Introduction: Navigating the Global Market for plastic model parts

Navigating the intricate landscape of the global market for plastic model parts presents a significant challenge for B2B buyers, particularly when sourcing high-quality components that meet diverse needs. As the demand for intricate detailing in model kits continues to rise, buyers from regions such as Africa, South America, the Middle East, and Europe—including countries like Vietnam and Germany—must adeptly navigate a myriad of suppliers and products. This guide is designed to empower you with actionable insights into the various types of plastic model parts available, their applications, and strategies for effective supplier vetting.

Within this comprehensive resource, you will discover an extensive overview of aftermarket parts, detailing options, and accessories that enhance the realism of model aircraft, vehicles, ships, and more. We delve into essential considerations such as pricing structures, shipping logistics, and the importance of quality assurance to help you make informed purchasing decisions. By leveraging the insights provided, you can streamline your sourcing process, mitigate risks, and ultimately enhance your product offerings. Whether you are looking to elevate your inventory or meet specific customer demands, this guide serves as your roadmap to successfully navigate the global market for plastic model parts.

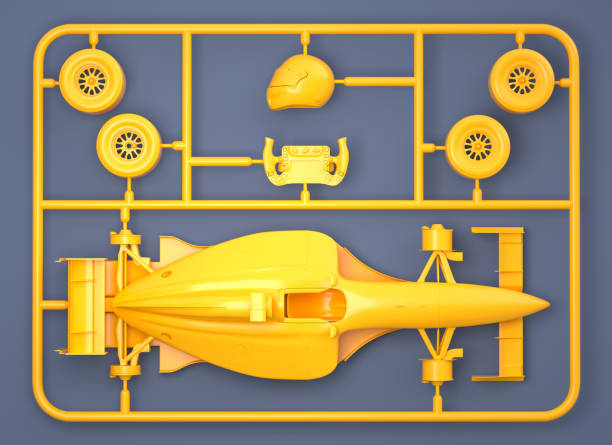

Understanding plastic model parts Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Aftermarket Detail Parts | Includes photo-etch, resin upgrades, and decals | Enhancing realism in models | Pros: Adds detail and realism; Cons: Can increase costs significantly. |

| Aircraft Accessories | Specialized parts like wheels, cockpit details | Aircraft modeling and restoration | Pros: Improves accuracy; Cons: Limited compatibility with various kits. |

| Vehicle Accessories | Custom parts for cars, trucks, and motorcycles | Automotive modeling and customization | Pros: Wide range available; Cons: Quality varies by manufacturer. |

| Military Model Parts | Unique components for military vehicles and aircraft | Military dioramas and displays | Pros: Enhances historical accuracy; Cons: Often requires advanced modeling skills. |

| Display Cases | Protective and aesthetic enclosures | Retail display and personal collections | Pros: Protects models; Cons: Can take up significant space. |

What Are Aftermarket Detail Parts and Their B2B Relevance?

Aftermarket detail parts are specialized components designed to enhance the realism and detail of plastic models across various categories, including aircraft, military vehicles, and cars. These parts often include photo-etch sets, resin upgrades, and decals, which can significantly elevate the visual appeal of a model. For B2B buyers, investing in these parts can differentiate their offerings in competitive markets, especially in regions where high-quality craftsmanship is valued. However, businesses should consider the cost implications, as these parts can increase the overall pricing of model kits.

How Do Aircraft Accessories Enhance Model Precision?

Aircraft accessories encompass a range of components tailored to improve the accuracy and detail of aircraft models. This category includes parts like cockpit interiors, landing gear, and engine details. For B2B buyers, sourcing high-quality aircraft accessories can enhance product offerings and meet customer demands for precision and authenticity. However, compatibility issues with various model kits can pose a challenge, necessitating careful selection to ensure that the accessories align well with existing inventory.

What Are the Benefits of Vehicle Accessories in Model Customization?

Vehicle accessories include a variety of custom parts designed for cars, trucks, and motorcycles. This segment is popular among hobbyists looking to personalize their models with unique features. B2B buyers can leverage this trend to attract customers interested in customization. The broad range of available accessories allows for creative expression, but buyers must be aware that quality can vary significantly between manufacturers, making it essential to establish reliable sourcing relationships.

Why Are Military Model Parts Essential for Historical Accuracy?

Military model parts are designed to replicate specific vehicles and aircraft used in historical contexts, making them vital for dioramas and educational displays. These parts often include weapons, insignias, and detailed components that enhance the authenticity of military models. For B2B buyers, offering these specialized parts can cater to niche markets focused on historical accuracy. However, it’s important to recognize that these models may require advanced modeling skills, which could limit the target audience.

How Do Display Cases Contribute to the Presentation of Models?

Display cases serve both protective and aesthetic functions for plastic models, allowing collectors to showcase their work while safeguarding against dust and damage. For businesses, providing high-quality display cases can add value to model kits and enhance customer satisfaction. However, buyers should consider the space requirements of display cases, as larger models may necessitate more significant investment in display solutions. Balancing aesthetics with functionality will be key for B2B buyers looking to offer comprehensive model solutions.

Key Industrial Applications of plastic model parts

| Industry/Sector | Specific Application of plastic model parts | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Detailed aircraft model components | Enhances accuracy and realism for training simulations | Quality certifications, compatibility with existing models |

| Automotive | Custom vehicle model parts for design validation | Speeds up prototyping and reduces costs for design iterations | Material specifications, scale accuracy, delivery timelines |

| Military & Defense | Scaled-down military equipment for training exercises | Provides realistic training environments for personnel | Durability, precision, and adherence to military standards |

| Education & Training | Educational models for STEM programs | Facilitates hands-on learning experiences for students | Educational value, safety standards, and material sourcing |

| Hobby & Collectibles | Aftermarket parts for model enhancement | Increases customer satisfaction and product value | Variety of options, brand reputation, and pricing strategies |

How Are Plastic Model Parts Used in the Aerospace Industry?

