Introduction: Navigating the Global Market for precise parts

In the increasingly competitive landscape of global commerce, sourcing precise parts poses a significant challenge for international B2B buyers. Whether you are in Africa, South America, the Middle East, or Europe, the quest for high-quality components that meet specific technical requirements can be daunting. This guide aims to demystify the process of procuring precise parts, offering insights into various types, applications, and the intricacies of supplier vetting. With a focus on critical factors such as cost, quality assurance, and logistical considerations, we empower businesses to make informed purchasing decisions that align with their operational needs.

Navigating the global market requires a strategic approach, particularly when dealing with customized components that vary across industries—from aerospace to medical devices. Understanding the nuances of the supply chain, including sourcing from reputable manufacturers and assessing the fit for specific applications, is essential. This guide will equip you with the knowledge to evaluate suppliers effectively, ensuring that your procurement process is efficient and successful. With actionable insights tailored to the unique challenges faced by buyers in diverse regions, you can approach your sourcing strategy with confidence, ultimately enhancing your operational efficiency and competitiveness in the marketplace.

Understanding precise parts Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Custom Adapters | Tailored connections, specific lengths, and device compatibility | Astronomy, photography, specialized machinery | Pros: Precision fit, optimized performance; Cons: Non-returnable, requires accurate specifications. |

| Investment Castings | Complex shapes, high strength, and intricate designs | Aerospace, automotive, energy sectors | Pros: High durability, excellent surface finish; Cons: Longer lead times, higher initial costs. |

| Precision Machined Parts | High tolerance, various materials, and surface finishes available | Medical devices, electronics, automotive | Pros: Superior accuracy, repeatability; Cons: Potentially higher prices for intricate designs. |

| Fasteners | Standardized sizes, various materials, and load ratings | Construction, automotive, machinery | Pros: Widely available, easy to source; Cons: May not meet specific application needs without customization. |

| Replacement Components | Specific to existing machinery, often standardized | Consumer appliances, industrial machines | Pros: Easy to replace, often readily available; Cons: Limited customization options, may not match original specs. |

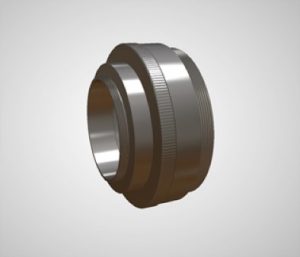

What Are Custom Adapters and When Are They Suitable for B2B Buyers?

Custom adapters are designed to connect two devices in a specific optical or mechanical configuration, making them essential in fields like astronomy and high-end photography. Their ability to be tailored in length and compatibility ensures optimal performance in complex setups. B2B buyers must carefully consider the specifications of the devices they intend to connect, as errors in design can lead to non-returnable products. This makes accurate measurements and understanding of the equipment crucial prior to purchase.

How Do Investment Castings Meet the Needs of Different Industries?

Investment castings are characterized by their ability to produce complex geometries and high-strength components, making them ideal for demanding applications such as aerospace and energy sectors. They offer superior surface finishes and dimensional accuracy, which are critical in high-performance environments. However, buyers should be aware of longer lead times and potentially higher costs, as the intricate manufacturing process can be resource-intensive. Understanding the specific requirements of their projects will help buyers leverage the benefits of investment castings effectively.

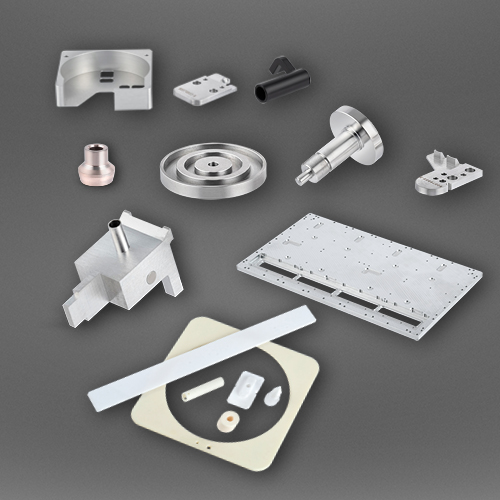

Why Are Precision Machined Parts Important for B2B Applications?

Precision machined parts are manufactured to exacting tolerances, making them crucial in industries such as medical devices and electronics, where precision is paramount. These parts can be made from a variety of materials and can feature different surface finishes, allowing for customization based on specific application requirements. While they offer exceptional accuracy and repeatability, buyers may face higher costs, especially for intricate designs. It is vital for buyers to balance their need for precision with their budget constraints.

What Role Do Fasteners Play in Various Industries?

Fasteners are essential components that provide mechanical connections in construction, automotive, and machinery applications. They come in standardized sizes and materials, making them easily accessible for procurement. While they are widely available and simple to source, buyers should consider the specific load ratings and material properties to ensure they meet the demands of their applications. In situations where customization is necessary, buyers may need to explore options beyond standard fasteners to find the right solution.

How Do Replacement Components Fit into B2B Supply Chains?

Replacement components are often specific to existing machinery and can be standardized for ease of replacement in consumer appliances and industrial machines. Their availability simplifies maintenance and reduces downtime for businesses. However, the limitation in customization may pose challenges if the replacement parts do not meet original specifications. B2B buyers should ensure that they source high-quality replacement components that align with their equipment’s requirements to maintain operational efficiency.

