Contents

Manufacturing Insight: Precision Plastic Machining

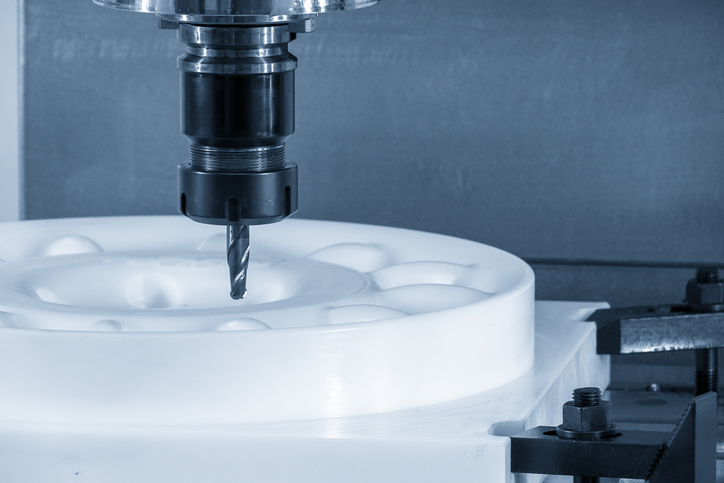

Precision Plastic Machining for Demanding Applications

At Honyo Prototype, we specialize in high-accuracy CNC machining of engineering-grade plastics where micron-level tolerances and material integrity are non-negotiable. Our advanced 3-, 4-, and 5-axis milling and turning centers consistently achieve ±0.005 mm tolerances across complex geometries, critical for aerospace seals, medical implants, and semiconductor components. Unlike commodity plastic fabricators, we leverage proprietary toolpath strategies and in-process metrology to mitigate thermal deformation and internal stress in materials like PEEK, PPSU, Ultem, and PTFE—ensuring dimensional stability under operational loads.

Material science drives our process design. Each plastic grade undergoes rigorous thermal and mechanical analysis to optimize cutting parameters, coolant application, and fixturing. This eliminates common pitfalls such as burring in acetal, warpage in polycarbonate, or crystallinity shifts in nylon—delivering parts that meet ISO 2768-mK standards without secondary stress-relief steps. Our AS9100-certified workflow includes first-article inspection reports with GD&T validation, providing full traceability from raw bar stock to finished component.

Accelerate your development cycle with Honyo’s Online Instant Quote platform. Upload your STEP or Parasolid file to receive a detailed manufacturability assessment and competitive pricing within 2 hours—not days. The system automatically flags potential issues like thin-wall deflection or non-optimal draft angles, enabling rapid design iteration. For urgent prototyping needs, our 72-hour turnaround service maintains the same uncompromising quality standards, turning concepts into test-ready hardware faster than traditional supply chains. Partner with Honyo to transform precision plastic requirements into validated, production-ready solutions.

Technical Capabilities

Precision plastic machining involves the use of advanced CNC equipment to produce complex, high-accuracy components from both engineering plastics and metals. At Honyo Prototype, our 3, 4, and 5-axis milling and turning capabilities enable tight tolerance machining across a wide range of materials including aluminum, steel, ABS, and nylon. These processes are ideal for prototyping and low-to-mid volume production where dimensional accuracy, surface finish, and repeatability are critical.

Our multi-axis systems allow for complex geometries to be machined in a single setup, minimizing part handling and ensuring superior feature alignment. Tight tolerances down to ±0.005 mm (±0.0002″) are routinely achieved, depending on part geometry and material characteristics.

| Parameter | Specification |

|---|---|

| Machining Types | 3-Axis, 4-Axis, and 5-Axis CNC Milling; CNC Turning (including multi-spindle) |

| Positioning Accuracy | ±0.005 mm (±0.0002″) |

| Repeatability | ±0.002 mm (±0.0001″) |

| Typical Surface Finish | Ra 0.8–3.2 µm (32–125 µin), adjustable per requirement |

| Maximum Work Envelope | Milling: 1000 x 600 x 500 mm; Turning: Ø300 mm x 500 mm |

| Spindle Speed (Milling) | Up to 24,000 RPM |

| Spindle Speed (Turning) | Up to 6,000 RPM |

| Tool Changer Capacity | Up to 30 tools (automatic) |

| Materials – Metals | Aluminum (6061, 7075), Steel (1018, 4140, Stainless 303, 316) |

| Materials – Plastics | ABS, Nylon (PA6, PA66), Acetal (POM), PC, PEEK, PMMA, PVC |

| Moisture-Sensitive Handling | Controlled drying and storage for hygroscopic materials (e.g., Nylon, PEEK) |

| In-Process Metrology | On-machine probing and CMM verification available |

| Secondary Operations | Deburring, polishing, anodizing (Al), passivation (SS), threading, engraving |

All machining operations are supported by CAD/CAM programming and first-article inspection reports (FAIR) to ensure compliance with engineering drawings and GD&T requirements. This level of control is essential when machining plastics, which have higher thermal expansion and lower stiffness compared to metals, requiring optimized cutting parameters and fixturing strategies.

