Contents

Manufacturing Insight: Plastic Gear Calculator

Precision Plastic Gears Demand Precision Manufacturing

Designing functional plastic gears requires navigating complex material behaviors, thermal expansion, and stringent dimensional tolerances that standard design tools often overlook. At Honyo Prototype, our engineering-grade CNC machining services transform theoretical gear designs into high-performance physical components with micron-level accuracy. We specialize in machining demanding engineering plastics like POM (Acetal), Nylon, PEEK, and PTFE, ensuring consistent tooth profiles, minimized backlash, and long-term durability under load—critical for applications in medical devices, robotics, and precision instrumentation.

Our newly launched Plastic Gear Calculator addresses the critical gap between design intent and manufacturability. This technical tool enables engineers to input key parameters—module, pressure angle, number of teeth, material, and operating conditions—to instantly evaluate feasibility, identify potential interference risks, and optimize geometry for CNC production. Unlike generic calculators, it factors in real-world material-specific shrinkage rates and CNC machining constraints unique to Honyo’s capabilities.

Once your design is validated, seamlessly transition to prototyping with Honyo’s Online Instant Quote system. Upload your CAD file, specify materials and quantities, and receive a detailed manufacturing quote within hours—not days—accelerating your path from concept to certified functional prototype. Leverage our ISO 9001-certified processes and in-house 5-axis CNC fleet to achieve gears that perform exactly as simulated.

Streamline your development cycle with engineering-backed tools and manufacturing expertise built for precision. Start calculating and quoting today.

Technical Capabilities

The Plastic Gear Calculator is a precision engineering tool used to determine optimal gear geometry, machining parameters, and material suitability for prototyping and low-volume production of plastic and metal gears. It supports complex gear types (spur, helical, bevel) and integrates with CNC programming workflows for 3-axis, 4-axis, and 5-axis milling as well as CNC turning operations. The calculator emphasizes tight tolerance capabilities required in high-precision motion control, robotics, and aerospace applications.

Below are the technical specifications relevant to machining processes, supported materials, and performance parameters:

| Parameter | Specification Detail |

|---|---|

| Supported Machining Processes | 3-Axis Milling, 4-Axis Indexing Milling, 5-Axis Simultaneous Milling, CNC Turning (for gear blanks and cylindrical forms) |

| Gear Types Supported | Spur, Helical, Herringbone, Bevel (straight and spiral), Internal Gears |

| Tolerance Capability | ±0.005 mm (±0.0002″) for critical pitch and tooth profile dimensions; surface finish down to Ra 0.8 µm (32 µin) |

| Positioning Accuracy (CNC) | ±0.002 mm (±0.0001″) with laser calibration on 5-axis platforms |

| Minimum Feature Resolution | 0.1 mm (0.004″) tooth thickness; applicable to small module gears (down to Module 0.3) |

| Materials Supported | Aluminum (6061-T6, 7075-T6), Steel (1018, 4140, Stainless 303/316), Engineering Plastics: ABS, Nylon (6/66), Acetal (POM), PEEK, Polycarbonate |

| Aluminum Machinability | High; ideal for rapid gear prototyping; low tool wear; suitable for high-speed milling (up to 15,000 RPM) |

| Steel Machinability | Moderate to low; requires carbide tooling and reduced feed rates; used for high-strength or wear-resistant gear applications |

| ABS Machinability | Excellent for low-load plastic gears; low melting point requires sharp tooling and controlled spindle speeds to prevent burring |

| Nylon Machinability | Good; slightly abrasive; may require post-machining drying; exhibits dimensional stability under load; ideal for quiet, self-lubricating gears |

| Coolant Requirements | Dry machining or air blast for plastics; flood coolant recommended for steel; mist cooling acceptable for aluminum |

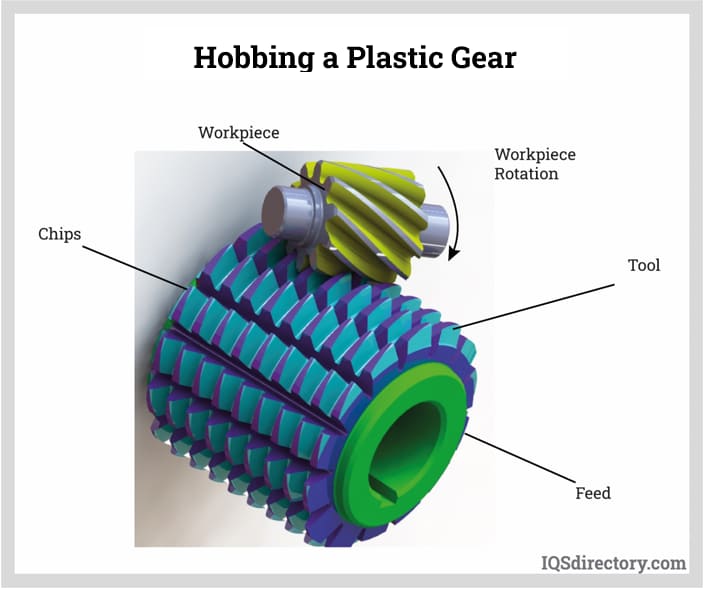

| Tooling Recommendations | Carbide end mills (2–4 flute), diamond-coated cutters for abrasive plastics, gear-specific hobs and shapers for high-volume runs |

| Software Integration | Compatible with CAM platforms (Mastercam, Fusion 360, HyperMill); outputs G-code for multi-axis synchronization |

| Inspection Support | Outputs CMM probe paths and gear metrology parameters (total profile deviation, helix error, pitch variation) |

