Guide Contents

Project Insight: Precision Cnc Machining China

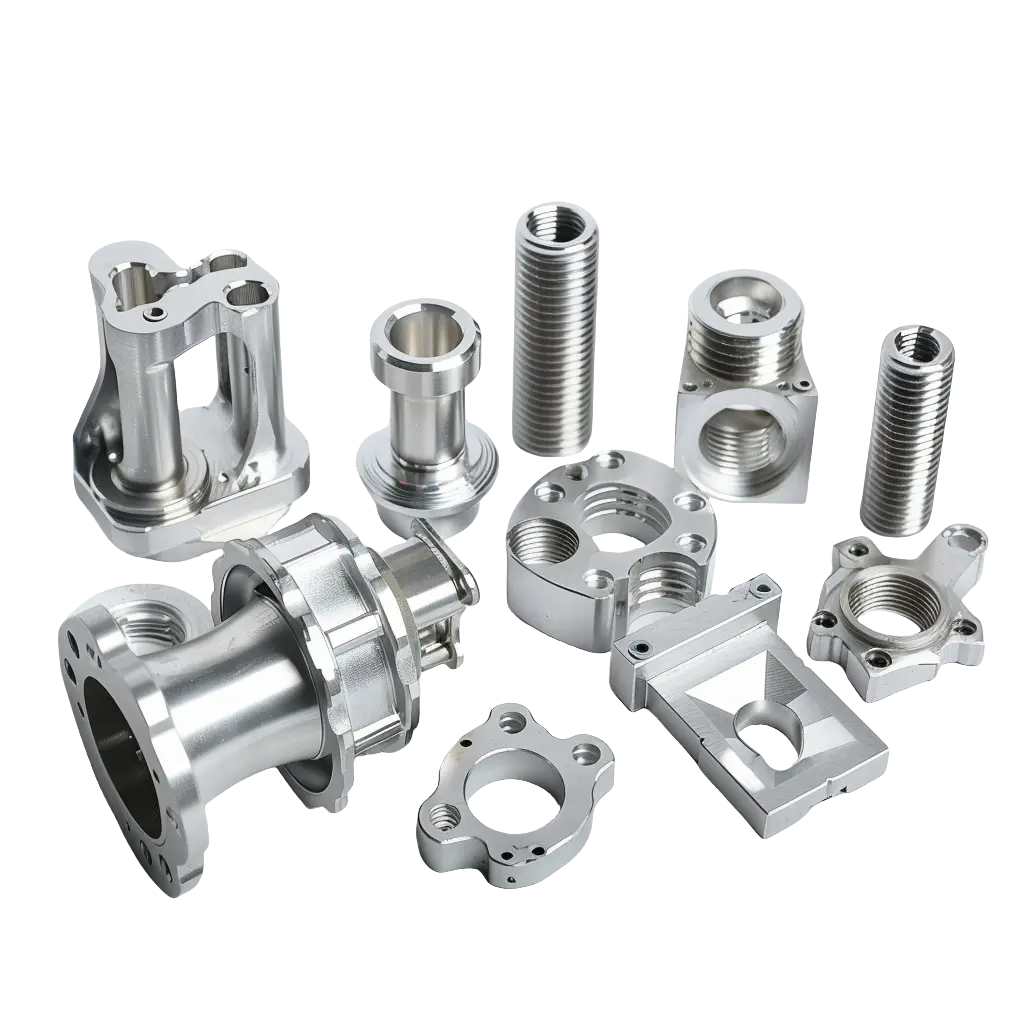

Manufacturing Insight: Precision CNC Machining China — Where Speed Meets Accuracy

The Product Development Imperative: Speed Without Compromise

Time-to-market is non-negotiable: Hardware startups face relentless pressure to iterate faster. A single prototyping delay can extend product launches by weeks—or worse, lose market opportunity.

Precision = reduced risk: Tolerances beyond ±0.05mm often lead to assembly failures or performance gaps. For functional prototypes, micron-level accuracy ensures your design validates correctly on the first try.

China’s evolution: No longer just “low-cost labor,” Chinese CNC manufacturing now delivers aerospace-grade precision at 30–50% lower costs than Western alternatives—without sacrificing speed or quality.

