Contents

Manufacturing Insight: Precision Cnc Punching Service

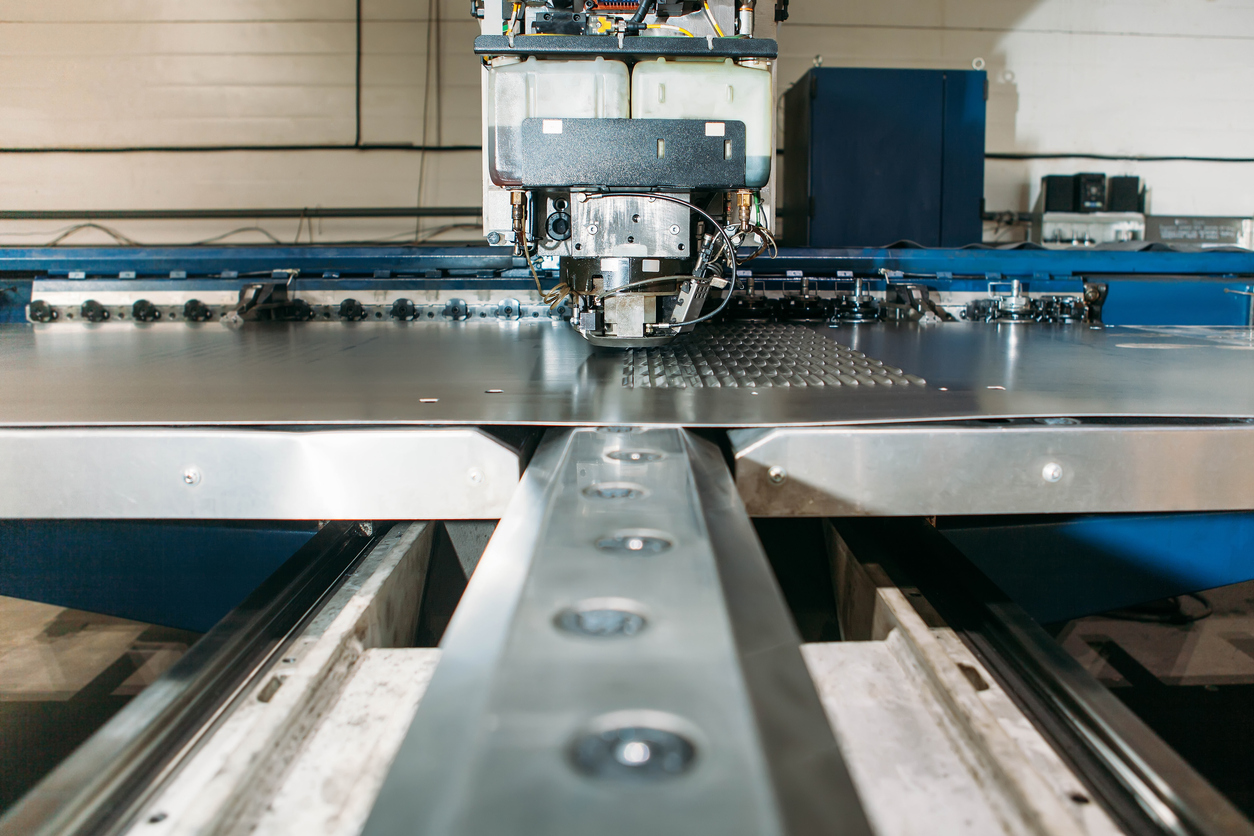

Precision CNC Punching Services Engineered for Manufacturing Excellence

At Honyo Prototype, we deliver industrial-grade precision CNC punching services designed to meet the exacting demands of modern manufacturing. Our advanced CNC turret punching systems leverage multi-tool configurations and high-speed automation to transform sheet metal into complex components with exceptional accuracy, repeatability, and throughput. Targeting critical applications in aerospace, medical device manufacturing, and industrial equipment, our process achieves tight tolerances down to ±0.05mm while supporting rapid prototyping and low-to-mid volume production runs.

We integrate precision punching within Honyo’s broader CNC machining ecosystem, ensuring seamless transitions between punching, laser cutting, bending, and finishing operations under a single quality-controlled workflow. This holistic approach eliminates supply chain fragmentation, reduces lead times by up to 40%, and guarantees dimensional consistency across all secondary processes. Our facility handles a wide spectrum of materials including aluminum alloys, stainless steel (up to 3.0mm), mild steel, and specialty composites, with optimized parameters for burr minimization and edge integrity.

Material Compatibility and Thickness Capabilities

| Material Type | Thickness Range | Key Applications |

|———————|—————–|——————————-|

| Aluminum Alloys | 0.5mm – 3.0mm | Enclosures, Brackets, Panels |

| Stainless Steel | 0.8mm – 2.5mm | Medical Housings, Fixtures |

| Mild Steel | 1.0mm – 3.0mm | Structural Components, Chassis|

Accelerate your project timeline with Honyo’s Online Instant Quote platform. Upload your STEP or DXF file to receive a detailed technical assessment and competitive pricing within minutes—not days. Our system automatically validates geometries against punching feasibility, material constraints, and cost drivers, providing actionable feedback before you commit. This transparent, engineer-to-engineer workflow ensures manufacturability from the earliest design phase, reducing costly revisions and expediting time-to-market.

Partner with Honyo Prototype to transform precision sheet metal requirements into flawless production outcomes, backed by ISO 9001-certified processes and dedicated engineering support. Request your instant quote today to experience manufacturing precision without compromise.