In the aerospace sector, plastic model parts are critical for creating detailed aircraft models that serve as training tools for pilots and maintenance crews. These models often include intricate components such as cockpit interiors and engine details, enhancing realism in simulations. Buyers in this industry must prioritize sourcing high-quality, certified parts that ensure compatibility with existing training equipment, as well as adhere to rigorous safety standards.

What Role Do Plastic Model Parts Play in Automotive Design?

The automotive industry utilizes plastic model parts to create scale models for design validation and prototyping. These models allow engineers to visualize and test vehicle designs before full-scale production, thereby reducing development costs and time. B2B buyers should focus on sourcing parts that meet specific material requirements and scale accuracy, ensuring that they can seamlessly integrate these models into their design processes.

How Are Plastic Model Parts Applied in Military Training?

In military and defense applications, scaled-down plastic models of equipment and vehicles are utilized for training exercises. These models provide a realistic environment for personnel to practice tactics and strategies without the need for full-scale equipment. Buyers in this sector must consider the durability and precision of the model parts, as they need to withstand rigorous training scenarios while adhering to military standards.

What Benefits Do Plastic Model Parts Offer in Education and Training?

Plastic model parts are extensively used in educational settings, particularly in STEM programs. These models facilitate hands-on learning by allowing students to engage with physical representations of complex concepts, such as engineering and aerodynamics. For international B2B buyers, it’s essential to evaluate the educational value of the models and ensure they meet safety standards to foster a safe learning environment.

How Do Aftermarket Parts Enhance the Hobby and Collectibles Market?

In the hobby and collectibles market, aftermarket plastic model parts are crucial for enhancing the detail and authenticity of model kits. These components allow hobbyists to customize their models, leading to increased satisfaction and higher resale value. B2B buyers should look for a wide variety of options from reputable brands, considering pricing strategies that align with market demand to maximize their offerings.

3 Common User Pain Points for ‘plastic model parts’ & Their Solutions

Scenario 1: Sourcing Quality Aftermarket Plastic Model Parts

The Problem: B2B buyers often struggle to find high-quality aftermarket plastic model parts that meet their specific needs. With a plethora of manufacturers and suppliers, distinguishing between quality products and subpar alternatives can be daunting. This issue is exacerbated by the wide variance in part specifications, leading to potential compatibility issues with existing models. Buyers from regions with limited access to international shipping or local suppliers face additional challenges in obtaining these necessary components in a timely manner.

The Solution: To effectively source quality aftermarket parts, B2B buyers should begin by identifying reputable suppliers with a solid track record in the industry. This can be done by consulting online forums and communities focused on plastic modeling, where experienced hobbyists and professionals share their recommendations. Additionally, leveraging platforms that specialize in user reviews can help buyers gauge product quality and supplier reliability. When selecting parts, ensure they are compatible with your existing models by checking detailed specifications, including scale and manufacturer compatibility. Establishing relationships with multiple suppliers can provide leverage for better pricing and faster shipping options, especially for international buyers. Regularly attending trade shows or industry expos can also facilitate direct connections with manufacturers, enabling buyers to assess product quality firsthand.

Scenario 2: Navigating Complex Product Specifications for Custom Builds

The Problem: Many B2B buyers working on custom model projects encounter difficulties in navigating the complex specifications of plastic model parts. This can lead to selecting components that do not fit or function as intended, resulting in wasted time and resources. For instance, a buyer may order a set of aircraft wings designed for a specific scale, only to find they do not align with the fuselage from another manufacturer, leading to compatibility issues.

The Solution: To mitigate these challenges, B2B buyers should invest time in developing a comprehensive understanding of the specifications relevant to their projects. This includes familiarizing themselves with terminology such as scale ratios, material types, and compatibility markers. Creating a detailed project plan that outlines the specific parts needed, along with their specifications, can serve as a valuable reference when sourcing components. Buyers should also consider reaching out to manufacturers for technical support or clarification on product specifications before making purchases. Many suppliers offer expert advice and can assist in identifying the right parts for custom builds. Additionally, utilizing CAD (Computer-Aided Design) software can allow buyers to visualize their projects and ensure all components will fit together before placing orders.

Scenario 3: Managing Inventory and Supply Chain Challenges

The Problem: B2B buyers often face significant challenges in managing inventory levels and ensuring a consistent supply of plastic model parts, particularly in regions where shipping delays are common. This issue can lead to production halts, backorders, and dissatisfied customers, ultimately impacting the bottom line. Additionally, fluctuating demand can make it difficult to maintain optimal inventory levels without overstocking or running out of essential components.

The Solution: To effectively manage inventory and supply chain challenges, B2B buyers should implement a robust inventory management system that tracks stock levels, orders, and lead times. Utilizing inventory management software can provide real-time data, enabling better forecasting of demand based on historical sales patterns and market trends. Establishing a diversified supplier network can also mitigate risks associated with single-source dependency, ensuring that buyers can pivot to alternative sources if one supplier faces delays. Furthermore, establishing minimum order quantities and reorder points can help maintain adequate stock levels while avoiding over-purchasing. Regular communication with suppliers about lead times and expected delivery dates can aid in planning, allowing buyers to adjust their orders proactively in response to market fluctuations.

Strategic Material Selection Guide for plastic model parts

What Are the Key Properties of Common Materials Used in Plastic Model Parts?

When selecting materials for plastic model parts, understanding the properties and performance characteristics of each option is crucial for B2B buyers. The most common materials include polystyrene, ABS (Acrylonitrile Butadiene Styrene), resin, and vinyl. Each material presents unique advantages and challenges that can significantly influence the final product’s quality and suitability for various applications.

How Does Polystyrene Perform in Plastic Model Parts?

Polystyrene is a widely used thermoplastic material known for its rigidity and ease of molding. It exhibits good dimensional stability and can withstand moderate temperatures, making it suitable for intricate designs.

