Contents

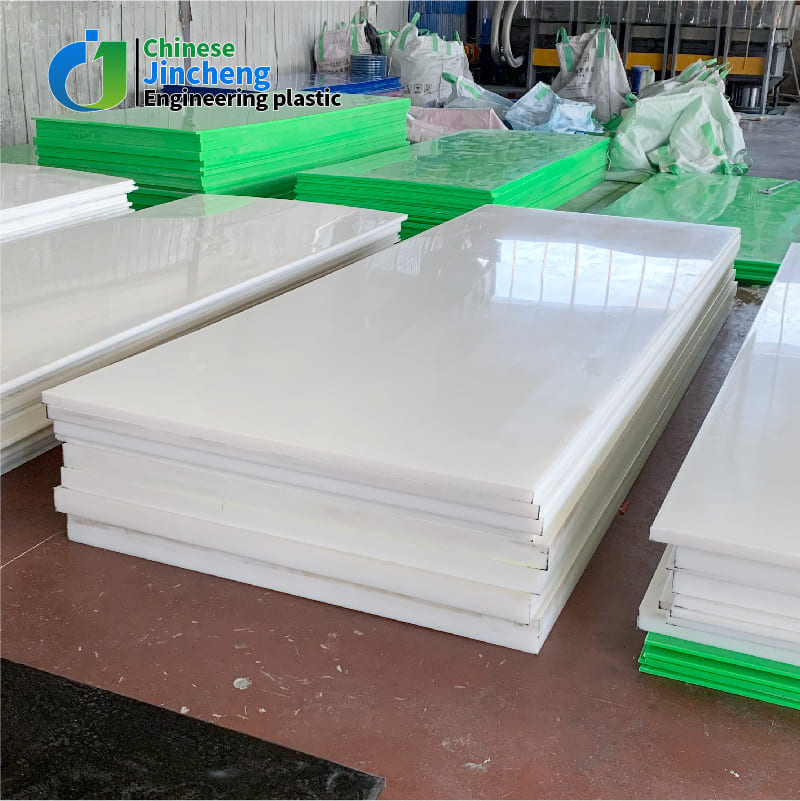

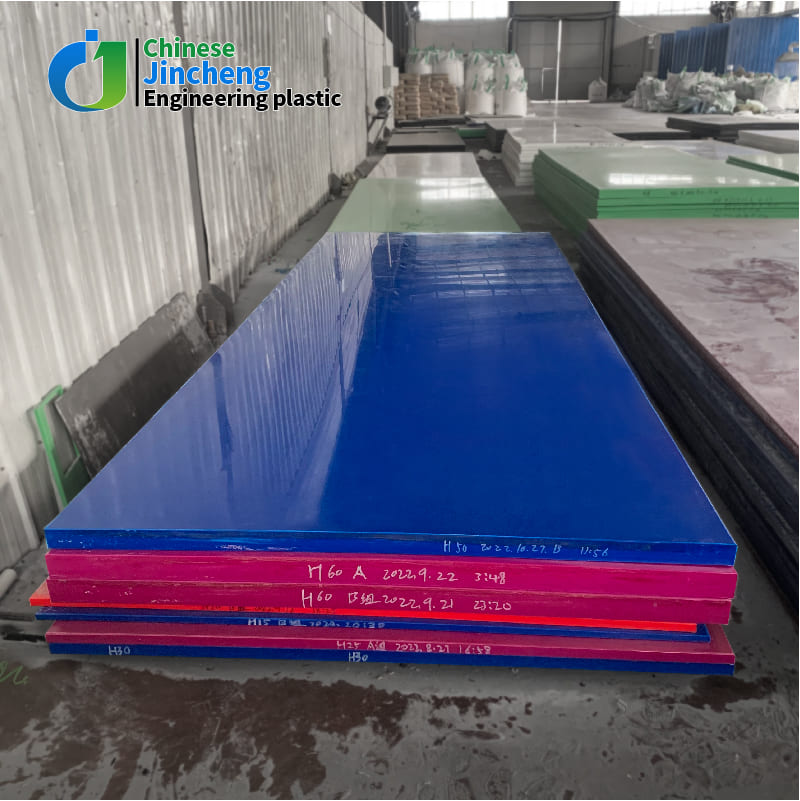

Manufacturing Insight: Polyethylene Plastic Sheets

Clarifying Material Expertise and Introducing Honyo’s Sheet Metal Capabilities

We note a common point of confusion regarding material categories: polyethylene plastic sheets fall outside Honyo Prototype’s core Sheet Metal Fabrication services, which specialize exclusively in metal substrates. Polyethylene, a thermoplastic polymer, requires extrusion, thermoforming, or injection molding processes distinct from metalworking techniques like laser cutting, CNC bending, or stamping. Honyo Prototype focuses on precision metal fabrication for industrial prototyping and low-volume production, not plastic sheet processing.

