Contents

Manufacturing Insight: Precision Engineering Machining Services

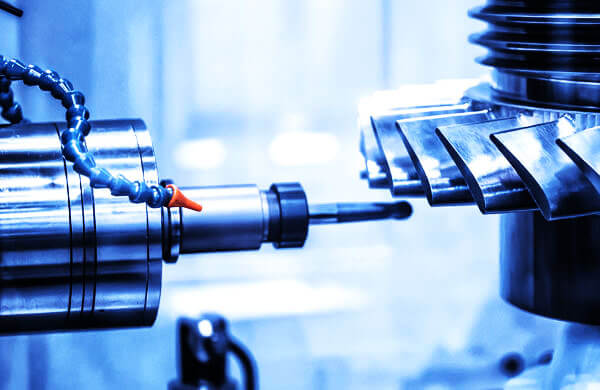

Honyo Prototype delivers mission-critical precision engineering machining services for demanding industries where component integrity is non-negotiable. Our advanced CNC machining capabilities form the cornerstone of this commitment, providing clients with the exacting accuracy and repeatability required for complex aerospace, medical, and industrial applications. We specialize in transforming high-grade materials from aluminum and stainless steel to exotic alloys and engineering plastics into components meeting stringent micron-level tolerances.

Our fully integrated CNC machining center employs state-of-the-art multi-axis milling and turning centers, operated by veteran manufacturing engineers with deep expertise in complex geometry and tight-tolerance production. This technical foundation ensures consistent part quality, superior surface finishes, and optimized cycle times for both rapid prototyping and low-to-mid volume production runs. We rigorously control every phase from material certification through in-process inspection to final validation using calibrated metrology equipment.

Core capabilities include:

5-axis simultaneous machining for intricate contours

High-speed precision milling and turning

Swiss-type machining for complex turned parts

Micron-level tolerance achievement (±0.005mm typical)

Comprehensive material expertise

Key technical specifications are summarized below:

| Parameter | Capability Range | Typical Performance |

|---|---|---|

| Tolerance | ±0.005mm to ±0.05mm | ±0.012mm |

| Surface Finish | Ra 0.2µm to Ra 3.2µm | Ra 0.8µm |

| Max Work Envelope | 1000 x 600 x 500mm | Varies by machine |

| Materials | Aluminum, Steel, Titanium, Plastics, Exotics | Full spectrum |

Accelerate your development cycle with Honyo’s Online Instant Quote system. Upload your CAD file to receive a detailed manufacturability analysis and competitive pricing within minutes, not days. This transparent, data-driven quoting process eliminates traditional procurement delays while providing immediate engineering feedback on design optimization opportunities. Partner with Honyo Prototype for precision machining where technical excellence meets operational efficiency.

Technical Capabilities

Precision engineering machining services at Honyo Prototype are designed for high accuracy, repeatability, and consistency in the production of complex components across a range of engineering materials. Our capabilities include 3, 4, and 5-axis CNC milling, precision turning, and tight tolerance machining to meet stringent industry standards in aerospace, medical, automotive, and industrial sectors.

Our advanced CNC equipment and skilled engineering team enable us to maintain tolerances as tight as ±0.005 mm (±0.0002″) depending on part geometry and material. We support a wide range of materials including metals and engineering plastics, ensuring optimal performance and fit for end-use applications.

| Parameter | Specification Details |

|---|---|

| Machining Processes | 3-Axis, 4-Axis, and 5-Axis CNC Milling; CNC Turning (including multi-axis turn-mill) |

| Tolerance Capability | Standard: ±0.025 mm (±0.001″) Tight Tolerance: ±0.005 mm (±0.0002″) achievable with inspection validation |

| Surface Finish | As-machined: 3.2 μm (125 μin) Polished/Custom: Down to 0.4 μm (16 μin) available |

| Max Work Envelope (Milling) | 5-Axis: 1200 x 600 x 500 mm (47″ x 24″ x 20″) 3/4-Axis: Up to 1500 x 900 x 600 mm |

| Max Turning Diameter | 300 mm (12″) Max Length: 500 mm (20″) |

| Spindle Speed (Milling) | Up to 24,000 RPM (high-speed options available) |

| Positioning Accuracy | ±0.003 mm (±0.0001″) |

| Repeatability | ±0.002 mm (±0.00008″) |

| Supported Materials | Metals: Aluminum (6061, 7075, 2024), Stainless Steel (303, 304, 316), Tool Steel, Mild Steel, Titanium Plastics: ABS, Nylon (PA6, PA66), PEEK, Delrin (POM), Polycarbonate |

| Inspection & QA | In-house CMM, optical comparators, micrometers, and surface profilometers Full first-article inspection reports (FAIR) and PPAP available |

| Secondary Operations | Deburring, anodizing (Type II & III), passivation, powder coating, laser marking, heat treating coordination |

All components are machined using high-rigidity CNC platforms with thermal compensation and real-time tool monitoring to ensure dimensional stability and process control. Our facility maintains ISO 9001:2015 certification, supporting consistent quality for low to medium volume production runs and rapid prototyping.

