Contents

Manufacturing Insight: Plastic Machine Shop

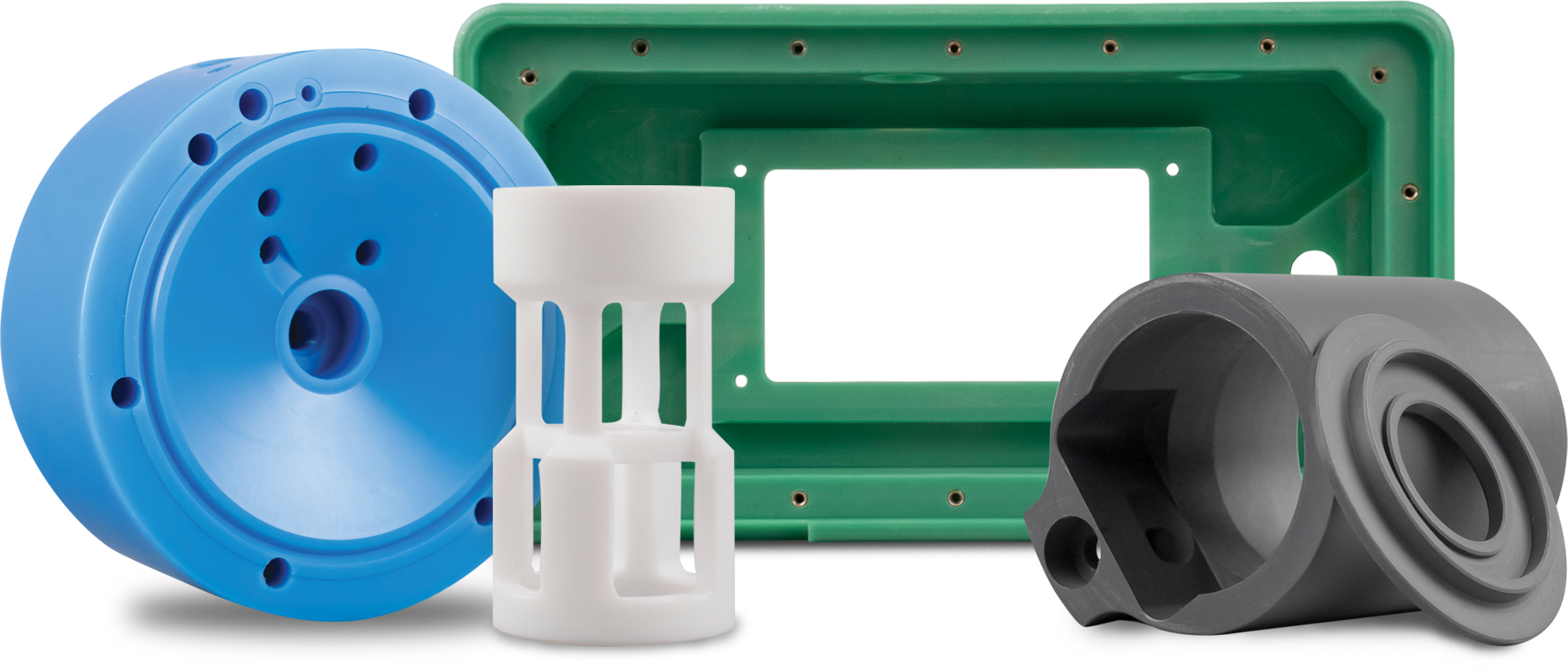

Honyo Prototype delivers precision plastic machining solutions through advanced CNC capabilities tailored for demanding engineering applications. Our dedicated plastic machine shop specializes in transforming complex designs into high-fidelity components using state-of-the-art 3-, 4-, and 5-axis CNC milling and turning centers. We excel in machining a wide range of engineering-grade thermoplastics and thermosets to exacting tolerances, typically holding ±0.005 mm, ensuring parts meet critical functional and dimensional requirements for prototyping and production.

