Contents

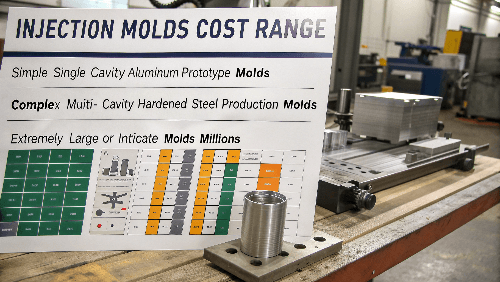

Manufacturing Insight: Plastic Mold Cost

Understanding Plastic Mold Cost Drivers and Honyo Prototype’s Value Proposition

Accurate plastic mold cost estimation is a critical factor in early-stage product development and low-volume manufacturing, directly impacting budget allocation, timeline feasibility, and overall project risk. Traditional mold procurement often involves lengthy quotation cycles, ambiguous pricing structures, and extended lead times, creating significant uncertainty for engineering and procurement teams. At Honyo Prototype, we specialize in demystifying this process through our integrated Rapid Tooling and Injection Molding services, engineered specifically for speed, precision, and cost transparency in prototype and bridge production scenarios.

Our Rapid Tooling solutions utilize advanced CNC machining and optimized mold design practices to deliver functional aluminum or pre-hardened steel molds within days, not weeks. This approach drastically reduces initial tooling investment compared to traditional hardened steel production molds while maintaining the dimensional accuracy and surface finish required for validation and limited commercial runs. For higher volume requirements, our precision Injection Molding services leverage hardened steel molds built to exacting standards, ensuring long-term part consistency and durability without compromising our core commitment to accelerated timelines. Both service lines are underpinned by our deep materials science expertise and rigorous quality control protocols.

A cornerstone of our cost-effective strategy is the Honyo Prototype Online Instant Quote platform. This proprietary digital tool allows engineers and project managers to upload CAD files and receive a detailed, binding mold cost estimate in under 60 seconds. The system dynamically calculates pricing based on real-time analysis of geometric complexity, material selection, mold base requirements, and production volume, eliminating guesswork and manual quotation delays. This immediate visibility into mold cost drivers empowers faster decision-making and seamless integration into your development workflow. Partner with Honyo Prototype to transform mold cost from a barrier into a strategic advantage for accelerated time-to-market.

Technical Capabilities

Technical specifications for plastic mold cost are influenced by several key factors including mold material (aluminum or steel), complexity of part geometry, surface finish requirements, expected production volume, and lead time. At Honyo Prototype, we specialize in rapid tooling solutions with a focus on delivering T1 samples within 7 days using either aluminum or steel molds, depending on project requirements.

Mold material choice directly impacts cost, durability, cycle time, and production lifespan. Aluminum molds are typically used for low to medium volume production (up to 10,000–50,000 parts) and offer faster machining times, making them ideal for prototyping and bridge tooling. Steel molds (e.g., P20, 718H, S136) are suited for high-volume production (100,000+ cycles), offering superior wear resistance and longevity.

The molded plastic material—such as ABS or Nylon—affects mold design due to differences in shrinkage rates, flow characteristics, and cooling requirements. For example, Nylon’s high shrinkage and hygroscopic nature require precise gate design and venting, increasing mold complexity and cost.

Below is a comparative table outlining key technical and cost-related specifications:

| Parameter | Aluminum Mold | Steel Mold |

|---|---|---|

| Material | 7075-T6 or 6061-T6 Aluminum | P20, 718H, H13, or S136 Steel |

| Mold Life | 10,000 – 50,000 cycles | 100,000 – 1,000,000+ cycles |

| Lead Time (T1 Sample) | 5–7 days | 7–14 days (can be 7 days expedited) |

| Typical Cost Range (USD) | $1,500 – $5,000 | $5,000 – $20,000+ |

| Cycle Time Impact | Faster cooling (lower thermal mass) | Slightly slower cooling |

| Surface Finish Options | SPI A2, B1, Textures, Polishing | Full SPI grades, chrome plating, texturing |

| Part Materials Supported | ABS, Nylon, PP, PC, PMMA | ABS, Nylon (reinforced grades), POM, PSU |

| Shrinkage Compensation | Adjustable for ABS (0.4–0.7%) and Nylon (0.7–1.2%) | Precision-machined for tight tolerances |

| Cooling Channel Machining | Simplified (conventional drilling) | Optimized (conformal cooling possible) |

| Best For | Prototypes, bridge tooling, low-volume production | High-volume, commercial production |

Honyo Prototype ensures T1 sample delivery within 7 days by leveraging high-speed CNC machining, experienced mold design engineering, and streamlined project management. Material compatibility, particularly with engineering resins like ABS and Nylon, is validated during the mold flow analysis phase to prevent defects and ensure first-time success.