Pros: Polystyrene is cost-effective and readily available, which is advantageous for large-scale production. Its smooth surface allows for excellent paint adhesion, enhancing the aesthetic quality of the finished model.

Cons: However, it has limited impact resistance and can become brittle over time, especially when exposed to UV light. This material may not be ideal for models that require high durability or are intended for outdoor display.

Impact on Application: Polystyrene is compatible with various paints and adhesives, but care must be taken to avoid solvents that can cause warping.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure that their suppliers comply with international standards such as ASTM or DIN to guarantee quality. In Europe, REACH compliance is also essential.

What Are the Advantages of Using ABS for Plastic Model Parts?

ABS is another popular choice for plastic model parts due to its excellent toughness and impact resistance. It can withstand higher temperatures than polystyrene, making it suitable for more demanding applications.

Pros: ABS is durable and can be easily machined or painted, providing flexibility in design and finishing. Its resistance to chemicals and heat makes it a reliable choice for models that may face harsher conditions.

Cons: On the downside, ABS can be more expensive than polystyrene, and its production process is more complex, requiring careful control of temperature and pressure during molding.

Impact on Application: ABS is compatible with a wide range of paints and adhesives, but its surface may require priming for optimal adhesion.

Considerations for International Buyers: For buyers in the Middle East and Europe, it’s essential to verify that ABS products meet local safety and environmental regulations.

Why Choose Resin for Detailed Plastic Model Parts?

Resin is favored for its ability to capture fine details, making it ideal for aftermarket parts and specialized models. It offers a high degree of customization and can be cast into complex shapes.

Pros: The primary advantage of resin is its superior detail reproduction and surface finish, which enhances the realism of models. It is also relatively lightweight, making it easier to handle.

Cons: However, resin can be more expensive and may require additional finishing work, such as sanding and priming. It is also less durable than other materials, making it susceptible to damage if not handled carefully.

Impact on Application: Resin models are often used in niche markets, such as military or sci-fi models, where detail is paramount.

Considerations for International Buyers: Buyers should ensure that resin products comply with local regulations regarding hazardous materials, as some resins can emit fumes during curing.

What Role Does Vinyl Play in Plastic Model Parts?

Vinyl is known for its flexibility and softness, making it suitable for parts that require bending or movement. It is often used in figures and accessories that need to withstand handling.

Pros: The flexibility of vinyl allows for easy manipulation without breaking, making it ideal for dynamic models. It is also resistant to fading and can withstand exposure to sunlight.

Cons: The downside is that vinyl can be less detailed than other materials, and its surface may not hold paint as well, requiring special formulations for optimal results.

Impact on Application: Vinyl is often used in toys and figures, where durability and flexibility are more critical than intricate details.

Considerations for International Buyers: Buyers should consider the impact of local climate on vinyl products, as extreme temperatures can affect their performance.

Summary Table of Material Selection for Plastic Model Parts

| Material | Typical Use Case for plastic model parts | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polystyrene | General model kits | Cost-effective and easy to mold | Limited impact resistance | Low |

| ABS | Automotive and aircraft models | Excellent toughness and durability | Higher cost and manufacturing complexity | Medium |

| Resin | Detailed aftermarket parts | Superior detail reproduction | More expensive and less durable | High |

| Vinyl | Flexible figures and accessories | Flexibility and sunlight resistance | Less detail and paint adhesion issues | Medium |

This guide provides an overview of the strategic material selection process for plastic model parts, helping international B2B buyers make informed decisions tailored to their specific needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for plastic model parts

What are the Main Stages of Manufacturing Plastic Model Parts?

The manufacturing of plastic model parts involves several key stages that ensure the final products meet the desired specifications and quality standards. Understanding these stages is crucial for B2B buyers who are sourcing plastic model components.

-

Material Preparation

The first step in the manufacturing process is the preparation of raw materials, primarily thermoplastics such as polystyrene and ABS (Acrylonitrile Butadiene Styrene). These materials are chosen for their lightweight, durability, and ease of molding. The preparation phase includes drying the plastic pellets to remove moisture, which is essential for preventing defects during molding. -

Forming

The next stage involves forming the plastic into desired shapes. This is typically done using injection molding, a process where heated plastic is injected into a mold under high pressure. This technique allows for high precision and the creation of complex geometries, essential for intricate model parts. Other methods, such as vacuum forming and CNC machining, may also be employed depending on the design requirements and production scale. -

Assembly

After forming, parts may require assembly, particularly in multi-part models. This can involve the use of adhesives, snap-fit designs, or mechanical fasteners. The assembly process is critical for ensuring that components fit together seamlessly, which is especially important for models that require high levels of detail and functionality. -

Finishing

The final stage of manufacturing is finishing, which can include processes such as sanding, painting, and applying decals. This step enhances the aesthetic appeal of the model and may involve the application of protective coatings to ensure durability. Quality control during this stage is vital, as any imperfections can affect the overall presentation and marketability of the model.

How is Quality Assurance Implemented in Plastic Model Parts Manufacturing?

Quality assurance (QA) is integral to the manufacturing of plastic model parts, ensuring that products meet international standards and customer expectations. For B2B buyers, understanding the QA processes can help in selecting reliable suppliers.

-

International Standards and Certifications

Adherence to international quality standards, such as ISO 9001, is essential for manufacturers of plastic model parts. This standard outlines requirements for a quality management system, emphasizing continuous improvement and customer satisfaction. Additionally, industry-specific certifications like CE (Conformité Européenne) and API (American Petroleum Institute) can indicate compliance with specific safety and quality regulations, especially important for markets in Europe and the Middle East. -

Quality Control Checkpoints

Quality control is conducted at various checkpoints throughout the manufacturing process, commonly referred to as IQC (Incoming Quality Control), IPQC (In-Process Quality Control), and FQC (Final Quality Control).

