Introduction: Navigating the Global Market for powder coating matte finish

In the ever-evolving landscape of industrial finishes, sourcing high-quality powder coating matte finish can present unique challenges for international B2B buyers. With diverse applications ranging from automotive components to architectural elements, the demand for durable, aesthetically pleasing matte finishes is on the rise. However, navigating the global market requires an understanding of various factors, including supplier capabilities, product specifications, and regional compliance standards. This guide aims to streamline that process, offering insights into the different types of matte powder coatings available, their applications, and essential considerations for vetting suppliers effectively.

As buyers from regions such as Africa, South America, the Middle East, and Europe—particularly in countries like Brazil and Saudi Arabia—seek to enhance their product offerings, this comprehensive resource will empower informed purchasing decisions. We delve into the nuances of matte finishes, exploring their unique characteristics, such as low gloss levels and texture options, while also addressing critical aspects like cost analysis and logistical considerations. By equipping buyers with actionable insights and a clear understanding of the market dynamics, this guide serves as a vital tool for achieving competitive advantage in the powder coating industry. Whether you are looking to elevate your product line or ensure compliance with quality standards, understanding the intricacies of matte powder coatings is essential for success in today’s global marketplace.

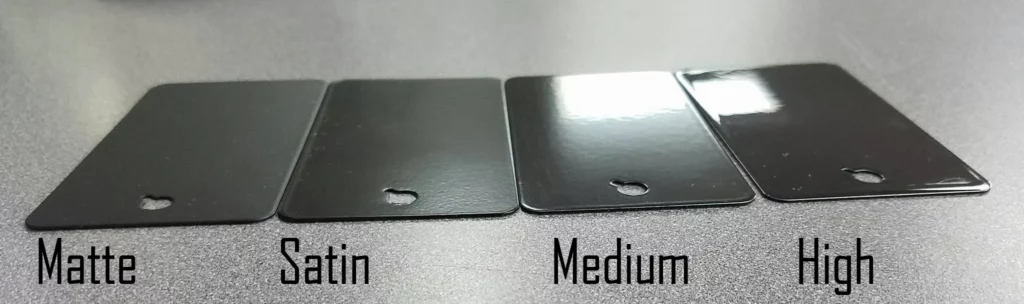

Understanding powder coating matte finish Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Matte Flat Clear | 0% gloss, smooth finish, durable TGIC Polyester | Automotive, architectural finishes | Pros: Excellent durability, ideal for illusion colors. Cons: Limited gloss options may not suit all design aesthetics. |

| Low Gloss | Subtle sheen, not completely matte, smooth texture | Furniture, fixtures, appliances | Pros: Balances between matte and gloss, versatile. Cons: May require specific cleaning methods to maintain appearance. |

| Satin Finish | Soft sheen, slightly reflective | Consumer goods, electronics | Pros: Aesthetic appeal, easy to clean. Cons: Can show fingerprints more easily than true matte. |

| Textured Matte | Textured surface, hides imperfections | Industrial equipment, outdoor furniture | Pros: Enhanced durability, effective at concealing scratches. Cons: Texture may not appeal to all buyers. |

| High-Temperature Matte | Resistant to high heat, retains matte finish | Automotive parts, exhaust systems | Pros: Ideal for high-heat applications, maintains aesthetics. Cons: Limited color options compared to standard finishes. |

What are the Characteristics of Matte Flat Clear Powder Coating?

Matte Flat Clear powder coating is characterized by its 0% gloss level, providing a smooth, flat finish that enhances the appearance of underlying colors. This type of coating is particularly suitable for automotive and architectural applications, where a sleek look is desired without the reflective properties of gloss finishes. When purchasing, buyers should consider the durability of TGIC Polyester, which offers excellent resistance to wear and environmental factors, making it ideal for both indoor and outdoor applications.

How Does Low Gloss Powder Coating Differ from Other Finishes?

Low gloss powder coating features a subtle sheen that sets it apart from fully matte and glossy finishes. This finish is commonly used in furniture and appliance manufacturing, where a sophisticated look is desired without the starkness of high gloss. Buyers should weigh the aesthetic versatility of low gloss against the need for specific maintenance, as this finish may require different cleaning methods to preserve its appearance over time.

Why Choose a Satin Finish for Consumer Products?

Satin finishes provide a soft sheen that is more reflective than matte but less so than gloss. This balance makes satin finishes popular in consumer goods and electronics, where aesthetics are paramount. While satin coatings are visually appealing and easier to clean, buyers should consider that they may show fingerprints more readily than matte finishes, potentially requiring more frequent upkeep.

What Advantages Does Textured Matte Powder Coating Offer?

Textured matte powder coating features a unique surface that can hide imperfections, making it an excellent choice for industrial equipment and outdoor furniture. This finish enhances durability and provides a rugged aesthetic, appealing to buyers looking for both functionality and style. However, the texture may not suit all design preferences, so it’s essential for buyers to consider their target market when selecting this option.

When is High-Temperature Matte Powder Coating Necessary?

High-temperature matte powder coatings are specifically designed to withstand extreme heat, making them ideal for automotive parts and exhaust systems. These coatings maintain their matte finish even under high-temperature conditions, ensuring both durability and aesthetics. Buyers should consider the limited color options available in this category, as the focus is often on functionality over variety, which may influence their purchasing decisions.

