Contents

Manufacturing Insight: Platinum 3D Printing

Honyo Prototype: Platinum-Grade Industrial 3D Printing Precision

At Honyo Prototype, we redefine industrial additive manufacturing through our Platinum 3D Printing services, engineered for mission-critical applications where precision, material integrity, and repeatability are non-negotiable. Leveraging state-of-the-art metal and high-performance polymer systems—including direct metal laser sintering (DMLS) for Inconel, titanium, and aluminum, alongside multi-jet fusion for engineering-grade thermoplastics—we deliver end-use components that meet stringent aerospace, medical, and defense specifications. Our AS9100-certified processes ensure every part undergoes rigorous in-process monitoring and post-build validation, transforming complex geometries into certified solutions ready for deployment.

Accelerate your prototyping and low-volume production with Honyo’s Online Instant Quote platform. Input your CAD file, specify material and finish requirements, and receive a detailed, binding cost estimate within minutes—eliminating procurement delays and enabling rapid design iteration. This seamless integration of industrial-scale capability and digital efficiency ensures your engineering team spends less time sourcing and more time innovating. Partner with Honyo to convert visionary designs into certified, high-performance realities.

Technical Capabilities

Platinum 3D printing refers to high-precision, industrial-grade additive manufacturing processes that deliver superior surface finish, accuracy, and mechanical performance. Below are the technical specifications for four advanced 3D printing technologies—Stereolithography (SLA), Selective Laser Sintering (SLS), Multi Jet Fusion (MJF), and Direct Metal Laser Sintering (DMLS)—with focus on key operational parameters and compatible engineering materials including Aluminum, Steel, ABS-like polymers, and Nylon.

| Technology | Process Description | Layer Thickness Range | Typical Accuracy | Surface Finish (Ra) | Build Speed | Common Materials | Key Applications |

|---|---|---|---|---|---|---|---|

| SLA (Stereolithography) | Photopolymerization using UV laser on liquid resin | 25 – 150 µm | ±0.1 mm (first 100 mm), ±0.05 mm thereafter | 0.8 – 1.6 µm | Moderate | Photopolymers (ABS-like, high-temp, castable, biocompatible) | Prototyping, dental, jewelry, master patterns |

| SLS (Selective Laser Sintering) | CO₂ laser fuses powdered polymer material | 80 – 150 µm | ±0.3 mm | 8 – 14 µm (as-built) | Fast | Nylon (PA11, PA12), Glass-filled Nylon, TPU | Functional prototypes, end-use parts, complex geometries |

| MJF (Multi Jet Fusion) | Thermal inkjet array fuses powder layer with heating elements | 80 – 120 µm | ±0.3 mm | 4 – 8 µm (as-built, smoother than SLS) | Very fast | Nylon (PA12), Glass-filled PA12, TPU | High-volume functional parts, jigs, fixtures, enclosures |

