Contents

Manufacturing Insight: Plastic Machining Vs Plastic Injection Molding

Strategic Material Selection for Plastic Component Production

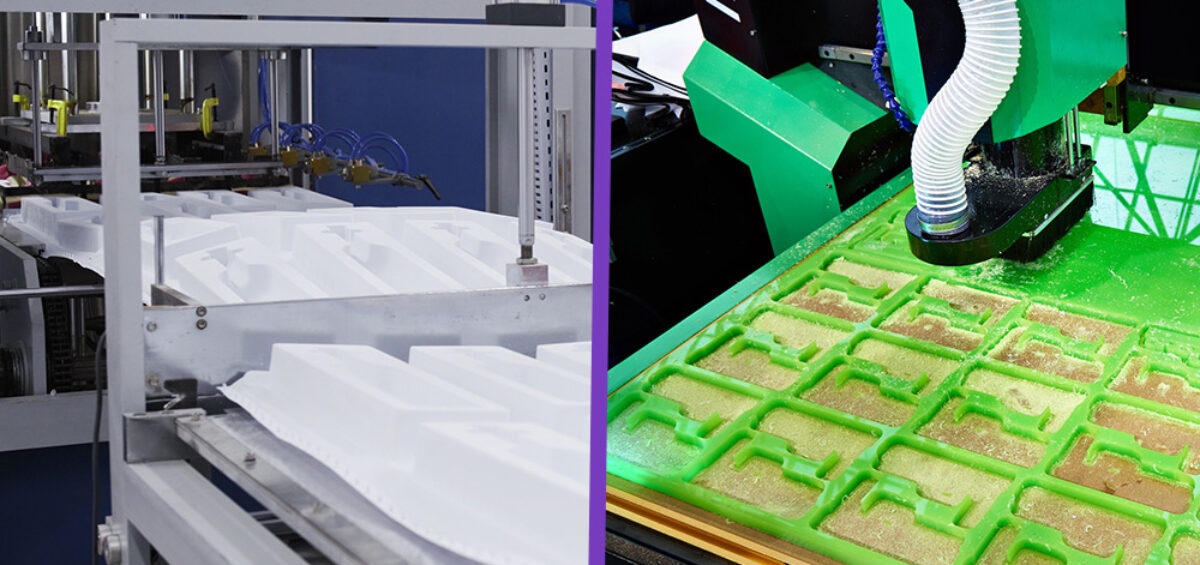

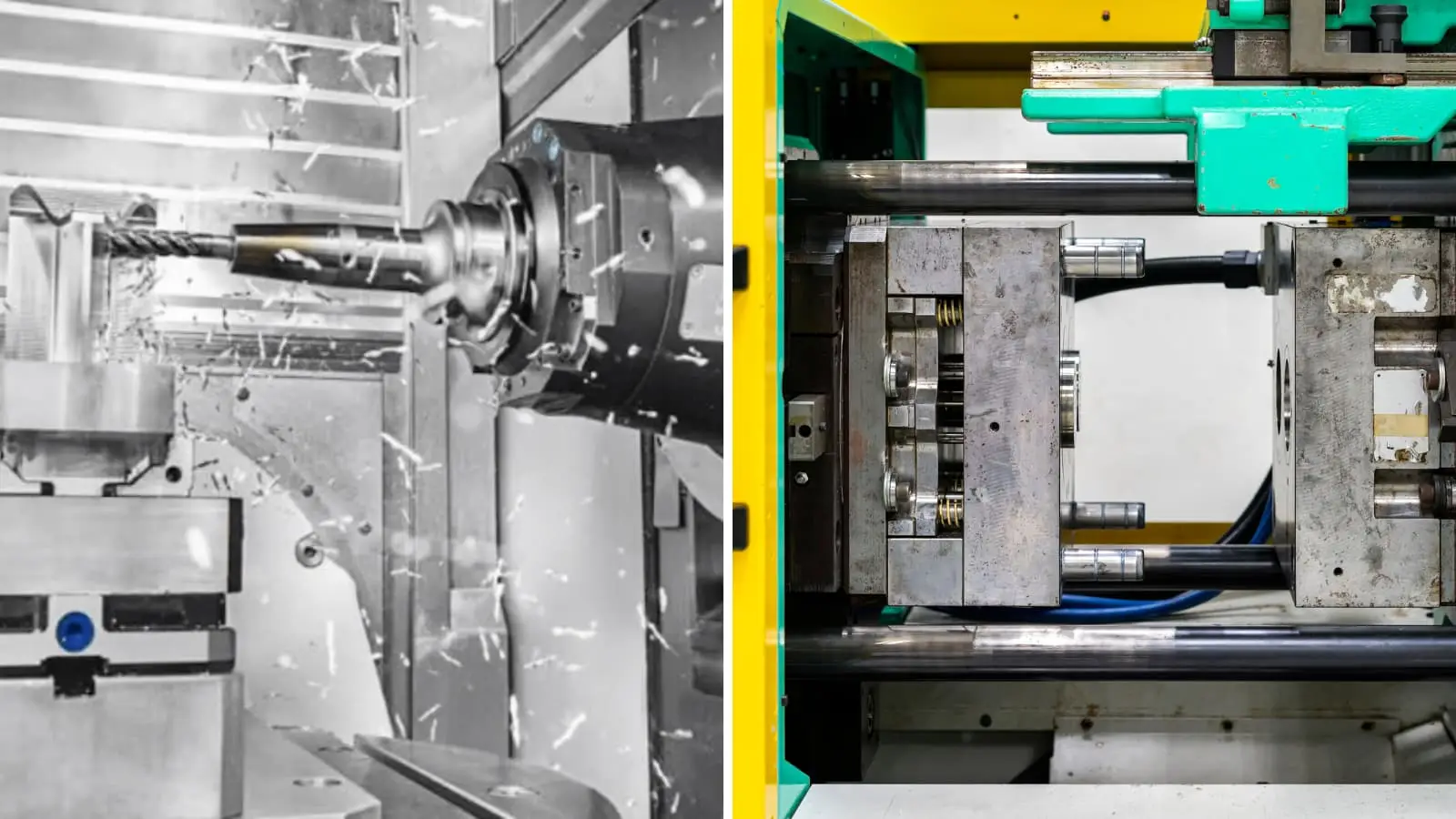

Choosing between plastic machining and plastic injection molding fundamentally impacts cost efficiency, lead time, and part performance for your project. Plastic machining, a subtractive process using CNC mills or lathes, excels for low-volume prototypes or custom one-off parts where design flexibility and rapid iteration are critical. It achieves tight tolerances without tooling investment but generates significant material waste and becomes cost-prohibitive beyond small batches. Conversely, plastic injection molding leverages engineered molds to produce high volumes with consistent precision, minimal waste, and lower per-unit costs at scale—though it requires substantial upfront tooling investment and longer initial lead times.

Honyo Prototype Optimizes Your Path to Production

We bridge this decision gap with integrated Rapid Tooling and Injection Molding services designed for engineering teams demanding speed without compromise. Our aluminum rapid tooling solutions enable functional testing and pilot runs for 100–10,000 parts at 30–50% lower cost than traditional steel molds, compressing development cycles by weeks. For full-scale production, our precision molding capabilities support complex geometries in engineering-grade resins with rigorous quality control.

Accelerate your evaluation with our Online Instant Quote platform, delivering detailed manufacturability feedback and pricing within hours—not days—for both machining and molding workflows. Submit your CAD file today to determine the optimal process for your volume, timeline, and performance requirements.

Technical Capabilities

When comparing plastic machining and plastic injection molding, key technical and operational differences emerge—especially regarding tooling materials, lead times, and material compatibility. A critical milestone in injection molding is achieving T1 samples (first article samples from production tooling), with rapid turnaround often required for prototyping and product validation.

For applications requiring T1 samples within 7 days, aluminum molds are typically preferred due to faster machinability and lower production time compared to steel. While steel offers superior durability for high-volume runs, aluminum enables accelerated development cycles essential for time-sensitive projects.

