Introduction: Navigating the Global Market for precision grinding company

In today’s competitive landscape, sourcing a reliable precision grinding company can be a daunting task for international B2B buyers, especially those operating in regions like Africa, South America, the Middle East, and Europe. The need for high-quality grinding services that meet stringent tolerances and diverse industry requirements—from aerospace to automotive—has never been greater. This guide is designed to navigate the complexities of the global precision grinding market, offering invaluable insights into various types of grinding services, applications, and the critical factors to consider when vetting suppliers.

Understanding the nuances of precision grinding is essential for making informed purchasing decisions. With detailed sections on supplier capabilities, compliance standards such as ISO certifications, and cost considerations, this guide empowers buyers to evaluate potential partners effectively. We will also explore how advancements in technology, including CNC machining and climate-controlled facilities, contribute to enhanced precision and reliability in grinding operations.

By equipping B2B buyers with actionable knowledge and strategic insights, this guide aims to simplify the sourcing process, reduce risks, and ultimately foster successful business relationships in the precision grinding sector. Whether you’re in Nigeria, Vietnam, or any other global market, you will find the tools necessary to make well-informed choices that align with your business goals.

Understanding precision grinding company Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Surface Grinding Company | Focuses on flat surfaces with high precision; uses magnetic chucks. | Automotive, Aerospace, Tooling | Pros: Excellent for flat finishes; versatile. Cons: Limited to flat surfaces. |

| Cylindrical Grinding Company | Specializes in grinding cylindrical parts; includes OD and ID grinding. | Aerospace, Military, Medical | Pros: Ideal for complex shapes; high tolerance. Cons: Equipment can be costly. |

| Centerless Grinding Company | Utilizes a unique setup allowing for high-speed and continuous grinding. | Automotive, Manufacturing, Hydraulic | Pros: Efficient for mass production; minimal setup time. Cons: Less flexibility for small runs. |

| Precision CNC Grinding Company | Integrates CNC technology for automated and complex grinding processes. | Electronics, Medical Devices, Aerospace | Pros: High precision and repeatability; complex geometries. Cons: Higher initial investment. |

| Specialty Grinding Company | Focuses on unique materials or processes, such as low-stress grinding. | Defense, Aerospace, Medical | Pros: Tailored services for niche applications; often includes inspection services. Cons: May have longer lead times. |

What Are the Characteristics of Surface Grinding Companies?

Surface grinding companies are characterized by their ability to achieve high precision on flat surfaces. They typically employ magnetic chucks to hold workpieces securely during the grinding process. This type of grinding is prevalent in industries such as automotive and aerospace, where smooth surface finishes are critical. Buyers should consider the company’s experience with specific materials and their ability to meet tight tolerances, as these factors can significantly impact the final product’s performance.

How Do Cylindrical Grinding Companies Operate?

Cylindrical grinding companies specialize in grinding parts with circular profiles, including both outer diameter (OD) and inner diameter (ID) grinding. These companies are essential in sectors like aerospace and military, where parts often require complex geometries and stringent tolerances. When selecting a cylindrical grinding provider, buyers should evaluate their capabilities in handling specific dimensions and materials, as well as their quality assurance processes.

What Makes Centerless Grinding Companies Unique?

Centerless grinding companies utilize a unique method that allows for continuous and high-speed grinding without the need for fixtures. This process is particularly advantageous for mass production in industries such as automotive and manufacturing. Buyers should consider the efficiency of the grinding process and the company’s ability to handle large volumes, but they should also be aware that this method may be less adaptable for smaller production runs.

Why Choose Precision CNC Grinding Companies?

Precision CNC grinding companies leverage computer numerical control (CNC) technology to achieve high precision and repeatability in their grinding processes. This capability is especially beneficial for complex geometries found in electronics and medical devices. Buyers looking for precision CNC grinding should assess the company’s technological capabilities and experience with CNC machinery, as these factors directly influence the quality of the end product.

What Are the Benefits of Specialty Grinding Companies?

Specialty grinding companies focus on unique materials or specialized processes, such as low-stress grinding, which is crucial for applications in defense and aerospace. These providers often offer tailored services that include additional inspection and testing capabilities. Buyers should evaluate the specific expertise of these companies in handling unique requirements, as well as their lead times, which can be longer than standard grinding services.

Key Industrial Applications of precision grinding company

| Industry/Sector | Specific Application of Precision Grinding Company | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Manufacturing of turbine components | Enhanced performance and safety due to precise tolerances. | Certification (e.g., AS9100), material specifications. |

| Medical Devices | Production of surgical instruments | Improved reliability and patient safety through precision. | Regulatory compliance, biocompatibility of materials. |

| Automotive | Grinding of engine components | Increased efficiency and durability of automotive parts. | Cost-effectiveness, quick turnaround times. |

| Defense & Military | Precision grinding of critical weapon components | Assurance of quality and reliability in high-stakes situations. | Government contracts, strict quality standards. |

| Hydraulic Equipment | Reconditioning of hydraulic rods and cylinders | Cost savings through refurbishment instead of replacement. | Compatibility with existing machinery, turnaround time. |

How Does Precision Grinding Benefit the Aerospace Sector?

In the aerospace industry, precision grinding is critical for manufacturing turbine components that require tight tolerances and exceptional surface finishes. The grinding process ensures that parts like blades and casings fit together seamlessly, enhancing performance and safety. Buyers in this sector must ensure that suppliers are certified under standards such as AS9100 and can provide materials that meet stringent specifications. This is particularly important for international buyers from regions like Africa and South America, where sourcing high-quality materials may present challenges.

What Are the Applications of Precision Grinding in Medical Devices?