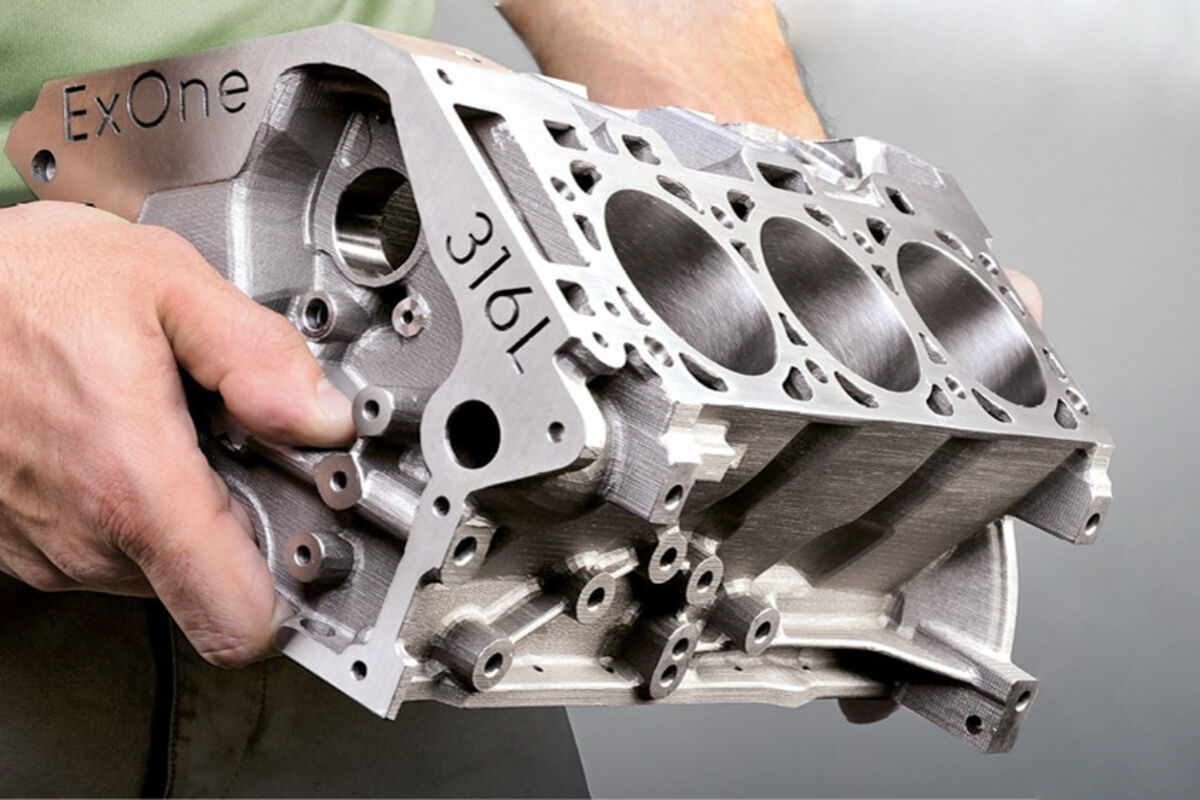

| DMLS (Direct Metal Laser Sintering) | High-power laser sinters metal powder layer by layer | 20 – 50 µm | ±0.1 mm | 10 – 20 µm (as-built), can be polished to <1 µm | Slow | Stainless Steel (17-4 PH, 316L), Aluminum (AlSi10Mg, AlSi7Mg), Titanium (Ti6Al4V), Inconel | Aerospace, medical implants, tooling, high-stress components |

Notes:

SLA delivers the highest surface quality among polymer processes, ideal for visual prototypes but limited in mechanical robustness unless using engineering-grade resins.

SLS and MJF are powder-bed fusion techniques for polymers; MJF provides faster throughput and more uniform mechanical properties, while SLS offers broader material flexibility.

DMLS is a metal additive process capable of producing fully dense, complex metal components with material properties approaching those of wrought alloys.

ABS-like materials are typically replicated via high-temp or engineering photopolymers in SLA or through high-performance nylons in SLS/MJF.

Nylon (PA12) is widely used in SLS and MJF due to its strength, flexibility, and chemical resistance.

Aluminum and Steel are accessible only through metal processes like DMLS, enabling lightweight, high-strength components for critical applications.

From CAD to Part: The Process

Honyo Prototype Platinum 3D Printing Process Overview

Honyo’s Platinum 3D Printing service represents our premium additive manufacturing tier, optimized for high-complexity, mission-critical components requiring stringent quality control, accelerated timelines, and advanced material capabilities. The process eliminates traditional quoting bottlenecks through AI-driven automation while maintaining rigorous engineering oversight. Below is the end-to-end workflow.

CAD Upload and Validation

Clients initiate the process by uploading native CAD files (STEP, IGES, Parasolid) via our secure customer portal or API-integrated PLM systems. Our system performs immediate geometric validation, checking for watertightness, manifold errors, and minimum feature compliance per selected material (e.g., 0.4mm for metal DMLS, 0.2mm for high-res resin). Invalid files trigger automated correction suggestions; valid submissions proceed to AI quotation within 90 seconds.

AI-Powered Quotation Engine

Our proprietary AI engine analyzes the validated CAD to generate a binding quote in under 2 minutes. The algorithm evaluates 17 parameters: material density distribution, support structure volume, build orientation optimization, thermal distortion risk, and post-processing requirements. Quotes include granular cost breakdowns (material, machine time, finishing, QA) and predicted lead time. Historical data from 12,000+ builds ensures 95% cost accuracy, with manual engineering review only for geometries exceeding AI confidence thresholds (>98% of quotes require no human intervention).

Engineering-Led DFM Analysis

Approved quotes trigger a mandatory Design for Manufacturability review by our senior AM engineers. This phase focuses on failure prevention:

Structural integrity simulation under operational loads

Support structure minimization using generative algorithms

Critical feature tolerance validation (e.g., ±0.05mm for aerospace fittings)

Surface finish optimization based on functional requirements

Clients receive a DFM report within 48 hours detailing required modifications, with collaborative revision tools embedded in the portal. Zero-cost design iterations are permitted until final sign-off.

