Contents

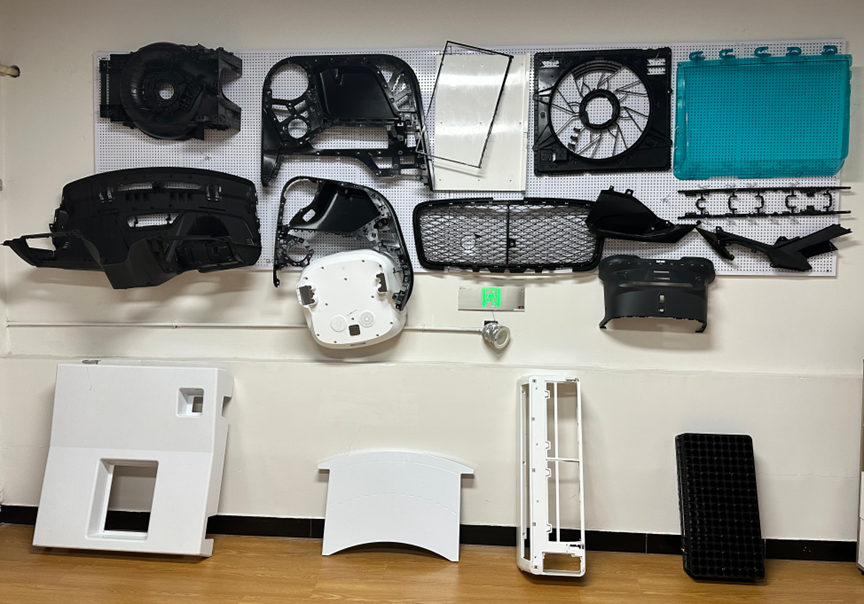

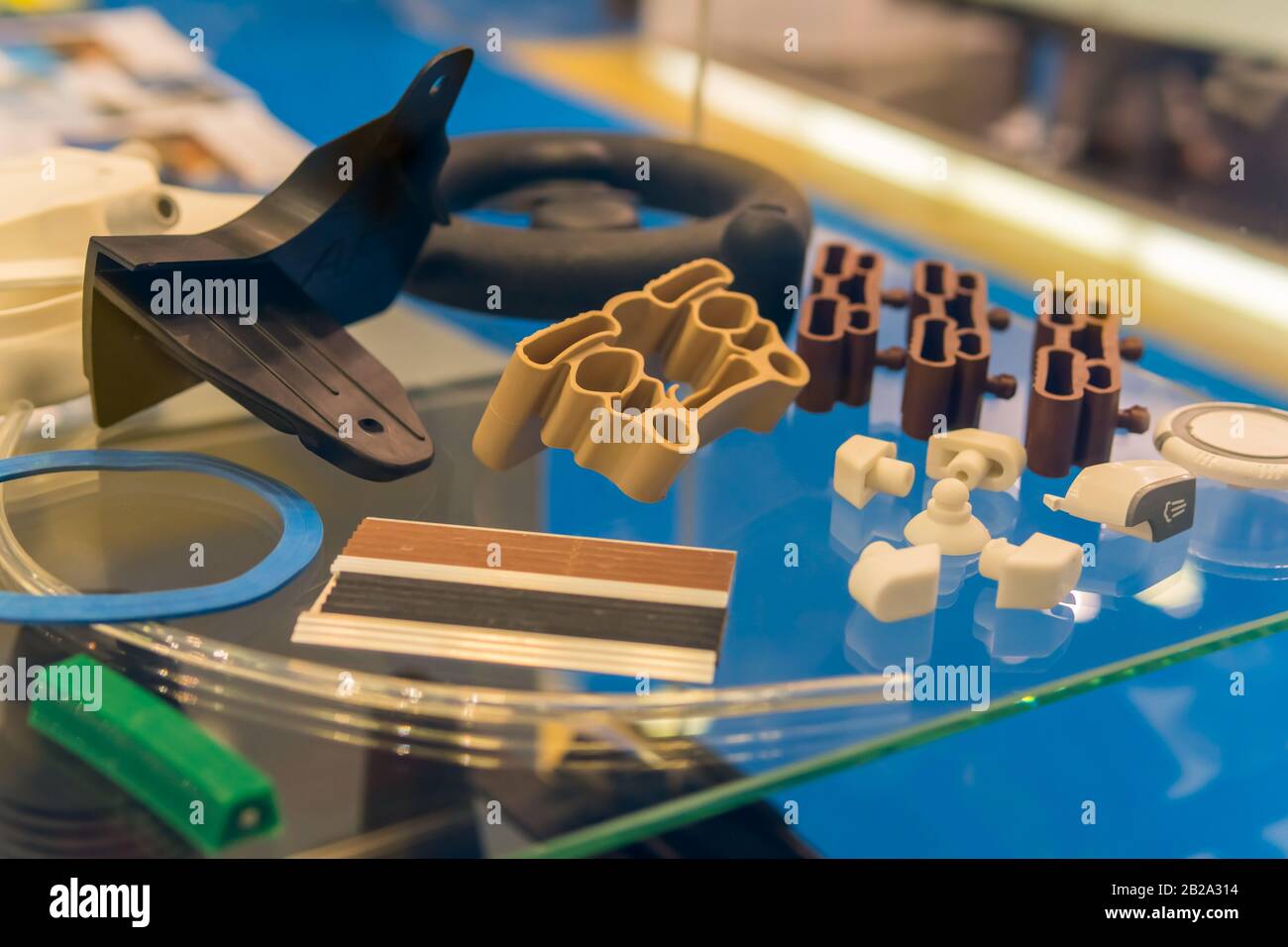

Manufacturing Insight: Precision Automotive Plastics Photos

Precision Automotive Plastics: Engineered for Performance and Reliability

At Honyo Prototype, we deliver mission-critical plastic components for the automotive sector through advanced CNC machining capabilities tailored to the industry’s exacting demands. Our ISO 9001-certified processes transform engineering-grade polymers—including PEEK, PPS, nylon, and polypropylene—into high-integrity parts with tolerances held to ±0.005mm. Every component undergoes rigorous in-process inspection to ensure dimensional stability, thermal resistance, and mechanical consistency under extreme operational conditions.

Automotive OEMs and Tier 1 suppliers rely on our expertise to bridge the gap between prototyping and production, accelerating time-to-market for fuel system components, sensor housings, and interior subsystems. Unlike conventional molding methods, our CNC machining eliminates tooling lead times and material waste while accommodating rapid design iterations—critical for validating complex geometries in low-to-mid volume runs.

The visual examples showcased in this gallery reflect our commitment to surface finish precision and structural integrity, directly impacting part functionality in safety-critical applications. To streamline your next project, leverage our Online Instant Quote platform for real-time pricing and manufacturability feedback within hours, not days. Submit your CAD files today to experience how Honyo Prototype turns precision plastic concepts into automotive-ready solutions.