For medical devices, precision grinding is used to produce surgical instruments and implants that must adhere to strict safety and performance standards. The precision achieved through grinding enhances the reliability of these instruments, directly impacting patient outcomes. International buyers should prioritize suppliers that demonstrate regulatory compliance and can provide materials with biocompatibility certifications, especially in markets like the Middle East and Europe, where regulations may vary significantly.

How Is Precision Grinding Used in the Automotive Industry?

In the automotive sector, precision grinding is employed for the production of engine components, such as crankshafts and camshafts, which require high efficiency and durability. The grinding process not only improves the performance of these parts but also extends their lifespan, leading to cost savings for manufacturers. Buyers should consider sourcing from suppliers who can offer competitive pricing and quick turnaround times, essential factors for maintaining efficiency in automotive production lines across diverse markets.

What Role Does Precision Grinding Play in Defense and Military Applications?

Precision grinding is vital in the defense sector for the production of critical weapon components, where the stakes are exceptionally high. The grinding process ensures that these components meet rigorous quality and reliability standards, which are essential for operational success. Buyers in this field must navigate complex government contracts and adhere to strict quality standards, making it crucial to partner with suppliers who have proven track records in defense manufacturing.

How Does Precision Grinding Help in Hydraulic Equipment Maintenance?

For hydraulic equipment, precision grinding is often used for reconditioning worn rods and cylinders, allowing companies to refurbish rather than replace expensive machinery. This application not only reduces costs but also minimizes downtime, enhancing operational efficiency. Buyers should ensure that suppliers can offer compatible solutions for existing machinery and maintain a rapid turnaround time to keep operations running smoothly, especially in regions with limited access to new parts.

3 Common User Pain Points for ‘precision grinding company’ & Their Solutions

Scenario 1: Tight Tolerances for Aerospace Components

The Problem: B2B buyers in the aerospace industry often face significant pressure to meet stringent tolerances for components. A buyer may receive an order for complex parts that require tolerances within a few microns. This level of precision is crucial because any deviation can lead to catastrophic failures, which could jeopardize safety and lead to costly recalls. Additionally, sourcing precision grinding services that can handle such tight specifications while maintaining compliance with industry standards can be a daunting task.

The Solution: To overcome this challenge, buyers should prioritize working with precision grinding companies that are ISO-certified and have a proven track record in the aerospace sector. When seeking a partner, it is vital to request detailed information about their capabilities and past projects. Buyers should ask for case studies or examples of similar projects that demonstrate the company’s expertise in achieving tight tolerances. Furthermore, engaging in an initial consultation can help clarify specific requirements and ensure that the grinding service provider understands the critical nature of the components. Establishing a clear communication channel will facilitate any necessary adjustments throughout the production process, thus ensuring that the final product meets the required specifications.

Scenario 2: Inconsistent Quality in Production Runs

The Problem: For manufacturers, especially in the automotive or medical industries, the consistency of precision-ground components is vital. A buyer may find that their current supplier struggles with quality control, leading to variations in product quality across different production runs. This inconsistency can result in increased scrap rates, production delays, and ultimately, higher costs. It can also damage the buyer’s reputation if end products are not up to standard.

The Solution: To address quality consistency issues, buyers should look for precision grinding companies with robust quality assurance processes. It is advisable to inquire about the supplier’s quality management system and how they ensure uniformity in their outputs. Buyers should also request access to quality control certifications and the latest inspection technologies used by the supplier. Another effective approach is to negotiate a trial run or a pilot project. This allows the buyer to evaluate the quality of the grinding service before committing to larger orders. Additionally, establishing key performance indicators (KPIs) for quality can help in monitoring and ensuring that the supplier adheres to the agreed-upon standards over time.

Scenario 3: Long Lead Times Affecting Project Timelines

The Problem: Timely delivery is often a critical factor for B2B buyers, particularly in fast-paced industries like defense or high-tech manufacturing. A buyer may experience frustration when a precision grinding company has extended lead times that disrupt project schedules. Delays can cascade through the supply chain, affecting everything from production schedules to customer delivery dates, leading to lost revenue and strained client relationships.

The Solution: To mitigate lead time issues, buyers should establish clear timelines and communicate their urgency upfront during the sourcing process. When evaluating potential precision grinding partners, it is essential to ask about their production capacity, scheduling flexibility, and any potential bottlenecks in their processes. A good practice is to seek companies that offer real-time tracking and communication regarding order status. Additionally, consider building a relationship with multiple grinding suppliers to create a backup plan. This diversification can provide alternative options should lead times become unmanageable with one provider. Lastly, discussing expedited service options and associated costs upfront can also help in planning and managing timelines effectively.

Strategic Material Selection Guide for precision grinding company

What Are the Key Properties of Common Materials Used in Precision Grinding?

In the realm of precision grinding, the selection of materials is crucial for achieving optimal performance and durability. Here, we analyze four common materials: stainless steel, aluminum, brass, and tool steel, focusing on their properties, advantages, disadvantages, and considerations for international buyers.

How Does Stainless Steel Perform in Precision Grinding Applications?

Stainless steel is renowned for its excellent corrosion resistance and strength, making it suitable for a variety of applications, particularly in the medical and aerospace industries. Its temperature rating allows it to withstand high-pressure environments, which is essential for components exposed to extreme conditions.

Pros: Stainless steel offers high durability and resistance to oxidation, ensuring longevity in demanding environments. It also provides a good surface finish, which is critical for precision components.

Cons: The primary drawback is its cost, as stainless steel is generally more expensive than other materials. Additionally, machining stainless steel can be more complex, requiring specialized equipment and tooling.

Impact on Application: Stainless steel is compatible with various media, making it ideal for components that require stringent hygiene standards, such as surgical instruments.

