Contents

Manufacturing Insight: Plastic Machine Services

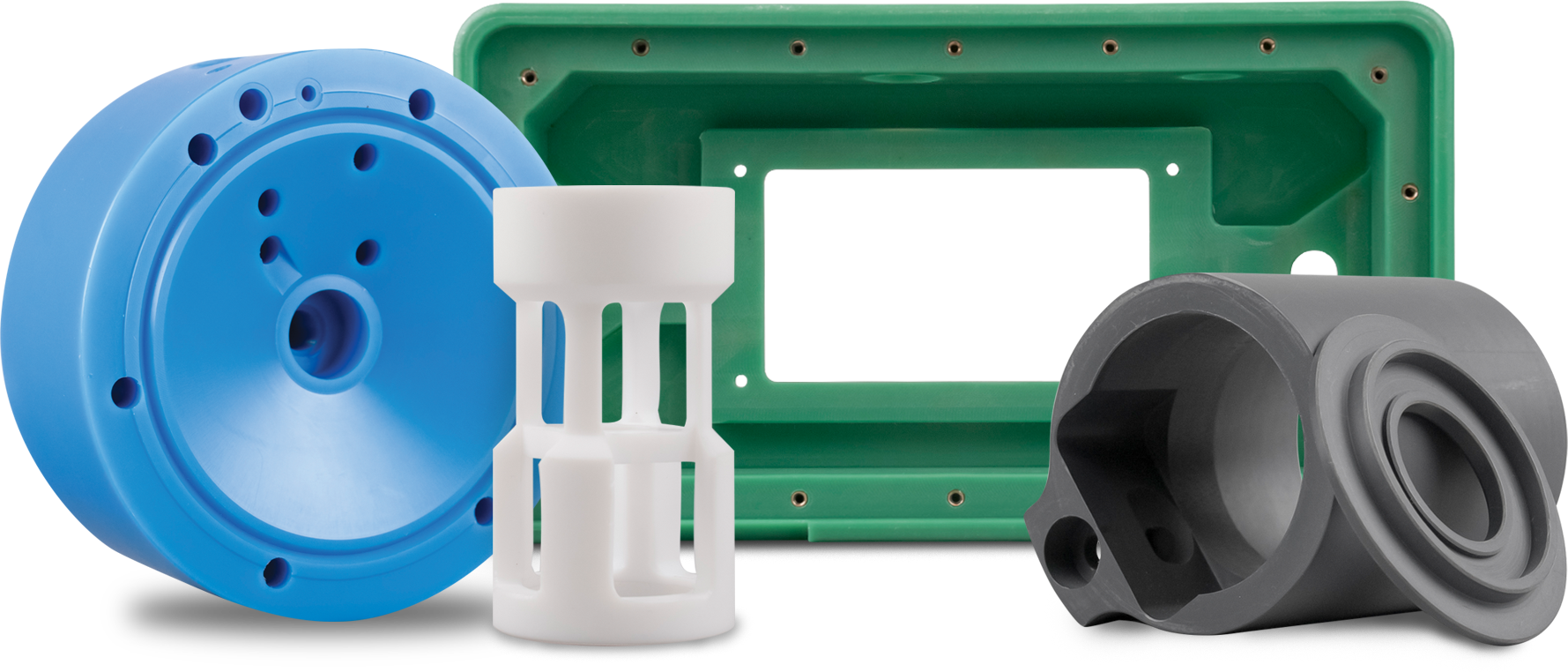

Precision Plastic CNC Machining Services for Demanding Applications

At Honyo Prototype, we specialize in high-precision CNC machining of engineering-grade plastics, delivering complex components that meet exacting dimensional and functional requirements. Our expertise spans critical materials including PEEK, Ultem, Acetal, Nylon, PTFE, and Polycarbonate, where thermal stability, chemical resistance, and mechanical performance are non-negotiable. Unlike generic machining providers, we optimize feed rates, spindle speeds, and tool geometries for each polymer’s unique behavior—minimizing stress-induced warpage and ensuring repeatability down to ±0.005mm tolerances.

