Contents

Manufacturing Insight: Precision Molding Services Inc

Precision Molding Services Inc. Delivers Accelerated Product Realization Through Honyo Prototype Partnership

Precision Molding Services Inc. partners exclusively with Honyo Prototype to provide end-to-end precision injection molding solutions engineered for speed, accuracy, and scalability. Our collaboration leverages Honyo’s advanced rapid tooling and high-precision molding capabilities to transform complex designs into certified production components faster than traditional methods allow. This synergy eliminates conventional prototyping bottlenecks while ensuring seamless transition from validation to volume manufacturing—all under stringent ISO 9001-certified processes.

Rapid Tooling Capabilities Drive Unmatched Speed-to-Market

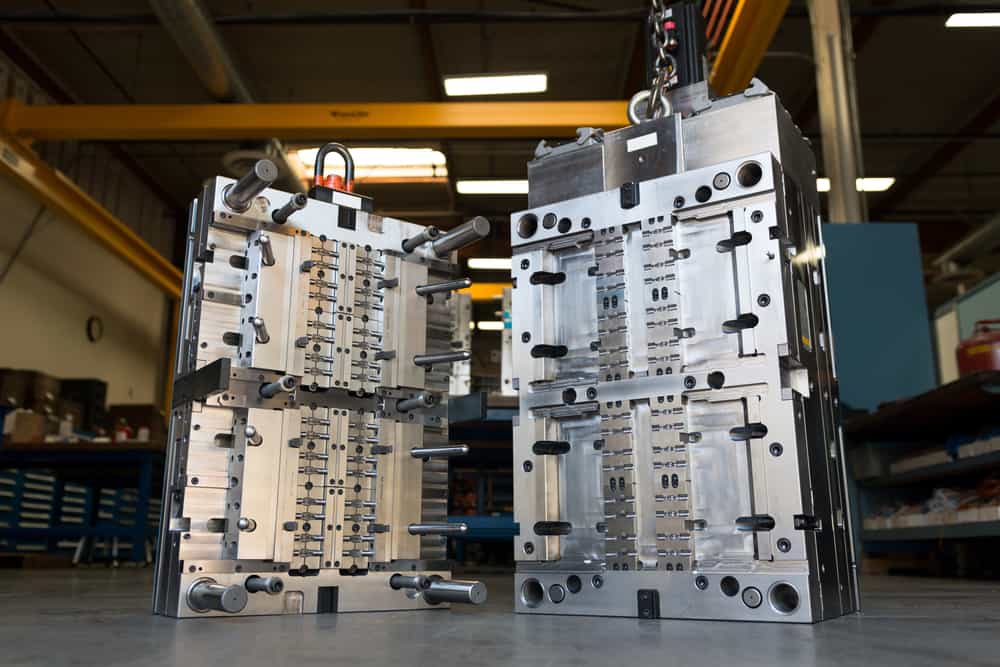

Honyo Prototype’s rapid tooling infrastructure utilizes CNC-machined aluminum and pre-hardened steel molds, achieving lead times as low as 5–10 business days for functional prototypes and bridge production. Our engineers optimize mold designs for geometric complexity down to ±0.005mm tolerances, incorporating conformal cooling channels and advanced venting to mitigate warpage and sink marks. This approach supports rigorous material validation across engineering-grade resins—including PEEK, liquid crystal polymers, and medical-grade silicones—ensuring performance fidelity before committing to production tooling.

Precision Injection Molding for Critical Applications

For volume production, Honyo’s 50–1,500-ton electric and hybrid presses deliver micron-level repeatability through real-time process monitoring and DOE-driven parameter optimization. Our cleanroom molding cells (ISO Class 8) and in-house metrology lab—featuring CMM, CT scanning, and rheological analysis—validate part integrity against ASTM/ISO standards. Material science expertise spans biocompatible polymers, flame-retardant composites, and conductive compounds, with full traceability from lot certification to first-article inspection reports.

Online Instant Quote System Accelerates Procurement

Eliminate procurement delays with Honyo’s algorithm-driven online quoting platform, accessible 24/7 via Precision Molding Services Inc.’s portal. Simply upload CAD files (STEP, IGES, Parasolid), specify material, volume, and tolerances to receive a DFM-reviewed quote with lead time and tooling cost transparency within minutes. This system integrates directly with our production scheduling, enabling immediate work order release upon approval—reducing RFQ cycles from weeks to hours while maintaining engineering rigor.

Partner with Precision Molding Services Inc. to leverage Honyo Prototype’s integrated rapid tooling and molding ecosystem, where technical precision converges with operational agility for mission-critical components across aerospace, medical, and advanced electronics sectors.

Technical Capabilities

Precision Molding Services Inc. specializes in rapid and high-precision mold manufacturing and prototyping, with a focus on delivering T1 samples within 7 days from mold completion. The company supports both aluminum and steel mold platforms, catering to low-to-medium volume production and rapid prototyping needs across industries such as automotive, medical, and consumer electronics.

