Contents

Manufacturing Insight: Polyurethane Clear Sheet

Precision Sheet Metal Fabrication for Demanding Applications

Honyo Prototype specializes in advanced sheet metal fabrication, delivering high-precision components for aerospace, medical, and industrial sectors. While polyurethane clear sheets serve specific polymer-based applications, our core expertise lies in transforming rigid metal substrates—including aluminum, stainless steel, and copper alloys—into mission-critical parts through laser cutting, CNC bending, and precision forming. Our processes ensure tight tolerances (±0.005″), superior edge quality, and seamless integration with secondary operations like welding and finishing.

For rapid prototyping or low-volume production, leverage our Online Instant Quote system to receive detailed cost and lead-time estimates within minutes. Simply upload your STEP or DXF file, specify material and finish requirements, and our platform generates actionable pricing without sales delays. This efficiency accelerates your design-to-manufacturing workflow while maintaining the engineering rigor Honyo Prototype is trusted for globally.

Partner with us to convert complex designs into certified, production-ready metal components—where material integrity and dimensional accuracy are non-negotiable.

Technical Capabilities

Technical Specifications for Polyurethane Clear Sheet – Laser Cutting, Bending, and Welding Compatibility

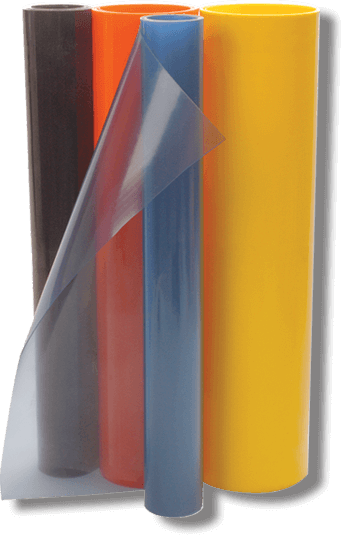

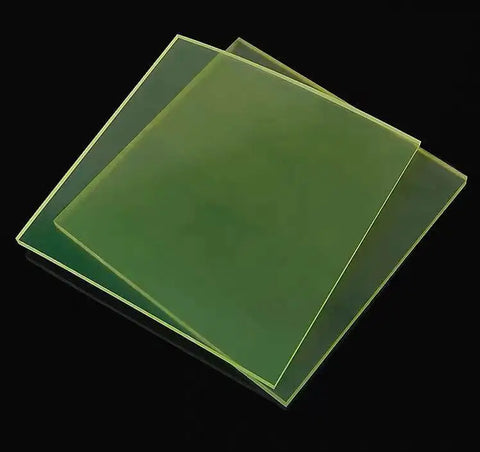

Polyurethane clear sheet is a versatile thermoplastic elastomer known for its excellent abrasion resistance, flexibility, and optical clarity. It is commonly used in protective covers, gaskets, and flexible components. Its performance in laser cutting, bending, and welding varies significantly compared to rigid materials such as aluminum, steel, ABS, and nylon. Below is a comparative overview of polyurethane clear sheet and other common engineering materials across these fabrication processes.

| Property / Material | Polyurethane Clear Sheet | Aluminum | Steel | ABS | Nylon (PA6/PA66) |

|---|---|---|---|---|---|

| Laser Cutting | Moderate to Poor – Tends to melt and discolor; emits toxic fumes (isocyanates). CO₂ lasers can cut thin sheets but require low power and high speed. Not recommended for precision or high-volume use. | Excellent – Clean, precise cuts with fiber or CO₂ lasers; minimal burr. | Excellent – Fiber lasers ideal for cutting; high precision on thin to medium gauges. | Good – CO₂ lasers effective; may produce soot or edge melting. Requires ventilation. | Good – CO₂ lasers work well; slight edge melting possible. |

| Bending | Excellent – High flexibility and elastic recovery. Can be cold bent with tight radii. No springback issues. Ideal for dynamic flexing applications. | Good – Requires tooling for sharp bends; springback must be compensated. Limited flexibility. | Fair – High strength but limited ductility; prone to cracking if bent improperly. | Good – Can be heat-bent; moderate flexibility with some risk of stress cracking. | Very Good – High toughness and flexibility; can be heat-formed with good results. |

| Welding | Poor – Not weldable using standard thermal or ultrasonic methods due to thermal degradation. Adhesive bonding is preferred. | Excellent – Weldable via TIG, MIG, laser, and resistance methods. | Excellent – Weldable using arc, MIG, TIG, and laser techniques. | Good – Ultrasonic, vibration, and hot-plate welding are effective. | Excellent – Easily welded using ultrasonic, hot-plate, and laser methods. |

| Typical Thickness Range | 0.5 mm – 10 mm | 0.8 mm – 25 mm | 1.0 mm – 50 mm | 1.0 mm – 20 mm | 1.0 mm – 15 mm |

| Heat Resistance (°C) | 80 – 100 (short term) | 150 – 400+ | 200 – 500+ | 80 – 100 | 120 – 180 |

| Common Joining Methods | Adhesives, mechanical fasteners | Welding, riveting, adhesives | Welding, bolting | Solvent bonding, adhesives, welding | Adhesives, welding, mechanical |

Notes:

Polyurethane clear sheet is not recommended for laser-based fabrication processes due to hazardous off-gassing and poor edge quality. Bending is one of its strongest attributes, making it suitable for flexible enclosures or protective membranes. For integration with metals or rigid plastics like ABS and nylon, mechanical fastening or adhesive bonding is advised. Always verify material grade and manufacturer specifications before processing.