Engineered for Speed Without Compromise

Our ISO 9001-certified facility combines 5-axis milling, precision turning, and multi-axis Swiss machining with rigorous in-process inspection protocols. This allows us to produce intricate plastic housings, fluidic manifolds, medical instrument components, and aerospace brackets with consistent surface integrity and material properties intact. We prioritize material science in every process step, from strategic fixturing that prevents part deformation to post-machining stress-relief cycles tailored to your polymer’s thermal profile.

Accelerate Your Development Cycle with Real-Time Quoting

Eliminate procurement delays with Honyo’s Online Instant Quote system. Upload your 3D CAD file (STEP, IGES, or native formats), specify material and finish requirements, and receive a detailed technical assessment with competitive pricing within minutes—not days. Our platform validates manufacturability in real time, flagging potential issues like thin-wall deflection or undercuts before you commit, ensuring your plastic components transition seamlessly from prototype to low-volume production.

Partner with Honyo Prototype for CNC-machined plastic solutions where precision, material expertise, and rapid turnaround directly impact your product’s success.

| Key Service Differentiators | Implementation Details |

|---|---|

| Material-Specific Machining Protocols | Custom toolpaths and parameters for 20+ engineering plastics to prevent melt or cracking |

| Tight Tolerance Capability | ±0.005mm achievable on critical features with CMM validation |

| Rapid Prototyping Integration | Quote-to-part in 5–7 business days for most geometries |

| Online Instant Quote System | Real-time cost analysis with DFM feedback; no registration required |

Technical Capabilities

Technical Specifications for Plastic Machine Services – Precision Machining (3/4/5-Axis Milling & Turning)

Honyo Prototype offers advanced plastic and metal machining services utilizing 3-axis, 4-axis, and 5-axis CNC milling as well as precision turning, designed for high accuracy and complex geometries. Our capabilities support tight tolerance requirements essential for aerospace, medical, automotive, and industrial applications. The following table outlines the key technical specifications, including compatible materials such as Aluminum, Steel, ABS, and Nylon.

| Parameter | Specification Details |

|---|---|

| Machining Processes | 3-Axis CNC Milling, 4-Axis Indexed & Continuous, 5-Axis Simultaneous Milling, CNC Turning |

| Tolerance Capability | ±0.005 mm (±0.0002″) typical; tight tolerances down to ±0.002 mm (±0.00008″) achievable |

| Surface Finish (Ra) | 0.8–3.2 µm (32–125 µin); custom finishes available with polishing or coating options |

| Maximum Work Envelope | Milling: 1000 x 600 x 500 mm (39.4 x 23.6 x 19.7 in); Turning: Ø300 mm x 500 mm (19.7 in) |

| Spindle Speed (Milling) | Up to 24,000 RPM with high-precision ER collet systems |

| Turning Capacity | Live tooling support, sub-spindle for backworking, bar feed compatibility up to Ø65 mm |

| Positioning Accuracy | ±0.003 mm (±0.0001″) |

| Repeatability | ±0.002 mm (±0.00008″) |

| Materials – Metals | Aluminum (6061, 7075, 2024), Steel (1018, 4140, 17-4 PH), Stainless Steel (303, 304, 316) |

| Materials – Plastics | ABS, Nylon (6 & 66), POM (Delrin), PEEK, PC, PMMA, PTFE – low-residue machining protocols |

| Fixturing & Workholding | Vacuum tables, custom soft jaws, modular fixturing, tombstones for high-volume batches |

| Coolant & Chip Management | High-pressure coolant for metals; air cooling and dry machining for sensitive plastics |

| Inspection & QA | CMM, optical comparators, micrometers, bore gauges; first-article and in-process checks |

| File Compatibility | STEP, IGES, X_T, DWG, DXF, native CAD (SolidWorks, Fusion 360, Creo, CATIA) |

Our machining centers are equipped with high-resolution encoders and thermal compensation systems to maintain dimensional stability across production runs. For plastic components, we apply optimized cutting strategies to minimize deformation and ensure repeatability, especially in hygroscopic materials like Nylon. Aluminum and steel parts are machined with coated carbide tooling to achieve superior edge definition and surface integrity under tight tolerance demands.

