Contents

Manufacturing Insight: Plastic Injection Mold Cost

Plastic Injection Mold Cost – From Instant Quote to First Shot in 10 Days

At Honyo Prototype, we erase the old rule that low-cost tooling means low-speed. Our Rapid Tooling & Injection Molding cells combine aluminum P20 inserts, automated CNC hard-milling, and in-house 50–500 T presses to deliver production-grade parts in as little as 7–10 calendar days—without the traditional tool-steel price penalty. Need a number right now? Upload your 3D CAD to our Online Instant Quote engine; within seconds you’ll see a mold cost breakdown (tool steel, cavitation, texture, hot-runner options) plus piece-part pricing for up to 100,000 shots. Whether you need 50 medical prototypes or 20K end-use covers, Honyo’s tooling strategy scales with your demand, keeping your injection mold cost predictable from the very first click.

Technical Capabilities

As a Senior Manufacturing Engineer at Honyo Prototype, I’ll clarify technical cost drivers for plastic injection molds with a focus on steel vs. aluminum molds and 7-day T1 sample turnaround. Crucially:

– “ABS” and “Nylon” are resin materials (not mold materials) – they impact mold design requirements but do not directly determine mold base cost.

– Mold cost is driven by base material (steel/aluminum), complexity, and timeline, not the plastic being injected.

– 7-day T1 is only feasible for simple aluminum molds – steel molds cannot meet this timeline for production-quality parts.

Here’s a detailed technical breakdown of cost drivers for your scenario:

1. Mold Base Material: Steel vs. Aluminum (Core Cost Driver)

| Factor | Aluminum Molds (e.g., 7075-T6, 6061-T6) | Steel Molds (e.g., P20, H13, S136) |

|————————–|——————————————–|—————————————-|

| Typical Cost Range | $3,000 – $15,000 (simple parts) | $20,000 – $100,000+ (production-grade) |

| Why? | Softer material; faster machining (50–70% less time than steel). No heat treatment needed. | Hardened steel requires EDM, heat treatment, and precision grinding – each adding days/weeks. |

| T1 Timeline Feasibility | ✅ 7 days possible for simple geometries (e.g., no slides, <10 cavities, <500mm² part size). | ❌ Impossible – even simple steel molds require 21–30+ days for heat treatment and finishing. |

| Lifespan | 10,000–50,000 shots (ideal for prototypes/low-volume) | 100,000–1M+ shots (production-ready) |

| Critical Note for ABS/Nylon | Safe for ABS (non-abrasive). Avoid for Nylon (especially glass-filled) – aluminum wears rapidly due to high melt temps and abrasives. | Required for glass-filled Nylon – hardened steel (e.g., H13) resists wear. Standard P20 works for unfilled Nylon. |

2. Why 7-Day T1 is ONLY Possible with Aluminum Molds

- Machining Speed: Aluminum molds can be CNC-machined in 2–3 days (vs. 10–15 days for steel).

- No Heat Treatment: Steel molds require quenching/tempering (adding 7–10 days + risk of distortion).

- Surface Finish: Aluminum molds often skip polishing (saving 2–3 days); steel molds need mirror polishing for high-gloss parts.

- Rush Fees: For 7-day delivery, expect +30–50% premium on base mold cost (e.g., $10k aluminum mold → $13k–$15k).

- Trade-offs:

- Only 1–2 cavities allowed (multi-cavity molds take too long).

- No complex features (e.g., slides, lifters, intricate cores).

- Surface finish may be “as-machined” (not polished).

- T1 parts are for fit/function checks only – not for production validation.

⚠️ Critical Warning: If your part is glass-filled Nylon, an aluminum mold will fail within 500–1,000 shots. You must use steel – but then T1 will take 21+ days. Honyo Prototype would not recommend aluminum for abrasive resins.

3. How Resin Material (ABS/Nylon) Affects Mold Cost (Indirectly)

- ABS:

- Low melt temp (220–250°C), non-abrasive.

- Safe for aluminum molds with no extra cost.

- Mold design: Standard cooling channels suffice.

- Nylon (Unfilled):

- Higher melt temp (250–290°C), moderately abrasive.

- Aluminum molds possible for prototypes (but lifespan reduced by 50% vs. ABS).

