Contents

Manufacturing Insight: Plastic Parts Made To Order

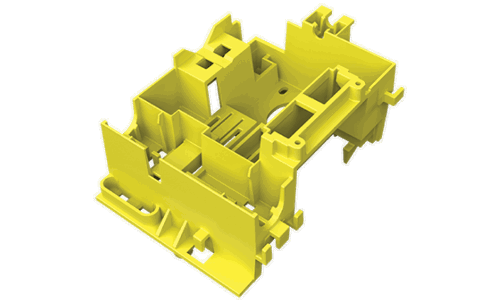

Precision Plastic Parts Made to Order: Engineered for Performance

Honyo Prototype delivers high-integrity custom plastic components through advanced CNC machining, engineered to meet exacting technical specifications for functional prototypes and low-to-mid volume production. Our expertise spans engineering-grade thermoplastics—including PEEK, Delrin, Ultem, and acrylic—where material behavior, thermal stability, and micron-level tolerances directly impact part performance. Unlike additive alternatives, CNC machining ensures superior dimensional accuracy, repeatability, and surface finish critical for sealing, load-bearing, or assembly-critical applications. We optimize toolpaths, spindle speeds, and fixturing to prevent material deformation while maintaining tight tolerances down to ±0.005mm, adhering to ISO 2768-mK standards.

Every project integrates design-for-manufacturability analysis to eliminate costly revisions, supported by in-house secondary operations like tapping, threading, and precision polishing. Accelerate your development cycle with Honyo’s Online Instant Quote platform: upload your STEP or IGES file, specify material and quantity, and receive a detailed manufacturability assessment with pricing in under 60 seconds—no sales call required. This seamless workflow reduces lead time from concept to certified part by up to 70%, ensuring your plastic components perform as engineered, on schedule.

Technical Capabilities

Technical Specifications for Plastic and Machined Parts Made to Order

Honyo Prototype delivers precision-manufactured components using advanced 3, 4, and 5-axis CNC milling and turning processes. Our capabilities support both plastic and metal materials, ensuring tight tolerances and high repeatability for demanding applications in aerospace, medical, automotive, and industrial sectors. Below is a detailed overview of the technical specifications for custom plastic and metal parts.

| Feature | Specification Detail |

|---|---|

| Machining Processes | 3-axis, 4-axis, and 5-axis CNC milling; CNC turning (including mill-turn for complex geometries) |

| Tolerance Capability | Standard: ±0.025 mm (±0.001″) Tight Tolerance: ±0.01 mm (±0.0004″) achievable with process control and inspection |

| Materials – Metals | Aluminum (6061, 7075, 2024), Stainless Steel (303, 304, 316), Tool Steel, Mild Steel |

| Materials – Plastics | ABS (Acrylonitrile Butadiene Styrene), Nylon (PA6, PA66), Acetal (POM), PEEK, Polycarbonate (PC), HDPE |

| Maximum Work Envelope | Milling: 1000 mm × 600 mm × 500 mm (X×Y×Z) Turning: Max diameter 300 mm, length 500 mm |

| Surface Finish | As-machined: Ra 3.2 µm (125 µin) Smooth finish options: Ra 1.6 µm, Ra 0.8 µm (with polishing or grinding) |

| Secondary Operations | Deburring, anodizing (Type II & III for aluminum), passivation (stainless steel), laser marking, heat treatment, coating |

| Inspection & Quality | First Article Inspection (FAI) reports, CMM measurement, GD&T verification, in-process and final quality checks |

| Lead Time | Typical: 5–15 business days, expedited options available based on complexity and volume |

| File Formats Accepted | STEP, IGES, DWG, DXF, SolidWorks, PDF (with dimensions) |

All parts are manufactured under ISO 9001-compliant processes, with full traceability and documentation. While plastics such as ABS and Nylon are commonly machined for prototypes and functional components, metal parts in aluminum and steel are ideal for high-strength or thermally demanding environments. Our 5-axis CNC systems enable complex contours and multi-sided machining in a single setup, reducing error and improving geometric accuracy.