Honyo Prototype: Your Digital Manufacturing Partner for Mission-Critical Parts

AI-Powered Instant Quoting:

Upload your CAD file → Receive a detailed quote with real-time DFM (Design for Manufacturability) feedback in under 10 seconds.

No more back-and-forth emails—our platform flags potential issues before production starts.

24-Hour Prototype Turnaround:

From design to delivery in as little as 1 day for simple parts (starting at $25).

Shenzhen’s strategic logistics hub enables same-day shipping globally—no supply chain bottlenecks.

Aerospace-Grade Precision:

Consistently achieve ±0.01mm tolerances across 3/4/5-axis CNC machining for high-stress components.

ISO 9001-certified quality control with in-process laser scanning and CMM verification.

Transparent Cost Efficiency:

Up to 50% savings vs. US-based manufacturers—no hidden fees, no minimum order quantities.

Real-time cost tracking via our cloud dashboard: Material, labor, and shipping broken down line-by-line.

Why Startups Choose Honyo for Precision Prototyping

“Honyo’s 24-hour turnaround on our drone’s titanium landing gear allowed us to validate the design 3 weeks ahead of schedule—critical for securing our Series A funding.”

— TechStartup X, CEO

Scalable from prototype to volume: Seamlessly transition from 10 parts to 10,000 with identical precision standards.

Engineer-to-engineer collaboration: Dedicated technical support for complex geometries, material selection, and high-tolerance challenges.

End-to-end digital workflow: Track production progress in real time, share feedback instantly, and adjust designs on the fly—all from a single platform.

Innovation thrives when manufacturing keeps pace. Honyo bridges the gap between design and reality—delivering precision-crafted parts at unprecedented speed and value.

Ready to accelerate your next prototype? [Get an Instant Quote Now] →

Honyo Capabilities & Technology

Honyo’s Manufacturing Capabilities

Advanced Multi-Axis Precision Engineering

3/4/5-axis CNC machining for complex geometries, undercuts, and intricate features

Tight tolerances of ±0.01mm for mission-critical aerospace, medical, and automotive components

Support for 50+ materials, including aerospace-grade titanium, medical-grade PEEK, and aerospace aluminum alloys

Comprehensive surface finishing options: anodizing, electropolishing, powder coating, and precision polishing

Scalable Production from Prototypes to Mass Production

Seamless transition from single prototypes to 10,000+ production units with zero retooling costs

No minimum order quantities (MOQs) – ideal for startups and iterative design phases

Automated process control ensures consistent quality across all volumes

Flexible batch sizing to match your product development lifecycle and budget constraints

ISO-Certified Quality Assurance

ISO 9001:2015 certified manufacturing processes with full documentation traceability

In-process inspections using CMM, optical comparators, and laser scanning systems

Material certification and production data tracking for regulatory compliance (e.g., FDA, AS9100)

Final inspection reports with GD&T analysis included with every order

Digital-First Service Platform

AI-powered instant quotes with real-time cost breakdowns delivered in <60 seconds

Automated DFM (Design for Manufacturing) feedback to eliminate production risks before machining begins

Expedited lead times: prototypes in 24-48 hours, production parts in 5-7 days with rush options

30-50% cost savings versus Western suppliers through optimized workflows and local manufacturing expertise

Materials & Surface Finishes

Material Selection & Finishes for Precision CNC Machining

At Honyo Prototype, we engineer materials and finishes to maximize performance and efficiency. Our AI-driven platform ensures you select the optimal combination for your prototype or end-use part—reducing costs, accelerating timelines, and guaranteeing precision within ±0.01mm tolerances.

Precision-Grade Materials

Aluminum 6061: Lightweight, corrosion-resistant, and ideal for structural prototypes (e.g., automotive, consumer electronics). Balances cost-efficiency with excellent machinability.

Aluminum 7075: Aerospace-grade strength for high-stress components where weight-to-strength ratios are critical (e.g., drone frames, military equipment).

Stainless Steel 304: Versatile corrosion resistance for food-grade, medical, and general industrial applications.

Stainless Steel 316: Superior chloride resistance for marine environments, chemical processing, and surgical instruments.

Brass: High electrical conductivity and aesthetic appeal for connectors, valves, and decorative hardware.