The core technical capabilities include CNC machining, EDM, and high-accuracy surface finishing to ensure mold integrity and part consistency. Compatible with a range of thermoplastics, including ABS and Nylon, the molds are engineered for optimal thermal regulation, durability, and cycle time efficiency.

Below is a summary of the key technical specifications and capabilities:

| Parameter | Specification |

|---|---|

| Mold Material Options | Aluminum (7075-T6, 6061-T6), Steel (P20, H13, S136, 420 Stainless) |

| Mold Type | Single-cavity, multi-cavity, family molds; 2-plate and 3-plate configurations |

| Tooling Lead Time | 2–4 weeks depending on complexity; T1 sample delivery within 7 days of mold completion |

| Part Material Compatibility | ABS, Nylon (PA6, PA66, glass-filled variants), PC, PP, PE, PMMA |

| Part Tolerances | ±0.005 mm (standard), ±0.002 mm (high-precision with inspection) |

| Surface Finishes | SPI (A1–B3), texture (VDI 14–36), matte, gloss, as-machined, anodized (Al) |

| Machine Capabilities | 3-axis and 5-axis CNC, Wire & Sinker EDM, CMM inspection, mold flow analysis |

| Max Mold Size | 600 mm × 600 mm × 500 mm (24″ × 24″ × 20″) |

| Max Shot Weight | 500 grams |

| Production Volume Support | Prototype to low-to-medium volume (1,000 – 50,000 parts per year) |

| Quality Standards | ISO 9001:2015 compliant; First Article Inspection (FAI) and PPAP available |

All molds undergo rigorous in-house testing, including mold trials and T1 sample validation, ensuring dimensional accuracy and material performance prior to customer release.

From CAD to Part: The Process

Honyo Prototype delivers precision molding services through a rigorously defined workflow engineered for speed, accuracy, and manufacturability. Our process begins with structured digital input and culminates in certified part delivery, ensuring alignment with demanding industrial specifications.

CAD File Upload and Validation

Clients initiate the process by uploading native or neutral CAD formats via our secure customer portal. Supported formats include STEP AP203/214, IGES, Parasolid X_T, and native SOLIDWORKS files. Our system performs immediate validation checks for geometry integrity, unit consistency, and file completeness. Unsupported formats or corrupted files trigger an automated notification for client correction, preventing downstream delays. This phase establishes the geometric foundation for all subsequent stages.

AI-Powered Preliminary Quoting

Upon CAD validation, our proprietary AI engine analyzes geometric complexity, part volume, feature tolerances, and surface finish requirements against historical production data and material databases. The system generates a preliminary cost estimate and lead time within two business hours, covering tooling, material, and secondary operations. This AI quote provides rapid initial feedback but is explicitly designated as non-binding; final commercial terms require engineering validation during DFM. Key parameters driving the AI calculation include draft angles, wall thickness uniformity, and undercuts.

Engineering-Led DFM Analysis

The core technical differentiator occurs in our Design for Manufacturability phase. Honyo’s senior molding engineers conduct a manual review alongside AI-driven simulation, assessing moldability, material flow, cooling efficiency, and ejection feasibility. We identify critical issues such as non-uniform wall sections risking sink marks, inadequate draft causing ejection damage, or gate locations inducing weld lines in structural zones. Clients receive a detailed DFM report with actionable recommendations—often resolving 85% of potential defects before tooling begins. This collaborative step requires client sign-off on the final manufacturable design and approved quote.

Precision Production Execution

With DFM approval, production commences under ISO 9001-controlled conditions. We utilize temperature-stabilized molding cells with electric or hybrid presses (50-1000 tons) and real-time process monitoring. Material lots undergo certificate verification and moisture testing prior to processing. Each production run includes first-article inspection per AS9102 standards, in-process dimensional checks at 30-minute intervals using calibrated CMMs, and final batch validation against the client’s critical-to-quality characteristics. Secondary operations like vapor polishing or insert molding occur in dedicated cleanrooms when specified.

Certified Delivery and Traceability

Finished parts ship with comprehensive documentation: FAI reports, material certs, process parameter logs, and dimensional conformance data. All shipments include serialized traceability tags linking to raw material lots and machine parameters. We partner with freight carriers offering real-time GPS tracking and climate-controlled options for sensitive polymers. Standard lead time from DFM approval to delivery is 12-18 business days for molded components, with expedited options available. Every shipment meets ITAR compliance requirements where applicable.

This integrated workflow minimizes risk through early engineering intervention while leveraging automation for efficiency. The DFM phase remains our critical value-add, transforming theoretical designs into reliably producible components without compromising precision tolerances.

Start Your Project

Precision Molding Services Inc. delivers high-accuracy injection molding solutions for complex, tight-tolerance components. With advanced capabilities in rapid tooling, cleanroom molding, and overmolding, we support industries ranging from medical devices to aerospace.

Our ISO-certified manufacturing facility in Shenzhen offers scalable production, fast turnaround, and full process validation to ensure consistent part quality and regulatory compliance.

For inquiries, contact Susan Leo at [email protected] to discuss your next project.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.