- Steel recommended for >10k shots (P20 steel adds ~$5k–$10k to base cost).

- Glass-Filled Nylon:

- Highly abrasive (glass fibers erode aluminum rapidly).

- Steel is mandatory (H13 or S136 hardening).

- Cost impact: +$15k–$30k vs. aluminum for similar geometry.

4. Realistic Cost Scenarios for 7-Day T1

| Part Type | Mold Material | Estimated Cost | T1 Feasibility | Notes |

|———————|——————-|——————-|——————-|———-|

| Simple ABS part (e.g., box, cover, no undercuts) | Aluminum | $4,000 – $8,000 | ✅ Yes | 1-cavity, basic cooling, no slides. |

| Complex ABS part (e.g., with slides, threads) | Aluminum | $10,000 – $15,000 | ⚠️ Marginal (may miss 7-day deadline) | Rush fees apply; slides add 2–3 days. |

| Unfilled Nylon part | Aluminum | $5,000 – $9,000 | ⚠️ Risky (short mold life) | Not recommended for >5k shots. |

| Glass-Filled Nylon part | Steel | $25,000+ | ❌ No (min. 21 days) | 7-day T1 impossible – steel requires heat treatment. |

5. Key Engineering Recommendations from Honyo Prototype

- For 7-day T1:

- Use aluminum only for ABS or unfilled Nylon prototypes (if part is simple).

- Never use aluminum for glass-filled resins – it will fail prematurely.

- If your part requires steel (e.g., glass-filled Nylon):

- Accept 21–30+ days for T1 – rushing steel molds compromises quality.

- Request a “prototype steel mold” (simplified design, no heat treatment) – but this still takes 14+ days.

- Cost-Saving Tip:

- For ABS prototypes, use aluminum with standard surface finish (no polishing) and simplified cooling to hit 7 days.

- Avoid undercuts/slide mechanisms – these add 3–5 days to the timeline.

💡 Bottom Line: “7-day T1” is a prototype-only capability for simple aluminum molds. Steel molds for production-grade parts (especially with abrasive resins) cannot meet this timeline. Always align resin selection with mold material – mixing glass-filled Nylon with aluminum is a costly mistake.

For your specific project, share the part geometry and resin type – we’ll provide a precise quote and timeline within 24 hours. At Honyo Prototype, we prioritize technical accuracy over false promises – your part’s success depends on it.

From CAD to Part: The Process

Honyo Prototype – Plastic-Injection Mold Cost Workflow

(what happens to your CAD file from the moment you upload it to the day the mold and parts land on your dock, and how every step either locks-in or eliminates cost)

-

Upload CAD

• Acceptable formats: STEP, IGES, Parasolid, SolidWorks, Creo, UG-NX, CATIA, STL (for reference only).

• Automatic geometry healing & wall-thickness check.

• Cloud engine instantly extracts: projected area, core/cavity surface area, number of under-cuts, parting-line length, deepest draw, # of sliders/lifters estimate, basic gate & ejector pin positions.

→ These geometric “cost drivers” feed the AI quote in <60 s. -

AI Quote (24 h or less)

• Algorithm built on 18 000+ Honyo molds; regression models map geometry drivers to real historic hours & spend.

• Outputs three tiers:

– Prototype mold (P20 class, 1–5 k shots, single-cavity, hand-load sliders if needed).

– Bridge mold (P20 or 718H, 10–100 k shots, hardened inserts, basic automation).

– Production mold (H13 or S136, 300 k–1 M shots, full hardening, hot-runner, interchangeable inserts, SPI Class 101–103).

• Line-item cost sheet: steel grade, cavitation, runner type, cycle estimate, mold base size, machining hours, EDM hours, polishing, texture, HASCO/DME standard components, packaging, shipping.

• You see a single “mold cost” number plus piece-price at three annual volumes.

• Accept & pay 50 % down → project moves to DFM. -

DFM (3–5 days)

Goal: remove every unnecessary penny before steel is cut.

a. Part Design Optimization

– Uniform wall, 0.8–3 mm recommended; eliminates sink, reduces cycle 5–15 %.

– Draft ≥ 0.5° (texture depth × 0.025 mm).