Key Industrial Applications of precise parts

| Industry/Sector | Specific Application of precise parts | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Custom fasteners and structural components for aircraft | Enhanced safety and reliability in high-stakes environments | Compliance with international standards and certifications |

| Automotive | Precision engine components and transmission parts | Improved performance and fuel efficiency | Material quality and compatibility with existing systems |

| Oil & Gas | Complex castings for drilling and extraction equipment | Increased operational efficiency and reduced downtime | Supplier reliability and ability to meet strict specifications |

| Medical Devices | Custom surgical instruments and implants | Enhanced patient safety and treatment outcomes | Regulatory compliance and precision in manufacturing |

| Electronics Manufacturing | Precision parts for circuit boards and assemblies | Higher product reliability and performance | Lead times, material sourcing, and technological compatibility |

What Are the Key Applications of Precise Parts in the Aerospace Industry?

In the aerospace sector, precise parts are critical for manufacturing custom fasteners and structural components used in aircraft assembly. These components must meet stringent safety and performance standards, as they directly impact the aircraft’s reliability and safety. International B2B buyers, particularly from regions such as Europe and the Middle East, should prioritize suppliers who comply with international aerospace standards, ensuring that all parts are certified and tested for use in high-stakes environments.

How Do Precise Parts Enhance Automotive Performance?

The automotive industry relies heavily on precise parts for engine components and transmission systems, which are crucial for vehicle performance and fuel efficiency. By sourcing high-quality precision parts, manufacturers can enhance the overall driving experience and minimize emissions. Buyers in South America and Africa should consider the compatibility of these parts with existing systems, as well as the supplier’s capability to provide materials that meet local regulations and standards.

What Role Do Precise Parts Play in Oil & Gas Operations?

In the oil and gas industry, precise parts, such as complex castings for drilling and extraction equipment, are vital for operational efficiency. These components help reduce downtime and improve the overall productivity of drilling operations. When sourcing these parts, international buyers must evaluate the reliability of suppliers and their ability to meet strict specifications, particularly for critical applications where failure is not an option.

Why Are Precise Parts Essential in Medical Device Manufacturing?

Medical devices require precise parts for custom surgical instruments and implants, where accuracy is paramount for patient safety and treatment efficacy. Buyers must ensure that the manufacturers adhere to regulatory compliance, as deviations can lead to severe consequences. Additionally, the precision in manufacturing these parts directly correlates to improved patient outcomes, making it imperative for international B2B buyers to prioritize quality and precision in their sourcing decisions.

How Do Precise Parts Impact Electronics Manufacturing?

In electronics manufacturing, precise parts are essential for circuit boards and assembly components that ensure higher product reliability and performance. The demand for precision in this sector is driven by the need for efficient and long-lasting electronic devices. Buyers should focus on lead times, sourcing materials that meet specific technological requirements, and ensuring compatibility with existing production systems, especially in emerging markets in Africa and South America.

3 Common User Pain Points for ‘precise parts’ & Their Solutions

Scenario 1: Difficulty in Custom Part Specifications

The Problem: Many B2B buyers encounter challenges when trying to specify precise parts for their applications. Whether they are sourcing components for manufacturing, aerospace, or other specialized fields, understanding the exact specifications—such as dimensions, materials, and tolerances—can be daunting. This lack of clarity often leads to miscommunications with suppliers, resulting in delays, increased costs, and sometimes, unusable parts that do not meet operational requirements. The stakes are high when precision is critical, and buyers feel frustrated when they cannot articulate their needs effectively.

The Solution: To overcome this challenge, B2B buyers should invest time in developing a detailed specification document that outlines all necessary parameters for the precise parts they require. This document should include dimensions, tolerances, material specifications, and any relevant industry standards. Collaborating with engineering teams or using CAD software can facilitate this process, ensuring that all technical aspects are covered. Once the specifications are drafted, buyers should engage with suppliers early in the process to discuss these requirements, allowing for any adjustments based on the supplier’s capabilities. This proactive approach not only clarifies expectations but also builds a stronger relationship with suppliers, leading to better alignment and reduced risk of errors.

Scenario 2: Incompatibility Issues with Existing Equipment

The Problem: A common pain point for B2B buyers is the incompatibility of new precise parts with existing machinery or systems. For instance, when integrating custom components into established manufacturing lines, discrepancies in threading, connection types, or physical dimensions can lead to significant operational disruptions. Such incompatibilities not only delay projects but may also necessitate costly modifications or replacements of existing equipment.

The Solution: To mitigate the risk of incompatibility, buyers should conduct a thorough compatibility assessment before ordering new parts. This involves reviewing existing equipment specifications and understanding the technical requirements of the new components. Engaging in discussions with both engineering teams and suppliers can help clarify potential issues early on. Additionally, utilizing design software that simulates the integration of new parts with current systems can provide valuable insights into compatibility. Finally, requesting prototype parts or samples before committing to a full order can further ensure that the new components fit seamlessly with existing operations, minimizing downtime and additional costs.

Scenario 3: Long Lead Times and Delivery Delays

The Problem: B2B buyers often face long lead times when ordering precise parts, which can severely impact project timelines. Delays in the delivery of critical components can halt production, lead to missed deadlines, and disrupt supply chains. This is particularly concerning in fast-paced industries where time-to-market is a competitive advantage. Buyers frequently express frustration over not being able to predict delivery times accurately, leaving them vulnerable to project delays.