From CAD to Part: The Process

Honyo Prototype Precision Engineering Machining Workflow

Honyo Prototype delivers end-to-end precision engineering machining services through a rigorously defined workflow designed to minimize lead times, ensure manufacturability, and guarantee component quality. This process integrates digital tools with expert engineering oversight, specifically structured for complex, low-to-medium volume prototyping and production runs.

CAD Upload and Initial Processing

Clients initiate the process by uploading native or neutral CAD files (STEP, IGES, Parasolid) via our secure customer portal. Our system automatically validates file integrity, extracts critical geometric data, and identifies key manufacturing features such as tight tolerances, thin walls, or complex contours. All data is encrypted and quarantined for confidentiality, adhering to ISO 27001 standards. This phase ensures the digital model aligns with our machining capabilities before proceeding.

AI-Powered Quoting Engine

Uploaded CAD data is processed through Honyo’s proprietary AI quoting engine, trained on 15+ years of machining logs and real-time machine utilization data. The system analyzes material removal volume, feature complexity, toolpath density, and fixture requirements to generate an accurate cost and lead time estimate within 2 business hours. Unlike basic online calculators, our AI cross-references historical data on material behavior (e.g., Inconel 718 work-hardening rates) and machine-specific constraints (e.g., 5-axis vs. Swiss lathe limitations). The quote includes a preliminary feasibility flag for geometric challenges, such as aspect ratios exceeding 10:1.

Engineering-Led DFM Analysis

Upon quote acceptance, Honyo’s manufacturing engineering team conducts a formal Design for Manufacturability (DFM) review. This is not an automated step but a collaborative human-AI process where engineers use simulated machining validation software to identify risks like:

Non-optimal wall thicknesses causing chatter in aluminum 6061

Unmachinable internal radii below 0.5mm in hardened steel

Suboptimal stock allowances increasing cycle time by >15%

We provide a detailed DFM report with actionable recommendations, such as adjusting fillet radii or suggesting alternative materials (e.g., switching from Ti-6Al-4V to Ti-5553 for improved machinability in high-volume runs). Client approval of the DFM report is mandatory before production to prevent costly revisions.

Precision Production Execution

Approved designs move to our climate-controlled machine shop, where work is allocated based on real-time machine availability and technical fit:

| Machine Type | Typical Applications | Tolerance Capability |

|---|---|---|

| 5-Axis Milling | Aerospace impellers, medical implants | ±0.005 mm |

| Swiss-Type Lathes | Micro-medical components, fuel system parts | ±0.002 mm |

| Wire EDM | Tooling inserts, hardened steel features | ±0.001 mm |

All processes follow documented work instructions with in-process gauging at critical stages. For example, titanium aerospace brackets undergo laser interferometer verification after roughing to prevent thermal distortion in finishing. Material certifications (e.g., EN 10204 3.1 for stainless steel) and first-article inspection reports (FAIR) per AS9102 are generated for traceability.

Quality-Controlled Delivery

Final components undergo comprehensive metrology in our ISO 17025-accredited lab. Critical dimensions are verified using calibrated CMMs (e.g., Zeiss CONTURA), surface roughness testers, and optical comparators. We deliver with:

Full dimensional inspection report (including GD&T callouts)

Material test certificates

Process validation data (e.g., spindle load monitoring logs)

Packaging certified for shock and humidity per customer specifications

Shipments include serialized tracking with real-time logistics updates, and all documentation is archived for 10 years to support regulatory audits in medical or aerospace sectors.

This integrated workflow reduces time-to-part by 30–50% compared to traditional quoting cycles while ensuring first-pass yield rates exceed 98.5% through proactive DFM intervention. Honyo’s process is certified to AS9100D and ISO 9001:2015, with continuous improvement driven by closed-loop feedback from production data to our AI quoting models.

Start Your Project

Partner with Honyo Prototype for precision engineering machining services delivered with accuracy, speed, and engineering excellence.

Our Shenzhen-based factory leverages advanced CNC machining and quality control systems to produce high-tolerance components for demanding industries. From rapid prototyping to low-volume production, we ensure consistent quality and on-time delivery.

Contact Susan Leo to discuss your next project.

Email: [email protected]

Let’s engineer precision together.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.