Contents

Manufacturing Insight: Plastic Injection Mold Cost

Understanding Plastic Injection Mold Cost Drivers with Honyo Prototype

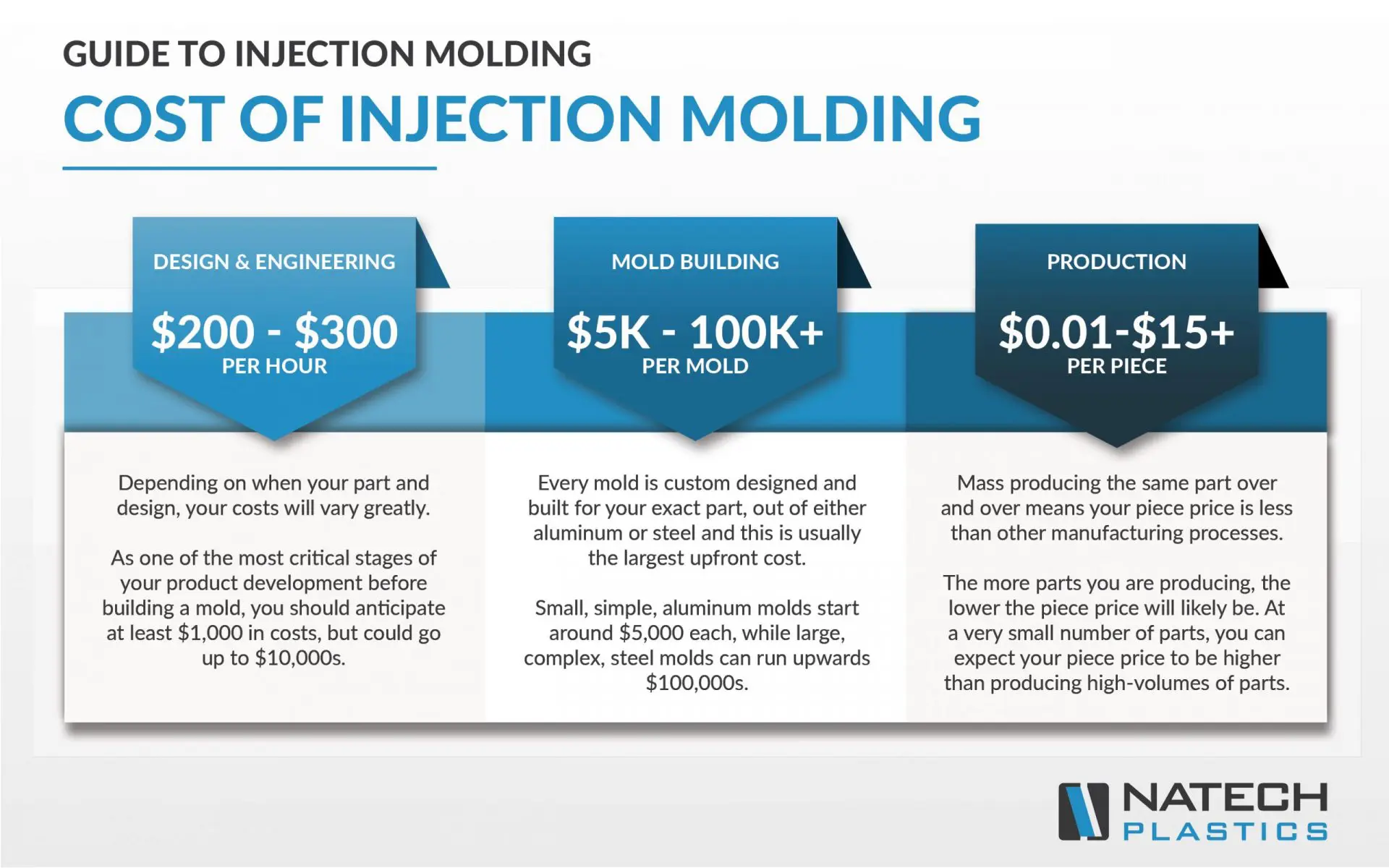

Plastic injection mold costs remain a critical yet often opaque factor in product development, significantly impacting time-to-market and overall project ROI. Traditional mold procurement involves complex variables—material selection, cavity count, steel type, surface finish, and part complexity—that create pricing uncertainty and delay critical design validation. At Honyo Prototype, we eliminate this barrier through engineered cost transparency without compromising on precision or speed.