Key Industrial Applications of powder coating matte finish

| Industry/Sector | Specific Application of powder coating matte finish | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Custom vehicle parts and accessories | Enhances aesthetic appeal and provides a durable, protective layer | Require high-temperature resistance and color consistency; consider local suppliers for better logistics. |

| Furniture Manufacturing | Production of metal furniture and fixtures | Offers a modern, sleek look while ensuring durability and scratch resistance | Ensure compliance with environmental regulations and availability of color options. |

| Architectural & Construction | Coating of structural steel and architectural elements | Improves corrosion resistance and aesthetic value in outdoor applications | Focus on weather resistance and UV stability; sourcing from reputable brands is crucial. |

| Electronics | Enclosure and casing for electronic devices | Provides a non-reflective finish that minimizes glare and enhances durability | Ensure compatibility with electronic components and adherence to industry standards. |

| Medical Equipment | Coating of metal components in medical devices | Ensures hygiene and durability, critical for compliance in healthcare | Sourcing should prioritize biocompatibility and resistance to cleaning agents. |

How is Powder Coating Matte Finish Used in the Automotive Industry?

In the automotive sector, powder coating matte finishes are extensively used for custom vehicle parts and accessories, such as rims, frames, and body panels. This application not only enhances the aesthetic appeal of vehicles with a modern, sleek look but also provides a robust protective layer that withstands harsh environmental conditions. For international B2B buyers, particularly those in Africa and South America, it is essential to consider high-temperature resistance and color consistency to meet local market demands and preferences.

What are the Benefits of Powder Coating Matte Finish in Furniture Manufacturing?

The furniture manufacturing industry utilizes powder coating matte finishes for metal furniture and fixtures, such as tables, chairs, and decorative elements. This finish offers a contemporary look while ensuring durability and scratch resistance, making it ideal for both indoor and outdoor settings. Buyers should focus on sourcing options that comply with environmental regulations, especially in Europe, where sustainability is a significant concern. Availability of diverse color options can also cater to varying design preferences in different markets.

Why is Powder Coating Matte Finish Important in Architectural and Construction Applications?

In architectural and construction sectors, powder coating matte finishes are applied to structural steel and architectural elements like railings and beams. This coating improves corrosion resistance and adds aesthetic value, particularly in outdoor applications exposed to the elements. International buyers, particularly from the Middle East, should prioritize products that offer exceptional weather resistance and UV stability to ensure longevity and performance in challenging climates. Sourcing from reputable brands can also assure quality and compliance with local building codes.

How Does Powder Coating Matte Finish Benefit Electronics?

In the electronics industry, matte finishes are used for enclosures and casings of electronic devices, providing a non-reflective surface that minimizes glare while enhancing durability. This application is crucial for maintaining the functionality and aesthetics of devices in various environments. B2B buyers should ensure that sourced coatings are compatible with electronic components and meet industry standards for safety and performance. Special attention to the coating’s resistance to heat and chemicals is also advisable.

What Role Does Powder Coating Matte Finish Play in Medical Equipment?

For medical equipment, powder coating matte finishes are applied to metal components to ensure hygiene and durability, which are critical for compliance in the healthcare sector. This application helps in maintaining cleanliness and resistance to wear and tear in high-use environments. Buyers in this sector should prioritize sourcing options that emphasize biocompatibility and resistance to common cleaning agents, ensuring that the products meet stringent health regulations, particularly in regions like Europe where compliance is heavily regulated.

3 Common User Pain Points for ‘powder coating matte finish’ & Their Solutions

Scenario 1: Achieving Consistent Matte Finishes Across Batches

The Problem: B2B buyers often face the challenge of achieving uniformity in matte finishes across multiple production batches. Variations in application techniques, environmental conditions, and material compositions can lead to discrepancies in gloss levels and surface texture. This inconsistency can affect product aesthetics and quality perception, leading to dissatisfaction among clients and potential financial losses.

The Solution: To ensure consistent matte finishes, it is crucial to standardize the application process. Implementing a robust quality control system that includes pre-application testing on sample panels can help identify the optimal parameters for powder application. Buyers should specify the use of TGIC polyester matte powders, which are known for their stability and durability. Additionally, consider investing in advanced powder coating equipment that maintains consistent temperature and airflow during curing. Regular training sessions for operators on best practices in powder application and curing can further enhance consistency and quality.

Scenario 2: Managing Durability Concerns in High-Traffic Applications

The Problem: In industries such as automotive or architectural design, matte finishes are often subjected to wear and tear due to high usage or exposure to harsh environments. B2B buyers may find that their matte-coated products show signs of scratching or fading more quickly than expected, which can lead to increased maintenance costs and customer dissatisfaction.

The Solution: To address durability concerns, buyers should select high-performance matte powder coatings specifically designed for high-traffic applications. Look for formulations that offer enhanced hardness and chemical resistance, such as those with a pencil hardness rating of 2H or higher. Additionally, consider applying a matte clear coat over colored powders to provide an extra layer of protection without sacrificing the desired finish. It’s also advisable to conduct rigorous testing in real-world conditions to validate the chosen coatings before full-scale production. Partnering with reputable suppliers who can provide detailed technical specifications and performance data will help ensure that the selected products meet durability standards.

Scenario 3: Overcoming Color Matching Difficulties

The Problem: Achieving the desired color match in matte finishes can be a significant pain point for B2B buyers, particularly when working with custom projects or specific brand colors. Variations in powder coating formulations and application methods can lead to discrepancies between the expected color and the final result, complicating client satisfaction and branding efforts.

The Solution: To overcome color matching difficulties, buyers should utilize advanced color matching tools and software that allow for precise digital visualization of finishes before production. Engaging with suppliers who offer sample panels and swatches can provide an accurate representation of the matte finish in real-world lighting conditions. Additionally, it is essential to communicate clearly with suppliers regarding the specific color requirements and any applicable industry standards. Using a consistent application technique and curing schedule across all projects will also help minimize variations. For critical projects, consider conducting small batch tests before full-scale production to ensure that the color meets expectations.

