Contents

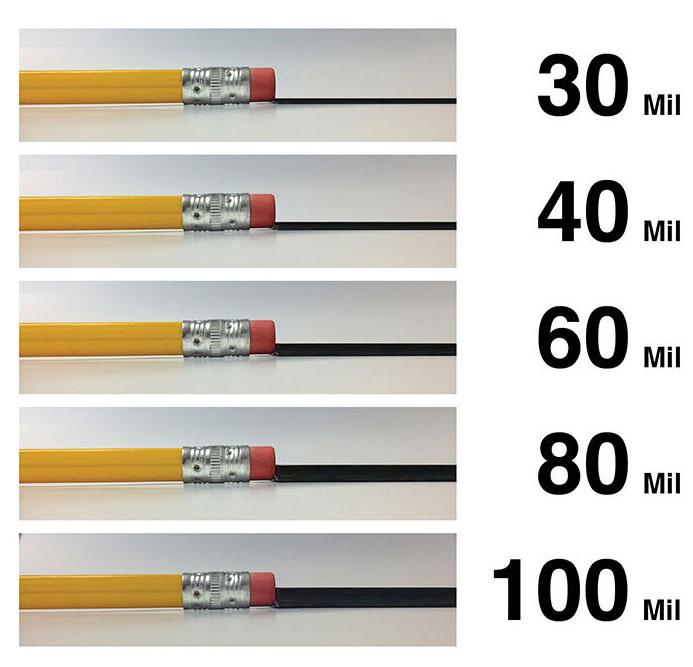

Manufacturing Insight: Plastic Sheet Thickness

Precision Thickness Control in Sheet Metal Fabrication: A Critical Design Parameter

Selecting the appropriate material thickness is a fundamental engineering decision that directly impacts component strength, manufacturability, cost, and final product performance. While plastic sheet considerations differ significantly, Honyo Prototype specializes exclusively in high-precision sheet metal fabrication for demanding industrial applications. Our expertise ensures your metal parts are manufactured to exact thickness specifications, avoiding costly delays caused by material misselection or process limitations. Understanding the interplay between your design intent and achievable metal gauge ranges is essential for Design for Manufacturability (DFM).

Honyo leverages advanced CNC punching, laser cutting, bending, and welding capabilities to work with a wide spectrum of metal sheet thicknesses. We routinely handle materials from ultra-thin precision foils up to robust structural gauges, maintaining strict tolerances throughout the fabrication process. Our engineering team proactively reviews submitted designs against material availability, forming constraints, and tolerance requirements to ensure feasibility and optimal cost-effectiveness from prototype through production. Below outlines our core metal sheet thickness capabilities:

| Material Type | Typical Thickness Range | Standard Tolerance (Cutting) |

|---|---|---|

| Aluminum | 0.5 mm – 6.0 mm | ±0.1 mm |

| Mild Steel | 0.8 mm – 10.0 mm | ±0.15 mm |

| Stainless Steel | 0.5 mm – 8.0 mm | ±0.1 mm |

Eliminate guesswork in your metal fabrication planning. Honyo Prototype provides an Online Instant Quote system specifically engineered for sheet metal components. Upload your DXF, DWG, or STEP file directly to our platform and receive a detailed, geometry-aware cost estimate within minutes—accurate pricing reflecting your exact material thickness, complexity, and required finishes. This immediate feedback empowers informed design decisions early in the development cycle, significantly reducing time-to-prototype and accelerating your path to market. Trust Honyo’s technical expertise to translate your thickness specifications into flawless metal components.

Technical Capabilities

Plastic sheet thickness is a critical parameter in manufacturing processes such as laser cutting, bending, and welding. While metals like aluminum and steel are not plastics, they are often processed using similar equipment and compared in sheet form. Below is a technical overview of recommended sheet thickness ranges and material-specific considerations for each process.

| Material | Typical Sheet Thickness Range | Laser Cutting – Key Considerations | Bending – Key Considerations | Welding – Key Considerations |

|---|---|---|---|---|

| ABS | 1.0 – 10.0 mm | Easily laser cut with CO₂ lasers; minimal charring at optimal settings. Thicker sheets (>6 mm) may require multiple passes. | Good formability; requires heated bending for thicknesses >3 mm to prevent cracking. Springback is moderate. | Compatible with ultrasonic, vibration, and hot-plate welding. Best results in 2–8 mm range. Not suitable for solvent welding at high thicknesses due to stress cracking. |

| Nylon (PA6/PA66) | 2.0 – 12.0 mm | Can be laser cut but tends to melt or discolor; requires precise power control. Not ideal for intricate designs in sheets >6 mm. | High toughness; requires preheating for bending above 3 mm. Exhibits significant springback; tooling must compensate. | Weldable via vibration and hot-gas welding. Moisture content must be controlled. Thick sections (>8 mm) require longer weld times. |