The Solution: To address lead time issues, buyers should develop a strategic sourcing plan that includes multiple suppliers. This diversification not only reduces dependency on a single source but also allows for quicker turnaround times by leveraging different manufacturing capabilities and locations. Establishing strong relationships with suppliers can also facilitate faster processing of orders. Buyers should communicate their timelines clearly and consider placing orders well in advance of when components are needed. Additionally, utilizing just-in-time inventory practices can help manage stock levels and reduce the impact of delays. By planning ahead and maintaining open lines of communication with suppliers, buyers can enhance their operational agility and minimize the effects of lead time variability.

Strategic Material Selection Guide for precise parts

What Are the Key Properties of Common Materials Used for Precise Parts?

When selecting materials for precise parts, it is essential to consider their specific properties that directly impact performance. Here, we analyze four common materials: aluminum, stainless steel, titanium, and plastics, focusing on their suitability for various applications.

Aluminum: Lightweight and Versatile

Aluminum is renowned for its lightweight nature and excellent corrosion resistance, making it suitable for applications requiring reduced weight without compromising strength. It typically operates well under moderate temperature and pressure conditions, with a melting point around 660°C.

Pros:

– High strength-to-weight ratio.

– Good thermal and electrical conductivity.

– Cost-effective for mass production.

Cons:

– Lower fatigue strength compared to steel.

– Limited performance at elevated temperatures.

Impact on Application: Aluminum is ideal for aerospace and automotive components, where reducing weight is crucial. However, it may not be suitable for high-temperature applications.

Considerations for International Buyers: Compliance with standards like ASTM and ISO is critical. Buyers in regions like Europe and the Middle East should ensure that suppliers meet local regulations regarding material quality and sourcing.

Stainless Steel: Strength and Corrosion Resistance

Stainless steel is a favored choice for precise parts due to its exceptional strength and resistance to corrosion and oxidation. With a melting point ranging from 1400°C to 1450°C, it can withstand high temperatures and pressures.

Pros:

– Excellent durability and longevity.

– High resistance to corrosion, making it suitable for harsh environments.

Cons:

– Heavier than aluminum, which may not be ideal for weight-sensitive applications.

– Higher manufacturing costs due to machining complexity.

Impact on Application: Stainless steel is commonly used in medical devices, food processing, and chemical industries where hygiene and durability are paramount.

Considerations for International Buyers: Buyers should be aware of the different grades of stainless steel (e.g., 304, 316) and their specific applications. Compliance with standards such as ASTM and DIN is essential, particularly in Europe.

Titanium: High Performance for Demanding Applications

Titanium is known for its high strength, low density, and outstanding corrosion resistance, making it suitable for high-performance applications. It has a melting point of approximately 1668°C, allowing it to perform well under extreme conditions.

Pros:

– Exceptional strength-to-weight ratio.

– Biocompatibility makes it ideal for medical implants.

Cons:

– Expensive compared to aluminum and stainless steel.

– Difficult to machine, leading to higher production costs.

Impact on Application: Titanium is often used in aerospace, medical, and high-end automotive applications where performance and reliability are critical.

Considerations for International Buyers: Buyers should consider the availability of titanium alloys and their compliance with international standards. Understanding the local market dynamics in regions like South America and Africa can also influence procurement strategies.

Plastics: Cost-Effective and Lightweight

Plastics, particularly engineering plastics like polycarbonate and nylon, offer a cost-effective alternative for precise parts. They are lightweight and can be molded into complex shapes, making them suitable for a variety of applications.

Pros:

– Low manufacturing costs and easy to mold.

– Good chemical resistance and lightweight.

Cons:

– Limited strength compared to metals.

– Temperature sensitivity, which can affect performance in extreme conditions.

Impact on Application: Plastics are widely used in consumer products, automotive components, and electronic housings where weight and cost are critical factors.

Considerations for International Buyers: Buyers should be aware of the specific grades of plastics and their certifications. Compliance with local environmental regulations is also crucial, especially in regions focused on sustainability.

Summary Table of Material Selection for Precise Parts

| Material | Typical Use Case for precise parts | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Aerospace components, automotive parts | Lightweight and corrosion-resistant | Lower fatigue strength | Medium |

| Stainless Steel | Medical devices, food processing equipment | Excellent durability and corrosion resistance | Heavier and higher manufacturing costs | High |

| Titanium | Aerospace, medical implants | High strength-to-weight ratio | Expensive and difficult to machine | High |

| Plastics | Consumer products, electronic housings | Cost-effective and easy to mold | Limited strength and temperature sensitivity | Low |

This guide provides a comprehensive overview of material selection for precise parts, enabling international B2B buyers to make informed decisions based on performance, cost, and compliance considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for precise parts

What Are the Main Stages of Manufacturing Precise Parts?

The manufacturing of precise parts involves several critical stages that ensure the final product meets stringent specifications. The primary stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: This initial phase includes selecting high-quality raw materials, which are often metals or plastics that meet specific engineering standards. Suppliers must ensure that materials are sourced from reputable vendors and undergo thorough inspections to verify their composition and integrity. Techniques such as chemical analysis and mechanical testing are commonly employed to confirm material properties.