From CAD to Part: The Process

Honyo Prototype Plastic Parts Made-to-Order Process Overview

Honyo Prototype delivers precision plastic components through a streamlined, technology-driven workflow designed for speed, accuracy, and manufacturability. Our process begins with client-supplied CAD data and concludes with certified delivery, integrating AI efficiency with engineering expertise at critical stages. Below is a detailed technical breakdown of each phase.

Upload CAD

Clients initiate the process by uploading native or neutral CAD files via our secure customer portal. We support industry-standard formats including STEP AP203/AP214, IGES, Parasolid (.x_t, .x_b), and native SOLIDWORKS, Creo, and NX files. Metadata such as material specifications, quantity requirements, surface finish, and critical tolerances must accompany the geometry. Our system automatically validates file integrity and flags common issues like unsealed surfaces or non-manifold edges before proceeding.

AI-Assisted Quoting

Uploaded CAD data feeds into our proprietary AI quoting engine, which analyzes geometric complexity, volume, wall thickness uniformity, and draft angles against historical production databases. The AI generates a preliminary cost estimate within 2 hours, factoring in material costs (from our vetted resin supplier network), tooling requirements, and machine-hour calculations. Crucially, this is a pre-qualified estimate—not a final quote. Senior process engineers review AI outputs to adjust for nuanced factors like undercuts requiring complex side actions or high-precision cavity requirements, ensuring realism before client presentation.

Engineering DFM Analysis

Upon quote acceptance, our engineering team conducts a rigorous Design for Manufacturability (DFM) review. This phase involves:

Automated simulation of mold fill, cooling, and warpage using Moldflow principles.

Manual assessment of parting lines, ejection strategies, and gate locations by degreed tooling engineers.

Collaborative feedback to the client via marked-up 3D PDFs highlighting risks (e.g., sink marks from thick sections, knit lines in structural zones) and actionable redesign suggestions.

DFM sign-off requires mutual agreement, ensuring the design is optimized for yield, cycle time, and cost before tool fabrication begins.

Production Execution

With approved DFM, we transition to production under strict quality controls:

Tooling: Precision steel molds are fabricated in-house using Makino EDM and CNC centers, with critical cavities hardened to 52–54 HRC. All tools undergo tryout validation with first-article inspection (FAI) per AS9102.

Molding: Parts are produced on electric injection molding presses (50–1,000 tons) with real-time process monitoring. Material drying, melt temperature, and injection profiles are logged per ISO 9001 traceability requirements.

Quality Assurance: Every batch includes CMM verification of critical dimensions, visual inspection against AQL 1.0 standards, and material certification. Statistical process control (SPC) charts track cavity-to-cavity consistency.

Delivery and Documentation

Completed parts undergo final packaging per client specifications (e.g., ESD-safe trays, vacuum sealing). Each shipment includes:

Certificate of Conformance with lot-specific material test reports

FAI documentation and SPC data

Dimensional inspection reports (digital PDF + physical label)

Logistics leverage DHL/FedEx with real-time tracking, typically achieving 10–15 day turnaround from DFM approval for quantities under 5,000 units. Expedited options are available for prototyping volumes.

Supported CAD Formats for Upload

| Format Type | File Extensions | Validation Requirements |

|——————-|———————-|—————————————|

| Native CAD | .sldprt, .prt, .ipt | Must include all features; no parasitics |

| Neutral Exchange | .stp, .igs, .x_t | Units must be mm; no faceted geometry |

| Mesh-Based | .stl, .obj | Not accepted for production; prototyping only |

This integrated workflow minimizes iteration cycles while enforcing manufacturing realities early. By coupling AI scalability with human engineering judgment, Honyo ensures plastic components meet functional, aesthetic, and delivery expectations—turning complex designs into reliable, high-yield production outcomes.

Start Your Project

Looking for custom plastic parts tailored to your specifications? Honyo Prototype delivers precision-manufactured plastic components made to order, with fast turnaround and consistent quality.

Our manufacturing facility in Shenzhen offers advanced injection molding, CNC machining, and rapid prototyping to support low to medium volume production runs.

Contact Susan Leo today to discuss your project requirements.

Email: [email protected]

Leverage our expertise in plastic part fabrication and local manufacturing advantage for reliable, cost-effective solutions.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.