Contents

Manufacturing Insight: Plexiglass Custom

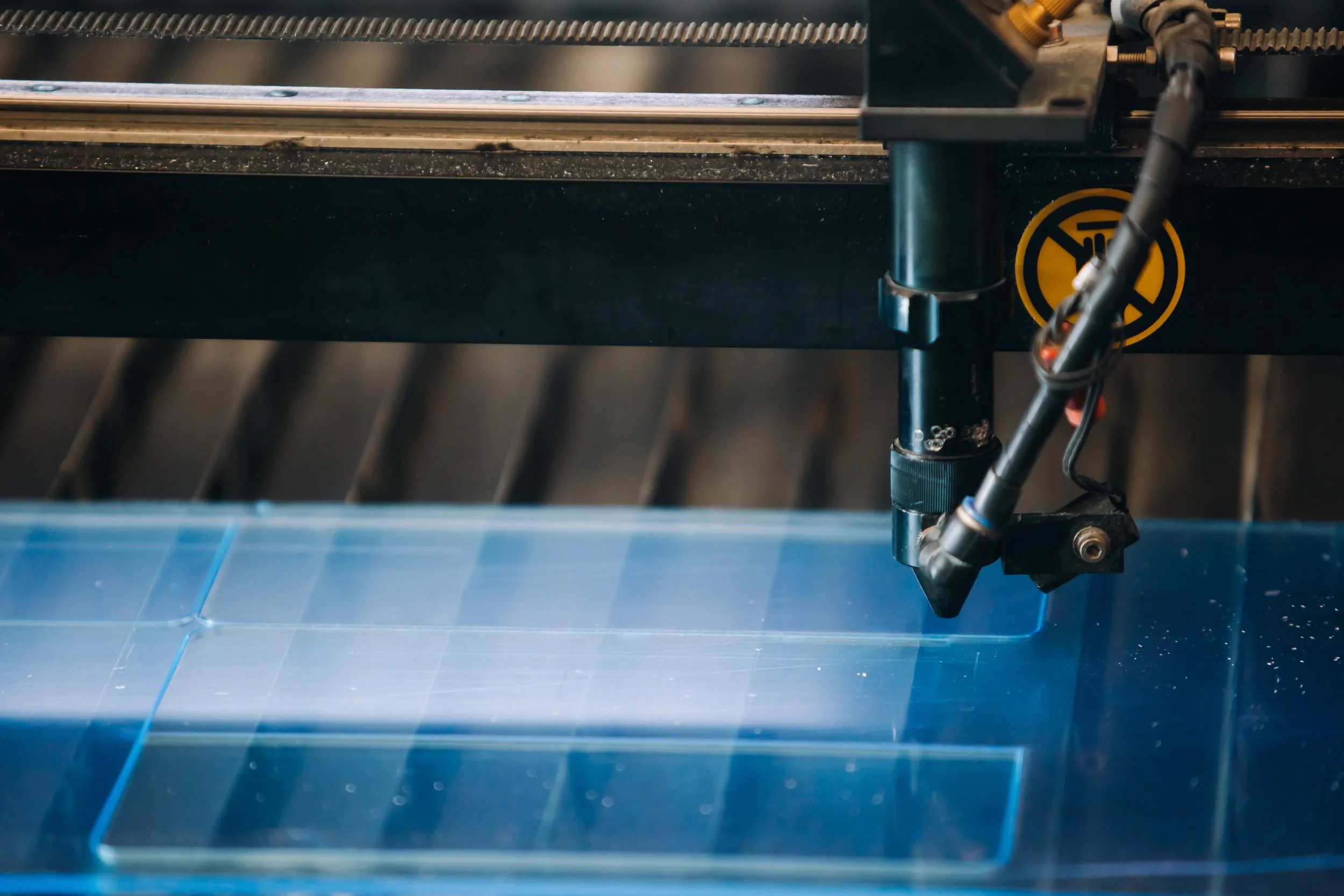

Precision Plexiglass Custom Components via CNC Machining

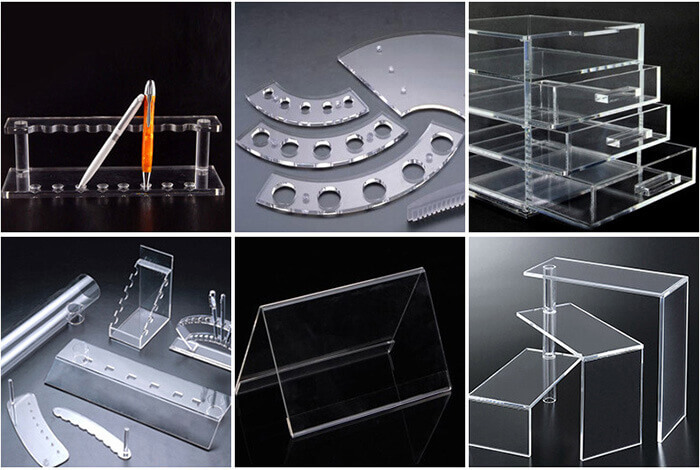

Honyo Prototype delivers engineered-to-spec plexiglass (acrylic) components through advanced CNC machining, serving industries where optical clarity, structural integrity, and dimensional accuracy are non-negotiable. Our 5-axis milling and turning centers achieve tolerances down to ±0.001″ while mitigating common acrylic challenges like micro-cracking, thermal distortion, and surface imperfections during fabrication. This precision ensures your custom light guides, display housings, or medical device enclosures meet rigorous performance standards on the first iteration.

Material expertise defines our process. We optimize feed rates, spindle speeds, and tool geometry for cast or extruded acrylic sheets up to 48″ x 96″, preserving the material’s inherent properties without compromising edge finish or transparency. Unlike laser cutting or manual methods, CNC machining eliminates melt lines and vaporized edges, producing optically neutral surfaces ready for bonding or coating.

Accelerate your prototyping cycle with Honyo’s Online Instant Quote system. Upload CAD files in STEP, IGES, or native formats to receive a detailed manufacturability analysis and formal quotation within 2 hours—no sales calls or email delays. This integration of precision engineering and digital procurement reduces time-to-prototype by up to 70% versus traditional RFQ workflows.

Key Technical Advantages

Material Compatibility Cast & extruded acrylic (PMMA), polycarbonate blends

Max Work Envelope 48″ x 96″ x 24″ (XYZ)

Standard Tolerances ±0.001″ (tight-tolerance options available)

Surface Finish As-machined: 32-64 μin Ra; Polished: 8-16 μin Ra

Partner with Honyo to transform plexiglass design concepts into functionally validated components, backed by metrology-certified quality control and seamless digital quoting.

Technical Capabilities

Technical Specifications for Plexiglass Custom Machining – Focus on 3/4/5-Axis Milling and Turning with Tight Tolerance Capabilities