-

Forming: In this stage, the prepared materials are shaped into the desired form. Techniques such as machining, casting, forging, and additive manufacturing are prevalent. Each method has its advantages; for example, machining is ideal for achieving tight tolerances, while casting can be more economical for complex shapes. The choice of forming technique is influenced by the part’s design, volume, and material properties.

-

Assembly: Once individual components are formed, they may require assembly. This can involve processes like welding, fastening, or bonding. Precision in assembly is crucial, as misalignment can lead to functional failures. Automated assembly systems are often utilized to enhance accuracy and efficiency, particularly for high-volume production.

-

Finishing: The final stage involves applying treatments that enhance the part’s performance and aesthetics. Finishing techniques may include surface grinding, polishing, anodizing, or coating. Each of these methods serves to improve durability, resistance to corrosion, and overall appearance. Quality checks during this stage are essential to ensure that the finishing meets specified standards.

What Quality Assurance Measures Are Essential in Manufacturing Precise Parts?

Quality assurance (QA) is a cornerstone of manufacturing precise parts, ensuring that each component meets international standards and customer expectations. B2B buyers should be familiar with the following key aspects of quality assurance:

-

International Standards: Compliance with international standards such as ISO 9001 is critical. This standard outlines requirements for a quality management system, focusing on continuous improvement and customer satisfaction. Additionally, industry-specific standards such as CE marking (for European markets) and API specifications (for oil and gas) are essential for particular sectors.

-

Quality Control Checkpoints: A robust quality control process typically includes several checkpoints:

– Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards.

– In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process helps identify defects early and prevent them from progressing to later stages.

– Final Quality Control (FQC): A thorough examination of finished products ensures they meet all specifications before delivery. -

Common Testing Methods: Various testing methods are employed to ensure quality, including:

– Dimensional Inspection: Using tools such as calipers and micrometers to verify that parts meet precise measurements.

– Non-Destructive Testing (NDT): Techniques like ultrasonic testing and X-ray inspection assess material integrity without damaging the part.

– Functional Testing: Evaluates the part’s performance under real-world conditions, ensuring it operates as intended.

How Can B2B Buyers Verify Supplier Quality Control Processes?

B2B buyers must take proactive steps to verify the quality control processes of their suppliers. Here are actionable strategies:

-

Conduct Audits: Regular audits of supplier facilities can provide insight into their quality control practices. These audits should assess compliance with international standards and the effectiveness of their quality management systems.

-

Request Quality Reports: Suppliers should be able to provide documentation that outlines their quality control processes, inspection results, and compliance with relevant standards. This transparency is essential for building trust.

-

Engage Third-Party Inspectors: Utilizing independent third-party inspectors can provide an unbiased assessment of a supplier’s quality control measures. These professionals can conduct inspections at various stages of production, offering additional assurance of quality.

What Are the Quality Control and Certification Nuances for International B2B Buyers?

For B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, understanding the nuances of quality control and certification is crucial. Here are key considerations:

-

Regional Regulations: Different regions may have specific regulations regarding manufacturing and quality assurance. Buyers must be aware of these regulations to ensure compliance. For example, CE marking is mandatory for many products in Europe, while other regions may have different certification requirements.

-

Cultural and Economic Factors: Cultural differences can impact business practices, including quality expectations and communication styles. Buyers should consider these factors when establishing relationships with suppliers from diverse regions.

-

Logistical Considerations: The logistics of international shipping can affect product quality. B2B buyers should ensure that suppliers have robust packaging and shipping processes to minimize the risk of damage during transit.

-

Ongoing Communication: Establishing open lines of communication with suppliers is essential for addressing quality issues promptly. Regular updates and feedback can help maintain product standards and foster a collaborative relationship.

In conclusion, understanding the manufacturing processes and quality assurance measures for precise parts is essential for B2B buyers. By focusing on these aspects, buyers can ensure they receive high-quality products that meet their specific needs while fostering strong supplier relationships across international markets.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘precise parts’

The following guide provides a structured approach for B2B buyers seeking to procure precise parts, ensuring a streamlined sourcing process that prioritizes quality and compatibility.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, it is essential to clearly outline the technical specifications of the precise parts you need. This includes dimensions, materials, tolerances, and any specific performance requirements. Having a well-defined set of specifications will not only help you communicate your needs effectively to suppliers but also ensure that the parts you receive meet your operational standards.

- Considerations:

- Identify the application requirements for the parts.

- Include any industry standards that must be adhered to.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers who specialize in the precise parts you require. Look for companies with a proven track record in your industry, and assess their capabilities in terms of production capacity, technology, and quality control processes.

- Sources to Explore:

- Online directories and industry-specific databases.

- Trade shows and exhibitions that focus on precise manufacturing.

Step 3: Evaluate Supplier Certifications

Before committing to a supplier, verify their certifications and compliance with relevant industry standards. Certifications such as ISO 9001 or specific industry certifications ensure that the supplier adheres to quality management practices, which is crucial for precise parts.

- What to Check:

- Validity and scope of certifications.

- Any recent audits or compliance reports.

Step 4: Request Samples or Prototypes

Once you have shortlisted potential suppliers, request samples or prototypes of the precise parts. This allows you to assess the quality, accuracy, and compatibility of the parts before placing a larger order.