Technical Capabilities

Precision CNC punching services at Honyo Prototype integrate advanced multi-axis milling, turning, and high-accuracy machining capabilities to deliver components with tight tolerances and superior surface finishes. Our 3, 4, and 5-axis CNC milling platforms enable complex geometries and high repeatability, while CNC turning ensures precision for rotational parts. These processes support a wide range of engineering materials including aluminum, steel, ABS, and nylon.

The following table outlines the key technical specifications for our precision CNC punching and machining services:

| Specification Category | Details |

|---|---|

| Machining Types | 3-Axis, 4-Axis, and 5-Axis CNC Milling; CNC Turning |

| Tolerance Capability | ±0.005 mm (±0.0002″) for critical dimensions; tight control on GD&T |

| Surface Finish | As machined: Ra 3.2 µm (125 µin); optional polishing or coating options |

| Materials Supported | Aluminum (6061, 7075, 2024), Steel (1018, 4140, Stainless 303, 316), ABS, Nylon (PA6, PA66) |

| Maximum Work Envelope | 5-Axis Milling: 1000 x 600 x 500 mm; Turning: Ø400 mm x 600 mm length |

| Spindle Speed | Up to 24,000 RPM (high-speed machining available) |

| Tooling System | Automatic tool changers (ATC) with HSK or BT40 interface |

| Positioning Accuracy | ±0.002 mm per axis |

| Repeatability | ±0.003 mm |

| Coolant Systems | Through-spindle and flood coolant for thermal stability |

| Inspection & QA | In-process probing, CMM verification, first-article inspection reports |

| Lead Time | As fast as 3–7 days for prototypes, depending on complexity |

These capabilities ensure high-performance output for industries requiring precision components such as aerospace, medical, automation, and industrial equipment. Material selection is optimized based on mechanical requirements, environmental exposure, and functional performance.

From CAD to Part: The Process

Honyo Prototype Precision CNC Punching Service Workflow

Honyo Prototype executes precision CNC punching through a streamlined five-phase process designed for speed, accuracy, and manufacturability assurance. This workflow leverages proprietary AI tools and engineering expertise to transform client CAD files into certified components with minimal lead time.

CAD Upload

Clients initiate the process by uploading native or neutral CAD formats (STEP, IGES, DXF, DWG) via our secure portal. Our system validates geometric integrity, layer consistency, and unit specifications. Non-conforming files trigger instant notifications specifying required corrections, ensuring only production-ready data advances to quoting. This phase typically completes within 15 minutes of submission.

AI-Powered Quoting

Uploaded designs undergo automated analysis by Honyo’s machine learning engine, which cross-references material libraries, machine capabilities, and historical production data. The AI calculates material utilization, tooling requirements, cycle times, and secondary operations while applying real-time scrap rate and energy consumption metrics. Quotes—including cost breakdowns, lead time estimates, and material surcharge disclosures—are generated in under 2 hours, reducing traditional quoting timelines by 70%. Critical parameters such as material grade compatibility and minimum feature size are flagged for immediate review.

Engineering-Driven DFM

All projects enter mandatory Design for Manufacturability (DFM) review led by our senior manufacturing engineers. This phase identifies geometric conflicts (e.g., hole-to-edge distances below 1.5× material thickness), nesting inefficiencies, or tooling constraints. Engineers collaborate directly with clients via secure video conference to propose optimizations—such as feature repositioning or material substitution—without compromising functional requirements. DFM reports detail cost-saving opportunities (e.g., 12–18% material reduction through optimized nesting) and validate tolerance stack-up for critical dimensions. Formal sign-off occurs only after client approval of revised specifications.

Precision Production

Approved designs proceed to our Amada V8NT turret punch press cells with ±0.05 mm positional accuracy. Production incorporates:

Real-time laser alignment verification during material loading

In-process CMM checks at 5% intervals for critical features

Automated tool wear compensation via integrated sensor feedback

Nitrogen-assisted punching for burr-sensitive alloys (e.g., 6061-T6 aluminum)

All operations adhere to ISO 9001:2015 protocols, with full traceability from raw material certs to operator logs. Secondary processes (deburring, bending, laser marking) occur in-line where specified.

Certified Delivery

Completed orders undergo final inspection per ASME Y14.5 standards, with first-article reports (FAIR) and PPAP Level 3 documentation provided. Parts ship in ESD-safe packaging with serialized barcodes linking to:

Dimensional inspection reports (including CMM scan data)

Material test certificates (MTRs)

Process parameter logs (tonnage, stroke speed, tool sequences)

Standard delivery is 5–7 business days from DFM sign-off; expedited 72-hour service is available for qualified projects.

Technical Performance Benchmarks

| Parameter | Capability Range | Industry Standard |

|————————-|—————————|——————-|

| Material Thickness | 0.5–6.0 mm | 0.8–4.5 mm |

| Hole Positional Accuracy| ±0.05 mm | ±0.10 mm |

| Minimum Hole Diameter | 0.8× material thickness | 1.2× thickness |

| Flatness Tolerance | ≤0.10 mm per 100 mm | ≤0.15 mm |

| Lead Time (Prototype) | 5–7 business days | 10–14 days |

This closed-loop process ensures first-time-right production while providing clients with actionable engineering insights. Honyo’s integration of AI validation with hands-on DFM oversight eliminates traditional prototyping bottlenecks, delivering precision-punched components with full compliance documentation.

Start Your Project

Looking for precision CNC punching services with tight tolerances and fast turnaround? Our advanced manufacturing facility in Shenzhen delivers high-quality metal fabrication for prototyping and low-volume production.

Trust Honyo Prototype for accurate, repeatable results using state-of-the-art CNC turret punching technology. From sheet metal enclosures to complex brackets, we support a wide range of materials and thicknesses with consistent precision.

Contact Susan Leo today to discuss your project requirements and get a competitive quote.

Email: [email protected]

Factory Location: Shenzhen, China

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.