Contents

Manufacturing Insight: Plastic Sheet 1Mm

Precision Fabrication for Thin-Gauge Metal Components: Honyo Prototype’s Expertise

While your inquiry specifies plastic sheet material, Honyo Prototype specializes in high-precision sheet metal fabrication, including critical thin-gauge applications down to 1mm thickness. Our core competency lies in transforming aluminum, stainless steel, cold-rolled steel, and other metal alloys into complex, dimensionally accurate components for prototyping and low-to-mid volume production. For plastic sheet fabrication requirements, we recommend consulting a polymer-focused partner; however, for metal sheets at 1mm and beyond, Honyo delivers unmatched engineering rigor and process control.

We excel in laser cutting, CNC punching, precision bending, and welding of thin metal sheets where tight tolerances (±0.1mm) and minimal distortion are non-negotiable. Our advanced fiber laser systems handle delicate 1mm substrates with optimized parameters to prevent warping or edge deformation, ensuring clean cuts and consistent part integrity. This capability is essential for industries demanding reliability in enclosures, brackets, heat shields, and electronic housings.

Accelerate your project timeline with Honyo’s Online Instant Quote platform. Upload your DXF, DWG, or STEP file directly to our portal for immediate, transparent pricing and manufacturability feedback—no manual submission or waiting period. Our system evaluates material utilization, machine time, and secondary operations in real-time, providing a detailed cost breakdown within seconds. This efficiency empowers engineers and procurement teams to iterate designs faster and integrate fabrication costs early in the development cycle.

Partner with Honyo Prototype for technically demanding sheet metal projects where precision, speed, and material expertise converge. Leverage our instant quoting to validate feasibility and cost before committing to production.