Our technical expertise spans challenging materials including PEEK, Ultem, Delrin, Nylon, Polycarbonate, and PTFE, with processes optimized to prevent warpage, maintain material integrity, and achieve superior surface finishes. This precision is critical for industries such as medical device development, aerospace subsystems, semiconductor tooling, and fluid handling systems where component performance is non-negotiable. The table below outlines key material capabilities:

| Material Category | Example Materials | Key Machining Strengths |

|---|---|---|

| High-Performance Thermoplastics | PEEK, Ultem, PPSU | Thermal stability, chemical resistance, precision under load |

| Engineering Plastics | Delrin (POM), Nylon (PA), Polycarbonate | Dimensional accuracy, wear resistance, impact strength |

| Specialty Thermosets | PTFE, Vespel, Phenolic | Low friction, electrical insulation, high-temperature stability |

Accelerate your development cycle with Honyo’s Online Instant Quote System, providing detailed pricing and lead time estimates for CNC plastic machining within minutes. Upload your CAD file, specify material and quantity requirements, and receive a transparent, no-obligation quote engineered for accuracy—enabling faster decision-making from rapid prototyping to low-volume production. Partner with Honyo Prototype for CNC machining where technical precision meets operational efficiency.

Technical Capabilities

Technical Specifications for Plastic Machine Shop – Precision Machining Capabilities