Strategic Material Selection Guide for powder coating matte finish

When selecting materials for powder coating matte finishes, it is essential to consider various properties and their implications for performance, durability, and application. Below, we analyze four common materials used in powder coating, focusing on their characteristics, advantages, limitations, and specific considerations for international B2B buyers.

What Are the Key Properties of Aluminum for Powder Coating Matte Finish?

Aluminum is a widely used substrate for powder coating due to its lightweight nature and excellent corrosion resistance. Key properties include a high strength-to-weight ratio, good thermal conductivity, and resistance to oxidation. Aluminum can withstand temperatures up to 600°F (315°C) without significant degradation, making it suitable for various applications, including automotive and architectural elements.

Pros: Aluminum’s durability and lightweight properties make it ideal for applications where weight savings are crucial. It also offers excellent aesthetic appeal when coated with matte finishes, providing a modern look.

Cons: The cost of aluminum can be higher than other materials like steel. Additionally, the manufacturing complexity can increase, especially for intricate designs.

Impact on Application: Aluminum’s compatibility with various powder coatings allows for a wide range of finishes, including matte. However, it is vital to ensure proper surface preparation to achieve optimal adhesion.

Considerations for International Buyers: Buyers from regions like Europe and the Middle East should be aware of compliance with standards such as ASTM and DIN, which dictate material quality and performance.

How Does Steel Compare as a Material for Powder Coating Matte Finish?

Steel is another popular substrate for powder coating, known for its strength and durability. Key properties include a high tensile strength and resistance to deformation under pressure. Steel can withstand temperatures up to 800°F (427°C), making it suitable for high-temperature applications.

Pros: Steel is generally more cost-effective than aluminum and offers excellent durability and impact resistance. It is also widely available and can be easily sourced.

Cons: Steel is prone to corrosion if not properly coated, which can limit its lifespan in outdoor applications. Additionally, the weight of steel can be a disadvantage in applications where weight is a concern.

Impact on Application: Steel substrates require thorough surface preparation to prevent rust and ensure good adhesion of the powder coating. Matte finishes can enhance the aesthetic appeal of steel products.

Considerations for International Buyers: Buyers in regions like South America should consider local environmental conditions, as humidity can accelerate corrosion. Compliance with JIS standards may also be necessary for specific applications.

What Are the Benefits of Using Galvanized Steel in Powder Coating Matte Finish?

Galvanized steel, which is steel coated with zinc, offers enhanced corrosion resistance. Key properties include a protective zinc layer that can withstand various environmental conditions. It can endure temperatures similar to regular steel, making it versatile for multiple applications.

Pros: The primary advantage of galvanized steel is its corrosion resistance, which extends the lifespan of the powder coating. It is also relatively cost-effective and readily available.

Cons: The surface of galvanized steel can sometimes be challenging to coat due to the zinc layer, which may require special surface preparation techniques. Additionally, the aesthetic appeal may be less than that of aluminum.

Impact on Application: Galvanized steel is compatible with matte finishes, but proper surface treatment is crucial to ensure adhesion and avoid peeling.

Considerations for International Buyers: Buyers from Africa should be aware of the local standards for galvanized materials, as compliance can vary significantly between countries.

How Does Stainless Steel Perform in Powder Coating Matte Finish?

Stainless steel is renowned for its excellent corrosion resistance and aesthetic appeal. Key properties include high tensile strength and the ability to withstand extreme temperatures without losing integrity. It is often used in high-end applications, such as kitchen equipment and architectural features.

Pros: Stainless steel offers superior durability and a premium finish. It is also resistant to staining and rust, making it ideal for outdoor applications.

Cons: The cost of stainless steel is typically higher than other materials, which can impact budget considerations. Additionally, the manufacturing process can be more complex due to its hardness.

Impact on Application: Stainless steel is highly compatible with powder coating, and matte finishes can enhance its modern aesthetic. However, surface preparation is critical to ensure proper adhesion.

Considerations for International Buyers: Buyers from Europe should consider compliance with EU regulations regarding material quality and environmental impact.

Summary Table of Material Selection for Powder Coating Matte Finish

| Material | Typical Use Case for powder coating matte finish | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Automotive parts, architectural elements | Lightweight and corrosion-resistant | Higher cost compared to steel | High |

| Steel | Industrial equipment, furniture | Cost-effective and durable | Prone to corrosion without coating | Medium |

| Galvanized Steel | Outdoor furniture, construction components | Excellent corrosion resistance | Challenging surface preparation | Medium |

| Stainless Steel | Kitchen equipment, high-end architectural features | Superior durability and aesthetic appeal | Higher cost and manufacturing complexity | High |

This strategic material selection guide provides valuable insights for B2B buyers considering powder coating matte finishes. By understanding the properties, advantages, and specific considerations for each material, buyers can make informed decisions that align with their operational needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for powder coating matte finish

What Are the Key Stages in the Manufacturing Process of Powder Coating Matte Finish?

The manufacturing process for powder coating matte finishes involves several critical stages, each ensuring that the final product meets high-quality standards.

1. Material Preparation

The first stage involves preparing the substrates that will be powder coated. This typically includes cleaning, degreasing, and sometimes etching the metal surfaces to remove any contaminants that could affect adhesion. Common methods include using alkaline cleaners, acid baths, or mechanical abrasives. The cleanliness of the surface is paramount, as any residues can lead to defects in the coating.

2. Forming

Once the materials are prepared, they are formed into the desired shapes. This may involve processes such as stamping, bending, or machining. For B2B buyers, understanding the forming capabilities of a supplier is essential, as it directly impacts the final product’s suitability for specific applications.