– IQC involves inspecting raw materials upon receipt to ensure they meet required specifications before production begins.

– IPQC takes place during the manufacturing process, where random samples are checked to catch any issues early.

– FQC occurs at the end of production, where finished products are thoroughly inspected for defects and compliance with specifications. -

Common Testing Methods for Quality Assurance

Various testing methods are employed to ensure product quality, including dimensional inspections, visual inspections, and functional testing. Dimensional inspections verify that parts meet design specifications using calipers and gauges, while visual inspections check for surface defects, color consistency, and overall finish. Functional testing may be conducted for parts that require specific performance characteristics, ensuring they operate correctly when assembled.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers, particularly those sourcing from international suppliers, must take proactive steps to verify the quality control measures in place. Here are some actionable strategies:

-

Conducting Supplier Audits

One of the most effective ways to assess a supplier’s quality control processes is through on-site audits. These audits allow buyers to evaluate the manufacturing facility, review quality management documentation, and observe production processes firsthand. This direct engagement can provide valuable insights into the supplier’s commitment to quality. -

Requesting Quality Reports and Documentation

Suppliers should be able to provide detailed quality reports, including inspection results, testing protocols, and compliance certifications. Buyers should request these documents to ensure that the supplier adheres to relevant quality standards and maintains thorough records of their quality control processes. -

Engaging Third-Party Inspection Services

Utilizing third-party inspection services can provide an unbiased assessment of product quality before shipment. These services can perform inspections at various stages of production, ensuring that any issues are identified and addressed prior to delivery. This is particularly beneficial for buyers in regions like Africa and South America, where local oversight may be limited.

What Are the Quality Control Nuances for International B2B Buyers?

When sourcing plastic model parts internationally, B2B buyers should be aware of specific nuances related to quality control:

-

Cultural and Regional Differences

Quality standards and expectations may vary significantly across different regions. For example, European manufacturers often adhere to stricter quality regulations compared to those in other regions. Buyers should familiarize themselves with the local quality norms and practices of suppliers in regions such as Asia or South America. -

Language Barriers

Communication issues can arise when dealing with international suppliers, potentially leading to misunderstandings about quality requirements. Buyers should ensure that they have clear, documented specifications and consider using translation services if necessary to facilitate effective communication. -

Regulatory Compliance

Different regions may have specific regulations governing the importation of plastic products. Buyers must ensure that their suppliers are compliant with these regulations to avoid legal complications and ensure product safety. This is particularly relevant for markets in Europe, where compliance with REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) is mandatory.

In summary, understanding the manufacturing processes and quality assurance measures for plastic model parts is crucial for B2B buyers. By familiarizing themselves with these processes, verifying supplier quality controls, and being aware of international nuances, buyers can make informed decisions that enhance their procurement strategies and ensure high-quality products.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘plastic model parts’

Introduction

In the competitive landscape of plastic model parts sourcing, making informed decisions is crucial for success. This practical guide provides B2B buyers with a step-by-step checklist to streamline the procurement process, ensuring that you find the right suppliers, products, and specifications to meet your business needs.

Step 1: Define Your Technical Specifications

Clearly articulating your technical specifications is the first step in sourcing plastic model parts. This includes the type of models you require (aircraft, military, automotive, etc.), material quality, scale, and any specific design features. A well-defined specification helps suppliers understand your needs and reduces the risk of receiving incorrect or substandard parts.

- Considerations:

- Scale (e.g., 1:24, 1:48)

- Material requirements (e.g., ABS, styrene)

- Desired detail level (e.g., aftermarket parts like photo-etch or resin upgrades)

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers who specialize in plastic model parts. Utilize industry directories, trade shows, and online marketplaces to compile a list of manufacturers and distributors. A diverse supplier base can provide options in pricing, quality, and delivery capabilities.

- Where to Look:

- Online B2B platforms (e.g., Alibaba, ThomasNet)

- Industry-specific trade shows

- Local and international model hobby retailers

Step 3: Evaluate Supplier Credentials

Before committing to a supplier, it’s essential to verify their credentials and reputation. Look for certifications that demonstrate compliance with industry standards and quality assurance processes. This step helps to mitigate risks associated with subpar suppliers.

- Key Checks:

- ISO certifications

- Customer testimonials and case studies

- Industry awards or recognitions

Step 4: Request Samples

Requesting samples from shortlisted suppliers allows you to assess the quality of the plastic model parts before placing larger orders. This hands-on evaluation can reveal the craftsmanship and material durability, helping you make an informed purchasing decision.

- What to Assess:

- Detail accuracy and finish quality

- Fit and compatibility with existing models

- Packaging and delivery conditions

Step 5: Analyze Pricing and Terms

Once you’ve evaluated samples, compare pricing structures among suppliers. Be sure to examine the total cost of ownership, including shipping fees, tariffs, and potential bulk order discounts. Understanding payment terms and conditions is also critical to avoid cash flow issues.

- Considerations:

- Bulk discounts versus per-unit pricing

- Payment terms (e.g., net 30, upfront)

- Shipping costs and lead times

Step 6: Establish Communication Channels

Effective communication with your supplier can enhance the procurement process. Establish clear channels for feedback, inquiries, and updates to facilitate timely responses and resolutions. This relationship is vital for ongoing orders and potential future collaborations.

- Best Practices:

- Set regular check-ins or updates

- Use professional communication platforms (e.g., email, business chat)

- Ensure clarity in order specifications and timelines

Step 7: Monitor Supply Chain Performance

After establishing a relationship with a supplier, continuously monitor their performance regarding quality, delivery times, and customer service. Regular assessments can help you identify any issues early and maintain a reliable supply chain.

- Metrics to Track:

- On-time delivery rates

- Quality defect rates

- Responsiveness to inquiries and issues

By following these steps, B2B buyers can navigate the complexities of sourcing plastic model parts effectively, ensuring they partner with the right suppliers to meet their business goals.

