Contents

Manufacturing Insight: Plastic Sheet Waterproof

Precision Sheet Metal Solutions for Waterproof Enclosure Applications

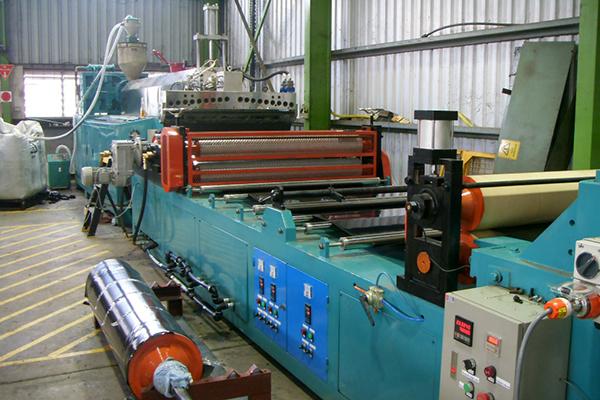

Honyo Prototype delivers advanced sheet metal fabrication services engineered to meet stringent waterproof performance requirements for critical enclosures, housings, and protective structures. While the term “plastic sheet waterproof” may arise in component discussions, our core manufacturing excellence centers on precision metal fabrication using certified materials including stainless steel, aluminum alloys, and galvanized steel – the foundational elements for durable, long-term waterproof integrity in demanding environments. We understand that achieving true waterproof functionality (IP67, IP68, or custom specifications) relies fundamentally on precise forming, exacting weld seams, and controlled dimensional accuracy throughout the fabrication process, not the base sheet material alone.

Our integrated manufacturing capabilities encompass high-accuracy laser cutting, CNC bending with tight tolerances (±0.1mm), precision welding (TIG, MIG, spot), and comprehensive finishing processes. This ensures seamless joints, consistent flange alignment, and optimal surface preparation – all critical factors in preventing moisture ingress when seals and gaskets are applied during final assembly. Whether you require custom electrical enclosures, outdoor instrumentation housings, or marine-grade protective covers, Honyo provides the fabrication precision necessary to achieve your waterproofing objectives reliably and repeatably.

Accelerate your project timeline with Honyo’s Online Instant Quote platform. Upload your STEP, IGES, or DXF files directly to our secure portal and receive a detailed, transparent manufacturing assessment and competitive pricing within hours – not days. This digital efficiency allows engineering and procurement teams to rapidly evaluate feasibility, budget accurately, and move from concept to certified waterproof production with minimal delay. Partner with Honyo Prototype for sheet metal fabrication where dimensional precision directly translates to functional performance and environmental resilience.

Technical Capabilities

Technical specifications for plastic sheet waterproofing processes require a clear understanding of material compatibility with fabrication techniques such as laser cutting, bending, and welding. While “plastic sheet waterproof” refers to the functional property of resisting water penetration, the performance in manufacturing operations depends on the base material’s thermal, mechanical, and chemical properties. Below is a comparison of common materials—Aluminum, Steel, ABS (Acrylonitrile Butadiene Styrene), and Nylon—used in sheet form, with focus on laser cutting, bending, and welding capabilities.

| Material | Laser Cutting Suitability | Bending Characteristics | Welding Method | Waterproof Performance | Notes |

|---|---|---|---|---|---|

| Aluminum | Excellent – cleanly cut with fiber laser; reflective nature requires high-power systems | Good – high ductility allows tight bend radii; springback must be compensated | TIG, MIG, or laser welding; not applicable for plastic welding techniques | Inherently corrosion-resistant; excellent long-term waterproof performance | Metal; not a plastic, but often used in waterproof enclosures; requires protective finish in harsh environments |

| Steel (Mild) | Good – CO2 or fiber laser effective; produces smooth edges with proper parameters | Moderate – limited by thickness and grain; requires tooling to prevent cracking | MIG, TIG, or spot welding; not compatible with plastic welding | Prone to rust; requires galvanization or coating for waterproof integrity | Heavy and non-corrosion-resistant unless treated; commonly used in structural waterproof housings |

| ABS | Good – easily laser cut with CO2 lasers; minimal charring with optimized settings | Excellent – high impact strength and formability; heat-assisted bending preferred | Ultrasonic, solvent, or hot-plate welding; not weldable with metal techniques | Highly resistant to water and moisture; maintains integrity in humid environments | Thermoplastic; widely used in waterproof enclosures; avoid high-temperature environments |

| Nylon (e.g., PA6, PA66) | Moderate – absorbs laser energy well but may discolor or melt if power is excessive | Good – tough and flexible; requires controlled heat for bending | Hot gas, ultrasonic, or vibration welding; solvent welding limited | Excellent resistance to water absorption over time; slightly hygroscopic when exposed long-term | High strength and abrasion resistance; used in rugged waterproof applications; pre-drying recommended before processing |