3. Powder Application

The application of the powder coating is a pivotal stage in the manufacturing process. Electrostatic spray guns are commonly used to apply the powder, which is charged and attracted to the grounded substrate. For matte finishes, specific powder formulations are used that ensure a low gloss level without compromising durability. Advanced techniques like fluidized bed coating can also be employed for certain applications.

4. Curing

Following application, the coated parts are cured in an oven at a predetermined temperature, typically around 180-200 degrees Celsius for 10 to 20 minutes, depending on the powder used. This curing process causes the powder to melt, flow, and chemically react to form a hard, durable finish. For matte finishes, it is crucial that the curing conditions are strictly adhered to, as variations can lead to inconsistencies in finish quality.

5. Finishing Touches

Post-curing, additional processes may include inspection, packaging, and labeling. This stage ensures that the products are ready for shipment and meet customer specifications. B2B buyers should inquire about the finishing capabilities of their suppliers to ensure all requirements are met.

How Is Quality Assurance Integrated into the Powder Coating Process?

Quality assurance (QA) is a vital component of the powder coating manufacturing process, ensuring that the products meet both international standards and customer expectations.

International Standards and Certifications

For B2B buyers, understanding the certifications that a supplier holds can significantly influence purchasing decisions. ISO 9001 is a prominent quality management standard that ensures consistent quality in products and services. Additionally, industry-specific certifications like CE (for European markets) and API (for petroleum and natural gas industries) are crucial for buyers in regulated sectors.

Key Quality Control Checkpoints

Quality control (QC) checkpoints are strategically placed throughout the manufacturing process to catch defects early:

- Incoming Quality Control (IQC): This initial checkpoint examines raw materials and components upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): During the manufacturing stages, periodic inspections are conducted to monitor the application process, curing conditions, and surface quality.

- Final Quality Control (FQC): Once the products are completed, a final inspection is performed to check for defects, gloss levels, and adherence to specifications before packaging.

Common Testing Methods

Several testing methods are employed to ensure the integrity and quality of the powder coating:

- Adhesion Testing: This assesses how well the coating adheres to the substrate, often performed using tape tests.

- Salt Spray Testing: Particularly relevant for outdoor applications, this test evaluates the corrosion resistance of the coating.

- Gloss Measurement: A gloss meter is used to verify the specified gloss level, which is critical for matte finishes.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, especially those in regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is essential to mitigate risks associated with subpar products.

Supplier Audits

Conducting regular audits is one of the most effective ways to evaluate a supplier’s quality assurance processes. These audits can reveal the effectiveness of their manufacturing practices, adherence to standards, and overall operational efficiency. B2B buyers should develop a checklist based on their specific requirements to guide these audits.

Quality Reports and Documentation

Requesting quality reports and documentation from suppliers is crucial. This documentation should include details of quality control processes, test results, and certifications. Suppliers should be transparent about their QC practices, including any third-party inspections they may undergo.

Third-Party Inspections

Engaging third-party inspection services can provide an unbiased assessment of a supplier’s quality control measures. These services can conduct random inspections and testing, providing additional assurance regarding the quality of the finished products.

What Are the Unique Challenges for International B2B Buyers in Quality Assurance?

International B2B buyers often face unique challenges regarding quality assurance, particularly in regions like Africa and South America, where manufacturing standards may vary.

Understanding Regional Standards

Different regions may have varying standards for powder coating processes. Buyers should familiarize themselves with local regulations and industry standards to ensure compliance. This includes understanding any specific certifications required for their market.

Communication Barriers

Language and cultural differences can pose challenges when discussing quality expectations with suppliers. Clear communication is essential to avoid misunderstandings that could lead to quality issues. B2B buyers should ensure that they establish a mutual understanding of quality standards during negotiations.

Supply Chain Considerations

Logistical challenges can impact the timely delivery of high-quality products. Buyers should consider the reliability of suppliers’ logistics and distribution networks, particularly when sourcing from regions with less established infrastructure.

Conclusion

In the competitive landscape of powder coating matte finishes, understanding the manufacturing processes and quality assurance practices is essential for B2B buyers. By focusing on supplier capabilities, quality control measures, and regional standards, companies can ensure they partner with reliable manufacturers that deliver high-quality, durable products tailored to their specific needs. This knowledge empowers buyers to make informed decisions that enhance their operations and customer satisfaction.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘powder coating matte finish’

The following guide provides a structured approach for B2B buyers looking to procure powder coating matte finish products. By following these steps, you can ensure that your sourcing process is efficient, effective, and aligned with your specific needs.

Step 1: Define Your Technical Specifications

Understanding your specific requirements is crucial for a successful procurement process. Determine the type of matte finish you need, whether it’s a flat or satin finish, and consider the substrate material that will be coated. This clarity will guide your discussions with suppliers and help you avoid costly mistakes.

- Consider durability: Look for powders with high hardness ratings and excellent resistance to environmental factors such as UV exposure and corrosion.

- Identify application methods: Ensure the coating is suitable for your application process, whether it’s electrostatic spray, fluidized bed, or other methods.

Step 2: Research Available Products

Take the time to explore the range of matte powder coatings available on the market. Different manufacturers may offer unique formulations that provide varying levels of durability, texture, and color options.

- Review product data sheets: These documents will provide essential information such as gloss levels, cure times, and coverage rates.

- Check compatibility: Ensure that the coatings you are considering are compatible with your existing processes and substrates.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. A robust supplier can significantly impact the quality and reliability of your finished products.

- Assess certifications: Look for suppliers with relevant industry certifications, such as ISO or environmental compliance, which can indicate a commitment to quality.

- Check customer feedback: Online reviews and testimonials can provide insights into the supplier’s reliability and product performance.

Step 4: Request Samples

Once you have narrowed down potential suppliers, request samples of the matte powder coatings you are considering. This step is critical to ensure that the product meets your expectations in terms of color, texture, and finish.