Considerations for International Buyers: Buyers from regions like Africa and South America should be aware of compliance with international standards such as ASTM and ISO certifications to ensure product quality and safety.

What Advantages Does Aluminum Offer in Precision Grinding?

Aluminum is lightweight and has good machinability, making it a popular choice in industries where weight reduction is critical, such as automotive and aerospace.

Pros: Its low density and excellent thermal conductivity make aluminum suitable for heat-sensitive applications. It is also relatively inexpensive compared to stainless steel.

Cons: However, aluminum has lower strength compared to steel and can be prone to deformation under high stress. Additionally, its corrosion resistance is less than that of stainless steel unless treated.

Impact on Application: Aluminum’s compatibility with various coatings can enhance its performance in specific environments, but care must be taken to ensure that the coatings do not compromise its structural integrity.

Considerations for International Buyers: Buyers should consider local availability and standards compliance, particularly in Europe, where aluminum grades are often specified according to EN standards.

Why Is Brass a Preferred Material for Precision Grinding in Certain Applications?

Brass is commonly used in precision grinding applications due to its excellent machinability and good corrosion resistance, particularly in plumbing and electrical applications.

Pros: Brass is easy to machine, allowing for intricate designs and shapes. It also has good acoustic properties, making it suitable for applications like musical instruments.

Cons: However, brass is less durable than steel and can be more expensive than aluminum. It may also be susceptible to dezincification in certain environments, which can compromise its integrity.

Impact on Application: Brass is particularly effective in applications that require non-sparking properties, making it ideal for environments with flammable materials.

Considerations for International Buyers: Buyers in the Middle East should ensure that the brass used complies with local standards, such as those set by the Gulf Cooperation Council (GCC).

What Role Does Tool Steel Play in Precision Grinding?

Tool steel is designed for high wear resistance and is often used in cutting and drilling applications. It can withstand high temperatures and is known for its toughness.

Pros: Its ability to maintain a sharp edge and resist deformation makes tool steel ideal for high-precision applications. It is also versatile, available in various grades for different applications.

Cons: Tool steel can be expensive and may require specialized heat treatment processes, which can increase manufacturing complexity.

Impact on Application: Tool steel is particularly effective in applications requiring high precision and durability, such as molds and dies.

Considerations for International Buyers: Buyers should be aware of the specific grades of tool steel that meet their application requirements and ensure compliance with international standards such as JIS or DIN.

Summary Table of Material Selection for Precision Grinding

| Material | Typical Use Case for precision grinding company | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Medical devices, aerospace components | Excellent corrosion resistance | Higher cost, complex machining | High |

| Aluminum | Automotive parts, heat exchangers | Lightweight, good thermal conductivity | Lower strength, prone to deformation | Medium |

| Brass | Plumbing fittings, electrical components | Easy to machine, non-sparking | Less durable, susceptible to dezincification | Medium |

| Tool Steel | Cutting tools, molds, dies | High wear resistance, maintains sharp edge | Expensive, requires heat treatment | High |

This strategic material selection guide provides valuable insights for international B2B buyers, ensuring they make informed decisions that align with their specific application needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for precision grinding company