- Key Points:

- Evaluate the samples against your specifications.

- Check for consistency and craftsmanship in the prototypes.

Step 5: Understand Pricing and Payment Terms

Discuss pricing structures and payment terms with your selected suppliers. Understanding the total cost of ownership, including shipping, taxes, and potential duties, is vital for budget management.

- Negotiation Tips:

- Inquire about bulk discounts or long-term partnership pricing.

- Clarify payment methods and timelines to avoid future issues.

Step 6: Assess Customer Support and Communication

Effective communication is critical in the sourcing process. Evaluate how responsive and helpful suppliers are in addressing your queries and concerns. Good customer support can significantly enhance your procurement experience.

- What to Look For:

- Availability of technical support for product-related inquiries.

- Responsiveness to emails and calls during the sourcing phase.

Step 7: Finalize the Contract and Terms

After selecting a supplier, ensure that all terms are clearly outlined in a formal contract. This should include delivery timelines, warranty conditions, and return policies for any defective parts. A well-drafted contract protects both parties and establishes clear expectations.

- Important Elements:

- Clearly defined scope of work.

- Dispute resolution mechanisms.

By following this structured checklist, B2B buyers can effectively navigate the procurement process for precise parts, ensuring quality and operational efficiency.

Comprehensive Cost and Pricing Analysis for precise parts Sourcing

What Are the Key Cost Components in Precise Parts Sourcing?

Understanding the cost structure involved in sourcing precise parts is crucial for international B2B buyers. The primary cost components include:

-

Materials: The choice of materials significantly impacts the overall cost. High-quality metals and alloys, especially those used in aerospace or specialized applications, command higher prices due to their performance characteristics and sourcing complexity.

-

Labor: Labor costs vary based on the region and the expertise required for manufacturing precise parts. Skilled labor in regions with a strong engineering base may incur higher costs, reflecting the advanced training and specialization.

-

Manufacturing Overhead: This includes costs associated with equipment maintenance, factory utilities, and administrative expenses. Overhead can be minimized through efficient production processes and optimized supply chain management.

-

Tooling: Custom tooling is often necessary for precision manufacturing, which adds to initial costs. However, this investment can lead to lower per-part costs in the long run, particularly for high-volume orders.

-

Quality Control (QC): Stringent QC processes are vital, especially for parts used in critical applications. Quality assurance measures can raise initial costs but are essential for maintaining product integrity and reducing liability.

-

Logistics: Transportation and handling costs are significant, particularly for international shipments. The choice of shipping methods, whether air or sea, and the associated tariffs can influence the final price.

-

Margin: Suppliers typically add a margin to cover their risks and profit expectations. This margin can vary based on market competition and the uniqueness of the product.

What Influences Pricing in the Precise Parts Market?

Several factors can influence the pricing of precise parts, making it essential for buyers to be informed:

-

Volume and Minimum Order Quantity (MOQ): Pricing often improves with larger order quantities. Suppliers may offer discounts for bulk purchases, helping to reduce the overall cost per unit.

-

Specifications and Customization: Custom parts designed to specific requirements usually come at a premium. Clear communication of specifications can help avoid costly modifications later.

-

Material Quality and Certifications: Parts that require specific certifications or are made from high-grade materials will generally be more expensive. Buyers should assess their needs to avoid unnecessary expenses.

-

Supplier Factors: The supplier’s reputation, reliability, and geographical location can impact pricing. Local suppliers may offer lower logistics costs but may not have the same quality assurance as larger, established suppliers.

-

Incoterms: Understanding Incoterms is crucial for international buyers. They determine who bears the cost and risk at different stages of the shipping process, which can significantly influence total expenses.

How Can Buyers Negotiate for Better Pricing on Precise Parts?

Effective negotiation can lead to better pricing and terms for B2B buyers:

-

Leverage Volume: Buyers should consider consolidating orders to meet MOQ thresholds, which can result in significant discounts.

-

Explore Long-term Relationships: Building a strong relationship with suppliers can lead to better terms, including preferential pricing and priority service.

-

Evaluate Total Cost of Ownership (TCO): When assessing price, consider not just the initial cost but also long-term factors such as durability, maintenance, and logistics. A higher upfront investment may yield lower TCO.

-

Be Aware of Pricing Nuances: Buyers from regions like Africa, South America, the Middle East, and Europe should be mindful of local market conditions, currency fluctuations, and regulatory changes that may affect pricing.

What Should Buyers Keep in Mind Regarding Pricing Information?

Buyers should be aware that prices for precise parts can vary widely based on the factors mentioned above. Therefore, it is advisable to request indicative pricing from multiple suppliers and understand that these figures may change based on market conditions and specific project requirements. Always seek clarity on terms and conditions before finalizing agreements to avoid unexpected costs.

Alternatives Analysis: Comparing precise parts With Other Solutions

Introduction: Exploring Alternatives to Precise Parts

In the competitive landscape of B2B manufacturing, identifying the right solution for precise components is critical. While ‘Precise Parts’ offers custom machining capabilities for specialized applications, businesses often seek alternatives that may better align with their specific requirements. This analysis will compare ‘Precise Parts’ with other viable solutions, focusing on performance, cost, ease of implementation, maintenance, and best use cases.