Honyo Prototype offers precision custom machining services for plexiglass and a range of engineering-grade materials including aluminum, steel, ABS, and nylon. Our 3-axis, 4-axis, and 5-axis CNC milling centers, combined with advanced CNC turning capabilities, enable complex geometries and high repeatability. We specialize in tight tolerance machining, ensuring dimensional accuracy and surface quality for prototyping and low-volume production.

Below is a comparison of technical capabilities and material-specific considerations:

| Parameter | 3-Axis Milling | 4-Axis Milling | 5-Axis Milling | CNC Turning | Tight Tolerance Capability |

|---|---|---|---|---|---|

| Max Working Envelope (mm) | 1000 × 600 × 500 | 800 × 600 × 500 + rotary | 700 × 500 × 400 + dual rotary | Ø300 × 500 length | Up to ±0.005 mm |

| Typical Tolerance (Standard) | ±0.05 mm | ±0.05 mm | ±0.05 mm | ±0.03 mm | Maintained across all axes |

| Surface Finish (Ra) | 1.6 – 3.2 µm | 1.6 – 3.2 µm | 0.8 – 1.6 µm | 0.8 – 1.6 µm | <0.8 µm achievable with polishing |

| Spindle Speed (max) | 24,000 RPM | 24,000 RPM | 24,000 RPM | 12,000 RPM | High-speed spindles for plexiglass |

| Positioning Accuracy | ±0.005 mm | ±0.005 mm | ±0.003 mm | ±0.005 mm | Laser-calibrated machines |

| Repeatability | ±0.008 mm | ±0.008 mm | ±0.005 mm | ±0.008 mm | ISO 2768-mk compliant |

Material-Specific Machining Notes:

Aluminum (6061, 7075): Ideal for high-speed 3–5-axis milling. Excellent for tight tolerance parts with good thermal stability. Commonly used in aerospace and automotive prototypes.

Steel (1018, 4140, Stainless 304/316): Requires rigid tooling and lower feed rates. Suitable for high-wear applications. Tight tolerances maintained with tool wear compensation.

ABS: Low melting point; optimized feeds/speeds prevent deformation. Excellent for functional prototypes. Easily machined on all CNC platforms.

Nylon (PA6, PA66): Low friction and high toughness. Requires secure fixturing due to material flex. Post-machining dimensional stability monitored.

Plexiglass (PMMA): Transparent thermoplastic requiring sharp tooling and controlled chip load to avoid cracking or melting. Polished edges achievable via slow feed and high RPM. Best results on 3-axis due to clarity requirements; 5-axis used for complex contours with post-process buffing.