PEEK: High-performance thermoplastic for extreme temperatures, chemical exposure, and biocompatible medical implants.

Advanced Surface Finishes

Anodizing: Electrochemical hardening for aluminum parts with customizable colors (e.g., black, blue, clear) and enhanced wear resistance.

Painting: Custom color matching with UV-resistant, durable coatings for visual branding or functional protection.

Polishing: Mirror or satin finishes for hygienic applications (e.g., medical devices) or premium aesthetics.

Powder Coating: Thick, scratch-resistant layer for outdoor industrial components requiring long-term durability.

Electroplating: Nickel or chrome plating for improved corrosion resistance and conductivity in electrical components.

Smart Material Selection Guide

Strength vs. Weight: Prioritize Aluminum 7075 for aerospace or PEEK for lightweight high-temp needs.

Environmental Factors: Stainless 316 for marine/chemical exposure; anodized aluminum for outdoor durability.

Electrical Properties: Brass for conductive parts; PEEK for insulating requirements.

Cost Optimization: Aluminum 6061 delivers the best value for most prototyping scenarios.

AI-Powered Recommendations: Our platform analyzes your CAD file in real-time to suggest optimal materials and finishes—reducing trial-and-error by 40% and cutting lead times by up to 30%.

Get an instant quote in seconds with Honyo’s AI-driven platform. Upload your design, and receive a detailed cost breakdown, material recommendations, and a guaranteed turnaround time—ensuring your project stays on schedule and on budget. [Start Your Quote Now →]

From Quote to Part: Our Process

How It Works: From CAD to Part

Honyo Prototype’s AI-driven workflow eliminates traditional manufacturing delays—delivering functional prototypes and end-use parts in record time with full transparency. Here’s how it works:

1. Upload CAD File

Drag-and-drop your design files in seconds. Supported formats: STEP, IGES, STL, SOLIDWORKS, and more.

No technical barriers—our platform handles complex geometries with ease.

2. Get Instant Quote (AI Engine)

AI-powered analysis delivers a transparent quote in under 60 seconds—no waiting days for estimates.

Real-time pricing includes material, quantity, lead time, and all costs with zero hidden fees.

30-50% cost savings vs. US suppliers, leveraging China’s strategic manufacturing ecosystem.

3. DFM Analysis

Our engineering team conducts proactive Design for Manufacturing review to optimize your design.

Receive actionable feedback on tolerances, material selection, and process improvements before production starts.

Reduce rework costs by up to 30% through early-stage design validation.

4. Production & Delivery

Precision CNC machining at ±0.01mm tolerances with 3/4/5-axis capabilities for functional prototypes and end-use parts.

As fast as 1-day turnaround for prototypes; scalable to high-volume production.

End-to-end tracking and proactive communication—your parts arrive on time, every time.

Start Your Project with Honyo

Start Your Project with Honyo

Precision Engineered for Innovation

3/4/5-Axis CNC Machining: Complex geometries with micron-level accuracy (±0.01mm) for aerospace-grade functional prototypes and end-use parts

Material Versatility: Aerospace alloys, stainless steel, engineering plastics, and composites – optimized for performance-critical applications

Design for Manufacturability (DFM) Expertise: AI-driven feedback to eliminate costly redesigns and accelerate time-to-market

AI-Powered Efficiency Engine

Instant Online Quote: Real-time pricing in <60 seconds via our smart platform – no hidden fees, no delays

30-50% Cost Savings: Outperform US/EU suppliers while maintaining ISO 9001-certified quality control

24-Hour Rapid Prototyping: Starting at $25 for custom metal/plastic parts – delivered in as fast as 1 day

Trusted by Industry Leaders

Founder Susan Leo: 15+ years leading precision manufacturing innovation for global startups and enterprise clients

Strategic Shenzhen/Dongguan Facilities: ISO-certified production hubs with real-time quality monitoring and scalable capacity

End-to-End Partnership: From prototype validation to mass production – we solve your toughest engineering challenges

[Get Your Free Quote Now] → [email protected] | +86 139 2843 8620 | Visit Our Facilities

🚀 Manufacturing Cost Estimator

Compare cost impact of different technologies for your parts.