Contents

Manufacturing Insight: Precision Machining And Fabrication

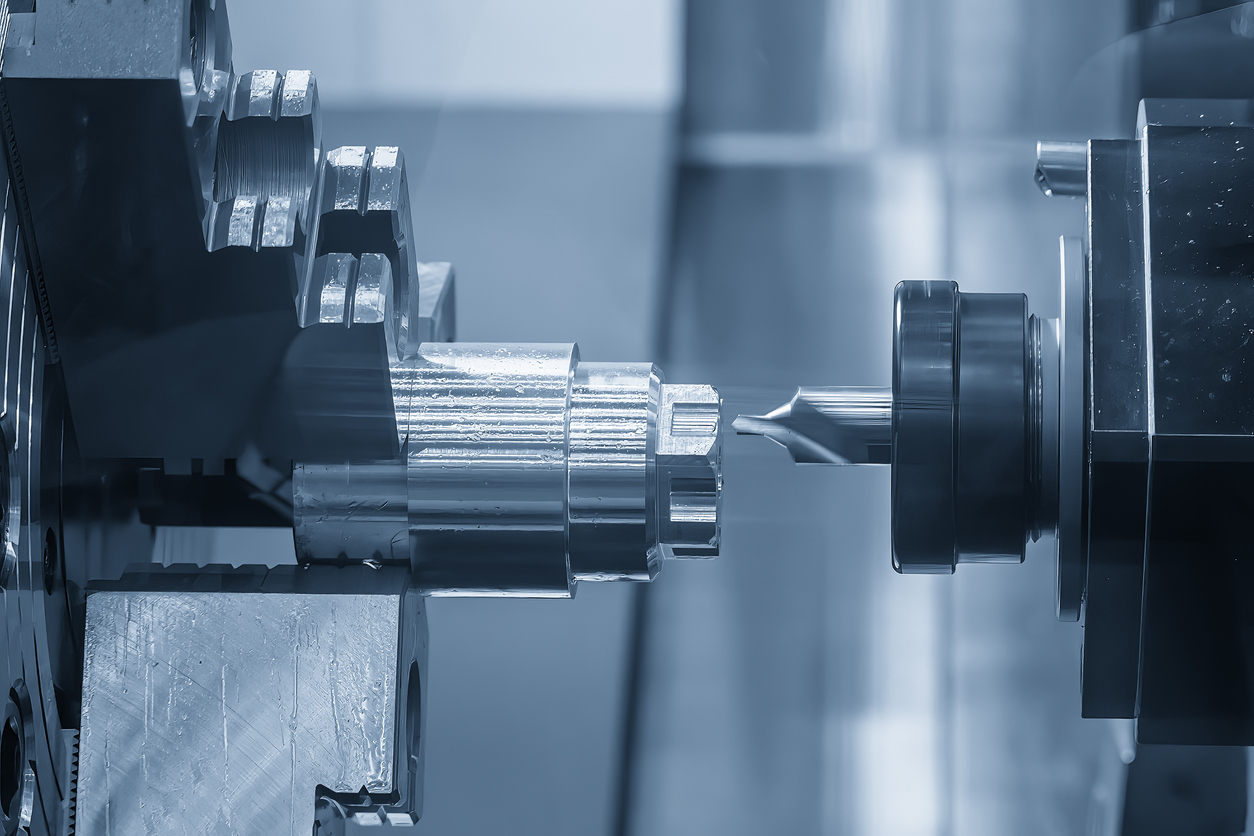

Precision Machining and Fabrication: The Foundation of Reliable Prototyping and Production

At Honyo Prototype, we understand that the success of your engineering project hinges on components manufactured to exacting specifications, delivered with unwavering consistency and speed. As a trusted partner for demanding industries including aerospace, medical device development, and advanced robotics, we specialize in high-precision CNC machining and metal fabrication services designed to transform your complex designs into reality. Our core competency lies in producing mission-critical prototypes and low-to-medium volume production runs where dimensional accuracy, superior surface finish, and material integrity are non-negotiable requirements.

Honyo Prototype leverages state-of-the-art multi-axis CNC milling and turning centers, advanced wire and sinker EDM capabilities, and skilled fabrication expertise to handle the most challenging geometries in materials ranging from aluminum and stainless steel to exotic alloys like titanium and Inconel. Our processes consistently achieve tight tolerances down to ±0.005mm, supported by rigorous in-process inspection using calibrated CMMs, optical comparators, and surface roughness testers, all operating within our ISO 9001:2015 certified quality management system. This technical capability ensures your parts meet stringent functional and regulatory demands from the very first iteration.

Eliminating quotation delays is critical in fast-paced development cycles. That is why we offer our proprietary Online Instant Quote platform, providing accurate, detailed cost and lead time estimates for CNC machined parts within seconds, directly from your browser. Simply upload your STEP or IGES file, specify material and quantity requirements, and receive a formal quotation without waiting for manual review – accelerating your path from concept to physical validation. Partner with Honyo Prototype for precision machining solutions where technical excellence meets operational efficiency.

