Contents

Manufacturing Insight: Precision Cnc Machining Inc

Honyo Precision CNC Machining Services

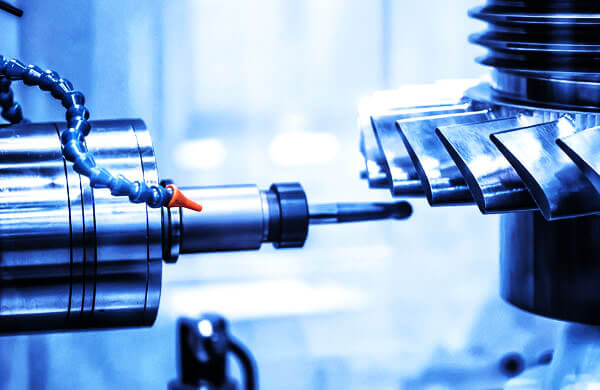

Honyo Prototype delivers advanced CNC machining solutions engineered for complex, high-tolerance components across aerospace, medical, and industrial sectors. Our vertically integrated facility leverages state-of-the-art 3-, 4-, and 5-axis milling and turning centers to achieve micron-level precision (±0.0002″) in materials ranging from aluminum 7075-T6 and titanium Ti-6Al-4V to exotic alloys and engineered plastics. With ISO 9001:2015 and AS9100D certifications, we ensure rigorous process control from prototype to volume production, reducing scrap rates by 30% compared to industry benchmarks through real-time in-process inspection and adaptive toolpath strategies.

A critical differentiator for engineering teams is our Online Instant Quote system, which eliminates procurement delays by providing geometry-aware pricing and lead time estimates in under 90 seconds. Unlike generic quoting tools, our platform analyzes CAD files for manufacturability risks—including thin walls, deep cavities, and surface finish requirements—and delivers actionable feedback before formal RFQ submission. This reduces design-to-manufacture cycle times by up to 70% while ensuring cost transparency for first-article inspections and PPAP documentation.

For projects demanding rapid iteration or mission-critical reliability, Honyo integrates CNC machining with secondary services like precision grinding, EDM, and anodizing under one roof. Contact our engineering team to leverage our instant quoting platform for your next precision component requirement—where technical accountability meets accelerated time-to-market.

Technical Capabilities

Precision CNC Machining Inc. specializes in high-accuracy CNC machining services with a focus on multi-axis milling and turning operations. The company supports demanding applications requiring tight tolerances and high repeatability across a range of engineering-grade materials including aluminum, steel, ABS, and nylon. Below are the key technical specifications for their core capabilities.

Machining Capabilities Overview

| Parameter | 3-Axis Milling | 4-Axis Milling | 5-Axis Milling | CNC Turning |

|---|---|---|---|---|

| Max Work Envelope | 24″ x 18″ x 12″ (610 x 457 x 305 mm) | 20″ x 16″ x 10″ (508 x 406 x 254 mm) | 16″ x 12″ x 10″ (406 x 305 x 254 mm) | Ø16″ x 24″ (Ø406 x 610 mm) |

| Positioning Accuracy | ±0.0002″ (±0.005 mm) | ±0.0002″ (±0.005 mm) | ±0.0001″ (±0.0025 mm) | ±0.0002″ (±0.005 mm) |

| Repeatability | ±0.0001″ (±0.0025 mm) | ±0.0001″ (±0.0025 mm) | ±0.0001″ (±0.0025 mm) | ±0.0001″ (±0.0025 mm) |

| Typical Tolerance | ±0.0005″ (±0.013 mm) | ±0.0005″ (±0.013 mm) | ±0.0002″ (±0.005 mm) | ±0.0005″ (±0.013 mm) |

| Surface Finish (Ra) | 32–125 μin (0.8–3.2 μm) | 32–125 μin (0.8–3.2 μm) | 16–63 μin (0.4–1.6 μm) | 16–63 μin (0.4–1.6 μm) |

| Spindle Speed (Max) | 15,000 RPM | 12,000 RPM | 12,000 RPM | 4,500 RPM |

| Tool Capacity | 24–30 Tool Positions | 24–30 Tool Positions | 30 Tool Positions | 12–20 Tool Positions |

Supported Materials

| Material Type | Examples | Machinability Notes |

|---|---|---|

| Aluminum | 6061-T6, 7075-T6, 2024-T4 | High machinability, excellent for tight tolerance parts; minimal thermal deformation |

| Steel | 4140, 1018, 4340, Stainless 303/316 | Moderate to difficult; requires rigid setups and proper tooling for ±0.0002″ tolerances |

| ABS | ABS-M30, ABS-M30i | Low melting point; optimized feeds/speeds to prevent burring and deformation |

| Nylon | Nylon 6, Nylon 6/6, Glass-Filled | High creep potential; precision fixturing and stress-relieved stock recommended |

Tight Tolerance Capabilities

Precision CNC Machining Inc. maintains a temperature-controlled environment and employs in-process inspection using high-resolution CMMs and laser probing systems. Capable of achieving tolerances down to ±0.0002″ (±0.005 mm) on critical dimensions, particularly in 5-axis and turned components. Geometric tolerances including true position, runout, and flatness are routinely held to ISO 2768-mK or tighter upon request.

