Contents

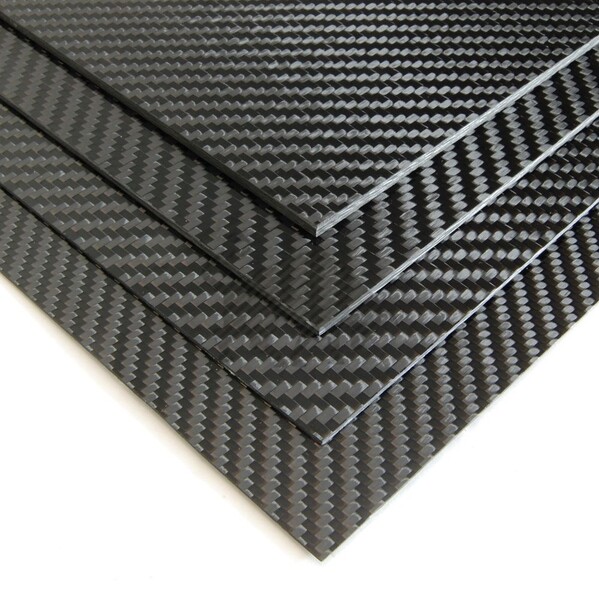

Manufacturing Insight: Plastic Carbon Fiber Sheet

Advanced Material Solutions for Precision Engineering Applications

Honyo Prototype delivers industry-leading fabrication expertise for next-generation materials, including carbon fiber-reinforced polymer (CFRP) sheets and traditional sheet metal components. Our engineered plastic carbon fiber sheets combine exceptional strength-to-weight ratios, thermal stability, and dimensional accuracy—making them ideal for aerospace, automotive, and medical device applications where performance under stress is non-negotiable. Unlike conventional composites, our proprietary layup and curing processes ensure consistent fiber alignment and minimal void content, directly addressing common failure points in structural implementations.

While sheet metal fabrication remains a core competency for aluminum, stainless steel, and titanium alloys, Honyo’s capabilities extend seamlessly into advanced composites. We bridge the gap between metal and polymer-based solutions through integrated design-for-manufacturability (DFM) analysis, precision CNC routing, laser cutting, and automated fiber placement. This holistic approach allows clients to optimize material selection without compromising on tolerances, lead times, or scalability—from rapid prototyping to low-volume production runs. Our engineering team collaborates directly with your design staff to resolve anisotropy challenges, edge delamination risks, and hybrid assembly requirements inherent in carbon fiber systems.

Accelerate your project timeline with Honyo’s Online Instant Quote platform, engineered for technical accuracy. Upload CAD files to receive validated cost and lead-time estimates within hours—not days—factoring in material grade, geometric complexity, and secondary operations. This tool eliminates procurement delays while ensuring manufacturability feedback is embedded from the earliest design phase. For carbon fiber sheet projects demanding micron-level precision or multi-material integration, our platform provides transparent, data-driven pricing without hidden engineering fees.

| Material Category | Key Applications | Tolerance Range | Max Work Envelope |

|---|---|---|---|

| Carbon Fiber Sheets | UAV frames, sensor housings | ±0.05mm | 1220x2440mm |

| Sheet Metal Fabrication | Enclosures, brackets | ±0.02mm | 1500x3000mm |

Elevate your next project with Honyo’s convergence of composite innovation and metal fabrication rigor. Initiate your quote today to experience how our technical partnership reduces time-to-market while guaranteeing repeatability in every component.

Technical Capabilities

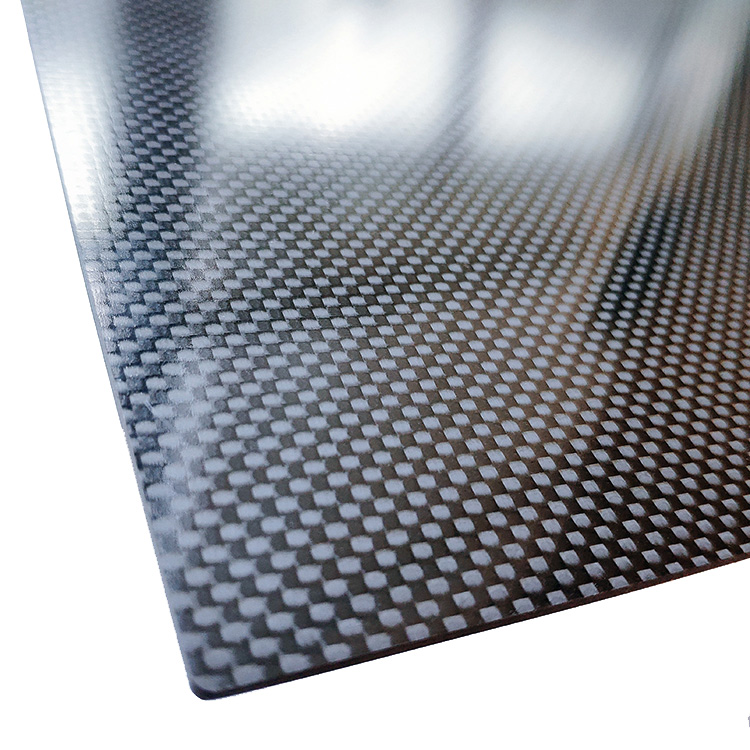

The term “plastic carbon fiber sheet” typically refers to a composite material consisting of a polymer matrix (such as ABS or Nylon) reinforced with carbon fibers. It is not a metal like aluminum or steel, though it is often compared to them due to its structural performance. True carbon fiber sheets for laser processing are made by embedding carbon fibers in thermoplastic or thermoset resins. Below are technical considerations for laser cutting, bending, and welding of such materials, with comparative notes on aluminum, steel, ABS, and nylon for context.

