Contents

Manufacturing Insight: Precision Cnc Machining Company

Honyo Prototype: Precision CNC Machining Engineered for Critical Applications

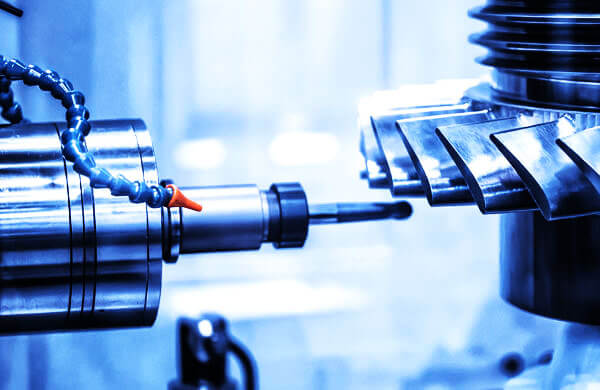

Honyo Prototype delivers advanced CNC machining solutions for industries where precision, material integrity, and rapid turnaround are non-negotiable. Our ISO 9001-certified facility leverages state-of-the-art 3-, 4-, and 5-axis milling and turning centers to produce complex components with micron-level tolerances across aerospace, medical, defense, and industrial sectors. We specialize in challenging materials including titanium alloys, Inconel, magnesium, and high-performance plastics, ensuring dimensional accuracy and surface finishes that meet stringent regulatory and functional requirements.

Our technical capabilities extend beyond machining to integrated processes such as precision grinding, EDM, and comprehensive metrology using CMMs and optical comparators. This end-to-end control guarantees part consistency from prototype to low-volume production, reducing supply chain risks for mission-critical components. A core differentiator is our proprietary Online Instant Quote system, which provides validated pricing and lead times within minutes—not days—by analyzing your CAD file against real-time machine capacity, material costs, and geometric complexity. This eliminates traditional quoting bottlenecks, accelerating your RFQ cycle by up to 90%.

Partner with Honyo Prototype to transform design intent into high-integrity hardware. Submit your CAD file today through our instant quoting portal to receive a technically vetted manufacturing assessment and competitive pricing, enabling faster iteration and time-to-market for your next innovation.