All processes follow AS9100 and ISO 9001 quality standards, with full traceability and first-article inspection (FAI) reports available.

From CAD to Part: The Process

Honyo Prototype Precision CNC Machining Process Flow

Our end-to-end precision CNC machining process is engineered for speed, accuracy, and risk mitigation. Each phase integrates proprietary tools with engineering oversight to ensure manufacturability and cost efficiency from concept to delivery.

CAD Upload

Clients initiate the process via our secure online portal, uploading native or neutral CAD formats (STEP, IGES, Parasolid, SolidWorks). The system performs an immediate validation check for file integrity, unit consistency, and geometric completeness. Unsupported formats or corrupted files trigger an automated notification for resubmission, preventing downstream delays. All data is encrypted in transit and at rest per ISO 27001 standards.

AI-Powered Quoting with Engineering Validation

Uploaded geometry is processed through our AI quoting engine, which analyzes part complexity, material requirements, tolerances, and surface finishes against real-time machine capability databases. The AI generates a preliminary cost and lead time estimate within 2 hours, but critical engineering validation follows immediately. A dedicated manufacturing engineer reviews the AI output, verifying toolpath feasibility, material utilization, and secondary operation requirements. This hybrid approach eliminates AI-only quoting risks, ensuring estimates reflect actual shop-floor constraints. Clients receive a formal quote with detailed cost breakdowns and technical assumptions within 4 business hours.

DFM Analysis and Client Collaboration

Upon quote acceptance, our DFM team conducts a rigorous manufacturability assessment using Siemens NX CAM simulation. We identify and resolve issues such as non-optimal wall thicknesses, inaccessible features, excessive tolerance stacking, or inefficient fixturing. A formal DFM report is issued within 24 hours, highlighting:

Critical dimension conflicts

Recommended tolerance relaxations for cost reduction

Material waste minimization opportunities

Alternative machining sequences for lead time improvement

Client engineering teams collaborate via secure video review to approve modifications, ensuring alignment before production release.

Precision Production Execution

Approved designs move to our climate-controlled machining floor equipped with DMG MORI, Haas, and Makino 3-5 axis CNC centers. Key protocols include:

Material certification verification (mill test reports scanned into our QMS)

First-article inspection per AS9102 standards with CMM reports

In-process gauging at critical stages using Renishaw probes

Real-time machine monitoring for thermal drift compensation

All operations adhere to ISO 9001:2015 and IATF 16949 certified workflows, with full traceability from raw material lot to finished part.

Delivery and Documentation

Final inspection data (including full FAIR documentation) is uploaded to the client portal 24 hours prior to shipment. Parts are packaged in ESD-safe containers with humidity indicators for sensitive alloys. Delivery includes:

Dimensional inspection reports (PDF and XML)

Material traceability certificates

Process validation records

Packing list with serialized part tracking

Standard lead times vary by complexity and material, as outlined below:

| Complexity Level | Typical Lead Time (Business Days) | Material Examples |

|---|---|---|

| Low | 5-7 | Aluminum 6061, ABS |

| Medium | 8-12 | Stainless 304, PEEK |

| High | 13-20 | Titanium Grade 5, Inconel |

This integrated workflow reduces prototyping risk by 40% compared to industry benchmarks, with 98.7% on-time delivery performance in 2023. Every phase maintains auditable records, providing clients with full transparency while accelerating time-to-market for mission-critical components.

Start Your Project

Precision CNC Machining Inc. delivers high-accuracy, custom-machined components for demanding industries. Backed by advanced CNC technology and rigorous quality control, we support prototyping and low-to-mid volume production with tight tolerances and fast turnaround.

Our manufacturing facility is located in Shenzhen, a global hub for precision engineering and supply chain efficiency. This strategic location enables rapid iteration, cost-effective production, and seamless scalability.

For project inquiries or quotations, contact Susan Leo at [email protected]. We respond to all requests within one business day.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.