| Material | Laser Cutting Suitability | Bending Characteristics | Welding Compatibility | Notes |

|---|---|---|---|---|

| Plastic Carbon Fiber (ABS-based) | Good – requires controlled power and airflow to minimize charring; CO₂ lasers (wavelength ~10.6 μm) are effective. Avoid excessive heat to prevent delamination. | Limited – high stiffness; cold forming possible with gradual radii. Heat-assisted bending at 80–100°C may be used. Risk of fiber breakage at tight bends. | Poor – ultrasonic or adhesive bonding preferred. Not fusion-weldable like metals. | Contains carbon fiber strands in an ABS matrix. Conductive surface may reflect or absorb laser differently than pure polymers. |

| Plastic Carbon Fiber (Nylon-based) | Moderate – higher melting point than ABS (~220°C); requires precise laser settings. More resistant to heat but prone to warping. | Better ductility than ABS variant; heat-assisted bending at 100–120°C feasible with proper tooling. | Limited – friction stir or hot-plate welding possible. Adhesives recommended. | Higher toughness and chemical resistance. Hygroscopic – must be dried before processing. |

| Aluminum | Excellent – reflective, so fiber lasers with high peak power and assist gas (N₂ or O₂) are used. Requires backside protection to avoid spatter. | Excellent – highly ductile, easily bent with standard press brakes (typical bend radii ≥ material thickness). | Excellent – TIG, MIG, or laser welding commonly used. High thermal conductivity requires preheat for thick sections. | Non-ferrous metal; lightweight and conductive. Often used as a structural alternative to carbon fiber composites. |

| Steel (Mild) | Good – fiber lasers efficiently cut steel up to moderate thicknesses. Oxygen assist enhances cutting speed. | Good – bendable with standard tooling; springback must be compensated. Minimum bend radius ~0.5–1x thickness. | Excellent – MIG, TIG, spot welding widely used. Easily joined with filler materials. | High strength and durability. Heavier than composites or aluminum. Magnetic and prone to corrosion. |

| ABS (neat resin) | Very Good – cleanly cut with CO₂ lasers; low melting point (~105°C). Use compressed air assist to reduce flaming. | Excellent – easily thermoformed; vacuum forming and strip heating are common. | Good – solvent welding, ultrasonic, or hot gas welding effective. | Pure ABS lacks reinforcement; lower strength and rigidity compared to carbon fiber variants. |

| Nylon (neat resin) | Moderate – CO₂ lasers can cut but require careful parameter control due to high melting point and thermal absorption. | Good – can be heat-bent with controlled heating. Susceptible to moisture absorption. | Good – hot plate, vibration, or ultrasonic welding suitable. | High impact resistance and wear properties. Requires pre-drying to avoid steam bubbles during laser processing. |

Key Notes for Processing Plastic Carbon Fiber Sheets:

Laser Cutting: Use lower power and higher speed to minimize heat-affected zones. Compressed air assist is critical to prevent flaming and resin degradation.

Bending: Not recommended for sharp bends. Use radii ≥ 3x material thickness. Heat-assisted forming should be done uniformly to avoid internal stresses.

Welding: Not applicable via traditional fusion methods. Joining is typically achieved through mechanical fasteners, adhesives, or ultrasonic techniques.

Material Selection: Plastic carbon fiber composites offer high strength-to-weight ratios but are anisotropic (direction-dependent strength). They are ideal for lightweight structural parts where metals would add unnecessary mass.