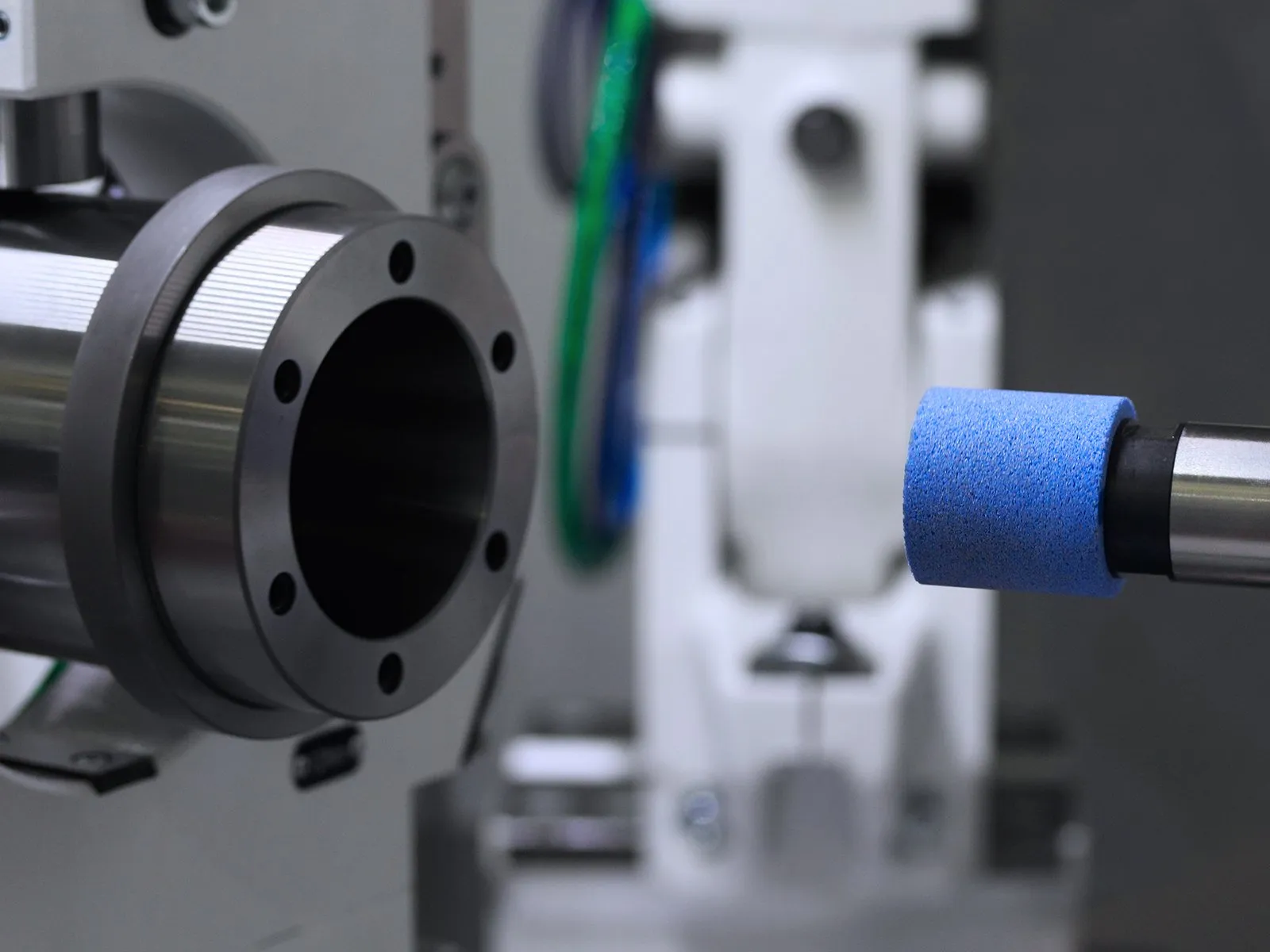

What Are the Key Stages in the Manufacturing Process for Precision Grinding?

The manufacturing process in a precision grinding company typically encompasses several critical stages: material preparation, forming, finishing, and assembly. Each stage is essential for achieving the high tolerances and surface finishes that B2B buyers demand.

Material Preparation

The first step involves selecting the right materials, which may include ferrous and non-ferrous metals, exotic alloys, and plastics. Suppliers often conduct a thorough evaluation of material properties to ensure compatibility with the grinding process. This stage may also involve cutting the raw material to manageable sizes, a process that may include sawing, shearing, or other forms of machining.

Forming Techniques

In the forming stage, various grinding techniques are employed, including:

- Centerless Grinding: Ideal for cylindrical parts where outer diameter is the focus.

- Surface Grinding: Used for flat surfaces, achieving precise finishes and tolerances.

- Internal Grinding (I.D.): Focused on the interior surfaces of tubes or cylinders.

- Thread Grinding: Necessary for parts with threaded features, ensuring accuracy in the thread profile.

- Honing and Lapping: For finishing operations that enhance surface quality and dimensional accuracy.

These techniques are tailored to meet specific requirements, enabling the production of complex geometries and tight tolerances.

Finishing Operations

Finishing operations are crucial in the precision grinding process. This stage may involve additional grinding methods or treatments such as heat treating to relieve stresses, as well as polishing or coating to enhance surface characteristics. The objective is to ensure that the final product meets or exceeds the stringent specifications set forth by the customer.

Assembly and Final Inspection

While assembly may not be a core function of all precision grinding companies, many offer integrated services that include assembling components into final products. Following assembly, a rigorous final inspection is conducted to ensure that all specifications are met. This may involve dimensional checks, surface finish evaluations, and functional tests.

How Is Quality Assurance Implemented in Precision Grinding?

Quality assurance (QA) is a cornerstone of any reputable precision grinding company. Adherence to international and industry-specific standards is critical for ensuring consistent quality and reliability.

What International Standards Are Relevant for Precision Grinding?

ISO 9001:2015 is perhaps the most recognized standard for quality management systems, applicable across various industries. Compliance with this standard signifies that a company has established processes to ensure product quality and customer satisfaction. Additionally, certifications like AS9100C are vital for companies operating in aerospace and defense sectors, while API certifications cater to the oil and gas industry.

What Are the Key Quality Control Checkpoints?

Quality control (QC) is typically structured around several checkpoints:

-

Incoming Quality Control (IQC): This involves inspecting raw materials before they enter the production process. Materials are verified against specifications to ensure they meet quality standards.

-

In-Process Quality Control (IPQC): During manufacturing, periodic checks are performed to monitor processes and detect any deviations from established parameters. This may include measuring dimensions and surface finishes at various stages.

-

Final Quality Control (FQC): After production, finished products undergo rigorous testing. This includes dimensional inspections, surface roughness checks, and functional tests to confirm that they meet customer specifications.

What Testing Methods Are Commonly Used in Precision Grinding?

To maintain high standards of quality, precision grinding companies employ various testing methods, including:

-

Dimensional Inspection: Using calipers, micrometers, and coordinate measuring machines (CMM) to verify dimensions.

-

Surface Roughness Testing: Employing profilometers to assess surface finishes, ensuring they meet specified roughness parameters.

-

Non-destructive Testing (NDT): Techniques like magnetic particle inspection (MPI) and ultrasonic testing are used to identify internal defects without damaging the components.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers should take proactive steps to verify the quality control measures of their suppliers. This can be achieved through:

-

Supplier Audits: Conducting on-site audits to evaluate the manufacturing processes, quality management systems, and certifications of the supplier.

-

Requesting Quality Reports: Buyers can ask for detailed quality assurance reports that outline the QC processes, inspection results, and compliance with international standards.

-

Utilizing Third-Party Inspections: Engaging independent inspection agencies can provide an unbiased evaluation of the supplier’s quality control systems and product conformance.

What Are the Quality Control and Certification Nuances for International B2B Buyers?

For international buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, understanding the nuances of quality control and certification is vital. Different regions may have varying standards and expectations, which can affect supplier selection.

-

Cultural and Regulatory Differences: Buyers should be aware of local regulations and industry standards that may differ from their own. This includes understanding how certifications are perceived in different markets.