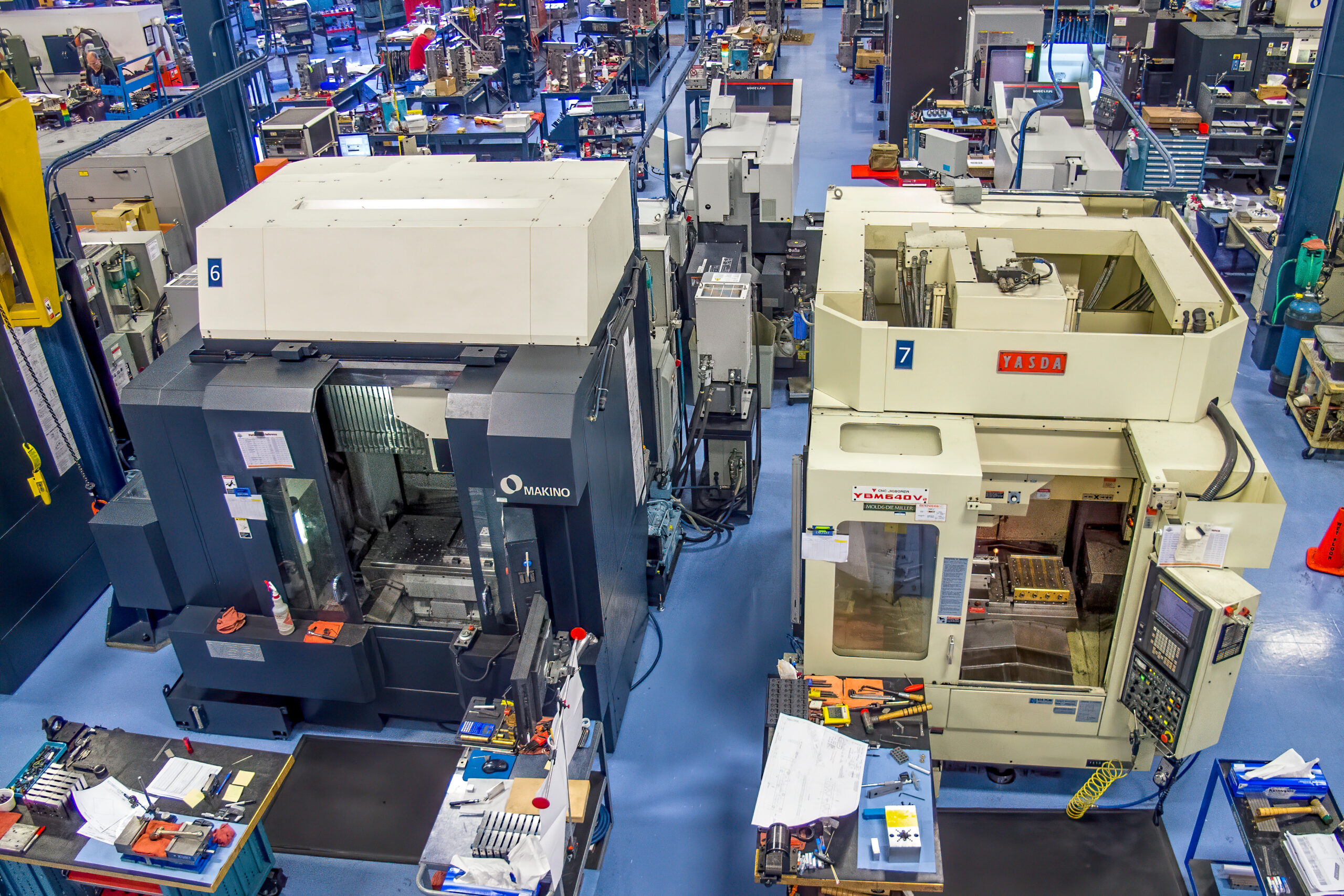

Honyo Prototype offers high-precision CNC machining services tailored for both engineering-grade plastics and metals. Our facility specializes in tight-tolerance components for aerospace, medical, and industrial applications. Below are the core technical capabilities of our plastic machine shop with focus on multi-axis milling, turning, and material compatibility.

| Parameter | Specification |

|---|---|

| Machining Processes | 3-Axis, 4-Axis, and 5-Axis CNC Milling; CNC Turning (Swiss and Standard) |

| Tolerance Capability | ±0.0002″ (±0.005 mm) for critical dimensions; feature-to-feature < ±0.0005″ |

| Surface Finish (Typical) | 32–125 μin Ra (machined); post-processing available for finer finishes |

| Max Work Envelope (Milling) | 5-axis: 24″ × 36″ × 20″ (610 × 914 × 508 mm); 3/4-axis up to 40″ in length |

| Max Turning Diameter | 2.5″ (63.5 mm); up to 12″ (305 mm) length for Swiss-type turning |

| Spindle Speed (Milling) | Up to 24,000 RPM with high-precision ER collet systems |

| Positioning Accuracy | ±0.0001″ (±0.0025 mm) with laser calibration and in-process probing |

| Tooling System | CAT-40 and HSK-63; automatic tool changers with 24–40 tool capacity |

| Coolant & Chip Management | High-pressure through-spindle coolant; enclosed systems for plastic swarf |

| Inspection Equipment | CMM (Coordinate Measuring Machine), optical comparators, micrometers, gauges |

Compatible Materials

We support a broad range of thermoplastics and metals, optimized for dimensional stability and performance under load. Key materials include:

Metals:

Aluminum: 6061-T6, 7075-T6, 2024-T3 – ideal for lightweight, high-strength components

Steel: 1018, 4140, 4340 – used in high-wear or structural applications

Engineering Plastics:

ABS (Acrylonitrile Butadiene Styrene) – good impact resistance, machinability, and surface finish

Nylon (PA 6, PA 66) – excellent wear and chemical resistance; suitable for moving parts

All plastic machining operations are performed with optimized feeds, speeds, and tool paths to minimize thermal deformation and maintain tight tolerances. Our CNC programs are verified using CAM simulation software (e.g., Mastercam, Fusion 360) to ensure accuracy and repeatability.