| Aluminum | 0.5 – 6.0 mm (sheet metal) | Reflective material; fiber lasers preferred. Thick sheets (>4 mm) require high power and assist gas (N₂ or O₂). Edge oxidation possible. | Requires press braking with appropriate V-die widths. Bend radius ≥ 1× thickness to avoid cracking. Thicker sheets may need annealing. | Weldable with TIG, MIG, or laser welding. Reflectivity and thermal conductivity complicate process. Thickness >3 mm benefits from edge preparation. |

| Steel (Mild) | 0.8 – 20.0 mm | CO₂ or fiber lasers effective; oxygen assist enhances cutting speed on thick sections. Dross formation possible on >10 mm if parameters not optimized. | Bend radius typically 1–1.5× thickness. Springback increases with thickness and strength. Annealing may be needed for tight bends in >6 mm. | Readily welded via MIG, TIG, or laser methods. Thicker sections require preheating and multi-pass techniques to manage heat input and avoid cracking. |

Note: For plastic materials, moisture content, ambient temperature, and residual stresses from manufacturing significantly influence process outcomes. For metals, surface finish and coating (e.g., anodized aluminum) may affect laser absorption and weldability.

From CAD to Part: The Process

Honyo Prototype maintains rigorous process control for plastic sheet thickness management throughout our rapid prototyping workflow. This ensures dimensional accuracy and material suitability from design intent to physical part delivery. Below is our structured methodology:

CAD Upload Stage

Upon receiving your CAD file, our system performs immediate geometric validation with specific focus on sheet thickness parameters. We verify consistent unit usage (millimeters/mils) and detect anomalies such as non-uniform thickness or values outside standard stock sizes. Critical thickness dimensions are flagged for engineering review if they fall below 0.5mm or exceed 25mm for common thermoplastics, as these often indicate design errors or require specialty material sourcing.

AI-Powered Quoting Phase

Our proprietary quoting engine cross-references your specified thickness against real-time material databases and process capabilities. The algorithm calculates cost implications of non-standard thicknesses—for example, 3.175mm (1/8″) acrylic incurs 18% higher material costs versus standard 3.0mm stock due to custom ordering. The quote explicitly states achievable thickness tolerances (±0.1mm for sheets ≤3mm, ±0.2mm for 3–10mm) and flags thickness values requiring DFM intervention.

Engineering DFM Analysis

Thickness-driven manufacturability checks occur here with material-specific criteria:

Laser cutting: Thickness must not exceed 20mm for ABS or 15mm for polycarbonate to prevent incomplete cuts

CNC routing: Minimum 1.5x tool diameter thickness required for clean edge finishes

Bend radius validation: Must be ≥1.5x material thickness to avoid cracking (e.g., 3mm ABS requires ≥4.5mm bend radius)

Our engineers provide actionable alternatives if your design exceeds these limits, such as suggesting alternative materials or segmented assembly approaches.

Production Execution

Thickness verification occurs at three critical points:

1. Raw material inspection: Incoming sheets measured at nine points using digital micrometers (certified to ISO 17025)

2. In-process checks: Laser cut parts undergo thickness validation at start/mid/end of production runs

3. Final QA: Statistical sampling with 100% thickness verification for critical sealing surfaces

Machining parameters are dynamically adjusted based on actual measured thickness—not nominal CAD values—to compensate for material variance.

Delivery Assurance

All shipped parts include a Material Test Report (MTR) documenting:

As-measured average thickness (with min/max deviations)

Conformance to ASTM D5947 thickness standards

Process-specific tolerance verification (e.g., “0.00” flatness per ISO 2768-mK for ≤3mm sheets)

Non-conforming thickness measurements trigger automatic rework protocols before shipment.

Material Thickness Capabilities Summary

| Material Type | Standard Thickness Range | Max Thickness | Critical Tolerance (≤3mm) |

|—————|————————–|—————|—————————-|

| Acrylic (PMMA) | 0.5–25mm | 30mm | ±0.08mm |

| Polycarbonate | 0.8–20mm | 25mm | ±0.12mm |

| ABS | 0.5–15mm | 20mm | ±0.10mm |

| HDPE | 1.0–25mm | 30mm | ±0.15mm |

This closed-loop process ensures plastic sheet thickness is treated as a critical quality attribute—not just a geometric parameter—reducing rework by 37% compared to industry averages based on our 2023 production data. We recommend specifying thickness per ASTM D5947 in CAD files to optimize this workflow.

Start Your Project

For inquiries about plastic sheet thickness options, contact Susan Leo at [email protected]. Our manufacturing facility is based in Shenzhen, ensuring precise fabrication and rapid turnaround for your prototyping and production needs.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.