Comparison Table

| Comparison Aspect | ‘Precise Parts’ | Alternative 1 Name: 3D Printing | Alternative 2 Name: Off-the-Shelf Components |

|---|---|---|---|

| Performance | High precision and customization | Variable precision, depends on technology | Standardized precision, may vary by manufacturer |

| Cost | Higher due to custom machining | Lower for small runs, higher for large | Generally lower, but varies with complexity |

| Ease of Implementation | Requires understanding of specifications | User-friendly, but may need design skills | Simple, immediate availability |

| Maintenance | Minimal, as parts are custom-made | Dependent on material and technology | Varies by component; often low maintenance |

| Best Use Case | Specialized applications (e.g., astronomy) | Prototyping and low-volume production | General applications with standard specifications |

Detailed Breakdown of Alternatives

3D Printing

3D printing has emerged as a significant alternative for creating precise components. This method allows for rapid prototyping and the production of complex geometries that would be difficult or impossible to machine. One of the main advantages of 3D printing is the reduced cost for small runs, as it eliminates the need for expensive tooling. However, the precision can vary based on the technology (e.g., FDM, SLA) and materials used. It is ideal for businesses looking to innovate quickly but may fall short in applications requiring the utmost precision.

Off-the-Shelf Components

Off-the-shelf components represent a traditional approach where businesses utilize pre-manufactured parts. These components are readily available, often at lower prices than custom solutions. The simplicity of implementation is a significant advantage, as companies can quickly source and integrate these parts into their systems. However, the trade-off is a lack of customization, which can lead to compatibility issues in specialized applications. This solution is best suited for standard industrial applications where precise specifications are not critical.

Conclusion: Choosing the Right Solution for Your Business Needs

When selecting the right solution for precise components, B2B buyers must consider their specific needs, including performance requirements, budget constraints, and the complexity of implementation. ‘Precise Parts’ offers unparalleled customization and precision for specialized applications, while alternatives like 3D printing and off-the-shelf components provide flexibility and cost-effectiveness for different scenarios. Ultimately, understanding the unique demands of each project will guide businesses in choosing the most suitable solution, ensuring they achieve both efficiency and quality in their operations.

Essential Technical Properties and Trade Terminology for precise parts

What are the Key Technical Properties of Precise Parts in B2B Transactions?

Understanding the critical specifications of precise parts is essential for B2B buyers to ensure compatibility and performance in their applications. Here are some key technical properties to consider:

1. Material Grade

Material grade refers to the specific classification of materials based on their chemical composition and mechanical properties. In industries such as aerospace, automotive, and manufacturing, selecting the right material grade is vital for ensuring durability, strength, and resistance to wear and corrosion. Buyers must be aware of material certifications to meet regulatory standards and ensure product longevity.

2. Tolerance

Tolerance defines the permissible limits of variation in a part’s dimensions. It is crucial for ensuring that components fit together correctly within an assembly. Tight tolerances are often required in precision engineering applications, where even minor deviations can lead to operational failures. B2B buyers should understand the tolerance specifications to avoid costly rework or product failures.

3. Surface Finish

Surface finish refers to the texture and smoothness of a part’s surface. It is an important property that affects the performance and aesthetic quality of a component. Different applications may require specific finishes, such as anodizing or powder coating, to enhance corrosion resistance or reduce friction. Buyers should specify surface finish requirements to ensure the final product meets operational needs.

4. Back-Focus and Focal Distance

In optical applications, back-focus and focal distance are critical specifications that determine how well components align in an optical train. Incorrect measurements can lead to poor image quality or system malfunction. B2B buyers in industries like astronomy or high-end photography must pay close attention to these metrics to ensure optimal performance of their systems.

5. Load Capacity

Load capacity defines the maximum weight or force a part can withstand without failure. This is particularly important in structural applications where safety and reliability are paramount. Buyers must evaluate load capacity specifications to ensure that components can handle the stresses they will encounter during use.

6. Clear Aperture

The clear aperture is the unobstructed opening through which light passes in optical components. It is a vital parameter for ensuring maximum light transmission and image quality in devices like cameras and telescopes. B2B buyers need to understand clear aperture requirements to optimize performance in their optical systems.

What are Common Trade Terms in the Precise Parts Industry?

Familiarity with industry jargon can streamline communication and enhance the efficiency of B2B transactions. Here are some essential trade terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In B2B, understanding OEM relationships is crucial for buyers looking for specific parts that fit into established systems.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest number of units a supplier is willing to sell. This term is significant for B2B buyers as it affects inventory management and pricing strategies. Understanding MOQ can help buyers negotiate better terms and manage their supply chain more effectively.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers asking for pricing and availability of specific products or services. This term is essential for initiating purchasing discussions and helps buyers compare offers from different vendors to make informed decisions.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in global transactions. Understanding these terms helps B2B buyers navigate logistics, shipping costs, and liability, ultimately aiding in smoother cross-border trade.

5. Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the goods. In the context of precise parts, understanding lead times is critical for project planning and inventory management, ensuring that production schedules are met without delays.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions that enhance operational efficiency and reduce the risk of costly errors.

Navigating Market Dynamics and Sourcing Trends in the precise parts Sector

What Are the Key Market Dynamics and Trends Affecting the Precise Parts Sector?