Comprehensive Cost and Pricing Analysis for plastic model parts Sourcing

What are the Key Cost Components in Sourcing Plastic Model Parts?

When sourcing plastic model parts, understanding the cost structure is essential for effective budgeting and pricing strategies. The primary cost components include:

- Materials: The choice of plastic and other materials significantly influences costs. High-quality plastics, such as ABS or polystyrene, are often more expensive but provide better durability and finish.

- Labor: Labor costs can vary widely based on the region of production. For instance, countries with lower labor costs may provide savings, but this can come at the expense of quality or consistency.

- Manufacturing Overhead: This encompasses costs related to factory operations, including utilities, rent, and equipment maintenance. Efficient manufacturing processes can help reduce these overheads.

- Tooling: Initial tooling costs for molds can be substantial, particularly for custom parts. It’s crucial to factor these into the total cost, especially for low-volume orders.

- Quality Control (QC): Investing in robust QC processes ensures that parts meet specifications and standards, which may increase upfront costs but can save money in the long run by reducing returns and rework.

- Logistics: Transportation costs can fluctuate based on distance, shipping methods, and the chosen Incoterms. Buyers should account for shipping costs in their total cost analysis.

- Margin: Suppliers typically include a profit margin in their pricing, which varies based on market demand and competition.

How Do Price Influencers Affect the Cost of Plastic Model Parts?

Several factors can influence the pricing of plastic model parts, particularly in international B2B transactions:

- Volume and Minimum Order Quantity (MOQ): Suppliers often provide discounts for larger orders. Understanding the MOQ can help buyers negotiate better pricing.

- Specifications and Customization: Custom parts or those with intricate designs may incur additional costs. Clear communication about specifications can help avoid unexpected expenses.

- Material Quality and Certifications: Higher quality materials and certifications (like ISO or ASTM) can increase costs but may be necessary for certain markets or applications.

- Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers may charge more due to their proven track record.

- Incoterms: The choice of Incoterms affects the distribution of shipping responsibilities and costs. Buyers should be aware of how these terms impact their overall pricing.

What Tips Can Help Buyers Negotiate Better Prices for Plastic Model Parts?

Effective negotiation and strategic sourcing can lead to significant cost savings. Here are some actionable tips for international B2B buyers:

- Research and Compare: Conduct thorough market research to understand prevailing prices and identify multiple suppliers. This knowledge can empower you during negotiations.

- Negotiate Volume Discounts: If your purchasing strategy allows, consider consolidating orders to meet higher volume thresholds for discounts.

- Evaluate Total Cost of Ownership (TCO): Look beyond the initial price. Consider factors such as quality, reliability, and logistics costs when calculating TCO.

- Understand Pricing Nuances for International Transactions: Be aware of currency fluctuations, tariffs, and local market conditions that can affect pricing. This understanding is particularly important for buyers from Africa, South America, the Middle East, and Europe.

- Build Long-Term Relationships: Establishing a strong relationship with suppliers can lead to better pricing, service, and priority during production schedules.

What Should Buyers Keep in Mind Regarding Indicative Prices?

While indicative prices can serve as a useful reference point, they are subject to change based on various factors, including market conditions and supplier pricing strategies. Therefore, it is advisable for buyers to request detailed quotes that reflect current pricing, taking into account all discussed cost components and price influencers. This approach ensures that budgeting is accurate and reflective of the actual costs involved in sourcing plastic model parts.

Alternatives Analysis: Comparing plastic model parts With Other Solutions

In the realm of model building, plastic model parts are a popular choice for enthusiasts and manufacturers alike. However, various alternatives exist that can also fulfill similar needs, each with its unique advantages and drawbacks. Understanding these alternatives allows B2B buyers to make informed decisions based on their specific requirements, whether they prioritize performance, cost, or ease of use.

Comparison of Plastic Model Parts and Alternatives

| Comparison Aspect | Plastic Model Parts | Aftermarket Resin Parts | 3D Printed Model Parts |

|---|---|---|---|

| Performance | High detail and realism | Superior detail, often more accurate | Variable quality, depends on printer and material |

| Cost | Moderate to low | Higher due to material and craftsmanship | Can be low to moderate, varies with complexity |

| Ease of Implementation | Easy to use with standard tools | Requires specialized tools for assembly | Requires design knowledge and software |

| Maintenance | Low maintenance | Moderate; can be fragile | Low; but may require post-processing |

| Best Use Case | General modeling, hobbyists | Professional-grade models, high fidelity | Custom models, prototyping, rapid development |

What Are the Advantages and Disadvantages of Aftermarket Resin Parts?

Aftermarket resin parts are designed to enhance the realism of plastic models, particularly in categories like military and aircraft modeling. Their primary advantage lies in their superior detail and accuracy, often capturing intricate features that plastic parts cannot. However, they tend to be more expensive and require specialized tools for assembly, which can complicate the building process for some users. Additionally, resin can be more fragile than plastic, necessitating careful handling and storage.

How Do 3D Printed Model Parts Compare to Plastic Model Parts?

3D printed model parts offer a modern alternative that allows for customization and rapid prototyping. This method provides flexibility in design, enabling users to create unique models tailored to specific needs. While the cost can vary widely depending on the complexity of the design and the quality of the printer, 3D printing can often be more affordable for small batches. However, the quality of printed parts can be inconsistent, and users may require knowledge of design software and post-processing techniques to achieve the desired finish.

Conclusion: Which Model Solution Is Right for Your Business?

When considering the right solution for model building, B2B buyers must evaluate their specific needs. Plastic model parts remain a reliable choice for general modeling due to their ease of use and low maintenance. However, for those seeking enhanced detail and professional-grade fidelity, aftermarket resin parts may be the better option, albeit at a higher cost. Conversely, 3D printed parts are ideal for businesses looking to innovate with custom designs and rapid development, provided they are equipped with the necessary technology and expertise. Each option has its own set of benefits and limitations, so careful consideration of the intended application and resources available will guide buyers to the most appropriate choice.