Below is a technical comparison focused on mold materials (aluminum and steel), lead time to T1 sample, and common engineering plastics used (ABS, Nylon):

| Parameter | Plastic Machining | Plastic Injection Molding (Aluminum Mold) | Plastic Injection Molding (Steel Mold) |

|---|---|---|---|

| Process Type | Subtractive manufacturing | Additive forming via mold cavity | Additive forming via mold cavity |

| Tooling Material | Not applicable (no mold required) | 7075-T6 or 6061 Aluminum | P20, H13, or 420 Stainless Steel |

| Mold Lead Time | Not applicable | 5–7 days (enables T1 sample in 7 days) | 2–6 weeks (not suitable for 7-day T1) |

| T1 Sample Availability | Immediate (part machined directly) | Achievable within 7 days | Typically exceeds 7-day window |

| Typical Materials | ABS, Nylon (machinable stock forms) | ABS, Nylon (injection grade pellets) | ABS, Nylon (injection grade, high flow) |

| Surface Finish | Good (depends on tooling and feed) | Excellent (polishable to SPI standards) | Excellent (high polish, texture capable) |

| Tolerances | ±0.05 mm (tighter with precision CNC) | ±0.1 mm (shrinkage-dependent) | ±0.05 mm (stable over high volume) |

| Volume Suitability | Low volume, prototypes, one-offs | Low to medium volume (up to 100,000 parts) | High volume (100,000+ parts) |

| Tooling Cost | None | Low to moderate | High |

| Part Cost (Unit) | High (labor and material intensive) | Low to medium | Very low at scale |

| Design Flexibility | High (no draft, undercuts easier) | Moderate (draft, gate, ejection required) | Moderate (similar to aluminum mold) |

| Mechanical Properties | Anisotropic (based on stock orientation) | Isotropic (uniform flow) | Isotropic (consistent across production) |

Summary:

For projects requiring T1 samples within 7 days, plastic injection molding with aluminum molds is the optimal balance between speed and production intent fidelity. While plastic machining provides immediate parts without tooling, it lacks the scalability and consistent part properties of molding. Aluminum molds support rapid validation using engineering resins like ABS and Nylon, whereas steel molds are reserved for long-term production due to extended lead times and higher initial investment.

From CAD to Part: The Process

Honyo Prototype applies a standardized digital workflow for both plastic machining and plastic injection molding projects, ensuring efficiency and transparency from initial inquiry to final shipment. The core process stages—Upload CAD, AI Quote, DFM, Production, and Delivery—remain consistent, but critical technical divergences occur at the DFM and Production phases based on the selected manufacturing method. Understanding these divergences is essential for optimal part realization.

Upon CAD file upload, our system initiates geometry analysis for both processes. The AI Quote engine then generates preliminary cost and lead time estimates by evaluating part volume, complexity, material selection, and requested quantity. For machining, the AI prioritizes factors like raw stock utilization, toolpath complexity, and secondary operations. For injection molding, it assesses mold complexity, gate location feasibility, and cycle time implications. This stage provides clients with immediate, data-driven visibility into process suitability before formal commitment.

The DFM (Design for Manufacturability) phase represents the critical decision point where process-specific expertise is applied. Honyo engineers conduct separate, rigorous analyses:

Plastic Machining DFM Focus

Material stress relief requirements, optimal stock size selection to minimize waste, accessibility for multi-axis toolpaths, tolerance stack-up analysis for complex features, and identification of features requiring secondary operations like tapping or threading. Design modifications typically target reducing setups or avoiding thin-wall instability.

Plastic Injection Molding DFM Focus

Wall thickness uniformity analysis to prevent sinks or warpage, gate type and location optimization, draft angle validation for all features, ejection strategy planning, mold steel selection based on resin abrasiveness, and weld line prediction. Design modifications concentrate on enabling flow, cooling efficiency, and part ejection.