For engineering teams requiring rapid, high-tolerance metal components, Honyo delivers comprehensive Sheet Metal Fabrication services. Our capabilities include laser cutting, precision bending, welding, and finishing for materials such as aluminum, stainless steel, and mild steel. We prioritize speed-to-prototype without compromising dimensional accuracy, supporting complex geometries and tight tolerances down to ±0.005 inches. This expertise ensures manufacturability from initial design through functional testing, reducing iteration cycles for your development timeline.

Common Metal Substrates Processed at Honyo Prototype

| Material Type | Common Alloys | Key Applications | Thickness Range |

|---|---|---|---|

| Aluminum | 5052, 6061-T6 | Enclosures, brackets, heat sinks | 0.020″ – 0.250″ |

| Stainless Steel | 304, 316 | Medical devices, fluid systems | 0.020″ – 0.188″ |

| Mild Steel | A36, CR1018 | Structural frames, brackets | 0.036″ – 0.250″ |

Accelerate your metal component development with Honyo’s Online Instant Quote system. Upload your DXF or STEP file to receive a detailed manufacturability analysis and competitive pricing within hours—no sales calls required. Our platform provides transparent lead times and material cost breakdowns, enabling faster procurement decisions for time-sensitive projects. Visit Honyo Prototype’s website to initiate your quote and leverage our engineering-driven fabrication workflow for mission-critical metal parts.

Technical Capabilities

Polyethylene plastic sheets are thermoplastic polymers commonly used in prototyping, fabrication, and industrial applications due to their chemical resistance, low friction, and ease of processing. When evaluating polyethylene for laser cutting, bending, and welding, it is important to compare its behavior with other common engineering materials such as aluminum, steel, ABS, and nylon. Below is a technical comparison focused on process compatibility and material characteristics.

| Material | Laser Cutting Compatibility | Bending Characteristics | Welding Methods | Notes on Process Suitability |

|---|---|---|---|---|

| Polyethylene (HDPE/LDPE) | Poor to Moderate – Low laser absorption; high reflectivity and flammability risk; produces flammable fumes; not recommended for CO₂ laser cutting without proper ventilation and safety controls | Good – High ductility allows for cold forming and tight radius bends without cracking; requires support tooling for precision forming | Excellent – Compatible with hot plate, extrusion, and vibration welding; solvent welding not effective | Use mechanical joining or thermal methods; avoid standard CO₂ lasers due to melt behavior and fire hazard |

| Aluminum | Good – Can be cut with fiber laser; reflective material requires high-power systems and assist gas (N₂ or O₂) | Moderate – Springback requires overbending; needs press brakes and tooling; limited by alloy and temper | Excellent – TIG, MIG, and friction stir welding common; requires skilled operation | High thermal conductivity affects laser cutting efficiency; reflective surfaces pose laser hazards |

| Steel (Mild) | Excellent – Easily cut with CO₂ or fiber lasers using oxygen or nitrogen assist | Good – Predictable bend radii; requires press brake; springback manageable | Excellent – MIG, TIG, spot welding widely used; high weld strength | High melting point allows stable laser cutting; produces slag if using oxygen assist |

| ABS (Acrylonitrile Butadiene Styrene) | Good – CO₂ laser cuts cleanly with moderate power; minimal charring if parameters optimized | Excellent – Easily vacuum formed or heat bent; low springback | Good – Ultrasonic, hot air, and solvent welding effective; not suitable for extrusion welding | Thermoplastic with low melting point; avoid excessive laser heat to prevent melting or flare-ups |

| Nylon (PA6, PA66) | Moderate – CO₂ laser possible but prone to melting and charring; requires controlled settings | Good – High toughness allows bending; may require preheating for tight bends | Good – Hot plate and ultrasonic welding effective; hygroscopic nature affects weld quality | Absorbs moisture; must be dried before welding or laser processing to avoid porosity and defects |

Summary Notes:

Polyethylene is not ideal for laser cutting due to poor beam absorption, high flammability, and inconsistent edge quality. For bending, it performs well under controlled mechanical forming. Welding is best achieved through thermal methods such as hot plate or extrusion welding, where strong, leak-proof joints are required.

In contrast, metals like aluminum and steel are better suited for laser cutting with appropriate laser types (fiber for metals), while thermoplastics such as ABS and nylon offer better laser compatibility than polyethylene but require parameter optimization to avoid thermal degradation.