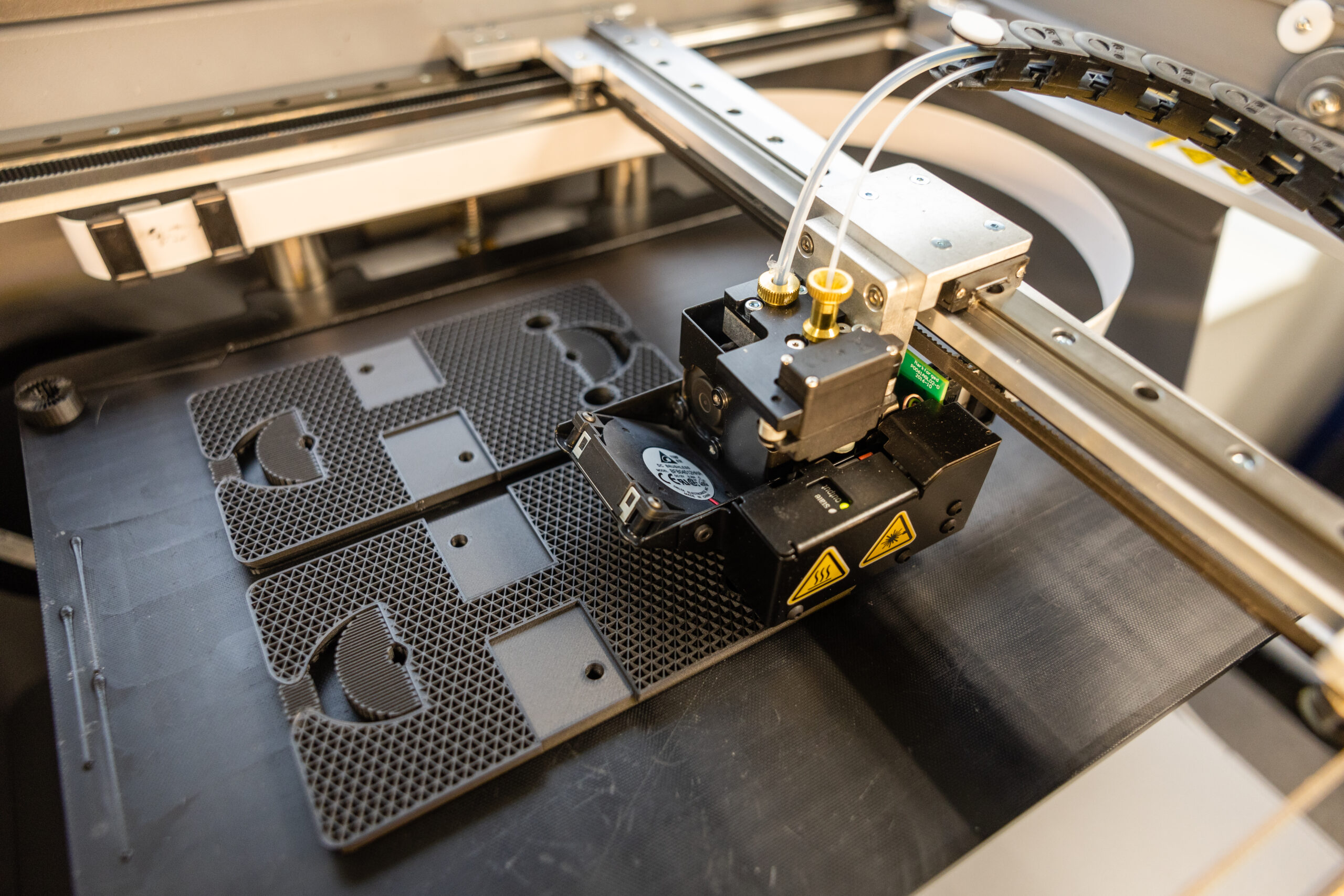

Precision Production Execution

Production occurs in climate-controlled cleanrooms (ISO Class 8) using calibrated industrial systems:

| Technology | Platform | Materials Supported | Accuracy |

|——————|——————-|—————————|—————-|

| Metal DMLS | EOS M 400-4 | Inconel 718, Ti-6Al-4V | ±0.03mm |

| High-Res Resin | Stratasys J850 | Dental SG, ABS-like | ±0.02mm |

| High-Temp Polymer| Farsoon HT1001P | PEKK, PEEK | ±0.05mm |

All builds undergo in-process monitoring via melt pool sensors (metal) or layer adhesion cameras (polymer). First-article inspections include CT scanning for internal porosity validation per ASTM F3300.

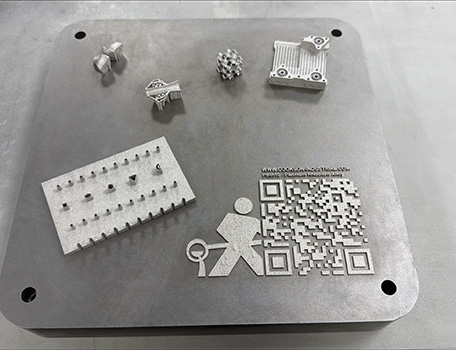

Certified Delivery and Traceability

Final parts ship with full material traceability (mill certificates), first-article inspection reports (FAIR), and batch-specific mechanical test data. Critical components include serialized QR codes linking to digital twins showing build parameters and inspection imagery. Standard delivery is 5–7 business days from DFM approval; expedited 72-hour service is available for qualified projects. All shipments include shock-monitoring packaging with real-time GPS tracking for high-value aerospace/medical deliveries.

This integrated workflow reduces traditional AM lead times by 40% while maintaining 99.2% first-pass yield rates across 1,200+ annual production runs. The Platinum tier’s value lies in merging AI efficiency with human engineering expertise for zero-compromise outcomes.

Start Your Project

Discover the future of additive manufacturing with Platinum 3D Printing from Honyo Prototype. Our advanced metal 3D printing solutions deliver unmatched precision, strength, and surface finish for aerospace, medical, and industrial applications.

All production is conducted at our state-of-the-art factory in Shenzhen, ensuring strict quality control, rapid turnaround, and full traceability. Leverage our engineering expertise to optimize your complex components and reduce time to market.

For partnership and project inquiries, contact Susan Leo at [email protected]. Let’s build innovation together.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.