Essential Technical Properties and Trade Terminology for plastic model parts

What Are the Key Technical Properties of Plastic Model Parts?

When sourcing plastic model parts, understanding the technical specifications is vital for ensuring quality and compatibility. Here are several critical specifications to consider:

-

Material Grade: The quality of plastic used in model parts, often defined by standards like ASTM or ISO. Common materials include polystyrene, ABS, and PVC. Higher-grade materials typically offer better durability and detail, which is essential for premium models. For B2B buyers, selecting the appropriate material grade can impact the longevity and visual appeal of the final product.

-

Tolerance Levels: This refers to the allowable deviation from a specified dimension. In model parts, precise tolerances ensure that components fit together seamlessly. Typical tolerances can range from ±0.1 mm to ±0.5 mm, depending on the part’s size and complexity. Understanding tolerance levels is crucial for manufacturers aiming to maintain quality control and reduce assembly issues in model production.

-

Surface Finish: The texture and quality of the model’s surface can significantly affect its aesthetic appeal. Common finishes include matte, gloss, and textured surfaces. A proper surface finish enhances paint adhesion and overall visual fidelity. For B2B buyers, knowing the desired surface finish can guide negotiations with suppliers, ensuring the end product meets customer expectations.

-

Shrinkage Rate: This property refers to the reduction in size that occurs when plastic cools and solidifies. Different plastics have varying shrinkage rates, which can affect the final dimensions of model parts. Understanding this rate helps manufacturers anticipate and compensate for size discrepancies during production, ensuring parts meet specified dimensions.

-

Impact Resistance: This property measures how well a plastic part can withstand sudden forces or shocks. A higher impact resistance is essential for model parts that may be handled frequently or displayed in environments where they could be bumped or dropped. For B2B buyers, sourcing parts with appropriate impact resistance can enhance the durability of the final model, reducing returns and increasing customer satisfaction.

What Are Common Trade Terms in the Plastic Model Parts Industry?

Familiarity with industry jargon is essential for effective communication and negotiation in the B2B space. Here are several common terms:

-

OEM (Original Equipment Manufacturer): Refers to companies that produce parts that are used in another company’s end products. In the context of plastic model parts, OEMs provide components that meet specific design and quality standards. Understanding OEM relationships can help buyers identify reliable sources for high-quality parts.

-

MOQ (Minimum Order Quantity): This term indicates the smallest number of units a supplier is willing to sell. Knowing the MOQ is crucial for buyers, as it can affect budgeting and inventory management. Negotiating lower MOQs may be necessary for smaller businesses or new product lines.

-

RFQ (Request for Quotation): A formal document sent to suppliers to request pricing and terms for specific products. An RFQ helps buyers compare offers from multiple suppliers efficiently. For B2B buyers, crafting a clear RFQ can facilitate better pricing and service agreements.

-

Incoterms (International Commercial Terms): These are globally recognized rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is essential for understanding shipping, insurance, and customs duties. Buyers should be aware of which Incoterms apply to their agreements to avoid unexpected costs.

-

Lead Time: The amount of time it takes from placing an order until the goods are delivered. This metric is critical for planning production schedules and ensuring timely market entry. Understanding lead times can help B2B buyers manage their supply chains effectively.

-

CAD (Computer-Aided Design): Refers to software used to create precise drawings and technical illustrations. In the plastic model parts industry, CAD files are often shared between buyers and manufacturers to ensure design accuracy. Familiarity with CAD can enhance communication and streamline the development process.

By understanding these technical properties and trade terminologies, B2B buyers can make informed decisions when sourcing plastic model parts, ensuring quality and efficiency in their procurement processes.

Navigating Market Dynamics and Sourcing Trends in the plastic model parts Sector

What Are the Current Market Dynamics and Key Trends in the Plastic Model Parts Sector?

The plastic model parts sector is witnessing a dynamic shift driven by several global factors. Increasing disposable incomes in regions like Africa, South America, and the Middle East have expanded the market for hobbies, including model building. Furthermore, the rise of e-commerce has enabled international B2B buyers to access a broader range of suppliers and products, facilitating competitive pricing and diverse sourcing options. Emerging technologies, such as 3D printing, are also transforming the landscape, allowing for the production of intricate and customized model parts that meet specific buyer demands.

Sourcing trends are increasingly leaning towards online platforms that offer a wide variety of aftermarket parts, including decals, photo-etch sets, and resin upgrades. As manufacturers and suppliers embrace digital transformation, B2B buyers can leverage advanced filtering and comparison tools to make informed purchasing decisions. Notably, brands such as Eduard Models and Trumpeter have become prominent in the market, reflecting a growing demand for high-quality, detailed components across various model categories, including military, aircraft, and vehicles.

International buyers, particularly from Europe and Asia, are also focusing on trends like local sourcing and just-in-time inventory to reduce lead times and costs. This not only enhances operational efficiency but also aligns with the growing emphasis on supply chain resilience in response to global disruptions.

How Is Sustainability and Ethical Sourcing Influencing the Plastic Model Parts Sector?

Sustainability has emerged as a critical consideration for B2B buyers in the plastic model parts sector. The environmental impact of plastic production and waste management is under scrutiny, prompting suppliers to adopt eco-friendlier practices. This includes the use of recycled materials and the development of biodegradable options. Buyers are increasingly seeking suppliers who demonstrate a commitment to sustainability, which can be a deciding factor in procurement decisions.

Ethical sourcing is also gaining traction, with many companies striving for transparency in their supply chains. This involves ensuring fair labor practices and compliance with environmental regulations. Certifications, such as ISO 14001 for environmental management, are becoming essential for suppliers looking to establish credibility in the market. Buyers are encouraged to prioritize partnerships with manufacturers who have these certifications, as they reflect a commitment to responsible sourcing and production.