Technical Capabilities

Precision Automotive Plastics Machining – Technical Specifications Overview

For high-precision automotive plastic components, advanced machining processes such as 3-axis, 4-axis, and 5-axis milling, along with precision turning, are critical to achieving tight tolerances and complex geometries. These processes are also applied to metal prototypes and tooling used in plastic part fabrication, such as molds and fixtures. Below is a detailed technical specification table outlining key capabilities and material compatibility.

| Parameter | Specification Details |

|---|---|

| Machining Processes | 3-Axis Milling, 4-Axis Rotary Milling, 5-Axis Simultaneous Milling, CNC Turning |

| Tolerance Capability | ±0.005 mm (±0.0002″) for critical features; typical ±0.01 mm (±0.0004″) |

| Surface Finish | Ra 0.8 µm (32 µin) standard; down to Ra 0.4 µm (16 µin) with polishing or fine toolpaths |

| Max Work Envelope (Milling) | 1000 x 600 x 500 mm (39″ x 23.6″ x 19.7″) for 3/4/5-axis platforms |

| Max Turning Diameter | 300 mm (11.8″); Max Length: 500 mm (19.7″) |

| Spindle Speed (Milling) | Up to 24,000 RPM with high-frequency spindles for fine plastic detailing |

| Tooling Compatibility | Carbide, diamond-coated, and polycrystalline diamond (PCD) tools for abrasive plastics |