– Eliminate thin steel (<0.5 mm) between holes to avoid breakage & weld repairs later.

b. Gate & Runner Simulation (Moldflow)

– Balance fill, minimize weld lines, predict clamp tonnage.

– Choosing edge gate vs. sub-gate vs. valve-gated hot runner can swing mold cost ±15 % and cycle ±20 %.

c. Mold Layout

– Cavitation decision: 1×1, 1×2, 2×2, 4×4… based on machine list at Honyo and your annual volume.

– Core/cavity insert size standardized on metric block (LKM) to avoid custom base surcharges.

d. Manufacturability Check

– Can we CNC everything or do we need copper EDM? Every EDM cavity adds ¥300–600 ($45-90) and 2 h.

– Slider vs. unscrewing vs. hand-load: hand-load cheapest for <5 k shots; cam-slider adds ¥1 500–3 000 each but pays for itself in cycle time after ≈20 k shots.

e. Final Sign-off

– 2-D drawings with critical steel safe dimensions, steel type, hardness, parting-line surface, gate vestige tolerance, texture specification.

– Customer e-sign triggers steel ordering; change orders after this point are 5–15 % cost-up. -

Production (15–25 calendar days for prototype mold; 25–35 for production mold)

Steel & Components

• Order LKM standard mold base + steel inserts (P20, 718H, H13, S136, 420SS).

• Pre-hardened steel saves heat-treat wait but adds ¥1.2/kg; through-harden to 48–52 HRC adds ¥2 000–3 000 overall but doubles mold life.

Machining Sequence (cost hours booked to your PO)

1. CNC roughing → 2. Heat treat → 3. CNC finishing → 4. EDM details → 5. Wire-cut → 6. Fitting & spotting (90 % of cycle-time prediction accuracy comes here).

• High-speed hard milling (30 000 rpm) replaces 30–50 % of EDM for simple shapes → saves ¥800–1 200/cavity.

• 5-axis deep-groove machining eliminates electrode cost for rib features.

Polishing & Texture

• SPI B-2 polish included; A-1 diamond adds ¥400/cavity; chemical texture (VDI 3400 ref) adds ¥60/cm².

Assembly & Spotting

• Blue-spot minimum 80 % contact on parting line prevents flash → reduces future molding downtime cost.

Mold Trial T0

• 50-ton to 1 300-ton Toshiba, Haitian, Engel machines with RJG eDART.

• Process sheet records fill time, peak pressure, cooling, cycle; samples + full dimension report sent for approval.

• If T0 parts pass → free storage of mold at Honyo for 2 yr; if not, we absorb rework cost for tool-related issues (terms & limits on quote).

- Delivery (3–7 days)

• Mold packed in vacuum-sealed VCI film + desiccant, plywood crate with lifting eyes, IPPC stamp.

• Optional: mold manual (2-D drawings, BOM, maintenance schedule), spare ejector pins, O-rings, heater bands.

• Courier (DHL/FedEx) for molds <100 kg; sea-air combo for >300 kg to avoid dimensional-weight surcharge.

• Track & trace code shared; ownership transfers on 50 % balance payment.

Cost Levers You Control at Each Stage

Upload CAD → Reduce # of undercuts, keep shut-off angles >5° → AI quote drops 8–12 %.

DFM → Accept standard LKM base, agree to 1×2 cavitation instead of 2×2 → save 20–25 % mold cost.

Production → Choose pre-hardened 718H if annual volume <80 k → save heat-treat line item (~¥2 000).

Delivery → Let Honyo store mold and ship parts in batches → avoid repeated mold freight.