-

Language Barriers: Communication regarding quality standards can be complicated by language differences. Buyers should ensure that they clearly articulate their quality expectations and verify that suppliers can meet them.

-

Supply Chain Considerations: International logistics can complicate quality assurance. Buyers should consider how their suppliers manage quality control throughout the supply chain, including any subcontractors involved in production.

By understanding these manufacturing processes and quality assurance practices, international B2B buyers can make informed decisions when selecting precision grinding suppliers, ensuring they receive high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘precision grinding company’

In the competitive landscape of precision grinding, selecting the right supplier is vital for ensuring quality, efficiency, and reliability in your operations. This guide provides a practical checklist for B2B buyers aiming to procure precision grinding services, particularly in international markets such as Africa, South America, the Middle East, and Europe. Follow these steps to streamline your sourcing process and make informed decisions.

Step 1: Define Your Technical Specifications

Before reaching out to potential suppliers, clearly outline your project requirements. This includes tolerances, surface finishes, materials, and dimensions. Having precise specifications ensures that suppliers understand your needs and can provide accurate quotes. Consider creating a detailed technical document to share with vendors.

Step 2: Research Supplier Credentials

Verify that potential suppliers hold relevant certifications, such as ISO 9001:2015 or industry-specific accreditations. These certifications indicate a commitment to quality management and operational excellence. Additionally, check their experience in your specific industry, whether it’s aerospace, automotive, or medical, to ensure they can meet your demands.

Step 3: Evaluate Potential Suppliers

Thoroughly vet suppliers by requesting company profiles, case studies, and references from clients in similar industries. Look for testimonials that highlight their reliability and quality of service. Engaging with previous clients can provide insights into the supplier’s performance and customer service.

Step 4: Assess Technological Capabilities

Investigate the technological capabilities of each supplier. Ensure they utilize state-of-the-art machinery and equipment that can handle the required grinding processes. Advanced technologies, such as CNC machining and climate-controlled facilities, can significantly enhance precision and consistency in the final product.

Step 5: Request Samples and Quotes

Once you have shortlisted potential suppliers, request samples of their work and detailed quotes for your project. Evaluating samples allows you to assess the quality of their grinding work firsthand. Ensure that quotes are comprehensive, covering all aspects such as lead times, shipping costs, and payment terms.

Step 6: Consider Logistics and Communication

Evaluate the logistics of working with each supplier, especially if they are located internationally. Consider shipping times, customs regulations, and potential tariffs that could impact your overall cost. Additionally, assess their communication practices; effective and timely communication is essential for a smooth procurement process.

Step 7: Finalize Your Decision

After thorough evaluation, compare the shortlisted suppliers based on quality, cost, and service. Make a decision that aligns with your business goals and ensures a reliable partnership. Once a supplier is selected, establish clear terms and conditions to foster a successful working relationship.

By following this checklist, B2B buyers can confidently navigate the complexities of sourcing precision grinding services, ultimately ensuring they partner with a supplier that meets their specific needs and quality standards.

Comprehensive Cost and Pricing Analysis for precision grinding company Sourcing

What Are the Key Cost Components in Precision Grinding Services?

In the realm of precision grinding, understanding the cost structure is paramount for B2B buyers. The primary cost components include:

-

Materials: The choice of materials significantly affects pricing. Common materials used in grinding include various alloys of steel, brass, bronze, and specialized plastics. Exotic metals may incur higher costs due to their unique properties and processing requirements.

-

Labor: Skilled labor is essential for achieving the precision required in grinding operations. The labor cost can vary based on the region and the expertise of the workforce. Countries with advanced technical training may offer better skilled labor, albeit at a higher cost.

-

Manufacturing Overhead: This encompasses costs related to utilities, facility maintenance, and administrative expenses. Efficient production processes can help mitigate overhead costs, but these efficiencies may not always be achievable for custom or low-volume orders.

-

Tooling: Tooling costs can be significant, particularly for specialized grinding operations that require custom tooling. The amortization of tooling costs over production volume can impact pricing.

-

Quality Control (QC): Ensuring that products meet stringent quality standards involves additional costs for inspection and testing. Certifications such as ISO 9001:2015 add to the credibility but also contribute to overall pricing.

-

Logistics: Shipping and handling costs can vary greatly, especially for international buyers. Factors such as shipping distance, mode of transport, and customs duties should be considered.

-

Margin: Finally, suppliers will add a margin to their costs, which can vary based on competition and market demand.

What Factors Influence Prices in Precision Grinding Services?

Several factors can affect the pricing of precision grinding services, including:

-

Volume and Minimum Order Quantity (MOQ): Larger orders typically benefit from economies of scale, leading to reduced per-unit costs. Conversely, low-volume orders may incur higher rates due to fixed costs being spread over fewer items.

-

Specifications and Customization: Custom jobs that require unique specifications may lead to increased costs. Buyers should clearly communicate their requirements to avoid surprises in pricing.

-

Material Selection: The choice of materials not only affects the cost of raw inputs but also influences processing time and complexity, thereby impacting the final price.

-

Quality and Certifications: Products that require higher precision or specific certifications will often come at a premium. Buyers should assess the necessity of these certifications based on their application.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers with proven track records may charge more due to their reliability and quality assurance.

-

Incoterms: Understanding Incoterms is essential for international buyers, as they determine who bears the costs and risks associated with shipping, delivery, and customs clearance.

How Can Buyers Negotiate Cost-Efficiency in Precision Grinding?

Buyers can adopt several strategies to enhance cost-efficiency when sourcing precision grinding services:

-

Negotiate Volume Discounts: Leverage larger orders to negotiate better pricing. Suppliers are often more willing to offer discounts for higher volumes.