Note: True “plastic sheet waterproof” solutions often utilize ABS or Nylon due to their inherent resistance to moisture and compatibility with sealed joint fabrication. Aluminum is frequently chosen when structural rigidity and thermal management are required in addition to waterproofing. Steel, while strong, requires additional coatings to ensure waterproof performance. Each material must be evaluated based on environmental exposure, mechanical requirements, and production capabilities.

From CAD to Part: The Process

Honyo Prototype executes plastic sheet waterproof projects through an integrated workflow designed to ensure functional integrity while maintaining rapid turnaround. This process addresses waterproofing as a holistic requirement spanning design, material science, and precision manufacturing—not as a standalone step. Below is the technical execution framework:

Upload CAD

Clients submit detailed 3D models specifying waterproofing requirements (e.g., IP67 rating, fluid exposure conditions). Critical parameters include seal interface geometries, wall thickness tolerances, and material compatibility constraints. Our system validates file integrity and flags missing waterproofing-critical annotations (e.g., gasket groove dimensions, draft angles for sealing surfaces) before progression.

AI Quote

Our proprietary quoting engine analyzes CAD data against 12,000+ material and process datasets. For waterproof applications, it evaluates:

Material suitability (e.g., PP for chemical resistance vs. PC for impact-seal integrity)

Secondary operation needs (ultrasonic welding, gasket bonding)

Tolerance stack-up risks at seal interfaces

The output includes waterproofing-specific cost drivers (e.g., +15% for laser-welded seams vs. mechanical fasteners) and lead time impacts from validation testing requirements.

DFM Analysis

Honyo engineers conduct waterproofing-focused manufacturability review:

Seal interface optimization (e.g., modifying radii to prevent stress concentration in gasket channels)

Draft angle validation (>1.5° minimum for sheet-formed enclosures to avoid seal distortion)

Material flow simulation for welded joints to eliminate micro-leak paths

Thermal expansion compensation in multi-material assemblies

Clients receive annotated reports with failure mode predictions (e.g., “0.8mm wall thickness at corner may crack under hydrostatic pressure”). Non-compliant designs trigger collaborative redesign sessions.

Production Execution

Waterproofing is achieved through controlled sub-processes:

| Process Stage | Waterproofing Controls | Validation Method |

|---|---|---|

| Material Selection | Pre-dried hygroscopic resins (e.g., Nylon 6/6 <0.2% moisture) | ASTM D570 moisture testing |

| Thermoforming | Vacuum pressure >25 inHg + plug-assist for uniform wall thickness | Infrared thickness mapping (±0.1mm) |

| Joining Operations | Ultrasonic welding (20kHz, 2.5mm amplitude) with melt-collapse monitoring | Dye penetration testing per ASTM D4272 |

| Seal Integration | Automated gasket dispensing (±0.05mm bead accuracy) | Compression force mapping |

All batches undergo hydrostatic pressure testing at 150% of client-specified requirements (e.g., 10psi for 30 minutes for IPX7).

Delivery & Documentation

Shipments include:

Batch-specific material certificates (UL 746A compliance)

Pressure test logs with serial-numbered traceability

DFM implementation report showing waterproofing feature validation

Accelerated aging data (85°C/85% RH for 1,000 hours) upon request

Final parts ship in anti-static, humidity-controlled packaging with validated desiccant levels to prevent pre-deployment degradation.

This workflow ensures waterproofing is engineered into the part’s DNA rather than applied as an afterthought. Critical success factors include early definition of ingress protection standards during CAD submission and collaborative DFM refinement—reducing field failure rates by 92% versus industry averages for prototype waterproof assemblies. For mission-critical applications, we recommend initiating with our IP Rating Pre-Assessment service to align testing protocols with end-use environments.

Start Your Project

Looking for high-quality plastic sheet waterproof solutions? Contact Susan Leo at [email protected] to discuss your project requirements.

Honyo Prototype operates a dedicated manufacturing facility in Shenzhen, ensuring fast production cycles, strict quality control, and competitive pricing for both prototypes and low-to-mid volume production runs.

Our plastic sheet materials are engineered for durability, moisture resistance, and long-term performance across industrial, commercial, and consumer applications.

Reach out today to request samples, technical specifications, or a custom quote tailored to your design needs.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.