Moreover, the demand for “green” materials is prompting innovation within the industry. Suppliers are exploring alternative materials that reduce the carbon footprint while still delivering the quality and performance expected by model builders. For international B2B buyers, aligning with suppliers who embrace sustainability not only enhances brand reputation but also meets the growing consumer demand for environmentally responsible products.

How Has the Plastic Model Parts Sector Evolved Over Time?

The plastic model parts sector has evolved significantly since its inception in the early 20th century. Initially, model kits were primarily made from wood or metal, but the introduction of plastic in the 1940s revolutionized the industry. This shift allowed for more intricate designs and mass production, making model kits more accessible to hobbyists worldwide.

Over the decades, the market has expanded, with a surge in popularity during the 1960s and 1970s, particularly in Europe and North America. The rise of aftermarket parts in the late 20th century further transformed the landscape, as enthusiasts sought to enhance the realism and detail of their models. Today, the sector continues to thrive, driven by advancements in technology and a growing community of passionate builders who value quality and customization. This evolution underscores the importance of staying abreast of market trends and sourcing strategies for B2B buyers navigating the plastic model parts sector.

Frequently Asked Questions (FAQs) for B2B Buyers of plastic model parts

-

How do I source high-quality plastic model parts for my business?

To source high-quality plastic model parts, start by identifying reputable manufacturers and suppliers that specialize in model kits and accessories. Research their product offerings, quality certifications, and customer reviews. Consider attending trade shows or industry exhibitions where you can meet suppliers face-to-face and evaluate their products. Additionally, request samples to assess the quality before making bulk purchases. Establishing a long-term relationship with suppliers can also ensure consistent quality and availability. -

What is the best way to evaluate suppliers of plastic model parts?

Evaluating suppliers involves several steps. First, verify their business credentials, including registration and compliance with international trade standards. Assess their production capabilities, quality control processes, and delivery timelines. Look for reviews and testimonials from other B2B buyers, especially in your region. It’s beneficial to request references and conduct site visits if possible. Engaging in a trial order can also provide insight into their reliability and product quality before committing to larger orders. -

What are the typical minimum order quantities (MOQs) for plastic model parts?

Minimum order quantities (MOQs) for plastic model parts can vary widely based on the supplier, product type, and customization options. Generally, MOQs range from 100 to 1,000 units for standard parts. However, specialized or custom-designed parts may have higher MOQs due to tooling and production costs. When negotiating with suppliers, clarify their MOQ policies and explore options for lower MOQs, especially if you are a new buyer or testing a new product line. -

What payment terms should I expect when purchasing plastic model parts internationally?

Payment terms for international purchases can vary by supplier and region. Common terms include a 30% deposit upon order confirmation, with the balance due before shipment. Some suppliers may offer letters of credit or escrow services for added security. Be sure to discuss payment methods (e.g., bank transfers, PayPal) and any associated fees. Establishing clear payment terms upfront can help prevent misunderstandings and facilitate smoother transactions. -

How can I customize plastic model parts to fit my specific needs?

Customization options for plastic model parts typically include design alterations, size adjustments, and material specifications. To initiate customization, communicate your specific requirements to the supplier, including dimensions, design files, and any unique features desired. Many suppliers have in-house design teams that can assist with modifications. Be prepared for additional costs and longer lead times, and ensure to review prototypes before final production to confirm that the customizations meet your expectations. -

What quality assurance measures should I look for when sourcing plastic model parts?

When sourcing plastic model parts, look for suppliers that implement rigorous quality assurance (QA) measures. This includes third-party inspections, adherence to international quality standards such as ISO 9001, and comprehensive testing protocols. Request documentation of quality checks, including material certifications and inspection reports. Establishing a clear QA agreement with your supplier can help ensure that all products meet your quality expectations before shipment. -

What logistics considerations should I keep in mind when importing plastic model parts?

Logistics is crucial when importing plastic model parts. Consider factors such as shipping methods (air vs. sea), delivery times, and customs clearance processes. Research import regulations in your country, including tariffs and duties applicable to plastic products. Working with a freight forwarder can streamline the logistics process and help navigate complexities. Ensure that your supplier provides accurate shipping documentation to prevent delays at customs. -

How do I handle disputes or issues with suppliers of plastic model parts?

Handling disputes with suppliers requires clear communication and documentation. Start by addressing the issue directly with the supplier, providing evidence such as emails, contracts, and product samples. If resolution is not achieved, refer to the terms outlined in your purchase agreement regarding dispute resolution procedures. Mediation or arbitration may be necessary for significant disputes. Building a strong relationship with suppliers can often prevent issues and facilitate smoother resolutions when problems arise.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 10 Plastic Model Parts Manufacturers & Suppliers List

1. MegaHobby – Aftermarket Detail Parts

Domain: megahobby.com

Registered: 1999 (26 years)

Introduction: Aftermarket Detail Parts available at MegaHobby.com include: Military Model Detail Parts (1/35 Update Sets, 1/72 Updates and Accessories, Decals and Transfers), Model Aircraft Detail Parts (Aircraft Decals, Aircraft Diorama Details, Aircraft Update Sets), Model Car Detail Parts (Car Decals, Car Exterior Details, Car Interior Details, Car Updates & Detailing Sets, Diorama Accessories & Figures, Eng…

2. Hobbylinc – Plastic Model Parts

Domain: hobbylinc.com

Registered: 1997 (28 years)

Introduction: Hobbylinc carries 12,741 plastic model parts and accessories from 96 manufacturers. Popular categories include plastic aircraft accessories, vehicle accessories, ship accessories, and display cases. Key manufacturers are Eduard Models, Trumpeter, Gofer Racing, and Quickboost. Products are discounted up to 66%. Featured products include: 1. Trumpeter Aircraft Display Stand – $7.39, 22% Off, 4.8 rat…

3. Auto World Store – Scale Model Kits

Domain: autoworldstore.com

Registered: 2009 (16 years)

Introduction: Auto World Store offers a wide variety of scale model kits including:

1. AMT 1963 Chevy Corvette 1:25 Scale Model Kit – $30.99

2. AMT 1966 Chevy Impala Modified Stocker 1:25 Scale Model Kit – $36.49

3. AMT 1971 Plymouth Duster 340 1:25 Scale Model Kit – $33.99

4. AMT Mack Cruise-Liner Semi Tractor 1:25 Scale Model Kit – $49.99

5. AMT Plymouth Valiant Scamp Kit Car 1:25 Scale Model Kit – $32.99

6….