From CAD to Part: The Process

Plastic Mold Cost Process at Honyo Prototype

Honyo Prototype employs a streamlined, technology-driven workflow to ensure transparent and accurate plastic mold cost estimation and execution. This process begins with client CAD submission and concludes with certified part delivery, integrating AI efficiency with engineering rigor to minimize risk and cost overruns.

CAD File Submission

Clients initiate the process by uploading a complete 3D CAD model in STEP, IGES, or native formats via our secure portal. Critical inputs include material specifications, part quantity requirements, surface finish standards, and geometric dimensioning and tolerancing (GD&T) callouts. Incomplete submissions trigger an immediate validation alert, ensuring all manufacturing variables are defined before cost calculation.

AI-Powered Preliminary Quote

Our proprietary AI engine analyzes the CAD geometry within 24 hours, generating a dynamic cost estimate based on real-time factors: mold complexity (e.g., undercuts, side actions), cavity count, steel type, machine tonnage requirements, and regional tooling labor rates. The output includes a breakdown of mold construction costs, estimated cycle times, and part unit pricing. This phase provides a rapid feasibility assessment but is explicitly labeled as a preliminary estimate pending engineering validation.

Engineering DFM Analysis

Honyo’s manufacturing engineers conduct a formal Design for Manufacturability review, scrutinizing the CAD model for moldability risks. We identify issues such as non-uniform wall thickness, inadequate draft angles, or problematic ejection surfaces that could escalate costs or cause production failure. Clients receive a detailed DFM report with actionable recommendations—such as modifying rib designs or adjusting gate locations—to optimize tool longevity and part quality. Crucially, this step refines the AI-generated quote into a firm quotation, with cost adjustments reflecting necessary design modifications.

Mold Production and Validation

Upon client approval of the DFM-adjusted quote, we proceed to mold fabrication using CNC machining, EDM, and surface texturing per ISO 9001 standards. For prototype needs, we typically deploy aluminum or mild steel molds; production volumes utilize hardened P20 or H13 tool steel. All molds undergo rigorous in-house validation:

First-article inspection against CAD nominal dimensions

Mold flow analysis verification of filling and cooling

Minimum 500-shot trial run with material certification

The following table summarizes mold type selection criteria directly impacting cost structure:

| Mold Type | Typical Use Case | Lead Time | Cost Range (USD) | Key Characteristics |

|---|---|---|---|---|

| Prototype (Al) | < 500 parts | 10-15 days | $1,500 – $5,000 | Low durability, rapid iteration |

| Bridge (P20) | 500 – 10,000 parts | 20-25 days | $5,000 – $25,000 | Moderate wear resistance, cost-effective |

| Production (H13) | > 10,000 parts | 30-45 days | $25,000 – $150k+ | Hardened cavities, 500k+ cycle life |

Part Delivery and Certification

After successful mold validation, we produce the client’s required quantity with full traceability. Every shipment includes:

First-article inspection report (FAIR) with CMM data

Material test certificates (e.g., UL, FDA compliance if specified)

Mold maintenance log and process capability (Cp/Cpk) metrics

Final invoicing reflects the contractually agreed DFM-validated cost, with no hidden fees. Average delivery from CAD upload to shipment is 25-35 days for production molds, excluding client revision cycles.

This integrated approach ensures cost predictability by resolving manufacturability conflicts early, leveraging AI for speed while anchoring estimates in engineering reality. Clients gain visibility into cost drivers at each phase, reducing total project risk by up to 40% compared to traditional quoting methods.

Start Your Project

Looking for an accurate quote on plastic mold costs? Contact Susan Leo at [email protected] for expert guidance and competitive pricing. With our in-house manufacturing facility located in Shenzhen, we deliver high-quality mold solutions with fast turnaround times. Reach out today to discuss your project requirements and receive a detailed cost assessment tailored to your needs.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.