-

Evaluate Total Cost of Ownership (TCO): Consider not just the purchase price but also the long-term costs associated with quality, durability, and maintenance. A higher upfront cost may be justified if it results in lower TCO.

-

Understand Pricing Nuances for International Buyers: International buyers, particularly from regions like Africa, South America, and the Middle East, should be aware of currency fluctuations, import tariffs, and local regulations that may affect overall costs.

-

Request Detailed Quotes: Ask suppliers for itemized quotes that break down costs. This transparency can help identify areas for potential savings.

-

Build Long-Term Relationships: Establishing a strong relationship with suppliers can lead to better pricing and service levels over time. Suppliers may be more inclined to offer favorable terms to repeat customers.

Disclaimer on Indicative Prices

Pricing in the precision grinding industry can fluctuate based on market conditions, material availability, and technological advancements. It is advisable for buyers to obtain updated quotes from multiple suppliers to ensure competitive pricing tailored to their specific needs.

Alternatives Analysis: Comparing precision grinding company With Other Solutions

Understanding Alternatives in Precision Grinding Solutions

In the realm of precision grinding, various solutions exist that cater to the diverse needs of industries requiring high-tolerance machining. While a precision grinding company, such as Precision Grinding Co., offers specialized grinding services, alternatives like CNC machining and abrasive water jet cutting may also fulfill similar objectives. Understanding these alternatives helps B2B buyers make informed decisions based on their specific operational requirements and budget constraints.

Comparison Table

| Comparison Aspect | Precision Grinding Company | CNC Machining | Abrasive Water Jet Cutting |

|---|---|---|---|

| Performance | High precision, excellent surface finish | Very high precision, adaptable to complex shapes | Good precision, limited to softer materials |

| Cost | Moderate to high | High initial investment, variable operating costs | Moderate, but costs can escalate with thicker materials |

| Ease of Implementation | Requires skilled operators, longer setup time | Complex setup, requires programming expertise | Easier setup, requires specific training |

| Maintenance | Regular maintenance of grinding machines | Maintenance of CNC machines, more parts to manage | Low maintenance, but requires regular inspection |

| Best Use Case | Aerospace, medical, and defense components | Complex geometries and high-volume production | Cutting materials without heat-affected zones, such as plastics and soft metals |

Detailed Breakdown of Alternatives

CNC Machining

CNC (Computer Numerical Control) machining is a versatile technology that utilizes computer programming to control machine tools. Its primary advantage lies in its ability to produce intricate parts with high precision and repeatability. CNC machining is ideal for complex shapes and can handle a wide variety of materials. However, it requires a higher initial investment and ongoing costs related to tooling and programming. Additionally, the setup process can be intricate, demanding skilled operators for optimal performance.

Abrasive Water Jet Cutting

Abrasive water jet cutting employs high-pressure water mixed with abrasive materials to cut through various substances. This technology is particularly advantageous for materials that cannot withstand the heat generated by traditional machining processes. The setup for abrasive water jet cutting is relatively straightforward, making it accessible for many operators. However, its precision is generally lower than that of precision grinding or CNC machining, and it is less effective on harder materials. This method shines in applications involving softer metals and composites, where heat-affected zones must be avoided.

Conclusion: Choosing the Right Precision Grinding Solution

When selecting a precision grinding solution, B2B buyers should assess their specific needs, including the material type, required tolerances, production volume, and budget. Precision grinding companies excel in delivering high-quality finishes for critical components, particularly in demanding industries like aerospace and medical. Alternatively, CNC machining offers flexibility for complex parts, while abrasive water jet cutting provides a unique advantage for softer materials. By carefully evaluating these alternatives, businesses can choose the most suitable method to enhance their operational efficiency and meet their production goals.

Essential Technical Properties and Trade Terminology for precision grinding company

What Are the Key Technical Properties in Precision Grinding?

1. Material Grade

The material grade refers to the specific classification of the raw materials used in grinding operations, which can include metals, alloys, and plastics. Each material grade possesses unique properties such as hardness, tensile strength, and thermal resistance. In B2B contexts, understanding material grades is vital for ensuring compatibility with customer specifications and application requirements. For example, aerospace components often require high-grade materials that can withstand extreme conditions.

2. Tolerance

Tolerance indicates the allowable variation in dimensions of a machined part. Precision grinding typically involves tight tolerances, often in the range of ±0.0001 inches or finer. This precision is crucial for industries like automotive and aerospace, where even minor deviations can lead to significant operational failures. B2B buyers must prioritize suppliers who consistently meet or exceed specified tolerances to ensure product reliability and performance.

3. Surface Finish

Surface finish refers to the texture of a part’s surface after grinding, which can significantly affect its performance, especially in applications involving friction or sealing. Surface finish is measured in microinches or Ra (roughness average). A smoother finish can reduce wear and improve fatigue resistance. B2B customers should assess a supplier’s capabilities in achieving the required surface finish to enhance product longevity and efficiency.

4. Grinding Wheel Specification

The specification of the grinding wheel, including its material, grit size, and bond type, plays a crucial role in the grinding process. Different applications may require specific wheel characteristics to achieve desired outcomes. For instance, a finer grit is suitable for achieving a high-quality finish, while a coarser grit is more effective for rapid material removal. Understanding these specifications helps B2B buyers select the right grinding services for their unique needs.

5. Production Volume

Production volume refers to the quantity of parts that can be processed within a specific timeframe. This specification is critical for B2B buyers who require consistent supply chains. High-volume production capabilities can lead to cost savings and faster lead times, essential for industries with tight deadlines or large-scale manufacturing needs.

What Are Common Trade Terms in Precision Grinding?