4. Ted’s Modeling Marketplace – Scale Model Parts & Kits

Domain: tedsmodelingmarketplace.com

Registered: 2012 (13 years)

Introduction: 1/25 Scale Model Parts & Kits including Ford, Trucks, Detailing & Accessories. Categories include Engine Related, Specific Engine Detailing, Engine Parts, Exhaust Related, Fuel Management, Ignition Components, Turbo Chargers, Drive Train & Chassis, Interior & Cockpit, Bodies & Parts, Hood Scoops, Wheels & Tires, Exterior Parts, Decals, Diorama, Truck Related, Truck Misc, Tires/Wheels, Truck Decals…

5. Plastruct – Plastic Scale Model Parts

Domain: plastruct.com

Registered: 1998 (27 years)

Introduction: Plastruct is the world’s leading supplier of Plastic Scale Model Parts for miniature scale model building, offering over 4,000 different Plastic Model Parts in scales ranging from 1:12 to 1:1800. Product categories include Structural Shapes, Structural Fittings, Tubings & Fittings, Strip & Rod, Plain & Patterned Sheet, Woodstock Detail & Architectural Parts, Interior Architectural Parts, Landscapi…

6. Eduard – Plastic Model Kits and Accessories

Domain: eduard.com

Registered: 1998 (27 years)

Introduction: Eduard offers a variety of plastic model kits and accessories, including:

– **Aircraft and Helicopters**: Available in scales 1/32, 1/48, 1/72, and others.

– **Armoured Fighting Vehicles**: Available in scales 1/35, 1/48, 1/72, and others.

– **Ships and Submarines**: Available in scales 1/350, 1/700, 1/72, and others.

– **Special Products**: Includes the Eduard Bunny Fighter Club, Brassin access…

7. Reskit – Scale Model Accessories

Domain: reskit-models.com

Registered: 2021 (4 years)

Introduction: Reskit offers a variety of scale plastic model accessories including resin parts and 3D printed components. Their product categories include:

– Resin & 3D accessories

– Resin model kits

– 3D decals

– Painting masks

Types of equipment covered are:

– Aircraft

– Helicopters

– Armoured Fighting Vehicles

– Auto Moto

Specific types of products available include:

– Wheels

– Wheel bays

– Py…

8. AOSHIMA – Tuned Parts No.108 Enkei Dish Wheel

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Best selling products include: AOSHIMA 1/24 Tuned Parts No.108 Enkei Dish Wheel 15inch Model Parts kit for $16.73, Tamiya 94382 Mini 4wd Propeller Shaft set for $2.55, AoShima Culture 1/24 Tuned Parts No.110 Wire Wheel Gold Plated 13 Model Parts for $13.15, Motul 7100 Oil 4Ltr 10W60 for $62.90, Nanoblock Sonic The Hedgehog Go Sega Kawada Complete for $35.99, and Motul 7100 Oil 1Ltr 10W60 for $20.2…

9. AMT – Plastic Model Kits

Domain: towerhobbies.com

Registered: 1995 (30 years)

Introduction: Plastic Model Kits | Accessories | Plastic Modeling | Price Range: Under $20, $20 – $49.99 | Brands: AMT | Categories: Vehicles, Motorcycles, Airplanes, Helicopters, Boats, Military, Space, Figures, Snap Kits, Miscellaneous Accessories | Types of Accessories: Plastic Model Adhesives, Airbrush Sets, Plastic Model Paint, Plastic Model Paint Brushes, Plastic Model Tools.

10. Tamiya – Model Kits and RC Vehicles

Domain: tamiyausa.com

Registered: 2001 (24 years)

Introduction: Free Ground Shipping on Orders $50+ (Cannot Ship To PO Boxes). Categories include Aircraft, Armor, Automotive, Ship, 1/35 Scale, Dinosaur Diorama, Finished Models, Display Goods, Model Accessories, Radio Control Off-Road Buggies, Trucks, Cars, Ready-To-Run Tanks, Nitro Engine, TamTech Gear, Mini 4WD Vehicles, Tracks, Tune-Up Parts, Tools & Accessories, Educational Construction Materials, Education…

Strategic Sourcing Conclusion and Outlook for plastic model parts

In the competitive landscape of plastic model parts, effective strategic sourcing is paramount for international B2B buyers. By prioritizing quality, variety, and supplier reliability, companies can enhance their product offerings and cater to the diverse needs of model enthusiasts across regions such as Africa, South America, the Middle East, and Europe. The increasing demand for aftermarket parts, detailed accessories, and specialized components underscores the importance of sourcing from reputable manufacturers and distributors.

Buyers should focus on building strong relationships with suppliers who offer comprehensive catalogs and innovative products, such as photo-etch detail parts, decals, and resin upgrades. This not only ensures access to the latest trends in modeling but also fosters collaboration that can lead to exclusive partnerships and better pricing.

Looking ahead, the market for plastic model parts is poised for growth, driven by a resurgence in hobbyist interest and advancements in manufacturing technologies. To capitalize on these opportunities, international buyers are encouraged to explore new suppliers, diversify their product lines, and stay informed about industry developments. Embrace strategic sourcing as a vital tool for success, and position your business to thrive in the evolving landscape of model parts.