voltage and Low Voltage Control Panel Design

– Process Design and Optimization

– Project Engineering …

Strategic Sourcing Conclusion and Outlook for precision processing

What Are the Key Insights for B2B Buyers in Precision Processing?

In navigating the landscape of precision processing, strategic sourcing emerges as a vital lever for B2B buyers seeking to enhance operational efficiency and product quality. The ability to partner with specialized processors not only allows companies to focus on their core competencies but also drives innovation and responsiveness in a competitive marketplace. With advanced techniques such as precision machining and laser processing, businesses can achieve unparalleled accuracy, meeting the stringent demands of industries like aerospace, automotive, and medical manufacturing.

How Can International Buyers Leverage Global Partnerships?

For international buyers, particularly from regions like Africa, South America, the Middle East, and Europe, the time is ripe to explore global partnerships. Engaging with reputable precision processing firms can unlock access to cutting-edge technology and expertise, fostering growth and ensuring compliance with international standards. As markets evolve, staying ahead requires adaptability and a proactive approach in sourcing strategies.

What’s Next for Your Precision Processing Strategy?

In conclusion, the future of precision processing lies in strategic collaboration and continuous innovation. By embracing these principles, B2B buyers can not only enhance their supply chains but also position themselves as leaders in their respective markets. Now is the moment to reach out, explore potential partnerships, and invest in the technologies that will drive your business forward.