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In precision grinding, OEMs often require custom machined components that meet specific performance criteria. Understanding OEM relationships can help B2B buyers navigate partnerships and ensure their suppliers can meet unique specifications.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to produce or sell at one time. This term is crucial for B2B buyers as it influences inventory management and pricing structures. Buyers should inquire about MOQs to align their purchasing strategies with their production schedules and cash flow.

3. RFQ (Request for Quotation)

An RFQ is a document issued by buyers to solicit price quotations from suppliers. It typically includes detailed specifications for the required products or services. B2B buyers should prepare clear and comprehensive RFQs to receive accurate and competitive pricing from potential suppliers, ensuring they can evaluate options effectively.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined international trade terms that clarify the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Understanding these terms is essential for B2B buyers engaged in international transactions, as they dictate who bears the risk and cost at various stages of the shipping process.

5. Lead Time

Lead time refers to the period between the placement of an order and the delivery of the product. In precision grinding, lead times can vary based on the complexity of the job and the supplier’s current workload. B2B buyers should consider lead times when planning production schedules to avoid delays and ensure timely project completion.

Understanding these technical properties and trade terms equips B2B buyers with the knowledge needed to make informed decisions, ensuring they select the right precision grinding partners for their specific needs.

Navigating Market Dynamics and Sourcing Trends in the precision grinding company Sector

What Are the Key Trends Shaping the Global Precision Grinding Market?

The precision grinding market is currently experiencing robust growth, driven by advancements in technology, increasing demand for high-precision components across various industries, and the globalization of supply chains. Industries such as aerospace, automotive, and medical are leading the charge, requiring tighter tolerances and superior surface finishes. With the rise of Industry 4.0, B2B buyers are increasingly focusing on automation, real-time data analytics, and smart manufacturing solutions to enhance production efficiency.

Emerging trends include the integration of artificial intelligence and machine learning in grinding processes, which optimize operations by predicting maintenance needs and reducing downtime. Additionally, the shift towards sustainable manufacturing practices is influencing sourcing decisions. Buyers are increasingly prioritizing suppliers who can demonstrate compliance with international standards, such as ISO certifications, and who invest in environmentally friendly technologies.

For international B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, understanding local market dynamics is crucial. Buyers must navigate varying regulatory environments, logistical challenges, and cultural differences that can impact sourcing decisions. As global supply chains become more interconnected, the ability to leverage local expertise while maintaining quality control standards will be a key differentiator.

How Can B2B Buyers Ensure Sustainability and Ethical Sourcing in Precision Grinding?

Sustainability and ethical sourcing are becoming paramount considerations for B2B buyers in the precision grinding sector. As environmental awareness grows, companies are compelled to assess their supply chains for ecological impact. Precision grinding operations often involve the use of energy-intensive machinery and can produce waste materials, making it essential for buyers to partner with suppliers who demonstrate a commitment to reducing their carbon footprint.

Buyers should look for suppliers that have obtained ‘green’ certifications, such as ISO 14001, which indicates an effective environmental management system. Additionally, suppliers that utilize sustainable materials and processes—such as water-based coolants instead of petroleum-based alternatives—can significantly reduce environmental impact.

Moreover, ethical sourcing practices extend beyond environmental concerns. Companies that ensure fair labor practices and responsible sourcing of raw materials can foster a more sustainable supply chain. By prioritizing suppliers with transparent operations and a demonstrated commitment to ethical practices, B2B buyers can not only enhance their corporate social responsibility profile but also mitigate risks associated with supply chain disruptions and reputational damage.

How Has the Precision Grinding Industry Evolved Over Time?

The precision grinding industry has undergone significant transformation since its inception. Initially focused on manual grinding techniques, advancements in technology have propelled the sector into an era dominated by CNC (computer numerical control) machining. This evolution has not only improved precision and efficiency but has also expanded the range of materials and geometries that can be processed.

Historically, precision grinding served niche applications, but as industries like aerospace and medical devices grew, so did the demand for high-precision components. The integration of quality management systems, such as ISO certifications, has further refined operational standards, ensuring consistent quality across the board. Today, the precision grinding industry is characterized by a blend of traditional craftsmanship and cutting-edge technology, positioning it as a critical component of modern manufacturing processes.

In summary, understanding the intricacies of market dynamics, sustainability, and the historical context of precision grinding can empower international B2B buyers to make informed sourcing decisions that align with their operational and ethical standards.

Frequently Asked Questions (FAQs) for B2B Buyers of precision grinding company

-

How do I choose the right precision grinding company for my needs?

Choosing the right precision grinding company involves assessing several key factors. Start by evaluating their industry experience, certifications (such as ISO 9001), and capabilities to ensure they can meet your specific requirements. Additionally, consider their technology and equipment, as advanced machinery often leads to better precision and quality. Finally, request samples or case studies to gauge their previous work, and ensure their customer service aligns with your expectations for communication and support. -

What are the common applications for precision grinding services?

Precision grinding services are widely used across various industries, including aerospace, automotive, medical, military, and commercial sectors. Common applications include manufacturing components with tight tolerances, such as shafts, gears, and tooling. Grinding can enhance surface finishes, improve dimensional accuracy, and extend the life of parts. Understanding your specific application will help you communicate your needs effectively to potential suppliers. -

What factors affect the cost of precision grinding services?

The cost of precision grinding services is influenced by several factors, including the complexity of the part, material type, required tolerances, and production volume. Additional elements such as setup time, lead time, and any secondary operations (like heat treating or finishing) can also impact pricing. It’s crucial to discuss your project details with suppliers to obtain accurate quotes and understand any potential cost-saving options. -

What is the minimum order quantity (MOQ) for precision grinding services?