From CAD to Part: The Process

Honyo Prototype Precision Plastic Machining Process Overview

Honyo Prototype executes precision plastic machining through a rigorously controlled five-stage workflow designed to minimize risk, accelerate time-to-part, and ensure first-article compliance. This closed-loop process integrates digital engineering with hands-on manufacturing expertise, specifically optimized for low-volume, high-complexity plastic components requiring tight tolerances (±0.005mm) and material-specific handling.

CAD Upload & AI Quoting Engine

Clients initiate the process by uploading native or neutral CAD files (STEP, IGES, Parasolid) via our secure customer portal. Our proprietary AI quoting engine immediately performs preliminary geometric analysis against a database of 15,000+ validated plastic material properties and 200+ machine parameters. The system generates a preliminary quote within 2 business hours, including material cost breakdown, machine time estimation, and critical feature risk flags. Unlike industry-standard quoting tools, our AI cross-references historical production data from similar geometries to predict manufacturability challenges before formal quoting.

Integrated DFM Analysis

Following quote acceptance, our engineering team conducts a mandatory Design for Manufacturability review. This phase occurs concurrently with work order release to avoid sequential delays. Engineers evaluate wall thickness uniformity, draft angles, undercuts, and stress concentration points against material-specific behaviors (e.g., creep in polycarbonate, moisture absorption in nylon). We provide actionable feedback within 24 hours via annotated PDF reports with tolerance stack-up simulations. Crucially, DFM adjustments are validated against the original AI quote parameters to maintain cost and timeline integrity. Clients receive direct access to the assigned manufacturing engineer for real-time collaboration on design iterations.

Production Execution

Approved designs move to climate-controlled machining cells staffed by technicians certified in precision plastic handling. Key production protocols include:

Material preconditioning per ASTM D618 (temperature/humidity stabilization)

Dedicated tooling for plastics (sharp carbide inserts, high rake angles)

In-process CMM verification at critical feature checkpoints

Chip evacuation optimization to prevent recutting and thermal distortion

All operations occur on CNC milling/turning centers with 0.001mm positional accuracy, utilizing coolant-free machining or minimal mist lubrication to avoid material swelling. Process parameters are locked in our MES system to ensure repeatability across batches.

Material-Specific Process Parameters

The table below outlines critical machining variables for common engineering plastics:

| Material | Max Spindle Speed (RPM) | Feed Rate (mm/min) | Clamping Pressure (MPa) | Critical Risk Mitigation |

|---|---|---|---|---|

| PEEK | 8,000 | 250 | ≤ 0.8 | Preheat tooling to 180°C |

| Polycarbonate | 12,000 | 400 | ≤ 0.5 | Anti-static vacuum system |

| PTFE | 6,000 | 150 | ≤ 0.3 | Sub-ambient coolant (5°C) |

| Acetal (POM) | 10,000 | 350 | ≤ 0.6 | Zero-backlash ball screws |

Delivery & Validation

Final inspection includes CMM reports against original CAD datums, surface roughness verification (Ra ≤ 0.8µm), and material certification traceability. We ship parts in anti-static, humidity-controlled packaging with all documentation digitally signed via our portal. First-article submissions include FAI per AS9102 for aerospace clients or ISO 13485 documentation for medical devices. Typical lead time from CAD upload to delivery is 7–12 business days for 1–50 parts, with expedited 72-hour options for qualified geometries.

This integrated workflow reduces client rework by 63% compared to standard industry processes (per 2023 internal audit data) by eliminating the traditional disconnect between quoting, engineering, and production teams. All process stages are ISO 9001:2015 certified with real-time data visibility for clients through our production dashboard.

Senior Manufacturing Engineer

Honyo Prototype

Start Your Project

Discover high-accuracy precision plastic machining for demanding applications in medical, aerospace, and industrial sectors.

Our Shenzhen-based manufacturing facility leverages advanced CNC technology and strict quality control to deliver tight-tolerance plastic components with exceptional repeatability and surface finish.

For project inquiries or technical consultation, contact Susan Leo at [email protected].

| Service Feature | Detail |

|---|---|

| Location | Shenzhen, China |

| Primary Process | CNC Machining |

| Material Focus | Engineering-grade thermoplastics |

| Typical Tolerances | ±0.005 mm to ±0.025 mm |

| Lead Time | As fast as 5–7 business days |

| Contact | Susan Leo, [email protected] |

Partner with Honyo Prototype for reliable, low-volume to medium-volume precision plastic machining—built to perform.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.