The following comparative table highlights key technical differentiators influencing DFM outcomes and process selection:

| Parameter | Plastic Machining | Plastic Injection Molding |

|---|---|---|

| Optimal Volume | 1–100 parts | 1,000+ parts |

| Lead Time (Tooling) | None (uses stock material) | 2–6 weeks (mold fabrication) |

| Material Waste | Higher (subtractive process) | Lower (near-net shape) |

| Part Complexity | Limited by tool access; internal features challenging | High complexity achievable with proper draft/core |

| Tolerance Capability | ±0.025 mm (machine-dependent) | ±0.1 mm (mold/warp dependent) |

| Surface Finish | As-machined (Ra 0.8–3.2 µm); post-ops for polish | Mold-textured (Ra 0.05–1.6 µm); consistent finish |

| Material Flexibility | Broad (all machinable thermoplastics/composites) | Limited by melt flow and thermal stability |

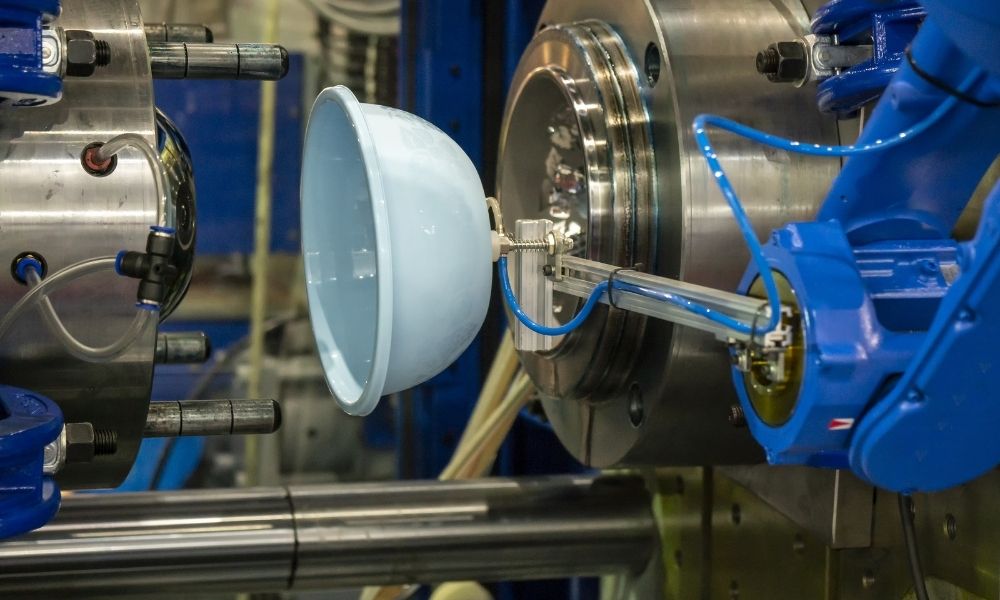

Production execution follows the validated DFM recommendations. Machining employs CNC milling, turning, or multi-axis centers with strict in-process CMM verification for critical dimensions. Injection molding utilizes scientific molding principles with cavity pressure monitoring, melt temperature control, and automated part handling. Both streams maintain full material traceability and adhere to ISO 9001 documentation standards, though process validation protocols differ significantly—machining focuses on tool wear compensation while molding emphasizes process window stability.

Delivery encompasses final inspection against client specifications, protective packaging validated for part geometry, and shipment with comprehensive documentation including first-article inspection reports and material certifications. For machined parts, this includes as-machined surface roughness data; for molded parts, it includes process parameter logs and molding machine validation records. Honyo’s integrated workflow ensures clients receive technically optimized parts through the most appropriate manufacturing method, with complete transparency at every decision point. The shared digital foundation enables rapid iteration should design changes necessitate process reevaluation post-DFM.

Start Your Project

When evaluating plastic machining versus plastic injection molding for your next project, understanding the trade-offs in cost, lead time, and part complexity is critical. Plastic machining offers rapid turnaround and design flexibility for low-volume or prototype runs, while injection molding delivers cost efficiency and consistency for high-volume production.

At Honyo Prototype, we specialize in both advanced plastic machining and precision injection molding, leveraging our state-of-the-art manufacturing facility in Shenzhen to support your prototyping and production needs. Our engineering team can help you determine the optimal process based on your volume, material requirements, and geometric specifications.

For expert guidance tailored to your application, contact Susan Leo at [email protected]. Let’s discuss how we can streamline your path from design to delivery.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.