| Materials – Plastics | ABS (Acrylonitrile Butadiene Styrene), Nylon (PA6, PA66, glass-filled options), POM (Acetal), PC (Polycarbonate), PEEK (high-temp engineering thermoplastics) |

| Materials – Metals (Tooling/Molds) | Aluminum 6061-T6, 7075-T6; Tool Steel (H13, S7, 4140, 17-4 PH), Stainless Steel (303, 304, 316) |

| Coolant / Lubrication | Air blasting and mist coolant for plastics; flood coolant for metals to prevent warping |

| Inspection Equipment | CMM (Coordinate Measuring Machine), Optical Comparators, Laser Scanning, Micrometers, Calipers |

| Data Input Formats | STEP, IGES, Parasolid, SolidWorks, DWG, DXF (with GD&T and critical feature callouts) |

These specifications support the production of precision automotive components such as sensor housings, fluid system connectors, interior trim prototypes, and under-hood assemblies requiring strict dimensional control and repeatability. Honyo Prototype leverages multi-axis machining to minimize setup changes and maintain tight tolerances across complex organic shapes typical in modern automotive design.

From CAD to Part: The Process

Honyo Prototype’s process for precision automotive plastic prototypes follows a rigorously controlled workflow designed to meet IATF 16949 standards and automotive-specific requirements. The term “photos” appears to be a typographical error; we assume the intended reference is to precision automotive plastic prototypes. Below is our standardized technical process:

CAD Upload and Initial Validation

Clients submit native CAD files (STEP or IGES preferred) via our secure portal. Our system performs immediate geometric integrity checks, verifying watertightness, surface continuity, and unit consistency. Non-compliant files trigger automated notifications specifying required corrections. This stage ensures downstream processes avoid interpretation errors common in automotive applications where tolerances often require ±0.05 mm accuracy.

AI-Powered Quoting with Engineering Oversight

Proprietary AI algorithms analyze the validated CAD geometry, material specifications, and quantity requirements to generate a preliminary quote within 2 hours. However, this is not an automated final quote. A dedicated manufacturing engineer reviews the AI output, focusing on automotive-critical factors: material suitability (e.g., UL94 V-0 ratings for under-hood components), tooling complexity for thin-wall features (<1.2mm), and secondary operations like ultrasonic welding. This dual-layer validation prevents quoting errors that could compromise part functionality in safety-critical systems.

Automotive-Grade DFM Analysis

The Design for Manufacturability phase is conducted by engineers with minimum 5 years of automotive plastics experience. We utilize Moldflow simulation alongside physical rule-based checks, specifically addressing:

Gate location analysis to prevent weld lines in structural load paths

Draft angle verification per SAE J1706 standards

Shrinkage compensation for engineered resins (e.g., PPA, PPS)

Venting validation to avoid burn marks in sealed enclosures

Clients receive a formal DFM report with actionable recommendations, not just observations. This stage typically resolves 92% of potential production defects before tooling begins.

Precision Production Execution

Prototypes are manufactured in our climate-controlled Class 8 cleanroom using electric servo-driven injection molding machines with ±0.1°C temperature control. Each run includes:

Real-time cavity pressure monitoring for consistency

First-article inspection per AS9102 format with full GD&T reporting

Material lot traceability to raw pellet certification

In-process validation of critical dimensions using calibrated CMMs

For sensor housings or fluid-handling components, we perform additional leak testing per ISO 11439 protocols.

Certified Delivery and Documentation

Delivery encompasses physical parts and mandatory automotive documentation:

PPAP Level 3 package including MSA reports and process capability data (Cp/Cpk ≥1.67)

Material test reports with UL E477279 certification where applicable

Dimensional results overlaid on 3D CAD for deviation visualization

Shipping in ESD-safe containers with humidity indicators

All shipments include a digital twin of the part’s actual measured data for client validation against simulation models.

This end-to-end process reduces time-to-prototype by 35% versus industry averages while ensuring compliance with automotive Tier 1 supplier requirements. Every stage is governed by our IATF 16949:2016-certified quality management system, with full traceability from CAD file to delivered component.

Start Your Project

Explore our precision automotive plastics manufacturing capabilities in action. High-accuracy injection molding, tight-tolerance components, and full production support—all from our Shenzhen factory.

Contact Susan Leo to request sample photos or discuss your next project.

Email: [email protected]

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.