Guide Contents

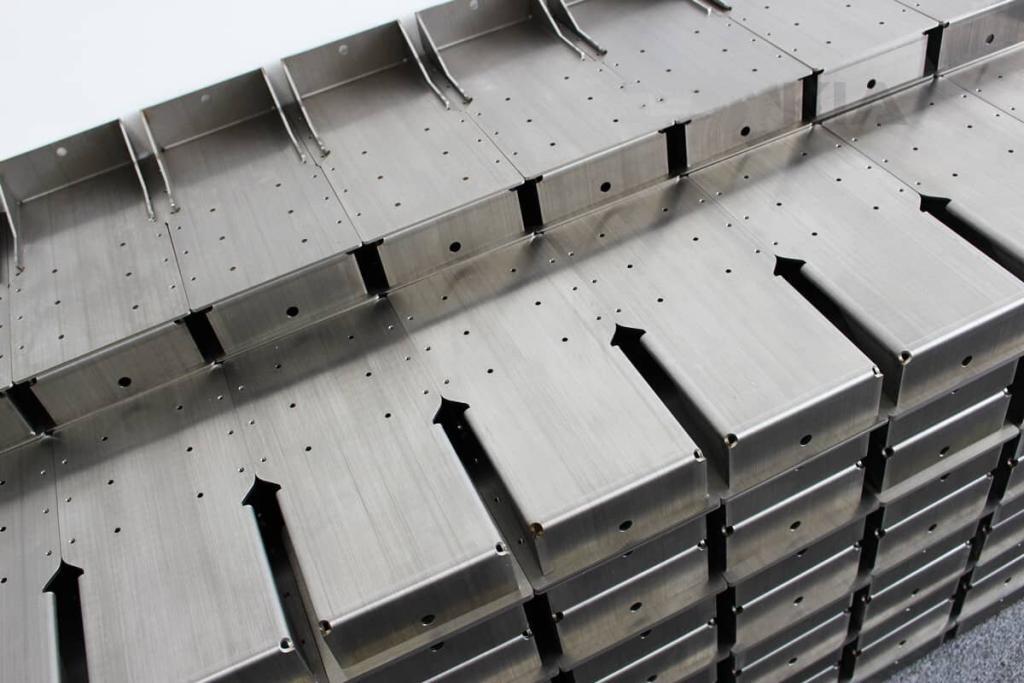

Project Insight: Precision Motors And Fabrication

Manufacturing Insight: Precision in Motion – Speed & Accuracy for Modern Product Development

Why Precision Sheet Metal Fabrication is Critical for Motor-Driven Products

Motor enclosures demand micron-level tolerances to ensure proper alignment and thermal management—precision is non-negotiable for reliability and performance.

Vibration control and structural integrity in brackets and chassis directly impact motor longevity; even minor deviations can lead to costly field failures.

Traditional fabrication delays and rework stall product development; Honyo’s precision capabilities eliminate bottlenecks while maintaining cost efficiency.

Honyo Prototype: Your Digital Manufacturing Partner for Rapid Innovation

Online Instant Quote: Upload your CAD file for real-time pricing and automated Design for Manufacturability (DFM) feedback—no more waiting days for quotes.

AI-Powered Platform: Proprietary algorithms optimize cutting paths, nesting, and bending sequences, reducing material waste by up to 25% and labor hours by 30%.

Fast Turnaround: Prototypes delivered in 3–5 days, production runs in 1–2 weeks—accelerate your time-to-market without compromising quality.

Real-World Impact: Cutting Costs Without Compromising Quality

A leading appliance manufacturer reduced overall manufacturing costs by 40% through Honyo’s optimized sheet metal processes, achieving 100% first-pass accuracy on motor enclosures.

Hardware startups using our platform see 35% faster prototyping cycles, with accurate BOM cost estimates generated in minutes—not weeks.

Scalable pricing models ensure cost-effectiveness for volumes from 100 to 10,000+ units—perfect for startups scaling from prototype to mass production.

“Precision isn’t just a metric—it’s the foundation of innovation. At Honyo, we turn your designs into reality faster, smarter, and more affordably.”

— Susan Leo, Founder

Honyo Capabilities & Technology

Honyo’s Precision Sheet Metal Fabrication Capabilities

Precision Laser Cutting

±0.1mm tolerance cuts for intricate motor housings, brackets, and chassis with zero heat distortion

Optimized nesting algorithms reduce material waste by 20%+ while handling complex geometries

Supports 0.5mm–25mm materials including stainless steel, aluminum, and copper alloys

CNC Bending & Forming

Multi-axis precision bending (0.5° accuracy) for brackets and chassis with zero retooling costs between iterations

Automated tooling changes enable rapid prototyping and seamless scaling to 10,000+ units

Consistent repeatability for high-volume production of motor mounting components

Advanced Welding Solutions

TIG/MIG welding for structural integrity in motor enclosures, eliminating vibration-induced failures

Precision seam welding ensures micro-crack-free joints for critical aerospace and industrial applications

Post-weld stress relief processes extend component lifespan in extreme environments

Industrial Powder Coating

Electrostatic application delivers uniform, scratch-resistant finishes across complex surfaces

10+ color options with optional textures (matte, gloss, anti-slip) for aesthetic and functional branding

Salt spray tested for 500+ hours—ideal for outdoor motor housings and harsh industrial use

Scalable Production Capacity

From single prototypes to 10,000+ units—no minimum order requirements

Dedicated production lines ensure consistent quality during R&D, validation, and mass production phases

Flexible scheduling adapts to urgent hardware startup timelines without compromising precision

ISO 9001:2015 Certified Quality Control

In-process GD&T inspections at every stage with real-time data logging

Third-party metrology validation for critical tolerances (±0.05mm achievable)

Digital quality reports with full traceability for compliance-sensitive projects

Digital Manufacturing Ecosystem

Online Instant Quote: AI-powered platform delivers real-time pricing with instant DFM feedback—no more waiting days for quotes

24-Hour Prototype Turnaround: Priority processing for hardware startups with expedited shipping options

Automated Cost Optimization: Machine learning analyzes designs to suggest adjustments that reduce costs by up to 40% while maintaining precision

Materials & Surface Finishes

Material Options & Finishes: Precision Engineered for Your Application

Selecting the right materials and finishes is critical for precision motors and fabrication—balancing performance, durability, and cost efficiency. At Honyo Prototype, our engineering expertise ensures optimal choices that align with your application’s demands while accelerating time-to-market.