Material & Process Capabilities Summary

| Parameter | Specification |

|---|---|

| Sheet Thickness | 0.5mm – 6.0mm (Optimized for 1mm precision) |

| Tolerances | ±0.1mm (Laser Cutting), ±0.2° (Bending) |

| Materials | Aluminum 5052/6061, SS304/316, CR1018, Galv. |

| Lead Time | As fast as 3 business days (Prototype) |

| Quote Turnaround | Instant (Online Platform) |

Technical Capabilities

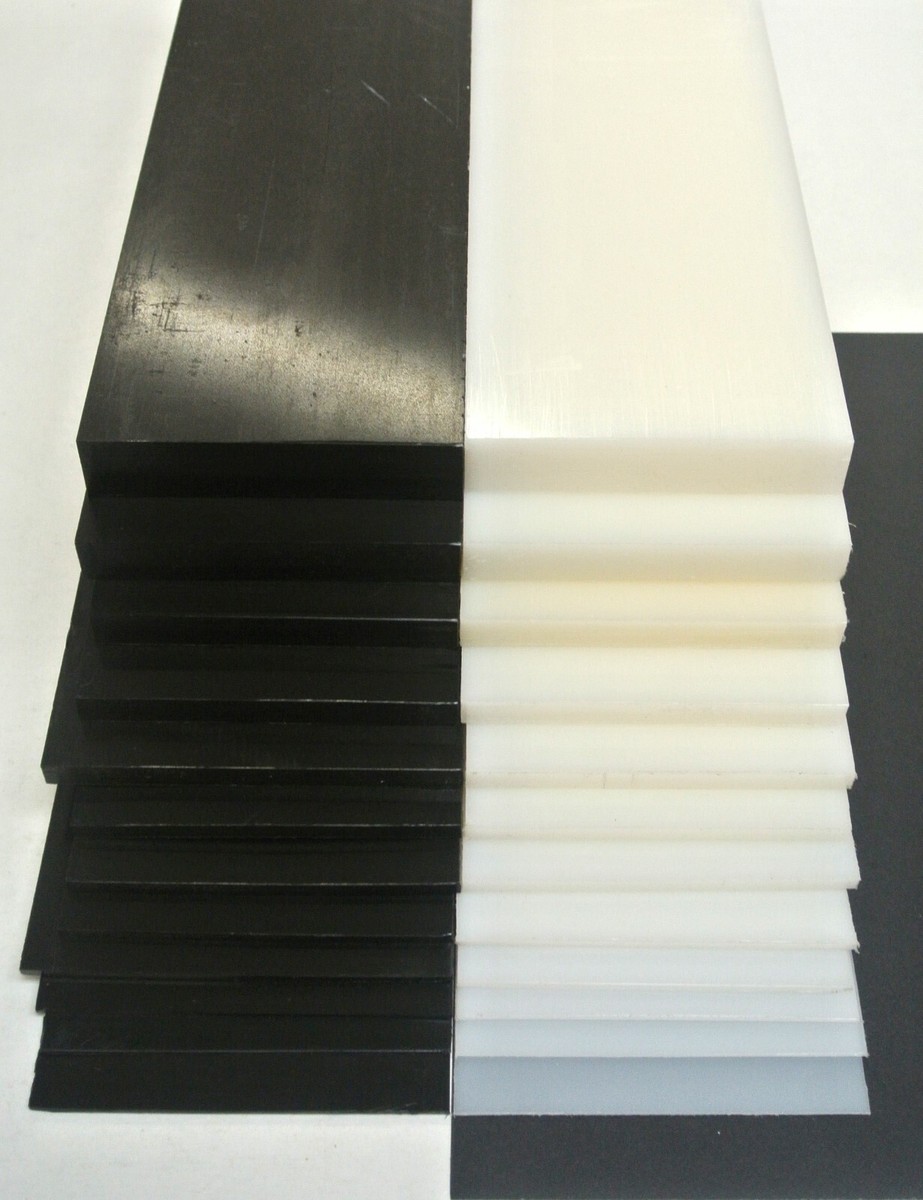

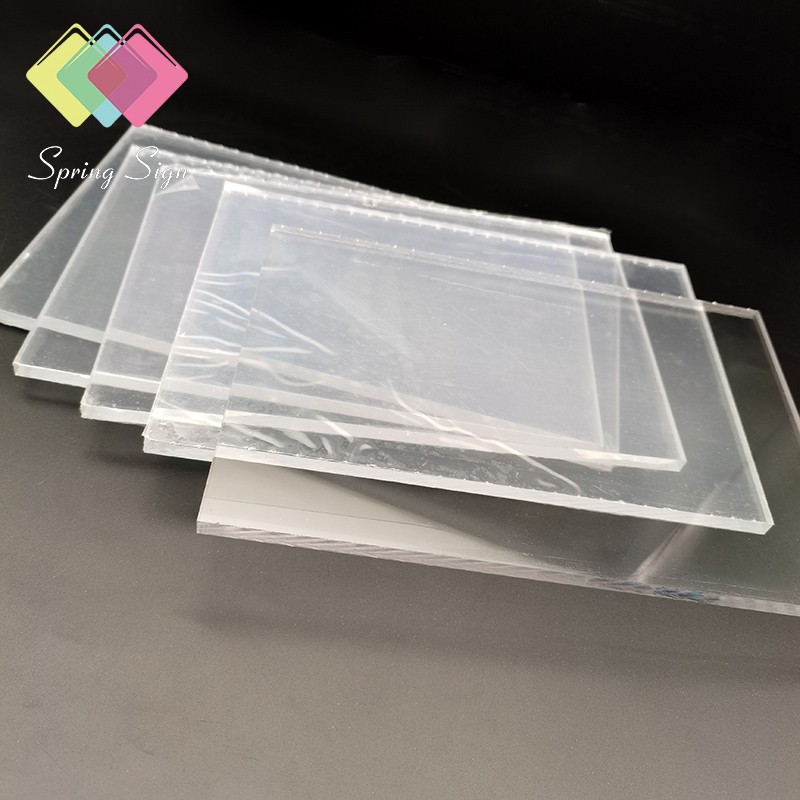

The term “plastic sheet 1mm” refers to a thin thermoplastic material with a thickness of 1 millimeter, commonly used in prototyping, enclosures, and structural components. While aluminum and steel are not plastics, they are included for comparative context in fabrication processes such as laser cutting, bending, and welding. Below is a technical comparison of 1mm thick sheets of ABS, Nylon, Aluminum, and Steel with a focus on laser cutting, bending, and welding performance.