From CAD to Part: The Process

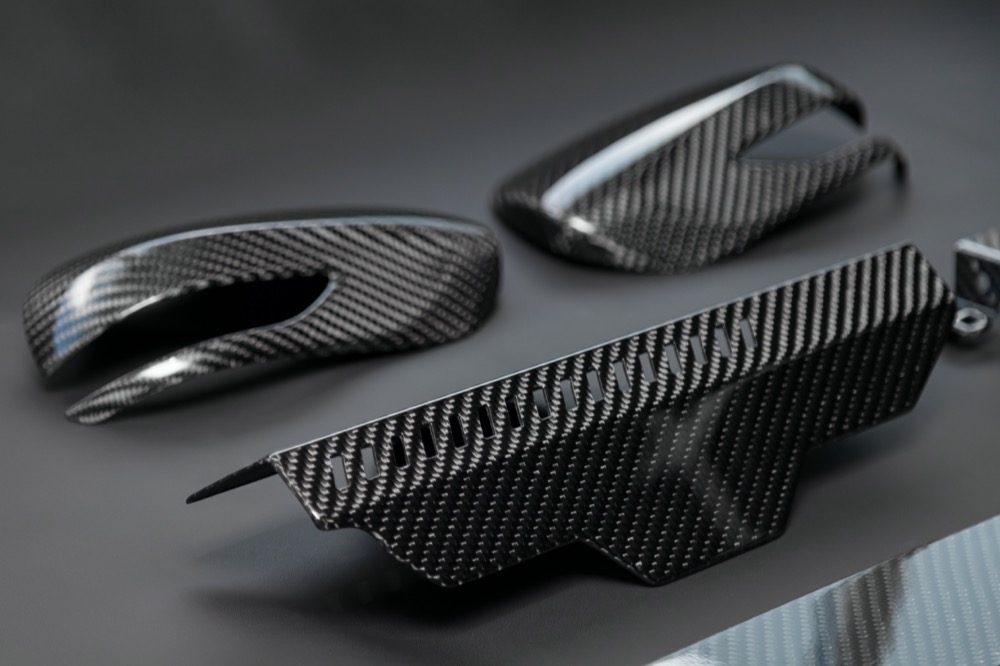

Honyo Prototype delivers precision-manufactured carbon fiber reinforced polymer (CFRP) components, not plastic carbon fiber sheets. CFRP is a high-strength composite material where carbon fiber fabric is embedded in a polymer resin matrix. Our streamlined process ensures technical accuracy and efficiency for CFRP parts:

CAD File Submission

Clients upload native CAD files (STEP, IGES, Parasolid, or native formats from SolidWorks, Creo, NX, CATIA) via our secure customer portal. We validate file integrity and material specifications against CFRP fabrication requirements, confirming resin type (e.g., epoxy, phenolic), fiber orientation, and ply schedule. All data undergoes ISO 27001-compliant encryption during transfer and storage.

AI-Powered Quoting Engine

Our proprietary AI analyzes the CAD geometry, material specifications, and tolerances to generate an instant preliminary quote within 2 hours. The system cross-references real-time data on carbon fiber tow size (3K, 6K, 12K), resin viscosity, tooling requirements, and shop floor capacity. Quotes include cost breakdowns for material consumption, autoclave cycle time, and post-cure machining, with options for expedited processing.

Engineer-Reviewed DFM Analysis

All projects undergo mandatory Design for Manufacturing review by senior composites engineers. We identify CFRP-specific risks such as resin-rich zones, ply drop-off conflicts, vacuum bagging accessibility, and cure-induced distortion. Typical resolutions include optimizing fiber orientation for load paths, suggesting core material integration for stiffness, or modifying radii to prevent resin starvation. DFM reports with actionable feedback are delivered within 24 business hours, including manufacturability scoring against ASTM D7264 standards.

Precision CFRP Production

Production follows stringent protocols:

Layup: Automated tape laying (ATL) or hand layup of pre-impregnated (prepreg) carbon fiber under Class 10,000 cleanroom conditions

Curing: Vacuum-bagged parts undergo controlled autoclave cycles (typically 120–180°C at 6–8 bar pressure) with real-time cure monitoring via embedded thermocouples

Finishing: CNC trimming with diamond-coated tools, followed by non-destructive testing (NDT) via ultrasonic C-scan per AMS-STD-2132

Quality-Controlled Delivery

Each shipment includes:

First article inspection (FAI) reports per AS9102

Material traceability certificates (mill test reports for fiber/resin)

NDT results and dimensional verification data

Climate-controlled packaging with humidity indicators

Standard lead time from DFM approval to delivery is 10–15 business days for prototype quantities. Expedited 5-day delivery is available for qualified projects. Real-time shipment tracking with temperature/humidity logs is accessible via the client portal.

Production throughput and lead times vary by part complexity as shown below:

| Part Complexity | Typical Lead Time (Days) | Max Dimension (mm) | Tolerance Capability |

|---|---|---|---|

| Low (Flat panels, simple contours) | 7–10 | 1500 x 1000 | ±0.15 mm |

| Medium (Compound curves, integrated features) | 10–15 | 1200 x 800 | ±0.10 mm |

| High (Multi-cavity, embedded hardware) | 15–20 | 800 x 600 | ±0.05 mm |

This integrated workflow reduces time-to-part by 40% compared to traditional composite prototyping while ensuring aerospace-grade quality compliance. All processes are audited to AS9100 Rev D and ISO 9001:2015 standards.

Start Your Project

Looking for high-quality plastic carbon fiber sheets for your next project? Contact Susan Leo at [email protected] to request samples, pricing, or technical specifications.

Honyo Prototype manufactures durable, lightweight plastic carbon fiber sheets at our Shenzhen factory, offering fast turnaround and custom fabrication options for prototyping and low-volume production.

Reach out today to streamline your material sourcing with precision-engineered solutions from China’s leading prototype manufacturing hub.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.