- Conduct tests: Apply the samples on your substrates to evaluate adhesion, finish quality, and durability.

- Consider color matching: If color consistency is important, ensure the supplier can provide matching services for future orders.

Step 5: Negotiate Terms and Pricing

Engage with suppliers to negotiate pricing, payment terms, and delivery schedules. This step can greatly influence your overall project costs and timelines.

- Inquire about bulk discounts: If you plan to order large quantities, ask about price breaks or discounts for bulk purchases.

- Clarify lead times: Understand the expected lead times for production and shipping to avoid delays in your project.

Step 6: Finalize Your Order and Confirm Delivery

After selecting a supplier and agreeing on terms, finalize your order. Make sure to confirm the details in writing to prevent misunderstandings.

- Review shipping methods: Ensure that the delivery method aligns with your project timelines.

- Track your order: Request tracking information to monitor the shipment and ensure timely delivery.

Step 7: Implement Quality Control Measures

Upon receipt of your order, implement quality control measures to assess the products. This step ensures that the materials meet your specifications and quality standards before use.

- Conduct visual inspections: Check for color consistency, texture, and any signs of damage during shipping.

- Test application performance: Apply the coating on a sample piece to verify that it performs as expected in real-world conditions.

By following this checklist, B2B buyers can streamline their procurement process for powder coating matte finishes, ensuring that they select the right products and suppliers for their needs.

Comprehensive Cost and Pricing Analysis for powder coating matte finish Sourcing

What are the Key Cost Components in Powder Coating Matte Finish Sourcing?

When sourcing powder coating matte finishes, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

-

Materials: The quality and type of powder coating directly affect the cost. Matte finishes often require specialized formulations, such as TGIC polyester, which can be more expensive than standard powders. For instance, prices for matte powders can range from $9.49 to $53.83 per pound depending on the color and specific properties.

-

Labor: Labor costs can vary widely based on geographic location and the complexity of the application process. Skilled labor is essential for achieving a flawless matte finish, which can increase labor costs, especially in regions with higher wage standards.

-

Manufacturing Overhead: This includes costs related to the production facility, equipment maintenance, utilities, and other operational expenses. Efficient operations can lower overhead costs, which is a vital factor for competitive pricing.

-

Tooling: Depending on the specifications of the project, tooling costs may be incurred for custom jobs. These costs can be substantial if the matte finish requires specialized application equipment or molds.

-

Quality Control (QC): Ensuring a consistent matte finish requires rigorous QC processes. The investment in testing for durability, gloss level, and adherence can add to the overall cost.

-

Logistics: Transportation and handling fees can vary based on the distance to the buyer, shipping methods, and volume. International shipping may involve additional customs duties and tariffs, impacting total costs.

-

Margin: Suppliers typically include a profit margin based on their operational costs and market demand. Understanding the margins can help buyers gauge if the pricing is competitive.

How Do Price Influencers Affect the Cost of Powder Coating Matte Finishes?

Several factors can influence the pricing of powder coating matte finishes:

-

Volume/MOQ: Bulk orders often lead to lower per-unit costs. Buyers should negotiate minimum order quantities (MOQs) to achieve better pricing.

-

Specifications/Customization: Custom formulations or specific color matches can increase costs. Buyers seeking unique finishes should be prepared for higher prices due to the additional R&D and material costs involved.

-

Materials: The choice of materials significantly impacts pricing. Premium powders with enhanced durability or specialized properties can be costlier, but they may offer better long-term value.

-

Quality and Certifications: Suppliers that meet international quality standards or environmental certifications may charge a premium. However, these certifications can assure buyers of the product’s reliability.

-

Supplier Factors: The supplier’s reputation, reliability, and production capabilities can influence pricing. Established suppliers may command higher prices due to their track record of quality and service.

-

Incoterms: Understanding Incoterms is essential for international buyers. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can affect the total landed cost of the product.

What Tips Can Help Buyers Optimize Costs in Powder Coating Matte Finish Sourcing?

B2B buyers can employ several strategies to enhance cost-efficiency in sourcing powder coating matte finishes:

-

Negotiate Effectively: Establishing strong relationships with suppliers can facilitate negotiations. Buyers should be clear about their requirements and be open to discussing pricing based on volume or long-term contracts.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the purchase price but also the long-term costs associated with maintenance, durability, and performance of the matte finish. A slightly higher upfront cost may be justified by lower maintenance expenses.

-

Understand Pricing Nuances for International Sourcing: Buyers from Africa, South America, the Middle East, and Europe should be aware of currency fluctuations, import duties, and shipping costs. It may be beneficial to source from local suppliers to mitigate these costs.

-

Request Samples: Before committing to large orders, requesting samples can help ensure the quality meets expectations without incurring the cost of a full order.

-

Stay Informed on Market Trends: Keeping abreast of industry trends can provide insights into pricing fluctuations and potential cost-saving opportunities.

Disclaimer on Pricing

Prices for powder coating matte finishes can vary widely based on numerous factors, including supplier, location, and market demand. The prices mentioned are indicative and may not reflect current market conditions. Always consult suppliers for the most accurate and up-to-date pricing information.

Alternatives Analysis: Comparing powder coating matte finish With Other Solutions

Introduction to Alternatives in Surface Finishing Solutions

When selecting a surface finishing solution, businesses often need to consider various alternatives that can meet their specific requirements. Powder coating matte finishes are popular due to their durability and aesthetic appeal. However, other methods such as liquid paint, anodizing, and electroplating also provide viable options, each with its unique advantages and limitations. This analysis will compare powder coating matte finishes with liquid paint and anodizing to help B2B buyers make informed decisions.