| Material | Laser Cutting Compatibility | Bending Characteristics | Welding Method | Notes |

|---|---|---|---|---|

| ABS (Acrylonitrile Butadiene Styrene) | Excellent – cleanly cut with CO₂ lasers; minimal charring with proper settings | Good – can be bent using heat-formed tooling; sharp bends may crack | Ultrasonic or solvent welding recommended; not suitable for traditional thermal welding | Low melting point; prone to warping under high heat; excellent for detailed laser-cut parts |

| Nylon (Polyamide, e.g., PA6 or PA66) | Moderate – tends to absorb laser energy unevenly; may char or melt; requires precise control | Fair – high flexibility but prone to springback; heat-assisted bending required for tight radii | Hot gas or vibration welding effective; not ideal for laser welding without additives | High toughness and wear resistance; hygroscopic (absorbs moisture), affecting dimensional stability |

| Aluminum (1mm sheet) | Poor for standard laser cutting without assist gas – reflective surface risks damaging laser optics | Excellent – highly formable; can be bent to tight radii with press brakes | TIG or MIG welding typical; laser welding possible with high-power fiber lasers | Requires protective coating or specialized nozzles for laser cutting; non-ferromagnetic; lightweight |

| Steel (1mm mild steel) | Good – easily cut with fiber lasers; clean edges with nitrogen or oxygen assist | Very good – predictable springback; suitable for acute bends with standard tooling | MIG, TIG, or spot welding commonly used; laser welding effective | Magnetic; prone to oxidation if uncoated; higher hardness than plastics and aluminum |

Summary of Process Suitability for 1mm Sheets:

Laser cutting is most effective with ABS and steel when using appropriate laser types (CO₂ for ABS, fiber for steel). Aluminum poses challenges due to reflectivity. Bending is most predictable in metals using press brakes, while plastics like ABS and nylon require heat for forming. Welding techniques differ significantly: thermoplastics use fusion or solvent methods, whereas metals require high-energy processes. Material selection should consider design requirements, environmental exposure, and production volume.

From CAD to Part: The Process

Honyo Prototype executes a streamlined yet rigorous workflow for 1mm plastic sheet fabrication, ensuring dimensional precision and material integrity for thin-gauge components. This process is optimized for materials like ABS, PC, PMMA, and PVC at this critical thickness where handling and thermal management become paramount.

Upon receiving a client’s CAD file via our secure portal, our system initiates automated geometry validation. The file undergoes immediate checks for unit consistency, non-manifold edges, and minimum feature compliance relative to 1mm stock. Validated designs enter our AI-powered quoting engine, which calculates material yield, machine time, and secondary operations using real-time shop floor data. Crucially for 1mm sheets, the algorithm factors in specialized handling requirements—such as vacuum table setup time and reduced feed rates to prevent chatter—and material-specific waste factors due to sheet warpage risks. Clients receive a detailed cost breakdown within 2 business hours, including lead time projections.

The Design for Manufacturability (DFM) phase follows quote acceptance, conducted by our engineering team with explicit focus on thin-sheet challenges. We analyze bend radii (minimum 1.5x material thickness for most plastics), hole-to-edge distances, and potential stress concentrations. For 1mm sheets, we prioritize recommendations like: avoiding sharp internal corners to prevent cracking during ejection, specifying optimal part orientation to minimize sag during cooling, and recommending sacrificial tabs for intricate profiles. Material choice directly impacts our DFM feedback—for instance, polycarbonate requires slower cooling rates than ABS to avoid internal stresses at this thickness. All suggestions include technical justification with tolerance implications.

Production leverages our dedicated thin-sheet workflow. Material is acclimatized in climate-controlled storage before processing. Laser cutting employs nitrogen assist gas for clean edges on flammable materials like ABS, while CNC routing uses polished carbide tooling at elevated spindle speeds (24,000 RPM) with shallow depth cuts (0.3mm pass depth) to prevent deflection. All 1mm parts undergo in-process flatness verification using granite surface plates; deviations exceeding 0.5mm/meter trigger automatic rework protocols. Secondary operations such as tapping or bonding occur in vibration-dampened stations to avoid micro-fractures.

Delivery includes critical post-processing for dimensional stability. Parts are stress-relieved per material-specific thermal profiles (e.g., 70°C for 30 minutes for PC), then packaged in anti-static foam with desiccant in rigid containers to prevent flexing during transit. Each shipment includes first-article inspection reports showing critical dimensions measured via calibrated CMMs, with flatness data captured across a 5-point grid per ASTM D6272. Typical lead time for quantities under 50 units is 5-7 business days from DFM sign-off, with expedited options available for simple geometries. This integrated approach ensures 1mm plastic components meet functional requirements while mitigating inherent thin-sheet manufacturing risks.

Start Your Project

Looking for high-quality 1mm plastic sheets for your next project? Source directly from our manufacturing facility in Shenzhen.

Contact Susan Leo today at [email protected] for fast, reliable service and competitive pricing.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.