The precise parts sector is experiencing a transformative phase, driven by globalization, technological advancements, and increasing demand for customized solutions. As international B2B buyers from regions such as Africa, South America, the Middle East, and Europe (including Saudi Arabia and Brazil) seek to optimize their supply chains, understanding these dynamics becomes crucial. The demand for tailored components, like those offered by platforms such as Build-An-Adapter, is on the rise, allowing buyers to create specific connections for unique applications with ease. This trend is supported by the growing reliance on digital tools that facilitate the customization of parts, enhancing operational efficiency and reducing lead times.

Moreover, emerging technologies such as additive manufacturing and advanced CAD systems are reshaping the landscape of precise parts sourcing. These innovations enable manufacturers to produce complex geometries that were previously impossible, catering to niche markets and specialized applications. Additionally, the rise of Industry 4.0, characterized by interconnected systems and data-driven decision-making, is influencing sourcing strategies. B2B buyers are increasingly looking for suppliers who can integrate seamlessly into their digital ecosystems, offering real-time tracking and transparency throughout the supply chain.

How Does Sustainability Influence Sourcing Decisions in the Precise Parts Sector?

Sustainability has become a pivotal consideration in the B2B landscape, particularly for international buyers of precise parts. The environmental impact of manufacturing processes is under scrutiny, prompting buyers to prioritize suppliers who demonstrate a commitment to sustainable practices. This includes the use of eco-friendly materials, energy-efficient production methods, and waste reduction strategies. For instance, companies that utilize recycled metals or sustainable manufacturing techniques can enhance their appeal to conscious buyers.

Ethical sourcing is equally important, as buyers seek transparency in their supply chains to ensure fair labor practices and responsible material sourcing. The demand for ‘green’ certifications and materials is growing, as companies recognize the long-term benefits of sustainable practices—not only for the environment but also for brand reputation and customer loyalty. By aligning with suppliers who prioritize sustainability, B2B buyers can enhance their own corporate responsibility initiatives, which is increasingly becoming a competitive differentiator in global markets.

What Historical Developments Have Shaped the Precise Parts Sector?

The precise parts sector has evolved significantly over the past few decades, influenced by technological advancements and shifting market demands. Initially dominated by traditional manufacturing methods, the industry has seen a gradual transition towards precision engineering and automated processes. This evolution has been driven by the need for higher accuracy and efficiency in producing components used across various applications, from aerospace to medical devices.

The rise of computer-aided design (CAD) and manufacturing (CAM) in the late 20th century marked a turning point, enabling manufacturers to create intricate designs and streamline production. As globalization took hold, the sector witnessed an influx of international players, fostering competition and innovation. Today, the precise parts sector is characterized by a blend of traditional craftsmanship and cutting-edge technology, positioning it as a vital contributor to the global supply chain. Understanding this history is essential for B2B buyers, as it informs current sourcing strategies and highlights the importance of adaptability in a rapidly changing market landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of precise parts

-

How do I ensure quality when sourcing precise parts internationally?

To ensure quality when sourcing precise parts, start by thoroughly vetting potential suppliers. Look for manufacturers with industry certifications such as ISO 9001, which indicates a commitment to quality management. Request samples or prototypes to evaluate craftsmanship and material quality. Additionally, consider visiting the supplier’s facility, if feasible, or utilizing third-party inspection services to assess production capabilities and quality control processes. Establish clear quality standards and specifications in your contracts to hold suppliers accountable. -

What factors should I consider when customizing precise parts?

When customizing precise parts, consider the specific application requirements, such as dimensions, materials, and tolerances. Collaborate closely with your supplier to communicate these needs clearly, including any industry standards that must be met. Evaluate the supplier’s ability to handle custom designs and their experience with similar projects. Additionally, factor in lead times for design, prototyping, and production, as these can significantly impact your project timeline. Always request a detailed quotation that includes all customization costs. -

What are the common minimum order quantities (MOQs) for precise parts?

Minimum order quantities (MOQs) for precise parts can vary widely depending on the supplier and the complexity of the parts. Generally, MOQs can range from a few pieces for simple components to hundreds or thousands for highly specialized or custom parts. It’s essential to discuss MOQs upfront with potential suppliers to ensure they align with your project needs. Some suppliers may offer flexibility on MOQs for repeat orders or long-term contracts, so be open to negotiations. -

How can I navigate international payment terms for precise parts?

Navigating international payment terms requires understanding various methods like wire transfers, letters of credit, or escrow services. Discuss payment terms during the negotiation phase to align on expectations—common practices include a deposit upfront and the balance upon delivery. Consider using secure payment platforms that offer buyer protection. Be aware of currency exchange rates and transaction fees, as these can affect the total cost. Lastly, ensure that all payment terms are clearly outlined in your contract to avoid misunderstandings. -

What should I know about logistics and shipping for international sourcing?

When sourcing precise parts internationally, it’s crucial to understand the logistics involved in shipping. Discuss with your supplier the best shipping methods based on urgency, cost, and part fragility. Familiarize yourself with customs regulations and import duties in your country to avoid unexpected delays and costs. Consider partnering with a freight forwarder to manage the shipping process, including documentation and compliance. Additionally, track shipments to ensure timely delivery and address any issues that may arise during transit. -

How can I effectively communicate my specifications to suppliers?