Comparison Table

| Comparison Aspect | Powder Coating Matte Finish | Liquid Paint | Anodizing |

|---|---|---|---|

| Performance | Highly durable; resistant to chipping and fading | Moderate durability; prone to scratches and fading | Excellent corrosion resistance; wear-resistant |

| Cost | Moderate initial investment; cost-effective for large volumes | Generally lower initial cost; higher long-term maintenance | Higher initial cost; economical for large quantities over time |

| Ease of Implementation | Requires specialized equipment and skilled labor | Easy application; can be done with basic tools | Requires specific equipment and expertise |

| Maintenance | Low maintenance; easy to clean | Moderate maintenance; may require frequent touch-ups | Low maintenance; long-lasting finish |

| Best Use Case | Automotive, industrial, and architectural applications | Household items, furniture, and decorative items | Aerospace, automotive, and high-end consumer products |

Detailed Breakdown of Alternatives

Liquid Paint

Liquid paint is a widely used finishing solution known for its ease of application. It can be sprayed or brushed on surfaces, making it accessible for various projects. While the initial cost is generally lower than that of powder coating, liquid paints often lack the same durability. They are more susceptible to scratches and fading over time, which may lead to increased maintenance costs. Liquid paint is best suited for projects where aesthetic appeal is prioritized, and the surfaces are not subject to harsh conditions.

Anodizing

Anodizing is an electrochemical process that enhances the natural oxide layer on metal surfaces, providing exceptional corrosion resistance and durability. This method is particularly effective for aluminum and is favored in industries requiring high-performance finishes, such as aerospace and automotive. Although anodizing has a higher initial cost and requires specialized equipment, it delivers a long-lasting finish that can significantly reduce maintenance over time. Anodizing is an excellent choice for high-end products where performance and longevity are critical.

Conclusion: Choosing the Right Surface Finishing Solution

Selecting the appropriate surface finishing solution depends on several factors, including the specific application, budget constraints, and desired performance characteristics. For businesses in need of a durable and aesthetically pleasing finish, powder coating matte finishes stand out as a robust option. However, for projects where ease of application is essential, or for specific material requirements, liquid paint or anodizing may be more suitable. B2B buyers should evaluate their unique needs and the trade-offs associated with each method to make an informed decision that aligns with their operational goals and market demands.

Essential Technical Properties and Trade Terminology for powder coating matte finish

What Are the Key Technical Properties of Powder Coating Matte Finish?

When considering powder coating matte finishes, several critical technical properties come into play. Understanding these specifications is vital for B2B buyers to ensure they select the right products for their applications.

1. Gloss Level

The gloss level of a powder coating is a measure of its shine. For matte finishes, this is typically at or near 0%, meaning the surface reflects minimal light. This property is essential for industries looking for a non-reflective finish that can minimize glare, making it ideal for applications in architecture and automotive parts.

2. Material Composition

Matte powder coatings are often made from TGIC (Triglycidyl Isocyanurate) polyester resins. This composition contributes to durability, chemical resistance, and a smooth application. Understanding material composition helps buyers assess compatibility with their substrates and environmental conditions, ensuring longevity and performance.

3. Cure Schedule

The cure schedule indicates the time and temperature required for the powder to fully adhere to the substrate. A common specification for matte finishes is a cure time of 10 minutes at 400°F (204°C) at the part’s metal temperature. Adhering to these parameters is crucial for achieving the desired finish and performance characteristics, thus reducing the risk of defects during production.

4. Coverage Rate

The theoretical coverage rate, often expressed in square feet per pound, indicates how much surface area a given amount of powder will cover. For example, a matte powder may cover approximately 79.83 square feet per pound at a thickness of 2 mils. Understanding this property allows buyers to calculate the amount of product needed for their projects, optimizing inventory and reducing costs.

5. Hardness Rating

The hardness of a matte finish is usually measured on the pencil hardness scale. A common rating for matte powders is 2H, indicating good resistance to scratches and abrasions. This property is vital for industries such as automotive and furniture, where durability and aesthetic appeal are paramount.

6. Environmental Resistance

Matte powder coatings often undergo tests for salt spray resistance, with some formulations lasting over 1,000 hours. This resistance is particularly important for applications in harsh environments, ensuring that the finish maintains its appearance and integrity over time.

What Are Common Trade Terms in the Powder Coating Industry?

Familiarity with industry jargon can facilitate smoother transactions and negotiations for B2B buyers. Here are some key terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products that are then marketed under another company’s brand. Understanding OEM relationships can help buyers identify potential suppliers or partners in the powder coating industry, ensuring they source high-quality finishes for their products.

2. MOQ (Minimum Order Quantity)

MOQ denotes the smallest quantity of a product that a supplier is willing to sell. This term is critical for buyers to understand, as it affects inventory management and budgeting. Knowing the MOQ helps businesses plan their purchases effectively and negotiate better terms with suppliers.

3. RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers requesting pricing information for specific products or services. Utilizing RFQs allows buyers to compare offers, negotiate terms, and ensure they receive competitive pricing for their powder coating needs.

4. Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Understanding these terms helps buyers manage logistics and shipping costs effectively, ensuring a smooth procurement process.

5. Lead Time

Lead time refers to the duration from placing an order to the delivery of the product. For powder coatings, lead times can vary based on production schedules and inventory levels. Knowing lead times is essential for project planning and ensuring timely delivery of materials.

By grasping these technical properties and trade terminologies, B2B buyers can make informed decisions, optimize their procurement processes, and enhance their overall operational efficiency in the powder coating sector.

Navigating Market Dynamics and Sourcing Trends in the powder coating matte finish Sector

What Are the Current Market Dynamics and Key Trends in the Powder Coating Matte Finish Sector?