From CAD to Part: The Process

Honyo Prototype executes precision plastic machining through a rigorously defined workflow optimized for speed, quality, and manufacturability. Our process begins with secure digital intake and concludes with certified delivery, ensuring seamless transition from concept to functional component. Below is the detailed sequence:

CAD Upload

Clients initiate the process via Honyo’s encrypted online portal, uploading native or neutral CAD formats (STEP, IGES, Parasolid, SLDPRT). The system performs automated validation for file integrity and geometric completeness, confirming unit consistency and absence of non-manifold edges. This stage establishes the foundational geometry for all downstream operations, with immediate confirmation of receipt and preliminary file assessment.

AI-Powered Quoting

Uploaded geometry undergoes rapid analysis by Honyo’s proprietary AI engine, which evaluates dimensional complexity, feature density, and material requirements against live machine capacity and material stock databases. The system generates a preliminary cost and lead time estimate within 15 minutes, incorporating real-time factors such as polymer grade availability (e.g., PEEK, Acetal, Ultem), machine hourly rates, and secondary operation needs. Crucially, all AI outputs are validated by our engineering team to ensure contextual accuracy—addressing nuances like cosmetic finish requirements or tolerance stack-ups that algorithms may overlook.

Engineering-Led DFM Review

Following quote acceptance, our manufacturing engineers conduct a comprehensive Design for Manufacturability (DFM) assessment focused explicitly on plastic machining challenges. This phase identifies risks such as thin-wall deformation, thermal stress points, or non-optimal tool engagement angles unique to polymeric materials. Key considerations include:

| DFM Factor | Plastic-Specific Risk | Honyo Mitigation |

|---|---|---|

| Wall Thickness | Warpage during cooling | Recommend ribbing or uniform cross-sections |

| Undercuts | Tool access limitations | Propose split features or alternative toolpaths |

| Tight Tolerances | Material creep (e.g., Nylon) | Adjust tolerances or suggest stabilized grades |

| Surface Finish | Melt fracture at high feeds | Optimize spindle speed/feed per polymer type |

The engineering team collaborates directly with the client to resolve conflicts, providing annotated CAD markups and alternative geometry suggestions. This iterative step typically reduces production iterations by 65% and prevents costly post-machining rework.

Precision Production

Approved designs move to Honyo’s climate-controlled machining floor, where CNC mills (3- and 5-axis) and lathes process virgin engineering plastics under strict environmental parameters. Critical protocols include:

Material preconditioning to 23°C ±1°C to minimize thermal expansion

Dedicated tooling libraries with sharp, polished carbide cutters to prevent melting

In-process CMM verification at defined checkpoints for features below ±0.025mm

Cleanroom protocols for medical/aerospace components (ISO Class 7)

All operations adhere to AS9100 and ISO 13485 standards, with real-time machine data logged for traceability. Secondary operations like threading, polishing, or bonding occur in specialized workcells with polymer-specific process controls.

Certified Delivery

Final components undergo first-article inspection per AS9102 or client-specific protocols, with full dimensional reports and material certifications packaged with the shipment. Honyo ships via tracked logistics with anti-static and moisture-barrier packaging tailored to polymer sensitivity. Every delivery includes a digital quality dossier accessible through our client portal, containing inspection data, process parameters, and environmental logs. Typical lead times range from 5 to 15 business days depending on complexity, with expedited options available for critical path items.

This integrated workflow ensures plastic components meet stringent functional requirements while minimizing time-to-part—turning digital designs into certified, production-ready hardware with engineering rigor at every phase.

Start Your Project

Looking for precision plastic machining services? Contact Susan Leo at [email protected] to discuss your project requirements.

Honyo Prototype operates a dedicated plastic machine shop with advanced manufacturing capabilities located in Shenzhen, China. Our facility specializes in high-accuracy CNC machining, injection molding, and custom fabrication for engineering-grade thermoplastics.

We support prototyping and low-to-mid volume production with rapid turnaround, tight tolerances, and full material traceability. From concept to final part, we deliver consistent quality for industries including medical, automotive, consumer electronics, and industrial equipment.

Reach out today to request a quote or technical consultation.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.