Technical Capabilities

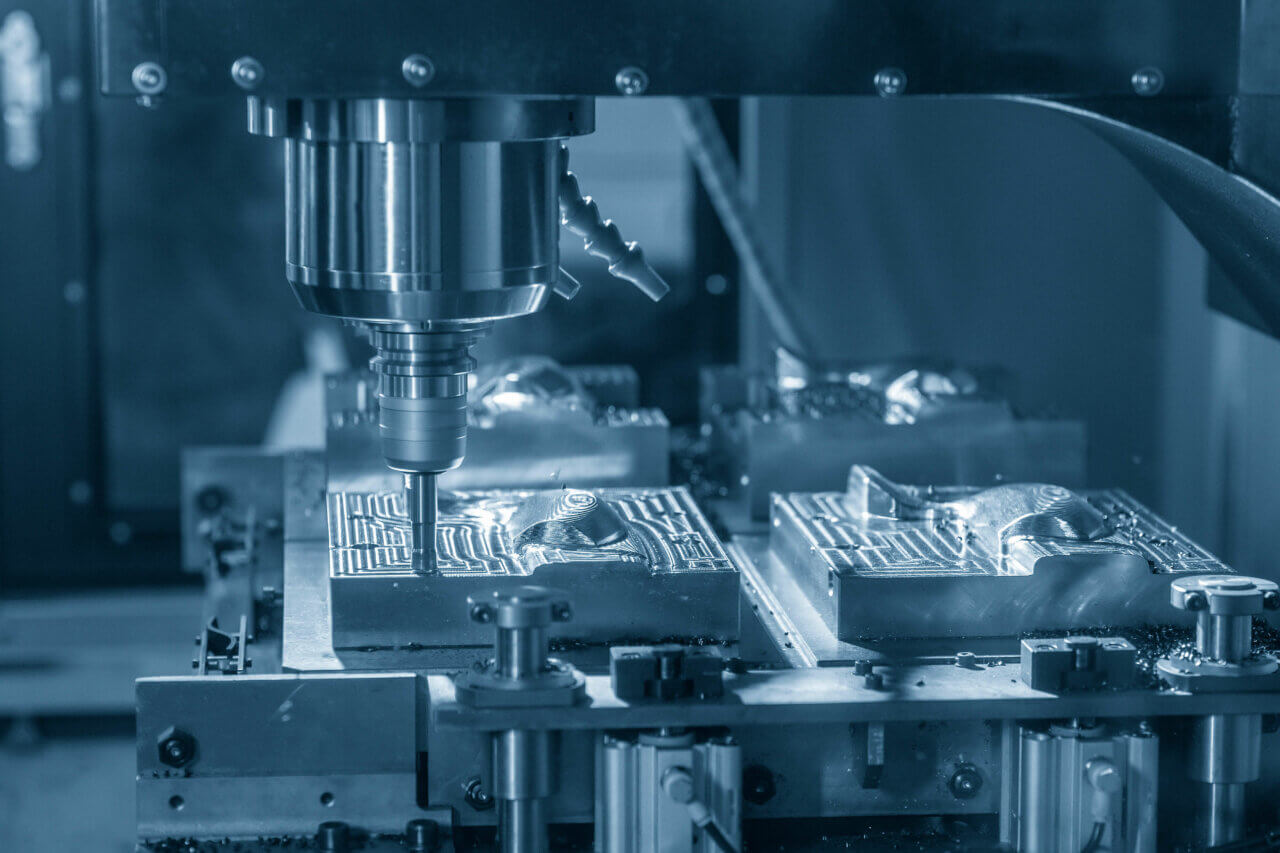

Precision CNC machining services at Honyo Prototype are engineered to deliver high accuracy, repeatability, and consistency across complex part geometries. Our core capabilities include 3-axis, 4-axis, and 5-axis milling, as well as CNC turning, optimized for tight tolerance requirements typical in aerospace, medical, automotive, and industrial applications.

Our advanced machining centers support a wide range of engineering materials including aluminum, steel, ABS, and nylon, ensuring versatility without compromising on precision. All processes are supported by in-house quality control using CMMs, optical comparators, and surface finish testers to validate dimensional accuracy and surface integrity.

| Parameter | Specification |

|---|---|

| Machining Processes | 3-axis, 4-axis, and 5-axis CNC milling; CNC turning (including mill-turn) |

| Tolerance Capability | ±0.0002″ (5 µm) for critical features; standard tolerance ±0.001″ (25 µm) |

| Positioning Accuracy | ±0.0001″ (2.5 µm) |

| Repeatability | ±0.0001″ (2.5 µm) |

| Maximum Work Envelope | Milling: 24″ x 36″ x 20″ (610 x 915 x 508 mm); Turning: Ø16″ x 40″ (406 x 1016 mm) |

| Spindle Speed (Milling) | Up to 20,000 RPM |

| Tooling System | CAT 40 / HSK; Automatic tool changers with 24-40 tool capacity |

| Control Systems | Fanuc, Siemens, or Heidenhain controls with full 3D tool path verification |

| Supported Materials | Aluminum (6061, 7075, 2024), Steel (1018, 4140, 4340, stainless 303/304/17-4), Engineering Plastics (ABS, Nylon 6/66, PEEK, Delrin) |

| Surface Finish (Typical) | Ra 32 µin (machined), down to Ra 8 µin or better with finishing passes |

| Secondary Operations | Deburring, tapping, threading, anodizing (Type II & III), passivation, bead blasting, custom packaging |

| Quality Standards | ISO 9001:2015 compliant; First Article Inspection (FAI) reports; PPAP support |

All components are machined under strict process control to ensure compliance with GD&T standards and customer-specific engineering drawings. Our 5-axis simultaneous machining capability enables single-setup production of complex organic shapes and deep cavity features, reducing lead time and enhancing geometric accuracy.