The powder coating matte finish sector is experiencing robust growth driven by several global factors. Firstly, the increasing demand for durable and aesthetically appealing finishes across industries such as automotive, architecture, and consumer goods is propelling the market. Matte finishes are particularly favored for their ability to hide imperfections and provide a modern, sophisticated look. Moreover, with rapid urbanization and infrastructure development in regions like Africa and South America, there is a surge in demand for high-quality coatings that can withstand varying climatic conditions.

Emerging technologies are reshaping sourcing trends within the sector. Digital platforms are facilitating easier access to suppliers and enabling buyers to compare products and prices seamlessly. Innovations such as 3D visualization tools, like the TIGERator, allow buyers to preview finishes digitally before making procurement decisions. Furthermore, the rise of e-commerce in B2B transactions is making it simpler for buyers in remote areas to source matte powder coatings, thus broadening their options and improving supply chain efficiency.

The market is also witnessing a shift towards customization, where buyers can request specific colors and finishes to meet their unique requirements. This trend is particularly significant for businesses looking to differentiate their products in competitive markets, such as those in Brazil and Saudi Arabia, where design and quality are paramount.

How Is Sustainability Shaping Sourcing Strategies in the Powder Coating Matte Finish Industry?

Sustainability is becoming a central theme in the sourcing strategies of B2B buyers in the powder coating matte finish sector. As environmental regulations tighten globally, companies are increasingly prioritizing eco-friendly products. Powder coatings inherently have a lower environmental impact compared to traditional liquid paints, as they emit negligible volatile organic compounds (VOCs) during application. This makes them an attractive option for businesses aiming to reduce their carbon footprint.

Moreover, ethical sourcing practices are gaining traction. Buyers are now more inclined to partner with suppliers who demonstrate a commitment to sustainable practices, such as using recycled materials or obtaining certifications like the Green Seal or ISO 14001 for environmental management. These certifications not only reflect a supplier’s dedication to sustainability but also enhance the credibility of the products offered, making them more appealing to conscientious consumers.

Implementing sustainable practices in the supply chain can also lead to cost savings over time. For example, optimizing the powder coating process can reduce waste and energy consumption, ultimately benefiting the bottom line. As buyers in regions like Europe and the Middle East increasingly demand transparency in sourcing, suppliers who can showcase their sustainable practices will likely gain a competitive edge.

What Is the Historical Context of Powder Coating Matte Finishes for B2B Buyers?

The history of powder coating dates back to the 1940s, but it wasn’t until the 1960s that it gained significant traction in commercial applications. The introduction of polyester and epoxy resins expanded the possibilities for various finishes, including matte options. Initially, powder coatings were primarily used for industrial applications, but over the years, advancements in technology and a growing emphasis on aesthetics led to their widespread adoption in consumer goods and architectural finishes.

As the demand for matte finishes grew in the late 20th century, manufacturers began developing specialized formulations that catered specifically to this market. Today, matte finishes are recognized for their durability and versatility, making them a staple in industries ranging from automotive to home decor. Understanding this evolution helps B2B buyers appreciate the technological advancements and market forces that have shaped the current landscape of powder coating matte finishes.

Frequently Asked Questions (FAQs) for B2B Buyers of powder coating matte finish

-

How do I ensure the quality of powder coating matte finish before making a bulk purchase?

To ensure quality, request samples from potential suppliers. Look for certifications such as ISO 9001, which indicates adherence to quality management standards. Additionally, consider conducting a factory audit to assess manufacturing processes and quality control measures. Checking customer reviews and case studies can provide insights into the supplier’s reliability and product performance. Lastly, inquire about their testing procedures, including salt spray tests and hardness ratings, to validate the durability of their matte finishes. -

What is the best type of matte finish powder coating for outdoor applications?

For outdoor applications, opt for TGIC polyester powder coatings, which offer excellent UV stability and corrosion resistance. These coatings maintain their matte finish under harsh weather conditions and provide long-lasting durability. Ensure the supplier provides detailed technical data sheets, including curing schedules and application methods, to achieve optimal results. Conducting field tests on a small scale can help determine the best product for your specific environmental conditions. -

How can I customize powder coating matte finishes for my specific project needs?

Many suppliers offer customization options, allowing you to specify colors, textures, and finishes. You can request custom color matching to ensure your matte finish aligns with your branding. Additionally, inquire about the possibility of adding special effects, like a textured matte or low-gloss finish. When discussing customization, be clear about your project requirements, and ask for prototypes to evaluate before committing to a larger order. -

What are the minimum order quantities (MOQs) for powder coating matte finishes?

MOQs for powder coating products can vary widely among suppliers, typically ranging from 10 to 100 kilograms. It’s essential to clarify MOQs upfront to avoid unexpected costs. Some suppliers may offer flexibility on MOQs, particularly for long-term partnerships or larger projects. Always discuss your needs and explore the possibility of smaller test orders to ensure the product meets your specifications before committing to larger quantities. -

What payment terms should I expect when sourcing powder coating matte finishes internationally?

Payment terms can differ significantly based on supplier policies and your buyer-supplier relationship. Common terms include advance payment, letters of credit, or payment upon delivery. It’s crucial to negotiate terms that suit both parties while ensuring sufficient protection against risks. Be aware of any additional costs related to international transactions, such as currency conversion fees or bank charges. Establishing a clear contract outlining payment milestones can help mitigate misunderstandings. -

How do I verify the reliability of a powder coating supplier in international markets?

To verify a supplier’s reliability, conduct thorough background checks, including their business history, customer references, and online reviews. Utilize platforms such as Alibaba or Global Sources to assess supplier ratings and feedback. Additionally, consider requesting documentation of certifications and compliance with international standards. Establishing a relationship through initial small orders can also help gauge their responsiveness and product quality before committing to larger contracts. -

What are the logistics considerations when importing powder coating matte finishes?