From CAD to Part: The Process

Honyo Prototype employs a rigorously defined workflow for plastic machining services designed to maximize efficiency, quality, and client transparency. This integrated process begins with secure digital submission and concludes with verified delivery, ensuring manufacturability and cost-effectiveness at every stage.

Clients initiate the process by uploading native or neutral CAD files (STEP, IGES, Parasolid, or native SolidWorks/Autodesk formats) through our secure customer portal. This portal validates file integrity, confirms geometric completeness, and automatically extracts critical parameters such as part dimensions, material requirements, and geometric tolerances. File security is maintained via AES-256 encryption during transfer and storage, with access restricted to authorized engineering personnel only.

The uploaded CAD data feeds directly into our proprietary AI-powered quoting engine. This system analyzes geometric complexity, material selection, required tolerances, surface finish specifications, and secondary operations against real-time machine utilization data and material cost databases. The output is a detailed preliminary quote within 2 business hours, including a breakdown of machining time estimates, material costs, and a preliminary lead time forecast. Crucially, this AI stage identifies potential high-risk features requiring immediate engineering review, such as thin walls below 0.5mm or deep cavities exceeding 10:1 aspect ratios, flagging them for the subsequent DFM phase.

Following client acceptance of the preliminary quote, the project enters the mandatory Design for Manufacturability (DFM) analysis phase. Our senior manufacturing engineers conduct a comprehensive review, focusing on optimizing the design for CNC milling, turning, or multi-axis machining. This includes evaluating tool access paths, recommending optimal stock sizes to minimize waste, suggesting minor geometric modifications to eliminate costly undercuts or reduce setups, and verifying material suitability against the application’s thermal and mechanical requirements. We provide a formal DFM report with actionable recommendations, cost-saving opportunities, and a finalized production timeline. Client feedback on DFM suggestions is incorporated before proceeding, ensuring alignment and preventing downstream rework.

Upon DFM sign-off, the order advances to production scheduling. Parts are assigned to optimized CNC machining cells based on complexity, utilizing our fleet of precision machines including 5-axis mills, high-speed vertical machining centers, and Swiss-type lathes. All plastic machining adheres to strict environmental controls (temperature and humidity stabilized) to prevent material warpage. In-process inspections at critical stages verify dimensional accuracy against GD&T callouts using CMMs and optical comparators, with full first-article inspection reports generated for client review prior to full batch release. Material traceability is maintained from raw stock certificate through final inspection.

Final delivery encompasses rigorous post-processing validation, including final dimensional certification, visual inspection for surface defects, and packaging tailored to part fragility (e.g., anti-static foam for acrylic components). All parts ship with comprehensive documentation: signed-off FAI reports, material certificates of conformance, and a final process validation summary. Standard lead time from DFM approval to delivery is 7-10 business days for simple geometries, extending based on complexity and volume as detailed in the formal quote.

The following table summarizes key phase characteristics and deliverables:

| Process Phase | Typical Duration | Primary Output | Client Action Required |

|---|---|---|---|

| CAD Upload & Validation | < 1 hour | Validated geometry file, initial risk flags | Submit complete CAD model |

| AI-Powered Quoting | ≤ 2 business hours | Preliminary cost estimate, lead time forecast, high-risk feature report | Review and approve quote |

| Engineering DFM Analysis | 1-3 business hours | Formal DFM report with optimization recommendations | Approve or discuss modifications |

| Production Execution | 7-10+ business days | Machined parts with full inspection documentation | N/A (process execution) |

| Quality Verification & Delivery | 1 business day | Certified parts, final documentation package | Receive and confirm acceptance |

This closed-loop process ensures manufacturability is validated before metal meets plastic, significantly reducing time-to-part while maintaining Honyo’s ISO 9001-certified quality standards. Continuous feedback from production directly informs our DFM database, enhancing the accuracy of future AI quotes and engineering recommendations.

Start Your Project

For professional plastic machine services, contact Susan Leo at [email protected]. Our advanced manufacturing facility is located in Shenzhen, ensuring high-quality production and efficient turnaround for your prototyping and manufacturing needs.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.