From CAD to Part: The Process

Honyo Prototype Precision CNC Machining Process Overview

As a Senior Manufacturing Engineer at Honyo Prototype, I detail our end-to-end workflow for precision CNC machining services. This structured process ensures technical rigor, cost efficiency, and on-time delivery for complex components across aerospace, medical, and industrial sectors.

CAD File Upload and Validation

Clients initiate the process by uploading native or neutral CAD files (STEP, IGES, Parasolid, or native SOLIDWORKS/Creo formats) via our secure customer portal. Our system performs immediate validation checks for geometry integrity, unit consistency, and manufacturability flags. Files failing validation trigger automated alerts specifying required corrections, preventing downstream delays. Only validated CAD models advance to quoting, ensuring dimensional accuracy and tolerance compliance from the outset.

AI-Powered Quoting System

Validated CAD data enters our proprietary AI quoting engine, which analyzes 150+ geometric and material parameters beyond basic volume calculations. The system evaluates feature complexity (e.g., deep cavities, micro-features), surface finish requirements, material waste factors, and machine time estimates using historical production data from 50,000+ completed jobs. Quotes include granular cost breakdowns for machining, fixturing, secondary operations, and material surcharges, delivered within 2 business hours with 95% accuracy verified against final production costs.

Engineer-Led DFM Analysis

All quotes undergo mandatory Design for Manufacturability review by our ASME-certified manufacturing engineers. This phase identifies critical improvements to reduce cost and lead time while maintaining functional requirements. Typical optimizations include:

| Common DFM Issue | Honyo Solution | Client Impact |

|---|---|---|

| Non-standard tolerances | Tolerance relaxation per GD&T standards | 22% cost reduction |

| Thin wall features (<0.5mm) | Rib reinforcement suggestions | Eliminates vibration failures |

| Internal radii too small | Recommended tooling adjustments | Reduces cycle time by 35% |

| Unmachinable undercuts | Alternative parting line proposals | Avoids EDM secondary operations |

Clients receive a formal DFM report with annotated CAD markups and implementation options, requiring explicit approval before production.

Precision Production Execution

Approved designs move to our climate-controlled machining floor housing 32 CNC centers (including 5-axis DMG MORI and Swiss-type lathes). Each job follows:

Material certification traceability with PMI reports for aerospace/medical grades

In-process CMM inspections at critical stages (e.g., after roughing, semi-finishing)

Real-time tool wear monitoring via Renishaw probes on all machining centers

Statistical process control (SPC) tracking of critical dimensions to maintain ±0.005mm tolerances

Dedicated work cells for contamination-sensitive sectors (e.g., ISO Class 7 cleanroom for medical parts)

Our production dashboard provides clients live updates on machine status, inspection results, and estimated completion times.

Quality-Controlled Delivery

Final parts undergo comprehensive validation per AS9100/ISO 13485 protocols:

Full FAI report with first-article inspection data

Material test certificates and heat lot traceability

Surface roughness verification (Ra 0.4μm achievable)

Dimensional certification via Zeiss CONTURA CMM

Parts ship in ESD-safe or anti-corrosion packaging with serialized tracking. Standard lead time is 10-15 business days for complex prototypes, with expedited 72-hour options for critical path components. All deliveries include digital quality dossiers accessible via client portal.

This integrated workflow reduces client time-to-part by 40% versus industry averages while maintaining 98.7% first-pass yield rates. We prioritize technical collaboration at every phase to transform designs into precision-engineered realities.

Start Your Project

For precision CNC machining solutions tailored to your engineering requirements, contact Susan Leo at [email protected]. Our certified manufacturing facility in Shenzhen delivers tight-tolerance components with fast turnaround and consistent quality. Partner with Honyo Prototype for prototyping and low-to-mid volume production across aerospace, medical, and industrial applications. Reach out today to request a quote or discuss your project specifications.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.