Material Selection Guide

Aluminum (6061, 5052, 7075)

Lightweight, high strength-to-weight ratio, and excellent thermal conductivity.

Ideal for motor housings, heat sinks, and enclosures requiring corrosion resistance.

6061-T6 offers superior weldability and structural integrity; 5052 excels in formability for complex bends.

Steel (Stainless 304/316, Carbon Steel)

Stainless steel provides exceptional corrosion resistance for harsh environments; carbon steel delivers high strength for structural components.

316 stainless ideal for marine or medical applications; carbon steel (e.g., SPCC) cost-effective for non-corrosive enclosures.

Copper

Superior electrical and thermal conductivity for busbars, motor windings, and grounding components.

Easily formed and soldered—perfect for precision electrical parts requiring minimal resistance.

Surface Finish Options for Enhanced Performance

Anodizing (Type II/III)

Enhances aluminum’s corrosion resistance and wear properties; enables vibrant color options without compromising conductivity.

Critical for outdoor motor housings where aesthetics and longevity matter.

Powder Coating

Durable, UV-resistant finish for steel and aluminum enclosures—ideal for industrial equipment requiring color consistency and scratch resistance.

Electropolishing

Smooths stainless steel surfaces to reduce micro-roughness, improving corrosion resistance and ease of cleaning for medical or food-grade applications.

Zinc Plating

Cost-effective corrosion protection for carbon steel parts in moderate environments, with optional chromate conversion for added durability.

Accelerate Your Project with Honyo’s Smart Solutions

✅ Online Instant Quote

Upload your CAD file for real-time pricing—no more manual calculations or waiting days for estimates.

✅ AI-Powered Material Advisor

Our platform analyzes your design specs and environmental factors to recommend the most efficient material/finish combo, slashing prototyping costs by up to 30%.

✅ Fast Turnaround Guarantee

Leverage our integrated workflow and in-house capabilities to deliver precision parts in 5–7 days—up to 50% faster than industry standards.

Ready to optimize your motor fabrication? Get Your Instant Quote Now and experience seamless precision engineering tailored to your needs.

From Quote to Part: Our Process

How It Works: From CAD to Part

At Honyo Prototype, we’ve redefined sheet metal fabrication with a seamless, AI-driven workflow that accelerates your time-to-market. Here’s how it works:

Upload CAD File

Drag and drop your STEP, STP, IGES, or native CAD files into our intuitive platform

No manual data entry—our system instantly analyzes geometry, tolerances, and specifications

Supports all standard formats for effortless integration into your design process

Get Instant AI-Powered Quote

Receive real-time pricing in seconds, not days

Transparent cost breakdown: materials, labor, finishing, and shipping—no hidden fees

AI evaluates 100+ manufacturing parameters (material thickness, complexity, finish) to ensure feasibility and cost optimization

Proactive DFM Analysis

AI identifies potential design flaws and suggests improvements to reduce costs

Optimize bend radii, weld points, and part geometry for enclosures, brackets, and chassis

Collaborate directly with our engineers to refine your design before production

Fast Track Production & Delivery

In-house laser cutting, bending, welding, and powder coating for end-to-end control

Prototypes delivered in 3–5 business days; production runs in 2–4 weeks

Real-time tracking from manufacturing to your doorstep—always in control

Transform your design into reality faster, smarter, and at 40% lower costs than traditional workflows. Ready to innovate?

Start Your Project with Honyo

Start Your Project with Honyo

Precision Engineering, Optimized for Your Success

Cost-Effective Solutions: Achieve up to 40% lower costs for enclosures, brackets, and chassis through optimized design and streamlined processes—no hidden fees, no waste.

End-to-End Tech Capabilities: Laser cutting, precision bending, welding, and powder coating—all under one roof for seamless production from prototype to scale.

AI-Powered Efficiency: Real-time design for manufacturability (DFM) feedback and automated cost analysis to eliminate guesswork and accelerate time-to-market.

Instant Quote in Seconds, Not Days

Online Instant Quote Platform: Upload your CAD files and receive an accurate, transparent quote within minutes—no manual back-and-forth, no delays.

AI-Driven Optimization: Our smart algorithms analyze your design for material efficiency, process optimization, and cost savings—so you get the best value upfront.

Fast Turnaround Guarantee: Prototype delivery in 72 hours, with production scaling to meet your deadlines without compromising quality or precision.

Let’s Build Something Great Together

Connect Directly with Susan Leo & Our Expert Team:

📧 [email protected] | 📞 +86 139 2843 8620

Visit Our State-of-the-Art Facilities:

Explore our Shenzhen & Dongguan campuses to witness precision manufacturing firsthand—where innovation meets industrial excellence.

Ready to transform your vision into reality?

👉 Get Your Instant Quote Now

🚀 Manufacturing Cost Estimator

Compare cost impact of different technologies for your parts.