All processes are supported by in-process inspection using CMM and optical comparators, ensuring compliance with GD&T requirements. First article inspection reports (FAIR) and material certifications available upon request.

From CAD to Part: The Process

Honyo Prototype Plexiglass Custom Manufacturing Process

Honyo Prototype executes a streamlined, technology-driven workflow for custom plexiglass (acrylic/PMMA) fabrication, ensuring precision, efficiency, and adherence to client specifications. Our process integrates AI automation with rigorous engineering oversight, eliminating traditional bottlenecks while maintaining industrial-grade quality control. Below is the end-to-end sequence:

CAD Upload

Clients initiate the process via our secure online portal, uploading native CAD files (STEP, IGES, SLDPRT, or DWG formats preferred) with detailed geometric and material requirements. The system validates file integrity, checks for unit consistency (metric/imperial), and confirms plexiglass-specific parameters such as sheet thickness, color, and optical grade. Unsupported formats trigger an immediate notification for resubmission, preventing downstream delays. All data is encrypted and stored in a client-dedicated project folder compliant with ISO 27001 standards.

AI-Powered Quoting

Within two minutes of upload, our proprietary AI engine generates a preliminary quote by analyzing 12+ dimensional and geometric factors, including part complexity, kerf allowances for laser cutting, minimum bend radii for thermoforming, and material waste optimization. The AI cross-references real-time plexiglass sheet inventory (Astra, Plexiglas, and Altuglas grades), current machine utilization, and regional logistics costs. Crucially, this is an engineer-validated estimate: a Honyo manufacturing engineer reviews the AI output within 15 minutes to adjust for edge treatments (flame-polished, routered), secondary operations (drilling, engraving), or tolerance-critical features, ensuring the final quote reflects manufacturability. Clients receive a formal quotation with a 72-hour lock period.

DFM Analysis

Upon quote acceptance, our Digital Manufacturing Engineering team conducts a dual-layer Design for Manufacturability review. First, an automated DFM algorithm scans for acrylic-specific failure risks: insufficient tab retention for nested parts, unsupported spans exceeding 1mm per 10mm thickness during CNC routing, or inadequate heat dissipation zones for laser cutting. Second, a senior engineer performs a manual review focusing on functional requirements—verifying optical clarity zones against light-transmission specs, confirming chemical resistance for intended environments, and optimizing part orientation to minimize internal stresses. Clients receive a DFM report with actionable recommendations (e.g., “Increase bend radius from 2mm to 4mm to prevent microfractures”) and a revised timeline. Zero-cost design iterations are permitted at this stage.

Precision Production

Production commences only after client sign-off on the DFM report. We deploy material from certified plexiglass lots with full traceability (mill certificates available upon request). Key production protocols include:

Laser Cutting: CO2 lasers with nitrogen assist gas to prevent yellowing; kerf compensated per material thickness (e.g., 0.15mm kerf for 3mm sheet).

CNC Machining: Diamond-coated tools with coolant mist to eliminate chip adhesion and thermal distortion.

Thermoforming: Vacuum-forming at 160°C ±5°C with programmable cooling rates to minimize warpage.

QC Gates: In-process inspections at 25%, 50%, and 100% of batch completion using calibrated optical comparators (±0.05mm tolerance) and ASTM D6284 scratch-resistance tests. All parts undergo 72-hour stress-relief annealing before final packaging.

Delivery & Logistics

Finished parts are double-wrapped in static-dissipative film with anti-scratch coating, secured in custom foam cavities within crush-resistant transit crates. We integrate with DHL, FedEx, and regional freight partners for global delivery, providing real-time GPS tracking. Every shipment includes a Certificate of Conformance detailing material lot numbers, dimensional verification data (via CMM report), and compliance with ISO 9001:2015. Standard lead times scale with volume as shown below:

| Order Volume | Standard Lead Time | Rush Option (24h surcharge) |

|---|---|---|

| 1-50 units | 5 business days | 2 business days |

| 51-200 units | 8 business days | 4 business days |

| 201+ units | 12 business days | 6 business days |

This closed-loop process ensures plexiglass components meet stringent optical, structural, and aesthetic requirements while reducing time-to-prototype by 40% versus industry averages. All projects include post-delivery technical support for integration validation.

Start Your Project

Looking for custom plexiglass solutions? Contact Susan Leo at [email protected] to discuss your project requirements. With our manufacturing facility based in Shenzhen, we deliver high-quality, precision-engineered plexiglass components tailored to your specifications. Fast turnaround, competitive pricing, and expert support from prototyping to production. Reach out today to request a quote or technical consultation.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.