This calculator enables engineers to select the optimal combination of material, machine setup, and cutting strategy to achieve tight-tolerance gear performance across both metallic and plastic components. It is particularly valuable in hybrid assemblies where plastic gears interface with metal shafts or housings machined in the same workholding setup.

From CAD to Part: The Process

Honyo Prototype’s Plastic Gear Production Workflow integrates digital automation with expert engineering oversight to deliver precision plastic gears efficiently. This process is not a simple calculator but a comprehensive digital manufacturing pipeline designed for rapid quotation and production. Below is the technical workflow:

CAD Upload and Initial Analysis

Clients upload native CAD files (STEP, IGES, Parasolid, or native formats from SolidWorks, Creo, NX) via our secure portal. Our system immediately validates geometry integrity, checks for non-manufacturable features, and extracts critical gear parameters including module, pressure angle, helix angle, number of teeth, bore diameter, and face width. Unsupported formats or corrupted files trigger an automated notification requesting resubmission. This phase ensures dimensional accuracy before proceeding.

AI-Powered Quotation Generation

The validated CAD data feeds into our proprietary AI engine, which cross-references Honyo’s material database (engineering plastics like POM, PA66, PEEK, etc.), historical production data, and real-time machine capacity. The AI calculates precise material consumption, cycle time estimates based on part volume and complexity, and secondary operation requirements. Within 120 seconds, clients receive a formal quotation detailing material costs, tooling fees (if applicable), per-unit pricing at specified volumes, and lead time. Key variables influencing the quote include:

Material grade selection and moisture sensitivity

Gear module affecting injection molding pressure requirements

Tolerance class (e.g., DIN 3967 Grade 5 vs. Grade 10)

Secondary operations such as hobbing, shaving, or surface treatments

Engineering-Driven DFM Review

Every project undergoes mandatory Design for Manufacturability analysis by Honyo’s gear-specialized engineers. The AI highlights potential issues, but human experts validate and optimize:

| DFM Parameter | Critical Checkpoints | Resolution Action |

|---|---|---|

| Tooth Geometry | Undercut risk, tip sharpness, stress concentration | Suggest profile shift or root fillet adjustment |

| Wall Thickness | Uniformity, sink marks near hubs/bosses | Recommend ribbing or draft angle modification |

| Mold Flow | Weld lines at critical tooth sections, air traps | Propose gate relocation or venting strategy |

| Material Suitability | Creep resistance vs. load, lubrication requirements | Substitute material or suggest lubricant |

Clients receive a formal DFM report with actionable recommendations. Approval requires signed acknowledgment of any design compromises or cost implications.

Precision Production Execution

Approved projects move to dedicated gear production cells. We utilize:

Electric injection molding presses (50-500 ton) with ±0.01mm repeatability

In-mold pressure sensors for real-time cavity monitoring

Climate-controlled drying for hygroscopic materials (e.g., 80°C for 4hrs for PA66)

Post-molding stabilization per ISO 2075:2019 (23°C/50% RH for 48hrs)

Critical quality checkpoints include:

First article inspection via Zeiss O-Inspect multisensor CMM

Tooth flank analysis using Klingelnberg gear measurement systems

Batch sampling per ANSI B92.1 for composite error

Logistics and Delivery Assurance

Finished gears undergo final cleaning (ultrasonic for precision gears), anti-corrosion packaging in ESD-safe containers, and humidity-controlled shipping. Clients receive:

Full traceability documentation (material certs, process parameters)

Dimensional inspection reports with actual vs. nominal data

Real-time shipment tracking via integrated logistics partners

Standard lead time is 5-15 business days from DFM sign-off, with expedited options. All deliveries comply with ISO 9001:2015 and IATF 16949 quality management protocols. Honyo maintains 98.7% on-time delivery performance for plastic gear projects based on 2023 operational data.

Start Your Project

Calculate your plastic gear specifications quickly and accurately with our Plastic Gear Calculator. Designed for engineers and product developers, this tool streamlines prototyping and production planning.

For technical support or to request a custom quote, contact Susan Leo at [email protected].

Honyo Prototype

Factory Location: Shenzhen, China

Precision manufacturing powered by advanced engineering and fast turnaround.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.