Technical Capabilities

Precision machining and fabrication at Honyo Prototype encompasses advanced CNC 3-axis, 4-axis, and 5-axis milling along with high-accuracy turning operations. These processes enable the production of complex geometries with tight tolerances, typically held within ±0.005 mm (±0.0002″) to ±0.025 mm (±0.001″), depending on part features and material. Multi-axis capabilities allow for reduced setup次数 and improved accuracy on intricate components. Turning operations support both bar-fed and chucking methods for cylindrical and turned parts. Materials routinely machined include metals such as aluminum and steel, as well as engineering thermoplastics like ABS and nylon, each selected based on mechanical requirements, environmental exposure, and functional performance.

| Process | Axis Configuration | Typical Tolerance | Surface Finish (Ra) | Common Materials | Key Capabilities |

|---|---|---|---|---|---|

| 3-Axis Milling | X, Y, Z | ±0.010 mm (±0.0004″) | 1.6 – 3.2 µm | Aluminum, Steel, ABS, Nylon | Planar features, pockets, drilling, slotting |

| 4-Axis Milling | X, Y, Z + A (rotary) | ±0.008 mm (±0.0003″) | 1.6 – 2.4 µm | Aluminum, Steel, ABS, Nylon | Indexing for side features, continuous contouring |

| 5-Axis Milling | X, Y, Z + A, B/C | ±0.005 mm (±0.0002″) | 0.8 – 1.6 µm | Aluminum, Steel, ABS, Nylon | Complex organic shapes, aerospace components, minimal setup |

| CNC Turning | X, Z (diameter, axial) | ±0.010 mm (±0.0004″) | 1.6 – 3.2 µm | Aluminum, Steel, ABS, Nylon | High-precision shafts, threads, undercuts, multi-feature turned parts |

| Tight Tolerance Machining | All above processes | Down to ±0.005 mm (±0.0002″) | As low as 0.4 µm | Aluminum (6061, 7075), Steel (1018, 4140, Stainless 303/316), ABS, Nylon (6, 66) | GD&T control, metrology validation, critical aerospace/medical components |

All parts undergo in-process and final inspection using calibrated CMMs, optical comparators, and surface roughness testers to ensure compliance with technical drawings and industry standards.

From CAD to Part: The Process

Honyo Prototype Precision Machining and Fabrication Workflow

Our end-to-end precision machining and fabrication process integrates advanced digital tools with rigorous engineering oversight to ensure manufacturability, quality, and on-time delivery. The workflow begins when a client uploads a native CAD file (STEP, IGES, or native SOLIDWORKS) to our secure client portal. This triggers an immediate analysis by our proprietary AI-Powered Quoting Engine, which evaluates geometric complexity, material requirements, tolerances, and secondary operations against live machine capacity, material stock levels, and labor rates. Unlike generic quoting systems, this engine incorporates real-time data from our shop floor—including spindle utilization and tooling availability—to generate a technically validated cost and lead time estimate within 2 business hours, with clear justification for any non-standard pricing factors.

Following client approval of the quote, the project enters Engineering-Driven DFM Analysis. Here, our senior manufacturing engineers conduct a manual review alongside AI-generated suggestions, focusing on critical aspects such as:

Geometric dimensioning and tolerancing (GD&T) feasibility

Material selection optimization for machinability and cost

Identification of non-value-added features (e.g., excessive tight tolerances)

Recommendations for assembly-friendly design modifications

This phase includes direct collaboration with the client’s design team via secure video review sessions to resolve conflicts, ensuring design intent is preserved while maximizing producibility. No design change is implemented without explicit client sign-off.

Production Execution leverages our climate-controlled facility equipped with 5-axis milling centers (DMG MORI, Haas), precision lathes (Mazak, Okuma), and wire EDM systems. Every job follows a documented process plan including:

First-article inspection (FAI) per AS9102 standards for aerospace clients

In-process CMM checks at critical stages using Zeiss CONTURA systems

Real-time SPC data logging for dimensional stability tracking

Dedicated material traceability from raw stock to finished part

Secondary operations such as anodizing, bead blasting, or welding are performed in-house by certified technicians under NADCAP or ISO 13485 protocols where applicable, eliminating third-party quality risks.

Delivery and Traceability concludes the workflow with comprehensive documentation packaged with the shipment. Each consignment includes:

Dimensional inspection reports with actual vs. nominal measurements

Material certification (e.g., Mill Test Reports for AMS 4928 titanium)

Process validation records for heat treatment or surface finishing

Unique lot numbering for full production chain追溯

All parts undergo final cleaning, anti-corrosion protection, and custom packaging per client specifications before shipping via tracked courier with delivery confirmation. This closed-loop system ensures zero non-conformances reach the client while providing actionable data for future design iterations.

Throughout this workflow, our clients maintain real-time visibility via a dedicated project dashboard showing machine status, inspection results, and logistical updates—transforming prototype manufacturing from a black box into a transparent, predictable partnership.

Start Your Project

For precision machining and fabrication solutions tailored to your project requirements, contact Susan Leo at [email protected]. Our advanced manufacturing facility in Shenzhen ensures tight tolerances, high repeatability, and fast turnaround times for prototyping and low-volume production. Partner with Honyo Prototype for CNC machining, sheet metal fabrication, and precision component manufacturing with rigorous quality control.

Reach out today to discuss your technical specifications and receive a competitive quote.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.