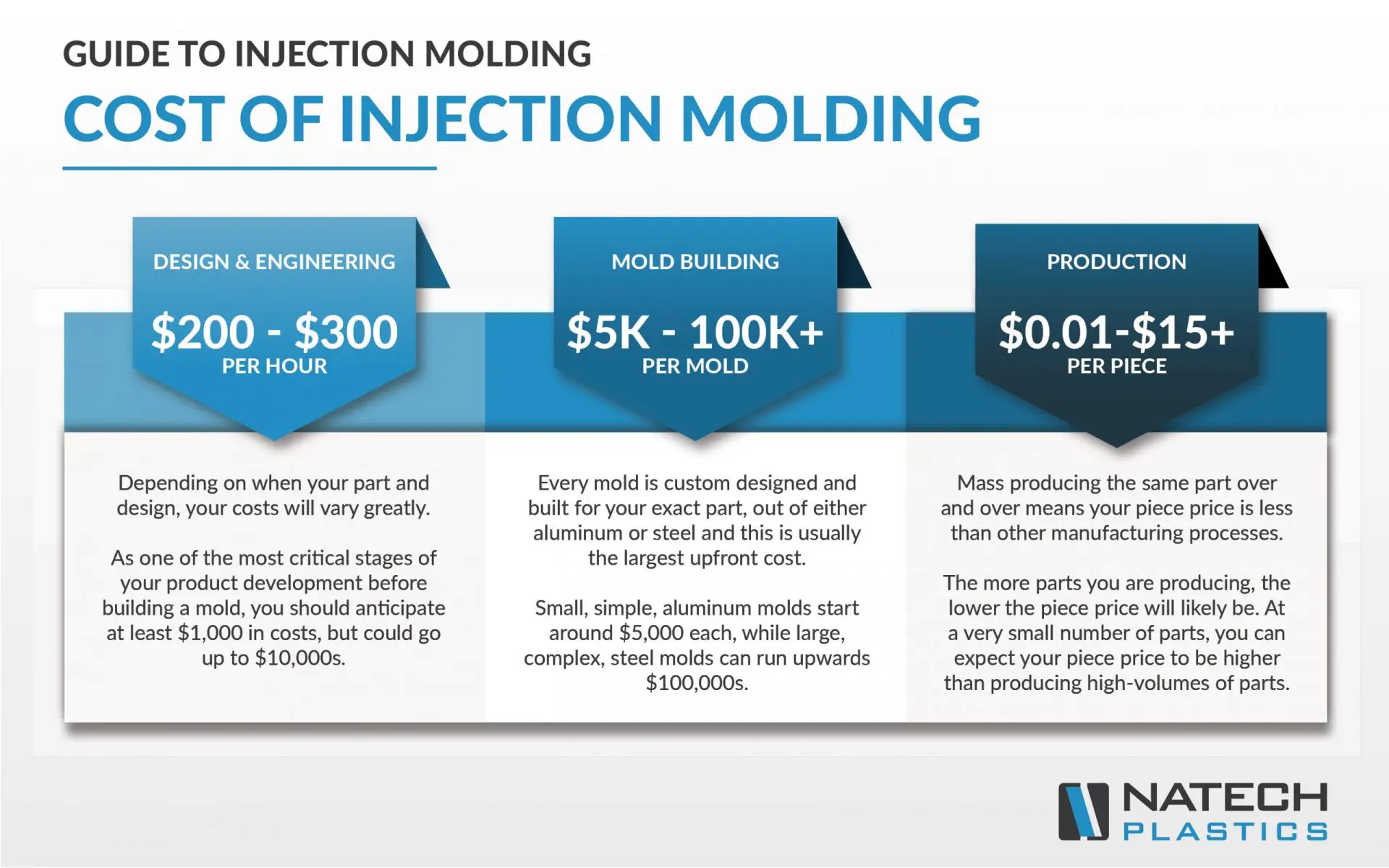

Typical Ranges (FOB Shenzhen, 2024 Q2)

Prototype (1-cavity, P20, 1 000 shots): USD 1 200 – 3 500

Bridge (1-cavity, 718H, 50 k shots, hot runner): USD 4 500 – 8 000

Production (2-cavity, H13, 500 k shots, valve gate): USD 12 000 – 22 000

Every step above is designed to make the cost transparent, locked, and non-creeping. Once you approve the DFM report, the only way the price increases is if you change the part geometry—or ask us to run faster than the agreed T0 date.

Start Your Project

Get Your Plastic Injection Mold Cost Estimate Now!

Contact Susan Leo at [email protected]

Shenzhen-based factory for precision, quality, and competitive pricing.

✅ Fast, accurate quotes

✅ Industry-leading expertise

✅ End-to-end manufacturing support

Ready to start your project? Email us today! 🚀

🚀 Rapid Prototyping Estimator