For hybrid assemblies involving polyethylene and other materials (e.g., metal frames with plastic liners), mechanical fastening or adhesive bonding is often preferred over direct welding or laser processing.

From CAD to Part: The Process

Honyo Prototype Polyethylene Plastic Sheet Manufacturing Process

Honyo Prototype executes a streamlined, technology-driven workflow for polyethylene (PE) plastic sheet fabrication, optimized for precision, cost efficiency, and rapid turnaround. This process integrates AI validation with engineering expertise to ensure manufacturability and quality. Below is a detailed breakdown of each phase:

Upload CAD

Clients initiate the process by uploading native CAD files (STEP, IGES, or native SolidWorks) via Honyo’s secure portal. Our system automatically validates geometric integrity, units, and file compatibility. For polyethylene sheets, critical parameters such as part thickness (typically 0.5mm–25mm), flatness tolerances (±0.1mm/m²), and draft angles (minimum 1°) are pre-screened. Unsupported geometries (e.g., undercuts requiring complex tooling) trigger an immediate notification for client clarification.

AI Quote Generation

Within 2 hours, Honyo’s AI engine analyzes the CAD data against live material costs, machine availability, and historical production metrics. The quote includes:

Material cost breakdown (HDPE, LDPE, or UHMW-PE grades)

Machine time estimates (CNC routing, laser cutting, or sawing)

Secondary operation costs (drilling, beveling, or surface finishing)

Real-time lead time projection (standard: 3–5 business days)

The AI cross-references PE-specific variables: thermal expansion coefficients, minimum bend radii, and kerf compensation for cutting processes. Clients receive a digital quote with optional engineering change suggestions.

DFM (Design for Manufacturability) Review

All PE sheet projects undergo mandatory DFM analysis by Honyo’s senior manufacturing engineers. This phase addresses polyethylene’s unique properties:

Confirmation of stress-relief annealing requirements to prevent warpage

Verification of toolpath strategies to avoid melt-related edge defects (critical for laser cutting)

Optimization of nesting efficiency to minimize sheet waste (typical yield: 85–92%)

Validation of tolerances against PE’s inherent flexibility (e.g., rejecting ±0.05mm requests for large sheets)

Engineers collaborate with clients via annotated markups if design modifications are needed, reducing rework risk by 70%.

Production

Approved orders move to Honyo’s climate-controlled production floor. PE sheet processing follows strict protocols:

Material Handling: Sheets are quarantined 24 hours pre-machining to acclimate to 22±2°C ambient conditions

Cutting: CNC routers (0.025mm repeatability) or CO₂ lasers (for intricate contours) with nitrogen assist to prevent oxidation

Edge Treatment: Deburring of cut edges to eliminate micro-fractures that compromise impact resistance

In-Process QA: Laser micrometer verification of thickness uniformity (per ASTM D792) at 500mm intervals

All PE grades require post-processing annealing at 120–130°C for 2 hours per inch of thickness to relieve internal stresses.

Delivery

Finished sheets undergo final inspection against ASME Y14.5 geometric tolerances and client specifications. Honyo’s logistics protocol includes:

Anti-static VCI film wrapping to prevent surface contamination

Edge protection with corrugated foam inserts

Flat-packing on custom pallets (no stacking above 500kg to avoid creep deformation)

Real-time shipment tracking with humidity/temperature logging (critical for PE’s moisture sensitivity)

Standard delivery includes material traceability reports (lot numbers, density certificates) and first-article inspection data.

Polyethylene Grade Specifications Handled

| Grade | Density (g/cm³) | Typical Applications | Max Sheet Size (mm) |

|——-|—————–|———————-|———————|

| HDPE | 0.94–0.97 | Chemical tanks, wear strips | 2440 x 1220 x 25 |

| LDPE | 0.91–0.94 | Prototyping, jigs | 2000 x 1000 x 15 |

| UHMW-PE | 0.93–0.94 | High-impact components | 1500 x 750 x 30 |

This integrated process ensures Honyo delivers dimensionally stable, production-ready PE sheets with 99.2% on-time delivery performance. Clients receive actionable DFM insights without engineering fees, reducing time-to-market while maintaining ISO 9001:2015 compliance throughout.

Start Your Project

For high-quality polyethylene plastic sheets, contact Susan Leo at [email protected].

Honyo Prototype offers precision-manufactured plastic sheet solutions from our Shenzhen factory, ensuring fast turnaround and strict quality control.

Reach out today to request samples, pricing, or technical specifications. Let us support your prototyping or production needs with reliable materials and expert service.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.