Effective communication of specifications to suppliers is vital for successful sourcing. Start by creating detailed technical drawings and documentation that outline dimensions, tolerances, materials, and finishes required for your precise parts. Utilize clear language and avoid jargon that may lead to misunderstandings. Arrange regular check-ins or updates with the supplier to discuss progress and address any concerns. Utilizing collaborative tools or project management software can also streamline communication and ensure everyone is on the same page. -

What are the best practices for supplier vetting in international trade?

Best practices for supplier vetting in international trade include conducting thorough research on potential suppliers’ backgrounds, including their financial stability, reputation, and experience in your industry. Request references from previous clients to assess their reliability and service quality. Visit their facilities if possible, or utilize third-party auditors to evaluate their operations. Additionally, review their compliance with international standards and regulations to ensure they meet your quality and ethical sourcing requirements. -

What quality assurance measures should I implement when ordering precise parts?

Implementing quality assurance measures when ordering precise parts involves establishing a comprehensive QA process. Start by defining quality standards that the parts must meet, based on your application needs. Require suppliers to provide inspection reports or certifications for each batch of parts. Consider conducting incoming inspections upon receipt to verify quality before use. Additionally, maintain open communication with suppliers to address any quality issues promptly and collaboratively work towards solutions.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 Precise Parts Manufacturers & Suppliers List

1. PreciseParts – Custom Astronomy Adapters

Domain: preciseparts.com

Registered: 2002 (23 years)

Introduction: PreciseParts specializes in custom adapters for astronomy, providing tailored solutions for various astronomical equipment needs.

2. Runescape – Precise Components

Domain: runescape.wiki

Registered: 2018 (7 years)

Introduction: This company, Runescape – Precise Components, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Presto – Precise® 12-Quart Digital Pressure Canner Parts and Accessories

Domain: gopresto.com

Registered: 1999 (26 years)

Introduction: Parts and Accessories for Presto Precise® 12-Quart Digital Pressure Canner:

– Stock No: 0214405

– Canner Rack: 4008208

– Cord Set: 4008058

– Instruction Book: 4008121

– Interlock Assembly: 81628

– Interlock Gasket: 4016054

– Pressure Regulator: 09506

– Quickstart Guide: 4008124

– Removable Pot: 81639

– Rubber Foot: 4016075

– Sealing Ring: 09507

– Sealing Ring Frame: 81626

– Thermal Probe O-Ring: 8…

4. Precise Printer Parts – Cast Aluminum Bed Plates

Domain: preciseprinterparts.com

Registered: 2020 (5 years)

Introduction: {“products”:[{“name”:”Artillery Sidewinder Cast Aluminum Bed Plate”,”price”:”$90.00″},{“name”:”Ender 3 S1/ S1 Pro – Ultra Flat Cast Aluminum Bed Plates”,”price”:”$75.00″},{“name”:”Ender 6 – Cast Aluminum Bed”,”price”:”$95.00″},{“name”:”Ender 6 – Silicone Pad Heater – Custom fit for our bed”,”price”:”$60.00 (Sale)”},{“name”:”Thermistor NTC3950 100K with Connector, 2 pieces”,”price”:”$5.00″}]}

5. Precise Parts – Custom Adapter

Domain: whcamera.com

Registered: 2004 (21 years)

Introduction: {“product_name”: “Precise Parts – Custom Adapter”, “sku”: “PRP-CUSTOM”, “price”: “$375.00”, “availability”: “More On The Way”, “shipping_info”: “Does Not Qualify for Free Shipping”, “description”: “This item will connect CDK 17 to Gemini focuser. To reach focus with FLI 4040, OAG, and filter wheel.”}

6. Astronomy Technology Today – Precise Parts Build-An-Adapter Platform

Domain: astronomytechnologytoday.com

Registered: 2006 (19 years)

Introduction: Precise Parts Build-An-Adapter Platform allows users to design and order custom telescope adapters online. The platform features a redesigned user interface for a streamlined experience, a rolling banner for guidance, and uses Secure Socket Layer (HTTPS) for security. It adapts to different screen sizes and utilizes WebGL for realistic 3-D rendering of parts. An Order Status page is available for …

7. Motor Parts – Key Accessories

Domain: find-and-update.company-information.service.gov.uk

Introduction: Retail trade of motor vehicle parts and accessories

Strategic Sourcing Conclusion and Outlook for precise parts

In today’s global marketplace, effective strategic sourcing of precise parts is pivotal for organizations aiming to enhance operational efficiency and product quality. By leveraging tailored solutions such as custom adapters and precision components, businesses can achieve significant cost savings and improve their supply chain resilience. International buyers, particularly from emerging markets in Africa, South America, the Middle East, and Europe, should prioritize partnerships with specialized manufacturers that offer comprehensive customization options and high-quality materials.

Understanding the specific needs of your projects—whether in aerospace, automotive, or specialized manufacturing—will empower you to make informed sourcing decisions. Collaborating with suppliers that emphasize quality assurance and can navigate complex regulatory environments will further enhance your competitive edge.

As we look to the future, the demand for precise parts will continue to grow, driven by advancements in technology and innovation. We encourage buyers to actively explore strategic partnerships and invest in sourcing solutions that align with their long-term goals. Take the next step in optimizing your supply chain by engaging with manufacturers who can deliver the precision and reliability your business demands.