Our Rapid Tooling solutions specifically address early-stage cost sensitivity by leveraging advanced aluminum and pre-hardened steel molds, reducing initial tooling investment by 30-60% compared to production-grade tooling while maintaining tight tolerances for functional testing. This approach bridges the gap between prototyping and high-volume manufacturing, allowing clients to validate designs, secure investor buy-in, and refine part geometry before committing to full-scale tooling. Crucially, our integrated Injection Molding services ensure seamless transition from rapid tooling to production, avoiding costly redesigns or secondary supplier handoffs that inflate total project costs.

Honyo’s technical differentiator lies in our proprietary cost modeling framework, which quantifies how design choices directly influence mold expenditure. For instance, strategic gate placement or draft angle optimization can lower steel requirements by 15-25%, while material selection directly correlates to mold longevity and cycle time efficiency. To provide immediate clarity, we offer an Online Instant Quote platform where engineers input core specifications—part geometry, material, and volume—to receive a validated mold cost estimate within minutes, not days. This eliminates guesswork and accelerates your NPI timeline from concept to first article.

Partner with Honyo Prototype to transform mold cost from a budgetary risk into a strategic advantage, backed by engineering rigor and real-time pricing intelligence.

Technical Capabilities

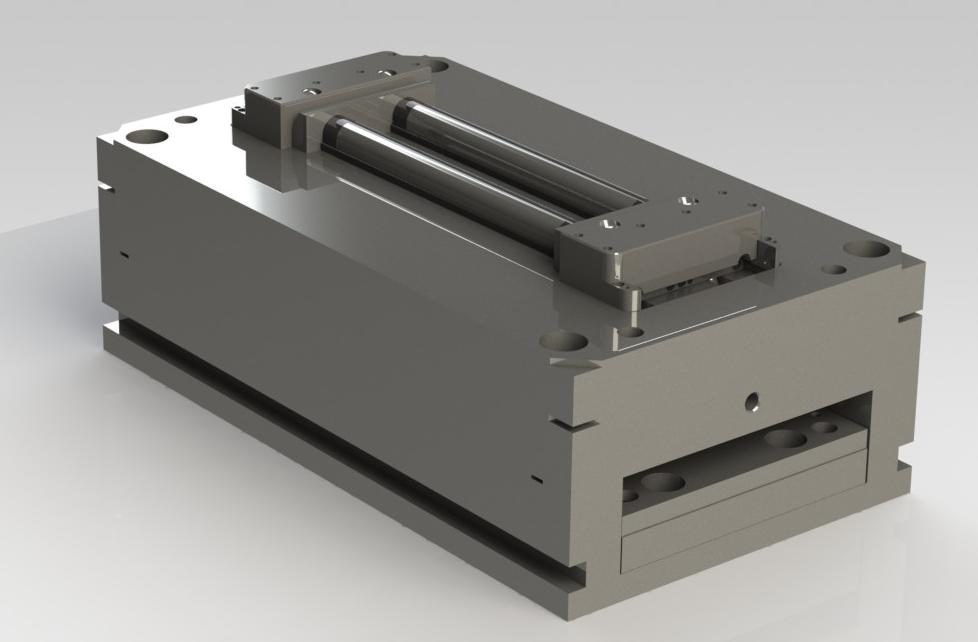

Technical specifications for plastic injection mold cost are influenced by several key factors including mold material (aluminum or steel), part complexity, material compatibility (such as ABS or Nylon), production volume, and lead time. At Honyo Prototype, we offer rapid tooling solutions with a T1 sample delivery within 7 days, enabling fast validation and iteration for product development.

The choice between aluminum and steel molds impacts initial cost, tool life, surface finish, and suitability for specific resins. Aluminum molds are cost-effective and faster to machine, ideal for prototypes and low-volume production. Steel molds are more durable and suitable for high-volume manufacturing but come with higher initial costs and longer lead times.

Below is a comparison of technical specifications and cost factors for aluminum and steel molds used in injection molding with common engineering thermoplastics such as ABS and Nylon.

| Parameter | Aluminum Mold | Steel Mold |

|---|---|---|

| Mold Material | 7075-T6 or 6061-T6 Aluminum | P20, H13, or NAK80 Steel |

| Typical Tool Life | 10,000 – 100,000 shots | 100,000 – 1,000,000+ shots |

| Lead Time for T1 Sample | 5–7 days | 7–14 days |

| Machinability | High – faster CNC machining | Lower – longer machining time |

| Surface Finish | Good (can achieve SPI finishes) | Excellent (superior polishability) |

| Corrosion Resistance | Moderate (anodizing improves it) | High (especially stainless steels) |

| Thermal Conductivity | High – faster cycle times | Lower – slower heat transfer |

| Initial Mold Cost (Relative) | Lower (30–50% less than steel) | Higher |

| Best For | Prototypes, low to medium volume | High-volume production |

| Compatible Resins | ABS, Nylon, PP, LDPE, PC (low wear) | ABS, Nylon, PC, POM, high-temp resins |

| Mold Maintenance Requirements | Low to moderate | Moderate to high |

| Part Quality Consistency | Good for prototyping | Excellent for mass production |

Material Compatibility Notes

ABS and Nylon are commonly processed in both aluminum and steel molds. However, Nylon’s hygroscopic nature and higher processing temperatures require proper mold venting and drying protocols. While aluminum molds can handle short runs of Nylon, steel is preferred for extended production due to better wear resistance.