Minimum order quantities for precision grinding services can vary significantly between companies and depend on the specific project requirements. Some suppliers may have no MOQ for prototypes or small batches, while others may require a minimum order to justify setup costs. Always clarify the MOQ with potential suppliers during your initial discussions to avoid misunderstandings and to plan your production schedule accordingly. -

How can I ensure quality assurance in precision grinding services?

To ensure quality assurance, verify that the precision grinding company adheres to recognized quality standards, such as ISO 9001. Inquire about their quality control processes, including inspection methods, equipment used, and the experience of their quality assurance team. Additionally, request documentation of their past performance metrics and certifications to ensure they consistently meet the required tolerances and specifications. -

What payment terms should I expect when working with international suppliers?

Payment terms can vary widely based on the supplier and the nature of the project. Common arrangements include upfront deposits, payment upon delivery, or payment within a specified period after receipt of goods (e.g., net 30 or net 60 days). It’s essential to establish clear payment terms during contract negotiations and consider using secure payment methods or letters of credit for international transactions to mitigate risks. -

How do logistics and shipping work for international precision grinding projects?

Logistics and shipping for international precision grinding projects involve careful planning to manage costs and timelines. Discuss with your supplier their shipping options, including freight forwarders and delivery methods. Understand the lead times for production and shipping, and factor in customs clearance processes for your country. It’s beneficial to collaborate with a logistics expert to navigate any import regulations and ensure timely delivery. -

What customization options are available for precision grinding services?

Many precision grinding companies offer customization options to meet specific client needs, such as tailored tolerances, specialized surface finishes, or unique geometries. When discussing your project, clearly communicate your requirements and ask about the flexibility of their processes. Some suppliers may also provide additional services, such as design assistance or prototyping, to help you achieve the desired outcome efficiently and effectively.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 6 Precision Grinding Company Manufacturers & Suppliers List

1. Duval Precision Grinding – Precision Grinding Services

Domain: duvalgrinding.com

Registered: 2012 (13 years)

Introduction: Duval Precision Grinding offers a variety of precision grinding services including ID Grinding, OD Grinding, Surface Grinding, Jig Grinding, and CNC Grinding. They work with a diverse range of materials such as aluminum, stainless steel, titanium, Inconel®, ceramic, PEEK, and various coatings and platings. The company provides custom tooling and fixturing for optimal finishes and accommodates both…

2. Arrow Grinding – Precision Grinding Services

Domain: arrowgrinding.com

Registered: 1996 (29 years)

Introduction: Arrow Grinding specializes in precision grinding services and close-tolerance part manufacturing. Key services include: Bar Grinding, Blanchard Grinding, Centerless Grinding, Cylindrical Grinding, Double Disc Grinding, Flat Lapping, Honing & Internal Grinding, and Surface Grinding. They also offer CNC machining services and produce high-quality Precision Ground Bar Stock and Plate to exact specifi…

3. Microlapping – Precision Grinding Services

Domain: microlapping.com

Registered: 2010 (15 years)

Introduction: Barile Precision Grinding and Micro Lapping and Grinding provide precision grinding services established in 1977 and 1955, respectively. They offer a comprehensive array of capabilities for jobs ranging from 1 piece to production lots of millions. The operation is ISO 9001:2015 certified, ensuring high quality results with state-of-the-art measurement equipment and disciplined production procedure…

4. Precision Grinding LLC – Tool Grinding & Industrial Saws

Domain: precisiongrindingandtool.com

Registered: 2019 (6 years)

Introduction: Precision Grinding LLC offers quality sharpening and custom tool grinding services, as well as sales of industrial saws, router bits, planner blades, shaper cutters, knife stock, and end mills. They are an authorized distributor for Whiteside Machine Co, FS Tool, Freeborn Tool Company, HTC Tool Cutting and Manufacturing, and Charles G.G. Schmidt & Company. Established in 1955, they have a reputati…

5. Midwest Precision Grinding – Precision Cylindrical & Centerless Grinding

Domain: mpgrinding.com

Registered: 2021 (4 years)

Introduction: This company, Midwest Precision Grinding – Precision Cylindrical & Centerless Grinding, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

6. Tri County Precision Grinding – Blanchard & Mattison Grinding Services

Domain: tricountygrinding.com

Registered: 2018 (7 years)

Introduction: Tri County Precision Grinding specializes in precision grinding services, particularly Blanchard and Mattison grinding. Key offerings include: 120″ Blanchard, 96″ Blanchard, 66″ Blanchard, and 42″ Blanchard grinders. Services include heavy stock removal for large components, precision surface finishing for various materials, and custom grinding solutions tailored to specific customer needs. Establ…

Strategic Sourcing Conclusion and Outlook for precision grinding company

In the competitive landscape of precision grinding, strategic sourcing remains a pivotal factor for international B2B buyers seeking reliability and excellence. By leveraging partnerships with established precision grinding companies, organizations can access a diverse array of specialized services, from traditional grinding techniques to advanced CNC machining. This not only enhances product quality but also streamlines supply chains, ensuring timely deliveries that meet the stringent demands of industries such as aerospace, automotive, and medical.

Moreover, as the global market evolves, the importance of quality assurance, adherence to ISO certifications, and the ability to meet tight tolerances cannot be overstated. Buyers from regions such as Africa, South America, the Middle East, and Europe should prioritize collaboration with precision grinding suppliers who demonstrate a commitment to innovation and customer satisfaction.

As you consider your sourcing options, embrace the opportunity to partner with industry leaders who can elevate your projects through unmatched expertise and cutting-edge technology. The future of precision grinding is bright, and with the right partnerships, your business can thrive in this dynamic environment. Engage with potential suppliers today to explore how their capabilities can align with your goals for success.