From CAD to Part: The Process

Honyo Prototype Polyurethane Clear Sheet Manufacturing Process

Honyo Prototype executes a streamlined, technology-driven workflow for polyurethane clear sheet fabrication, ensuring optical clarity, dimensional precision, and rapid turnaround. The process begins with CAD Upload, where clients submit detailed 3D models via our secure portal. Our system validates file integrity and extracts critical geometric data, including sheet thickness, cutouts, and edge treatments. Polyurethane clear sheets demand exacting tolerances for optical applications, so we prioritize parameters affecting light transmission and surface finish during initial review.

The AI Quote phase leverages machine learning trained on historical polyurethane processing data. Unlike generic quoting tools, our AI analyzes material-specific variables: UV stability requirements, hardness grade (e.g., 80A–95A Shore), and post-processing needs like anti-scratch coating. It cross-references real-time resin pricing, laser-cutting speed optimizations for minimal thermal distortion, and yield calculations to generate accurate cost and lead time estimates within 2 hours. This eliminates manual quoting errors common in transparent material fabrication.

DFM (Design for Manufacturability) is rigorously applied by our engineering team, focusing on polyurethane’s unique properties. We identify risks such as warpage from uneven cooling, stress fractures at sharp internal corners, or haze from improper polishing. Key DFM parameters include:

| Parameter | Standard Tolerance | Critical for PU Clear Sheet |

|---|---|---|

| Flatness | ≤ 0.05 mm/mm | Prevents optical distortion |

| Edge Radius | ≥ 0.5 mm | Eliminates micro-cracks |

| Hole Diameter | ≥ 1.5x material thickness | Avoids delamination |

| Surface Roughness | Ra ≤ 0.8 µm | Maintains 90%+ light transmission |

Clients receive annotated DFM reports with actionable revisions, such as adding stress-relief features or adjusting draft angles for molding. For optical-grade sheets, we mandate secondary annealing cycles to relieve internal stresses.

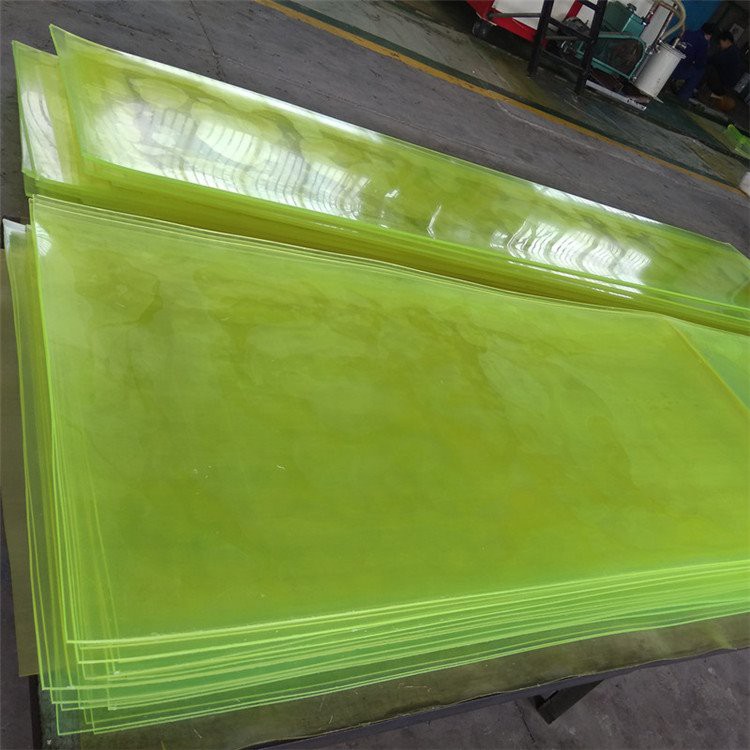

Production utilizes CNC machining and precision laser cutting under climate-controlled conditions (22±2°C, 45% RH) to prevent moisture absorption that causes cloudiness. Polyurethane sheets are processed on dedicated tooling to avoid cross-contamination from other polymers. All edges undergo multi-stage diamond polishing to achieve optical clarity, followed by automated inspection using spectrophotometers to verify haze levels per ASTM D1003. Critical dimensions are verified via CMM with 0.001 mm resolution.

Delivery includes custom anti-static packaging with desiccant and UV-blocking film to maintain clarity during transit. Each shipment includes a material certificate (including optical density and hardness validation) and first-article inspection report. Standard lead time is 5–7 business days from DFM approval, with expedited options for urgent optical prototypes. All polyurethane clear sheets undergo final visual inspection under ISO Class 5 cleanroom conditions to ensure zero particulate contamination.

This integrated process minimizes rework risks inherent in transparent polyurethane fabrication, delivering optically perfect components that meet stringent industry standards for medical, automotive, and display applications.

Start Your Project

Looking for high-quality polyurethane clear sheets for your next project? Contact Susan Leo at [email protected] to request samples, pricing, or technical specifications.

Honyo Prototype manufactures precision polyurethane sheets at our factory in Shenzhen, ensuring consistent quality, fast turnaround, and material performance tailored to demanding industrial applications.

Reach out today to discuss your requirements and discover how our Shenzhen-based manufacturing capabilities can support your production goals.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.