Honyo Prototype leverages advanced CNC machining and quality control systems to deliver high-precision molds with T1 samples in as fast as 7 days, supporting rapid development cycles without compromising on technical integrity.

From CAD to Part: The Process

Honyo Prototype Plastic Injection Mold Cost Process Explanation

Honyo Prototype employs a streamlined, technology-driven workflow to deliver precise plastic injection mold cost estimates and production outcomes. This process minimizes delays, reduces risk, and ensures cost transparency for B2B clients. Below is a detailed technical breakdown of each phase.

CAD Upload and Initial Assessment

Clients initiate the process by uploading native CAD files (STEP, IGES, or Parasolid formats) via Honyo’s secure client portal. Our system performs immediate geometry validation, checking for common issues like non-manifold edges, gaps, or incorrect units. This step ensures the file is manufacturable before cost analysis begins, eliminating quoting errors from flawed inputs. All data is encrypted and handled under strict NDA protocols to protect intellectual property.

AI-Powered Preliminary Quoting

Uploaded CAD data is processed through Honyo’s proprietary AI engine, which cross-references real-time material pricing, machine utilization rates, and historical production data from our global facility network. The AI analyzes geometric complexity, part volume, material selection (e.g., ABS, PC, POM), and surface finish requirements to generate a granular cost breakdown within 2 business hours. This includes mold base costs, cavity count impact, steel selection (e.g., P20, H13), and estimated cycle times. Crucially, the AI flags potential cost drivers such as deep ribs, undercuts, or tight tolerances exceeding ±0.05mm, providing actionable insights for early-stage optimization.

Engineer-Validated DFM Analysis

The AI-generated quote undergoes rigorous review by Honyo’s senior manufacturing engineering team. We conduct a formal Design for Manufacturability (DFM) assessment, focusing on moldability, cost-saving opportunities, and long-term production viability. Key evaluations include wall thickness uniformity, draft angle adequacy (minimum 1° per side), gate location optimization, and ejection strategy. Our engineers collaborate directly with the client to suggest modifications—such as simplifying core-cavity interfaces or adjusting radii—that reduce mold complexity by 15–30% without compromising functionality. This phase includes a detailed DFM report with annotated CAD markups and cost-impact analysis.

Mold Production and Validation

Approved designs move to Honyo’s ISO 9001-certified production facilities. Mold fabrication leverages high-precision CNC machining, wire EDM, and surface texturing capabilities. We implement a phased validation protocol:

T0 Trial: First-article mold trials using client-specified material

Dimensional Verification: CMM inspection against GD&T callouts

Process Optimization: Scientific molding parameters finalized (packing pressure, cooling time)

This stage includes mold maintenance planning and lifetime estimates (e.g., 500k+ cycles for hardened tool steel). All process data is logged for traceability, ensuring consistency across production runs.

Delivery and Documentation Handover

Upon successful validation, molds are shipped with comprehensive documentation:

Mold maintenance manuals with wear-part schematics

Full dimensional inspection reports (PDF and Excel)

Process capability data (Cp/Cpk values for critical dimensions)

Certificates of conformity for steel and heat treatment

Honyo guarantees on-time delivery through real-time production tracking and buffer capacity allocation. Post-delivery, our engineering team remains available for production support, including mold modifications or annual maintenance planning to extend tool life.

This integrated methodology ensures clients receive not just a mold, but a validated, cost-optimized manufacturing solution. By embedding AI efficiency with human engineering expertise, Honyo reduces total project risk while delivering transparent, data-backed cost structures from quotation through delivery.

Start Your Project

Looking for an accurate quote on plastic injection mold costs? Contact Susan Leo at [email protected] to discuss your project requirements. With our in-house manufacturing facility located in Shenzhen, we offer fast turnaround times, competitive pricing, and expert engineering support throughout the entire mold development process. Whether you’re prototyping or preparing for high-volume production, Honyo Prototype delivers precision and reliability. Reach out today to optimize your mold design for manufacturability and cost-efficiency.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.