When importing, consider factors such as shipping methods, customs clearance, and lead times. Collaborate with suppliers to determine the best shipping options, including air freight for faster delivery or sea freight for cost-effectiveness. Ensure you understand import regulations in your country, including any duties or taxes applicable to powder coating materials. Establishing a reliable logistics partner can streamline the process and mitigate potential delays. -

What quality assurance measures should I look for in powder coating matte finishes?

Seek suppliers that implement robust quality assurance protocols, including regular product testing and compliance with industry standards. Inquire about their production processes, including batch testing for consistency in color and finish. Look for suppliers that can provide quality reports, including results from salt spray tests, abrasion resistance tests, and other relevant certifications. A reliable supplier will be transparent about their QA procedures and willing to address any concerns that may arise.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 8 Powder Coating Matte Finish Manufacturers & Suppliers List

1. PPG – Matte RAL Powder Coatings

Domain: powdercoatings.ppg.com

Registered: 1990 (35 years)

Introduction: This company, PPG – Matte RAL Powder Coatings, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. The Powder Coat Store – Matte Flat Clear Powder Coating Paint

Domain: thepowdercoatstore.com

Registered: 2013 (12 years)

Introduction: {“product_name”: “Matte Flat Clear Powder Coating Paint”, “weight”: “1 LB”, “price”: “$16.99”, “packaging_options”: [“Heavy Duty Resealable Bag”, “Reusable Plastic Container”, “1/2 LB Sample and Blank Panel”], “gloss_level”: “0%”, “type”: “TGIC Polyester”, “cure_schedule”: “10 Minutes at 400 Degrees (Part Metal Temperature)”, “theoretical_coverage”: “79.83/sq ft per pound @ 2 MIL”, “pencil_hardnes…

3. Cedar & Moss – Matte Black Sample

4. Columbia Coatings – Super Matte Black

Domain: columbiacoatings.com

Registered: 2001 (24 years)

Introduction: Product Name: Super Matte Black

Price per Pound: $12.36 (bulk powder in box increments only)

Quantity Pricing:

– 1-10 lbs: $12.36 each

– 11-24 lbs: $10.53 each

– 25-54 lbs: $9.24 each

– 55-109 lbs: $5.99 each

– 110+ lbs: $5.89 each

Color: Flat Black (No gloss)

Durability: Durable for all conditions

Application: Single step process, can be used alone or as a base for color flake clears

Uses: Ideal…

5. Powder Buy The Pound – Low Gloss/Matte Powder Coatings

Domain: powderbuythepound.com

Registered: 2006 (19 years)

Introduction: Low Gloss/Matte Powder Coatings available at Powder Buy The Pound. Same day shipping for most orders placed before 2pm CT Mon-Fri. Free U.S. ground shipping for all qualifying powder orders over $100. Various powder colors including RAL, Bass Boat, Trawler, Candy & Transparent, Chameleon, Clears, Dormant, FDA, High Temp, Neon, Low Cure Temp, Metallic, Mirror Silvers, Primers, Base Coat, Super Dura…

6. TIGER – Powder Coating Colors

Domain: tiger-coatings.com

Registered: 2000 (25 years)

Introduction: Shop Powder Coating Colors Online | Over 1,000+ Finishes. TIGER Drylac® applications include Metallics & Special Effects, TIGER Trend Colors & Finishes 2025, BattleCoats by TIGER & HyperShock. Featured products include TIGER Drylac® metallics, 3D Metallics, and Pearlescent RAL Finishes. The shop offers a revolutionary 3D Powder Coating Visualization tool for hyper-realistic digital finishes. New p…

7. Rice Rocket – Powder Coating Solutions

Domain: rice-rocket.com

Registered: 2016 (9 years)

Introduction: Powder coating is a durable, weatherproof, and environmentally friendly finish for metal products. It offers thousands of colors and finishes, including popular options such as:

– Matte: Shine-free finish with subtle texture.

– Satin Pearl: Purple/blue sheen that catches light.

– Gloss with Coloured Sparkles: Base color with colored flakes.

– Gloss: High shine, wet-looking appearance.

– Semi-…

8. Crosslink South – Matte Black Powder Coating

Domain: crosslinksouthpowdercoating.com

Registered: 2005 (20 years)

Introduction: Matte black powder coating, also known as matt black or flat black, is a popular finish that provides a sleek, non-reflective surface. It is durable, protecting items from rust, scratches, and damage, and is easy to clean with just soap and water. Common applications include automotive parts, furniture, tools, home décor, and bike/motorcycle parts. The powder coating process involves spraying dry …

Strategic Sourcing Conclusion and Outlook for powder coating matte finish

In conclusion, the strategic sourcing of powder coating matte finishes presents significant opportunities for international B2B buyers seeking to enhance product durability and aesthetics. The growing demand for matte finishes across various industries—from automotive to architectural design—highlights the necessity for suppliers to offer a diverse range of colors and formulations. Leveraging high-quality matte powders, such as TGIC polyester options, ensures not only a visually appealing finish but also resilience against environmental factors.

Furthermore, the importance of understanding regional market dynamics cannot be overstated. Buyers from Africa, South America, the Middle East, and Europe should prioritize partnerships with suppliers who can meet local regulations and preferences while providing reliable logistics. By adopting a proactive approach to sourcing, companies can capitalize on emerging trends and maintain a competitive edge.

Looking ahead, the powder coating industry is poised for innovation, with advancements in eco-friendly formulations and application technologies. We encourage international buyers to explore these developments actively, engage with suppliers, and invest in matte finishes that align with their brand vision and sustainability goals. Take the next step in elevating your product offerings today.